7 Quality Basics In Development 656i4g

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View 7 Quality Basics In Development as PDF for free.

More details w3441

- Words: 19,443

- Pages: 191

7 Quality Basics in Development

FRASER – June 17th, 2011

7 Quality Basics in Development Opening Comments Jean-Michel RENAUDIE FRASER – June 17th, 2011

7 Quality Basics in Development Introduction Ken SATO

One reminder

Property of Faurecia - Duplication prohibited

Please switch off your mobile phone and close your laptop

4

Breakthrough Quality Plan "Breakthrough Quality Plan" start from Oct.1, 2006 • Practical instead of conceptual • Preventive action instead of fire-fighting

Production Quality

Development Quality

Supplier Quality

Property of Faurecia - Duplication prohibited

Customer Quality

Breakthrough !!

FES Quality ( 7 Quality Basics !! in Production & Development ) 5

2008 0 S/R Alert 15 Customer PPM

Property of Faurecia - Duplication prohibited

The plan does not introduce any new tools ………aims to build a new « quality mindset »

I am expecting this plan to give lasting results and will closely track its implementation by all concerned in our company. I am counting on your responsiveness and rigor …

6

From 6 Quality Basics to 7 Quality Basics in Production Quality Variability Reduction

Supplier Partnership Employee Empowerment

Property of Faurecia - Duplication prohibited

Quality Wall Final Inspection

Includes Temporary Quality Wall

Standardized Work

5S 7 Quality Basics

Self -Inspection

Red Bins

Includes Stop at Defect

Rework under Control

Poka Yoke

N° 1 2 3 4 5 6 7 8 9 10

Check point

By

Deformation Visual Dimension A Micrometer Dimension B Gauge

... ... ... ... ... ... ...

5 1 3

OK 1st piece

... .. .... ... ... ... ...

Frequency Criteria If not OK OK - NOK sample Repair 100% +0,2 mm 1/120 Scrap Go - No go gauge Scrap 100% ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

4 2

7

8 9

QRCI Quick Response Quality Control

7

1 60

7 Quality Basics in Development

Functional Milestones, Program Steering Committee and Gate Reviews

Program QRCI

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

FMEA

Validated Strict Control Engineering Changes Plans

Key Characteristics 8

Mandatory Program Deliverables CUSTOMER INQUIRY

Program Go/No Go Target Review

GR 2A

Program GR 1 Quote Review

Quality Target Study * Quality

CAR Approval

GR 2B

Quality Management Plan

Gauges requirements *

Prototype control plan

Prototype control plan implemented * Pre Production control plan

Human Resources

Program Management

Program Teams staffed Program internal contract (program objectives) Master schedule *

Sales

Product Engineering

GR 4

GR 3

Initial Samples Submitted to Customer *

I.S. for additional capacity

Pre Production control plan implemented *

Production Control Plan *

Detailed SOW

Make or Buy finalized (Subcontractors)

Lessons Learned *

Prototype build plan

CAR approved

Pre-series build plan

Single List of Issues managed *

S/R concerns solved (SLI) *

Activities during ramp-up *

ECM for pre-series & series in place

Initial Business Plan

Initial product concept

END OF PRODUCTION

Product team staffed

Single List of Issues in place

Customer Contract

START OF PRODUCTION

Plant Start-up team planned

ECM for development In place Finance

CUSTOMER PRODUCTION PART APPROVAL

CUSTOMER TOOL RELEASE

PROGRAM AWARD

Actual BP Agreed prototype prices

Agreed tool & pre-series & series prices

Updated series price with PO

Prototypes paid

Pre-series parts paid

Product definition for DV *

Product definition freeze*

Design FMEA *

Design FMEA Actions implemented

Key characteristics *

BOPs definition released

Design Validation Plan *

DVP test results successful

Control of process & design change * Actual BP

Outstanding payments

Production Validation test results successful *

Property of Faurecia - Duplication prohibited

Prototypes approved Process definition

Process definition released

Mass Production Trial Run @ Rate *

Process FMEA

Process FMEA * actions launched

Process flow realized *

Prel. Manufacturing footprint

Facilities / Footprint specifications

Facilities definition released

Initial equipment concept

Production System definition

Equipment & tooling specs * released

Production process Instruction *

Logistic& Packaging definitions released *

Logistic & packaging in place *

Initial process capability study plan *

Process capability achieved *

BOPs, tools, gauges, equipment ordered

Supplier PPAP *

Initial process concept

Manufacturing

Initial supply chain concept (internal/external MIFD*) Purchasing

V1.0

Expert suppliers contracts signed

1 ACQUISITION

Designers suppliers contracts signed

2A DESIGN

2B DESIGN VERIFICATION

3 PRODUCTION SET-UP

EMPT Run @ Rate

4 LAUNCH

5 Series PRODUCTION

9

PDCA in Program • Background: Bad launches come from bad execution of: • Costing, • Engineering key deliverables • Quality deliverables etc…

Need to audit not only on Quality

• Today Quality responsible in program for: • Training • Audit

FES Program audit

Action

Plan

Property of Faurecia - Duplication prohibited

Reaction to Audit & to standard

Standardization & Training (coaching) 7 Quality basics in Dev - FES School Mandatory Program Deliverables

Check

Do

Audit FES Program Audit

Implementation Excellent Program Plan KPI - Reporting System

10

Property of Faurecia - Duplication prohibited

Objective

Confirm rigor and discipline in programs. – Level of execution must be deep enough – Timing of execution must be respected System audit for Programs after GR3, GR 2B and GR1 from each R&D center (Start from 1/2008). – Check evidences : real documents, real processes, real products – Check organization, timing of implementation, level of evidence

11

Scope

Mandatory Program Deliverables & Reporting – –

Level of completion of the 72 PMS Key Deliverables Program reporting system

Seven Quality Basics in Development – – – – – – –

Capitalization and Transversalization Key Characteristics FMEA (Failure Mode and Effect Analysis) Strict Control Plan Validated Engineering Change Program QRCI Functional Milestones, Program Steering Committee and Gate Reviews

Property of Faurecia - Duplication prohibited

Acquisition Process –

Target definition with PLM, Acquisition phase staffing, Concept validation, Costing robustness, Program Quote Review, Program Kick-off meeting with Core Team staffing, Acquisition debriefing, Operating Margin.

12

Example: results summary It’s “Good” level overall. But, some of deliverables in “Product validation” are not so good. (For example, (1).”Design FMEA actions” were not well implemented before 2b (2)”Results of DVP tests” were not formalized before RO) 100% 80%

Property of Faurecia - Duplication prohibited

PROCESS INDICATOR

76%

77%

72%

PROC

COST

70% 53%

60% 40% 20% 0% TOTAL

PROG

PROD

13

Property of Faurecia - Duplication prohibited

Example of “Bad” answer for “Program Quote Review”

14

Property of Faurecia - Duplication prohibited

Example of “Good” answer for “Program Quote Review”

15

15 items of "Good & Bad answers on Faurecia Intranet through PMS Portal →Good&Bad examples PMS Portal

Intranet

Bad Answer Asnwer for Program Quote review Example of“ Bad” answer for“ Program Quote Review ”

“ Do you organize internal “ Program Quote Review” with your top managements before RFQA submission to customer ?”

- There is only “

Price estimation with assumptions”

Description of vehicle & targeted business” no “ Competitor - There is no “ study”, no “ Customer decision making timeline” no “ Business plan (OI, IRR)”, no “ Risk analysis” -

Good Answer for Program Quote Review

Finally, RFQA submission without top managements approval

Example of “Good” answer for “Program Quote Review” “ Do you organize internal“ Program Quote Review” with your top managements before RFQA submission to customer ”?

Price estimation with assumptions base-price add. Value expected Target

VW 250

AU353

AU210

90,00 €

120,00 €

90,00 €

120,00 €

170,00 €

tbd

Property of Faurecia - Duplication prohibited

acc. group values (3,7% SG&A) long distance JIT price Brussels

107,00 €

155,80 Audi € A3

RFQA submission with top managements approval by clear presentat ion base-price add. Value

Price estimation with assumptions

First BP Sittard

expected Target

Description of vehicule & targeted business Market Code: AU353

Neuburg

EOP:

90,00 €

AU353

Complete Seat

Metal incl. Mechanisms

()

2004

Prod. Volume total:

AU210

120,00 €

Current Production (Faurecia) location: SOP:

AU353

90,00 €

Targeted business

n.a.

OEM: Audi AG

VW 250

2011

VW250

RFQ

Competitor study

!

JCI JCI

CS Polo / A3 Comments

market position

w 18/07

CS - JCI is very aggressive because they w 20/07 A1 want to cover the lost Golf business - JCI is current supplier of VW

- CS

Front seats

PQ35

PQ25

PQ25

Rear seats

AU350

PQ25

PQ25

- CS

Intier Intier

- CS

Sitech Sitech

- CS

excellent

COP Magna-Intier /Sitech

First

Expected

Offer

Award

Business plan

w 34/07

(OI,IRR)

w 22/07

w 24/07

Turnover OI IRR CAPEX R&D Tooling Launch cost

136.180 k€ 6.918€ 5,0% 70,30% 1.361 k€ 300 k€cash payment 200 k€ cash payment 943 k€

w 34/07

The TOP Risks, if we are awarded

Risks analysis

Brussels - Audi requests to keep the current supplier-structure --> no JCI business

Lear Lear

comments

770.000

Customer decision making timeline

will be competitor on

AU210

targeted from Sittardor long distance JIT

- no signals for aggressive behaviour due to low volume - generally very agressive behaviour - but not appreciate due to bad R&D performance and to low volume

MTP and target low in TBL

problems in long-distance JIT concept (120kmSittard

Higher requirements on quality than Mitsubishi Colt

Brussels)

- no signals for aggressive behaviour due to low volume

good

average

limited

Capacities for additional AU210 project is not part of Faurecia

16

1

Program Z X

A: Excellent

2

80%

B: Satisfactory

60%

C: Marginal ok

Program Y X

3

•FR1t •Red Alert S/R •Warranty •PPM •Customer Quality indicators •Misdeliveries •IRR •Operating Income

100%

40%

D: Not ok

4

Result Indicators

better

Results (Image)

0%

c

d 0%

60%

a

b 70%

80%

Property of Faurecia - Duplication prohibited

Process Indicators (Checked by FES program audit) •Program Management •Product Validation •Process validation •Cost Management

better 100%

Property of Faurecia - Duplication prohibited

5 Mandatory Rules added to the 15 existing MRs

18

Property of Faurecia - Duplication prohibited

5 Mandatory Rules added to the 15 existing MRs

19

Property of Faurecia - Duplication prohibited

Machine Evaluation Form

20

Property of Faurecia - Duplication prohibited

2. 2011 Plan

21

Overall 2011 Plan

3 Programs after GR3, GR2b and GR1 2 days per site => 93 programs

Brieres

System audits

100

100

80

80

60

60

40

40

20

20

0 Property of Faurecia - Duplication prohibited

Méru

GR1

GR2

Shanghaï

Toledo

GR3

100

100

80

80

60

60

40

40

20

20

0

0 GR1

GR2

GR3

0 GR1

GR2

GR3

GR1

GR2

GR3

22

2011 plan: R&D centers involved

Property of Faurecia - Duplication prohibited

Sites Jan : Feb: March: April: May: Jun: Jul : Sep: Oct: Nov: Dec:

Shanghaï (S), Peine-Hagenbach Stadthagen, Neuburg, Bavans Méru, Shanghaï(FIS), Brieres Columbus, Auburn hills, Troy Augsburg, Audincourt, Gamersheim-Weissenburg Neuburg, Mouzon, Stadthagen Brieres, Peine-Hagenbach Bavans, Méru, Limeira Quatro-Barras, Diadema, Augsburg, Audincourt, Gamersheim-Weissenburg Troy, Columbus, Auburn Hills, Stadthagen, Neuburg Mouzon 23

2010 Certified Auditors

Netwk

PG

Group FAS FIS

PMS FECT FAE

FAS

Property of Faurecia - Duplication prohibited

Program Quality

FIS

FECT FAE

Name

Certified

SATO Kiichiro SOULA Paul-Louis YGOUT Jacques BROGNIART Eric CANIVAL J. Sebastien MAJCHROWICZ Christian ROTHAN Marie-Noelle KLINGAUF Lutz KUSIAK Jacek THURET Gauthier GIELATA Pawel

Yes Yes

MESNARD Pierre KWIATKOWSKI Frank LACOUX Philippe BECKER Rolf MANSKE Carsten REBOURS Olivier JACQUOT Eric PATA Martial

Yes Yes 1 1

Netwk

US

PG

Name

Certified

FAS

DUDDLES Mark KERSUZAN Olivier HAWLEY Brian OBERHAUS Serena HACK Thomas MURRAY Todd OLIVEIRA Clodoaldo VILLARINHO Elessandra

Yes

FIS FECT

1 2

Brazil China

1 Yes

FIS FAS FECT FAS-FIS FECT

2

LI Li LEE YW GAO FENG Eva

Legend: 1: Only for GR1 2: For GR1 and 2

24

7 Quality Basics in Development

Property of Faurecia - Duplication prohibited

Agenda 7:45 8:00 8:20 8:35 9:00 10:10 11:10 11:25 12:05 12:45 15:45 16:00 16:55 17:00

Welcoming coffee Opening comments Introduction Capitalization & Tranversalization Key Characteristics & Strict Control Plans FMEA Break Validated Engineering Changes Lunch Program QRCI Break Functional Milestones & Gate Reviews Conclusion End

J.M. Renaudie K.Sato K.Sato V.Garcia Parra PL.Soula E.Jacquot J.Burke PL.Soula K.Sato

25

7 Quality Basics in Development

Functional Milestones, Program Steering Committee and Gate Reviews

Program QRCI

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

Let’s start! FMEA

Validated Strict Control Engineering Changes Plans

Key Characteristics 26

7 Quality Basics in Development

Capitalization & Transversalization

Ken SATO

7 Quality Basics in Development

Functional Milestones, Program Steering Committee and Gate Reviews

Program QRCI

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

FMEA

Validated Strict Control Engineering Changes Plans

Key Characteristics 28

Property of Faurecia - Duplication prohibited

Examples

29

2.1 Example (Blockage 1.1)

- Mistake the connection of harness Bad Terminal (A) Harness (2.5mm) Same color

Same size

- Risk the immobility of the vehicle due to the problem of injection pump

Harness (0.5mm)

Terminal (B)

Property of Faurecia - Duplication prohibited

OK

Terminal (A)

• Check similar problem of all harness - Same size of terminals

Harness (0.5mm)

- Same color of harness Harness (2.5mm)

Terminal (B)

30

2.2 Example (Blockage 1.2)

• Ask to check, not only exact same problem, but also similar potential risk - Found 11 exact same problems & 45 similar problems and took countermeasure - Capitalization : Change “Design Standard” - Transversalization : Apply all same products (programs, plants) C ar m aker

U n it

A

Property of Faurecia - Duplication prohibited

R E NA ULT

...

T y p e o f p ro b l e m

H a rn e s s 1

2

3

4

5

6

a

OK

OK

OK

B ad

OK

OK

b

B ad

c

B ad

d

OK

C o u n te rm e a s u re

D a te

B

...

...

...

...

C

...

...

...

...

...

...

...

...

...

31

3.1 Example (Blockage 2.1)

• Mistake of parts drawing, after design change

• Heater of seat doesn’t work properly Over heat

= Bad

No heat

Property of Faurecia - Duplication prohibited

SEAT = OK • Standardize the validation process after design change

3.1 Example (Blockage 2.2)

- Capitalization : Validation Process Standard for Design Change - Transversalization : Apply to all programs (products, plants) Design Review by past quality concerns Not OK

Property of Faurecia - Duplication prohibited

Design Supplier Change Validation

Check Parts design

Production Validation for Mass production

Design Validation for the trial parts OK

OK

OK delivery

Renault ANPQP

Design change Request

Parts submission warrant

Good parts

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

34

Turning PDCA for Capitalization & Transversalization Lessons Learned is source of Standards >Each function department is able of Lessons Learned in its respective area

Property of Faurecia - Duplication prohibited

1-B

2. Program Quality Program Program Management Management System System

2-D

Acquisition

Tools

1-A Quality System System Standard Standard Quality

(Lessons Learned ) (Lessons

1. Group Quality

Design

Validation

Production

2-A

Design Design Standard Standard

2-B

Process Process Engineering Engineering Manual Manual

2-C

Supplier Supplier Management Management System System

3. Customer Quality

(Lessons Learned )

3-A

Customer Customer Quality Quality Standard Standard

3-B

Customer Customer PPM PPM Data Data base base (8D) (8D)

3-C

S S& &R R Alert Alert // Warranty Warranty Data Data base base (8D) (8D)

35

8D and Lessons learned

Property of Faurecia - Duplication prohibited

8D – problem solving report for Quality D1. Description & Sketch

_

D2. Risk on similar products and processes

_

D3. Containment

In 1 day

D4. Root cause of non detection

_

D5. Root cause of non conformance

_

D6. Countermeasure to non detection and non conformance

In 10 working days

D7. Effectiveness of action plan

_

D8. Lessons learned

In 60 working days

> Access through Faurecia intranet ● Group Intranet Homepage -> Quality -> 8D – S&R Logistics -> FAU-F-LSG-0230 ● Lessons Learned Template is the last sheet of standard 8D 36

Lessons Learned: Practice

Property of Faurecia - Duplication prohibited

<4 Key points for Before/After> 1).Need picture, drawing or photo 2).Need quantitative value 3).

needs to prevent same or similar problem beforehand 4).Need to understand easily even by your wife, husband (or partner)

All BGs use the Spider System under names of LOLA, I-Know & Knowledge Mgt

37

Lessons Learned: 2 examples

LESSON LEARNED SHEET

LESSON LEARNED SHEET Application date : UAP 1 / AU 716

Author :

Willibald Dimpfl

WHAT WAS THE PROBLEM? (5W + 2H)

Application date :

Detection

Logistics

BG/Div/Site:

SMPG, Wałbrzych Frames

Occurrence

Internal

UAP/Line:

Wojciech Mazgis

Management

Suppliers

Author :

Wojciech Mazgis

WHAT IS THE CAUSE?

WHAT WAS THE PROBLEM? (5W + 2H)

Buckling of Boomerang door- and tunnelside ECE-R14 test on rear seat 2nd row high variante NOK on fixed All materials inside drawing specifications Why it is a problem? Materials in N.O.K validation ca. 10%-15% weaker Seat is on the borderline between dynamic and static requirements The side (bumerang) were deformed under laod and so that horizontal displacement of the H-point was not Parameters of materials are changing meeting specification When did it happen ? Boomerang must absorb the energy in crash test Jan 24th 06 Who has detected it ? DIN allowed these changes SDS Validation Stadthagen and Design Engineering

What happened?

Where has it been detected ?

How has it been detected?

What happened?

Boomerang must be weak to fullfill the dynamic specification

Faurecia Stadthagen / Validation

Internal

Management

Suppliers

WHAT IS THE CAUSE? Sensors NOK, Uncontrolled resetting

Wrong position of parts When did it happen ?

4.11.2005 Who has detected it ?

Customer JCI Geel Where has it been detected ?

At Customer site Visually How many ?

1 piece

BEFORE

AFTER

Workstation could have been reset by conventional key by anyone who copied it.

Workstation can be reset only by electronic key which cannot be copied without controll.

Bucket position sensor allowes to start process even when was out of order

Bucket position sensor allowes to start process only when position OK.

Possible uncontrolled unscrew operation (quick rework)

Unscrew operation not possible. This function is blocked in screwdriver.

How many ?

AFTER

Logistics

Occurrence

Why it is a problem?

ECE-R14 test

BEFORE

8.05.2006

Detection

Gap between side member and crossmember

How has it been detected?

1 part

Type

SMPG /Frames-Div. / Geiselhöring

Type

BG/Div/Site: UAP/Line:

08/02/2006

ET 4448124 A

ZSB

Property of Faurecia - Duplication prohibited

4448718 A

without additional wire

WHAT WE LEARNED

with additional wire

FACTOR

WHAT WE LEARNED FACTOR

Relevant factors of ECE-R14 test

CONTROL POINT (What to do?, how?, when?, who?)

what: SDS Validation Stadthagen how: ECE-R14 test when: see crash-test schedule who: SDS Validation Stadthagen

UAP 1 AU 716 2nd row Plant Geiselhöring SMPG / Frames / Plant Geiselhöring

(What to do?, how?, when?, who?)

STANDARD / REACTION RULES

STANDARD / REACTION RULES

Following NOK procedure countinously result crash test (COP)

NOK procedure audit for every employee Every 3 months Done by Quality Inspector Confirmed in Training Records

"Confirm'"is when bad part is proceed by operator according NOK procedure "Not Confirm" is when it is not proceed acurately

Potential Applicability

Potential Applicability Plant: Division: BG's/Group:

CONTROL POINT

Plant: Division: BG's/Group:

Aplicable N/A N/A

38

Property of Faurecia - Duplication prohibited

FAS

39

Property of Faurecia - Duplication prohibited

FIS

40

7 Quality basics in Development Evaluation form NAME :_____________________________Session:_____________________________________ Value added of the module 1 2 3 4

Comments

Introduction

Capitalization & Transversalisation

Key Characteristics

FMEA

Evaluation Form to fill in

Strict control plans

Program QRQC

Validated Engineering Changes

Property of Faurecia - Duplication prohibited

Functional milestones & Progr Steering Com & Gate Reviews How to accelerate

Conclusion Rating: 1 = Poor

2=Average

General Appraisal

1

2

3=Good 3

4= Excellent

4 Comments:

41

7 Quality Basics in Development

Key Characteristics & Strict Control Plans Victor GARCIA PARRA

7 Quality Basics in Development

Functional Milestones, Program Steering Committee and Gate Reviews

Program QRCI

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

FMEA

Validated Strict Control Engineering Changes Plans

Key Characteristics 43

Key Characteristics

Agenda

Property of Faurecia - Duplication prohibited

How to manage Key characteristics How to build a Control Plan Workshop Debriefing

20 mn 20 mn 25 mn 5mn

44

Introduction Critical dimension “X” = S/R = 1 Which dimension is critical as well? A±a

B±b

C±c

=> A, B, C, D or All ? D±d

“Sub-Assy”

Property of Faurecia - Duplication prohibited

X±y

1

“Slide” 45

Introduction For an appropriate answer => apply Key Characteristics Management:

• Objective: determine which dimensions are critical and which have to be kept under control!

• Use Tolerance Chain Management (TCM)

Property of Faurecia - Duplication prohibited

X±y A±a

B±b

C±c

1

D±d

“Assy” 46

Property of Faurecia - Duplication prohibited

Introduction

Reality is more complex

47

Objectives

• Transform key customers requirements into a manageable list of key characteristics

• Drive focus on priorities during product & process development

• Allow early warning for non quality due to capabilities not met on customers priorities Property of Faurecia - Duplication prohibited

• Key characteristics management is a process which contributes to build an efficient control plan A±a

B±b

C±c

D±d

48

How to manage “Key Characteristics”

• Understand interactions between product and process characteristics.

• Know guidelines to minimize the initial control size.

Property of Faurecia - Duplication prohibited

• Implement 3 step process to define & monitor Key Characteristics.

49

How to manage “Key Characteristics”

• Understand interactions between product and process characteristics.

• Know guidelines to minimize the initial control size.

Property of Faurecia - Duplication prohibited

• Implement 3 step process to define & monitor Key Characteristics.

50

Product & Process Characteristics

Product Characteristics

Non-Key Product Characteristics

Characteristics

Process Characteristics Property of Faurecia - Duplication prohibited

Key Product Characteristics KPC

Key Control * Characteristics KCC Non-Key Control Characteristics

Product Characteristic which affects 1

2

Process Characteristic which affects 1

2

Need to be controlled to ensure minimized variation of product characteristics * “Key Process Characteristics” = “Key Control Characteristics” / KCC

51

Interactions between KPC & KCCs

EFFECT

CAUSE Material

Method

Manpower

KCC KCC

KCC

KCC

KCC

KPC

KCC KCC KCC

Property of Faurecia - Duplication prohibited

Machine

Measure

KCC

Environment

Many KCCs KCCs factors can affect KPC Ongoing of is required KCCs are determined Once Control ofcontrol KCCs are defined willKPC ensure and that in aplace, theifvariation KPC checks of not themay related be reduced KPC is minimized and performed during validation => e.g. changes in material candesign affect or theproduction KPC 52

Interactions between KPC & KCCs

EFFECT

CAUSE Method

Material

Manpower

Suspension Deflection

Qualified operator

Inspection measurement

Cushion foam density

Mannequin

Test Protocol

Metrology hard & software

Training

KPC

Humidity

H - Point Conditioning V

Property of Faurecia - Duplication prohibited

Machine

Measure

Environment

Y

E M P C G

Example : H-Point / Seat

H Ch D

53 S

How to manage “Key Characteristics”

• Understand interactions between product and process characteristics.

• Know guidelines to minimize the initial control size.

Property of Faurecia - Duplication prohibited

• Implement 3 step process to define & monitor Key Characteristics.

54

Guidelines to minimize control size 1.KPC KPCwhich which can is validated and fulfill automatically the requirements through inits DV KCC &isPV because (e.g. ECE, 3.2. needs tocontrolled be controlled regularly there no related “Control ofbe Process Characteristics ( because KCC) will ensure that the The series control size of KPC can be reduced or eliminated along the FMVSS, etc) can beof reduced to zero or few numbers of the “Continuous or Poka-Yoke in place. The control hascontrolled) tominimized” be defined variation the Characteristics is • KCC Its process is stable (process variation issize under development phases asProduct following: ComplianceisTesting” • accordingly. Poka-Yoke in placeRequirements Design

Pre-Series/

Verification

Series Production

KPC KPC

Initial

KPC

KPC KPC

KPC

Control PMS

KCC

Size Property of Faurecia - Duplication prohibited

KPC

KPC

KCC

KPC

KPC

KCC KCC

KPC

KPC

KPC

KCC

Customer’s called volume

KCC KCC Control

Size KPC

KCC

Series

KPC

KPC

Non Conformity Cost = ppm x called volume 55

How to manage “Key Characteristics”

• Understand interactions between product and process characteristics.

• Know guidelines to minimize the initial control size. • Implement 3 step process to define & monitor Key Property of Faurecia - Duplication prohibited

Characteristics.

56

3 step process Program award

Customer Inquiry

1

2 a&b

G R 1: Designate KPCs Step1 Management decisions

QUOTATION

GO / NO GO

DECISION

GR 2

DRAWINGS S R

PROGRAM CONFIRMATION

FIT FUNCTION

Non-KPCs

PRODUCT CHARACTERISTICS

Property of Faurecia - Duplication prohibited

Customer production part approval

Customer tool release

KPC SPECS

INVESTMENT APPROVAL

3

INPUTG R

SOP

4 GR 4

3

5

KPC’s list Cust. requirements (CtC) Warranty data Suppliers concerns

OUTPUT Control Plans Process Flow Diagram Record KPCs Record KCCs

Responsible: R&D Engineer : Program/Acquisition Manager, PQL, Buyer, Supplier, Quality, Sales, Product Manager

PROPOSAL

Recommended Tools: FA, D-FMEA, PRODUCTION SET- UP TCM, FEA PRODUCT & PROCESS LAUNCH & PRE-SERIES DESIGN & DEVELOPMENT T DEVELOPMEN C.t.C = Critical to customer lists, TCM = Tolerance Chain Management, FEA = Finite Element Analysis Max 2 Months

SERIES PRODUCTION

Min 3 Months Max 6 Months

57

3 step process

Customer Inquiry

1

Program award

2 a&b

GO / NO GO

3

G R 1 Step1 : Designate KPCsG R 2

QUOTATION DECISION

S R

Step2 : Monitor KPCs,KCCs GR 3 KCC

DRAWINGS

Management decisions

Customer production part approval

Customer tool release

KCC

KPC

SPECS

Non-KPCs

5

KP C

INVESTMENT APPROVAL

KCC

FIT FUNCTION

4 GR 4

KCC

PROGRAM CONFIRMATION

SOP

KCC

KCC

Cause

Input

Effect

PROCESS CONTROL PLAN KPC

KCC

Output

CONTROL

PRODUCT CHARACTERISTICS

Property of Faurecia - Duplication prohibited

S/R list Fit & Function list Product Drawings Industrial Drawings Product Specs.

Control Plans Process Flow Diagram Record KPCs Record KCCs

Responsible : PQL : Program Manager, Supplier Quality, Validation Engineer, Proto Lab, Plant Quality, R&D, Process Pilot, Plant Launch team (Launch Mgr.)

Recommended Tools: P-FMEA, Process Flow Diagram, Control Plan, DoE, PRODUCTION SET- UP PRODUCT & PROCESS SERIES Cause-Effect Diagram, Pareto Analysis, Capability Study LAUNCH PROPOSAL & PRE-SERIES DESIGN & DEVELOPMENT DEVELOPMEN T

DoE = Design of Experiment Max 2 Months

PRODUCTION

58

Min 3 Months Max 6 Months

Action steps along PMS

Customer Inquiry

Program award

GR 1 Step1 : Management decisions

GO / NO GO

QUOTATION DECISION

2 a&b

DRAWINGS

S R Designate

FIT FUNCTION

KPCs KPC SPECS DRAWINGS

KPC

PRODUCT CHARACTERISTICS FIT FUNCTION

Property of Faurecia - Duplication prohibited

Control Plans PRODUCT CHARACTERISTICS Process Flow Diagram Record KPCs Record KCCs

KCC

GR 2

KCC

KCC

GR 3 3 Step2 : Plan & Apply control KP duringC the

4 GR 4

5

1st :Designate KPCs system KPCs,KCCs ph.1 & 2 KCC KCC team collects input data/Lessons learned - KCCDesign KCC KCC KCC Effect Caus of relevant characteristics, e.g. customer KPC list, e PROCESS CONTROL KP Spec., PLAN C KP KCC.t.C, CONTRO Warranty, supplier concerns,… L C KCCC KCC KCC - Define KPCs, Non-KPCs of designed product Effect Cause - Step3 The respective team (R&D, PQL, : Improve program KPCs,KCCs Buyer, …) controls PROCESS CONTROL PLAN KCC KCC KPC identify KPC Series the S/R or Fit/Function INVESTMENT APPROVAL

S Non-KPCs PROGRAM CONFIRMATION R

INPUT Non-KPCs

SOP

Step2 : Monitor KPCs,KCCs

Step1 : Designate KPCs

1

Customer production part approval

Customer tool release

SPECS KPC

Initial

KPC

KCC

CONTROL

KCC

KCC

VARIABLES CONTROL CHART

OUTPUT

Step3 : Improve KPCs,KCCs controls KPC 2nd:Plan & Apply control systems KPCs/KCCs during the Instructions ph. 2 & 3 KCC Initial KCC KPC KPC Series - Reduction Each KPC’s related KCCs are determined (shown in cause-effect of Variation Control records KCC diagram) VARIABLES CONTROL - Planning ways to control KCCs or KPCs KCCs are KCCif no related CHART 3rd :Improve KCCs controls during the ph. 3&4 (&5) identified Responsible : Plant Launch Team Leader (Launch Manager) - Planning methods for reducing the - Record the tests results (dimension, functional, …) : Program Manager, variation within the targetedPlant value Manager, PQL, Supplier Quality, Plant Quality, Process Pilot - Monitoring the results Reduction of Variation - Maintain/improve control planSPC, size & DVP&R, P-FMEA, Recommended Tools: DoE, Control Plan, QRCI, QSE, R@R frequency PRODUCTION SET- UP

PRODUCT & PROCESS DoE = Design of Experiment, SPC = Statistical Process Control, DVP&R = Design Verification Plan & Report, LAUNCH PROPOSAL & PRE-SERIES DESIGN & DEVELOPMENT DEVELOPMEN T

SERIES PRODUCTION

QRCI = Quick Reaction Quality Control, R@R = Run at Rate Max 2 Months

Min 3 Months Max 6 Months

59

Key Messages: Key Characteristics:

• Improves better understanding of customer

Property of Faurecia - Duplication prohibited

requirements • Helps to focus on product & process priorities to reduce & permits control size reduction • Allows early warning on capabilities not met & prevents S/R issues in the field & customer recalls • Can ensure robust designs Is a prerequisite to define efficient control plans 60

7 Quality Basics in Development

Functional Milestones, Program Steering Committee and Gate Reviews

Program QRCI

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

FMEA

Validated Strict Control Engineering Changes Plans

Key Characteristics 61

Key Characteristics

Agenda

Property of Faurecia - Duplication prohibited

How to manage Key characteristics How to build a Control Plan Workshop Debriefing

20 mn 20 mn 25 mn 5mn

62

Introduction: Session Objectives Ensure a Global Understanding of Control Plans Improve the Content and Execution of Control Plans

Property of Faurecia - Duplication prohibited

Clarify the Contribution of each Function Be aware of incurred risks if not properly deployed and applied 63

Bad Control Plan can kill People!

Renault Vel Satis

Property of Faurecia - Duplication prohibited

Red alert NOK COP test Field campaign

Root cause 1. Why: IP insert broken 2. Why: Material brittel

Aug/2003:

3. Why: NOK glass fiber and PU rate

16 cars NOK/400 in the field.

4. Why: Not checked at OK first part 5. Why: Not a KPC (absent in drawing & control plan) 64

Introduction: Control Plan Objectives Protect Internal & External Customers (Safety / Fit & Finish / Function) Efficiently ensure Product Conformity in spite of Supplier and Process Variability,

Property of Faurecia - Duplication prohibited

Define Reaction Rules in case of deviations Reduce Variability 65

Introduction: Control Plan Definition

• •

Written Description of Activities for Process Controlling List of Planned Tasks to be applied by Defined Responsible People People (Operators, GAP Leaders, Maintenance, Quality, Lab …) to ensure Product Conformity => Who does what, when, where and why ? • Control Plan lists all Process Parameters and Product Characteristics Characteristics that require Specific Quality Actions ⇒ 3 levels exist according to the Programs Phases

Property of Faurecia - Duplication prohibited

GR1

1 ACQUISITION

GR2A

2A DESIGN

Prototype Control Plan

GR2B

2B DESIGN VERIFICATION

GR3

3 PRODUCTION SET-UP

PreProduction Control Plan

GR4

5 4 LAUNCH PRODUCTION

Production Control Plan

66

Prototype Control Plan Layout

Prototype Phases

PT

Prototype Shop

Suppliers

Property of Faurecia - Duplication prohibited

•100% Visual Inspection •100% Measurement on Key Characteristics

0p 1

0p 2

0p 3

100% Visual Inspection

100% KC Measurement

100% Visual Inspection & Measurement of Key Characteristics @ Supplier & Faurecia Locations Complete Design Validation Plan Initiate Production Validation Plan

Customer Internal & External Customer Satisfaction

67

Pre-Production Control Plan Layout Target: achieve 15 Ppm & 100% Efficiency @ SOP

PT

Manufacturing Plant

Sorting of Finished Goods on selected Key Characteristics Quality Wall

Supplier

Property of Faurecia - Duplication prohibited

Sorting of BOP on selected Key Characteristics

Quality Wall

Incoming Goods Inspection

0p 1

0p 2

0p 3

Final Inspection

Quality Wall @ Supplier & Faurecia Locations

Incoming Goods Inspection Higher Frequency & Sampling Size on Key Characteristics Monitoring Initiate SPC on Key Characteristics Complete Production Validation Plan

Customer Internal & External Customer Satisfaction

No Non-Conformity on Critical Characteristics allowed on Saleable Cars

S R 68

Production Control Plan Layout Target: achieve 15 Ppm & 100% Efficiency @ SOP

Manufacturing Plant

0p 1

Supplier

Property of Faurecia - Duplication prohibited

BOP delivered in Self-Certification Status

0p 2

0p 3

Final Inspection

Adjust Frequency & Sampling Size on Key Characteristics monitoring according to Product & Process Variability Drive Continuous Improvement through SPC on Key Characteristics Product Audit Lessons Learned to Programs

Customer Internal & External Customer Satisfaction

69

How to apply Control Plan ? (Sample Check) Clear decision rules Process No is stable

Natural Process Limits

Need 100% check for Key Control Characteristics

Natural Process Limits

Yes Could be checked by sampling with basic rules:

Property of Faurecia - Duplication prohibited

: Suspected lot must be checked 100% with traceability OK Lot

Suspected Lot

OK

OK

OK

OK

OK

NOK

OK

OK

OK

100% check Time

: SPC control with action rule UPR limit

X

Action limit

X

ACTION !!

X

Nominal Action limit

X

LWR limit 70

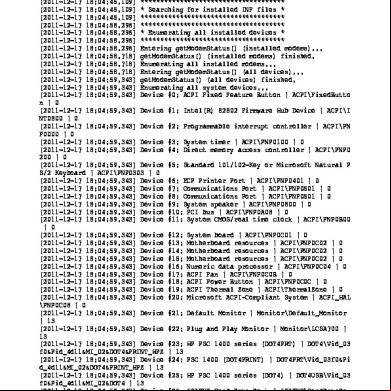

How to apply Control Plan ? (Instructions Sheet) Parts name (process : final check) N°

Check point

By

Frequency

Criteria

If not OK

1

Deformation

Visual

100%

OK - NOK sample

Repair

2

Dimension A

Micro meter

1/120

+ 0,2 mm

Scrap

3

Dimension B

Gauge

100%

Go - No go gauge

Scrap

4

...

...

...

...

5

...

...

...

6

...

...

...

7

...

...

8

...

...

9

Property of Faurecia - Duplication prohibited

10

No Subjective Criteria

...

...

Clear Decision Rules ...

...

...

...

...

...

...

...

...

... ... ... ... ... Maxi 10 Points to be Checked per Work Station ... ... ... ... ...

4

7

8

Pictures or Schemes5 to position the Criteria

1 3

10 2

9

6 71

Control Plan – Good Practices Pre-Production

Reaction Rules defined

Key Characteristics defined with Nominal + Tolerances

Property of Faurecia - Duplication prohibited

Production

Higher Sampling Size

72

Property of Faurecia - Duplication prohibited

Responsibilities

Actor

Validator

Prototype Control Plan

Product Development Leader + Program Quality Leader

Program Manager

PrePre-Production Control Plan

Program Manufacturing Leader+ Program Quality Leader + Plant Quality Manager

Program Manager Plant Manager

Production Control Plan

Program Manufacturing Leader + Plant Quality Manager

Plant Manager

Program Managers and Plant Managers are responsible for the strict application of the Control Plans Control Plan is the “Safety Belt” to protect us about “Past Quality Concerns” 73

How to write a control plan ?

Property of Faurecia - Duplication prohibited

General Information

Product characteristics only: -dimension, -appearance, -function, -part number -physical & chemical properties (temperature, fiber glass content, porosity, crack, adhesion, etc.)

Process parameters only: -temperature -pressure -velocity -torque -force -handling -positioning -labeling -scanning -packaging -etc. Poka-yoke identification nber

Process / ToolsKPC KCC To be Monitored Description

Checking / Monitoring Reaction Rules Methods

74

Workshop : Practical exemple (30’)

Property of Faurecia - Duplication prohibited

Built production control plan related to shoot channel 8 nuts screwing operation : Documents provided: Drawing KPC/KCC Ishikawa diagram DFMEA/PFMEA SR fastening mandatory points Blank control plan format Share by table conclusions 75

Interactions between KPC & KCCs Proposed answer CAUSE Material

Method

EFFECT Manpower

Ergonomics Backup (tools angle, procedure if overview, ...) Training Poka Yoke Nut Alloy S/R rules Inoperative Faurecia (eg : 2 Self-locking remaining nut P/N threads / stud Poka Yoke …) part blocked at Torque & angle Grease Torque Station Calibration free Torque range Dirt or painting Screwdriver accuracy Maintenance free in acc. with torque. Stud Alloy

Property of Faurecia - Duplication prohibited

Machine

Speed / Angle / Torque ramp-up programming method

Measure

KPC Torque (6+/-1 Nm)

Environment

Example : Chute channel assembly to Airbag Flap Reinforcement 76

T5 Airbag shoot channel assembly control plan

Prototype

Pre-launch

Key / Telephone Demmy Yoosuf / 0044 7787 516731

Production

Date (Original) 12/03/03

Signature (Quality)

Date (Revision) 17/03/2005

Part Number / Latest Change Level FAB500150XXX (LHD NoNav), FAB500140XXX (RHD NoNav) FAB500160XXX (RHD Nav), FAB500170XXX (LHD Nav)

Core Team D. Yoosuf, T. Giraud, L. David, Richard Cornick Stephane Beaupere, Michael Levasseur, Fadel Wade, , Manuel Ventura, Dave Herrington

Customer Engineering Approval / Date (If Required) 28/11/03

Part Name / Discription TOPPER PAD ASSY NO NA V & NO NAV LH&RH

Supplier / Plant Approval / Date

Customer Quality Approval / Date (If Required) 28/11/03

Other Approval / Date (If Required)

Other Approval / Date (If Required)

Supplier Code CXVNA

Supplier / Plant Faurecia / FRADLEY

Property of Faurecia - Duplication prohibited

Part/ Process Number

Process Name/ Operation Description

Characteristics

Machine, Device Jig, Tools for Mfg.

No.

Product

Specia Process

Char. Class.

Product / Process Specifications / Tolerance

Sample

Evaluation/ Measurement Technique

Size

Frequence

Control Method

Reactio Plan

Resp.

77

T5 Airbag chute channel assembly control plan 300

300

300

Property of Faurecia - Duplication prohibited

310

Assembly Line - Post-Welding

Fixation of Airbag Chute to Georges Renault Driver Topper Pad Assembly System

Fixation of Airbag Chute to Georges Renault Driver Topper Pad Assembly System

Traceability Recording

Scanner, Manual backup

1

-

2

-

3

Airbag Chute Batch, Chute fixation nuts batch number

Torque

Torque

-

CC

6NM +/- 1NM

Screw driver with inbuilt torque transducer

1

a) Follow Poka Yoke validation Instruction b) Record results on Poka Yoke Shift Start Up validation record sheet c) Record on start up sheet set & actual torque for 1st off part

CC

6NM +/- 1NM

Screw driver with inbuilt torque transducer

1

Every Part a) Automated check.

CC

Critical components are traceable to manufacturing batch

Recorded electronically or manually held logs

1

Every Part

a) Follow Standard Operation FIS-F-PS-241/EN V2

a) Inform GAP Leader & Supervisor if Poke Yoke system fails. b) Inform maintenance to rectify problem.

a) Inform GAP Leader & Supervisor if Poke Yoke system fails part. b) Inform maintenance to rectify problem. c) Backup driver to be used if original cannot be repaired otherwise stop production.

a) Record batch information on manual traceability sheets.

…and additionally , electrical fastener initial torque calibration and then …regular checking ! 78

Property of Faurecia - Duplication prohibited

Key Messages

Control Plan is a living document! Continuously upgraded Information should be shared

Control Plan is a contractual document! Strict application is mandatory Any deviation or modification must be submitted to Customer before release

Control Plan is a confidential document!

Control Plan is requested also from our Suppliers! 79

7 Quality basics in Development Evaluation form NAME :_____________________________Session:_____________________________________ Value added of the module 1 2 3 4

Comments

Introduction

Capitalization & Transversalisation

Key Characteristics

FMEA

Evaluation Form to fill in

Strict control plans

Program QRQC

Validated Engineering Changes

Property of Faurecia - Duplication prohibited

Functional milestones & Progr Steering Com & Gate Reviews How to accelerate

Conclusion Rating: 1 = Poor

2=Average

General Appraisal

1

2

3=Good 3

4= Excellent

4 Comments:

80

7 Quality Basics in Development

Property of Faurecia - Duplication prohibited

Agenda 7:45 8:00 8:20 8:35 9:00 10:10 11:10 11:25 12:05 12:45 15:45 16:00 16:55 17:00

Welcoming coffee Opening comments Introduction Capitalization & Tranversalization Key Characteristics & Strict Control Plans FMEA Break Validated Engineering Changes Lunch Program QRCI Break Functional Milestones & Gate Reviews Conclusion End

J.M. Renaudie K.Sato K.Sato V.Garcia Parra PL.Soula E.Jacquot J.Burke PL.Soula K.Sato

81

FMEA Training Module Paul-Louis SOULA

7 Quality Basics in Development

Functional Milestones, Program Steering Committee and Gate Reviews

Program QRCI

Property of Faurecia - Duplication prohibited

Capitalization & Transversalization

FMEA

Validated Strict Control Engineering Changes Plans

Key Characteristics 83

Failure Mode and Effect Analysis

1. 2. 3. 4. 5. Property of Faurecia - Duplication prohibited

6.

Reasons for FMEAs Objective of FMEAs Types of FMEAs How to build a Design FMEA How to build a Process FMEA Workshop

84

Red Alert with Customer impact Defect: No-relocking of one of the 2 slides. Bad hafting of the handle bar inside the slide : handle bar assembly inside the leg for recall of the handle bar. LESSON LEARNED SHEET

D5 - Root Causes of Occurrence Applica tion da te :

No g en t s ur Ve rn iss on

U AP/Line: A uthor :

Qua li ty De pa rt

Type

B G/D iv/Site :

All a n GOUR ET

WHAT WAS THE PROBLEM? (5W + 2H) What happ ened? Bad hafting of the handle bar inside the slide : handle bar assembly inside the leg for r ecall of the handle bar. Why it is a p ro blem? No-relocking of one of the 2 slides.

nov- 09

Detection

Lo gistics

Occu rre nce

Internal

Manag ement

Supp liers

1. No product poka yoke ; estimated nonnecessary by mechanisms 2. New operator (2 days of experience) without the good sensibility

WHAT IS THE CAUSE? Possibility to assembly the handle bar in the slides but in a bad position in the slide's locking spring.

Sl ide Fema le pro file

When did it happ en ? Detected the 29th Apr il of 2009. Cr eated the 24th April of 2009 at 12AM07. Loc k

Who has det ect ed it ? Detected by operator in SOT EXO . Where has it b een det ect ed ? Detected dur ing tr iming of the seat in Ho w h as it been d etected ? Detected during triming of the seat : not

Gu idi ng at 22°5

Male p rofil e

Ho w m any ? 1 case

BEFORE

In stall ation o f the h an dle b ar

AFTER

Possibility to put the handle bar in this hole of the locking spr ing

New design of the locking spring with adding of a product's poka-yoke

Property of Faurecia - Duplication prohibited

D4 - Root Causes of Non-Detection No specific inspection concerning this point in the control plan and FMEA cotation at 32. 1. Assembly of the handle bar without visibility 2. FMEA Gravity at 8 : Missing of hierarchisation at 1 on the drawing and preconisation from Flers 3. FMEA detection and occurence at 2 : No case before this one. 4. Detection : potentialy sensitive but depending of the operator ITEM (Control Factor)

WHAT WE LEARNED METHOD

CRITERIA

D:\maniae\A Perso\ D:\maniae\A Perso\ SRC\Alerte s Qualité\X95\JR95\Mauv SRC\Alertesais Qualité\X95\JR95\Mauv ass palonnier gliss ièreai s\Workshop s ass palonnier R ed ga

Assembly in t he good hole of the slide's locking spring

Product poka yoke

I mpossibility of assembling the handle bar in another hole t hat necessary to it s function

9700 slides checked out of which 2000 vehicles checked at customer place 85

Background # 6442

SR Alert Re-Occurrence prevention Memo Application date :

26-oct

BG/Div/Site:

SMPG Nompatelize

UAP/Line:

Backrest T7

Author :

T.Delattre/A.Moussaïd

WHAT WAS THE PROBLEM? (5W + 2H)

Design Process Mix OK/NOK Testing Supplier

Link to AMS 6442

Cause

NC freeplay on backrest and potential recliner Unclear definition of cable tension neither unlcking. efficient tool to set it right (gap setting) 36 NC parts segregated on July 12th by resident at customer PSA during function test. Not OK (Before)

No clear instruction for the operator who was left alone to decide correct fitting

OK (After)

Gages in place to garantee repeatable cable and recliner positionning as well as proper cable tension

D 5 Root cause of non conformance The backrest unlocking cable was set up too short. Consequently the backrest was partially unlocked and there was a noticeable freeplay D 4 Root cause of non Detection

Control method was not defined with clear criteria Risk was wrongly evaluated during FMEA Study and no precise action was defined to prevent defect to be stopped

Property of Faurecia - Duplication prohibited

Defect detected during Preproduction, 405 seats checked at customer

86

Before to start… 1 Proposal

At which stage of the PMS

2A Design

should be performed:

Property of Faurecia - Duplication prohibited

2B Design Verification

A Design FMEA ? A Process FMEA ?

3 Production SetSet-up 4 Launch 87

5 Sé Séries Production 87

FMEA: At what stage of PMS ? 1 Proposal

FUNCTIONAL Analysis KPC (Key Product Characteristics) Characteristics) identified from customer Requirements

Property of Faurecia - Duplication prohibited

continuus updating

2A Design

Product FMEA initiation KPC list completed Expert/Designer suppliers product KPCs identified on 2D and BOM Process FMEA initiation KCC List identified

2B Design Verification

Product FMEA completed Expert/Designer suppliers KPCs validated KPC/KCC included in Pre-production control plan BOPs, BOPs, tools, gauges, equipments ordered

3 Production SetSet-up

Process FMEA completed Pre--Production Control Plan Implemented Pre PVP tests results successful Mass Production Trial Successful Process Capability achieved

4 Launch 5 Sé Séries Production

Production Control Plan Implemented Lessons learned Product and Process FMEAs review and feed back 88

Property of Faurecia - Duplication prohibited

FMEA Objectives

1.

Reduce risks related to the Product and the process definition and improve reliability and be documented

2.

Drive focus on priorities (Safety, reliability and functionality) during product & process development after criticality ranking

3.

Identify the key needed verifications during the product/process development phase and during the production cycle

4.

Reduce costs and Development time

5.

D-FMEAs and PP-FMEAs are the links between Key Characteristics and Control Plans

Risks

89

FMEA Definitions

Failure Mode & Effect Analysis

Ref: FAU-S-DSG-3040

The FMEA is a preventive analysis tool aimed at

reducing risk during definition and validation of the Product and the Process designs against a

functional specification. It is a way of improving product reliability

Design FMEA identifies potential failures of the product design during the complete life cycle of the product ( part manufacturing,

The

subcomponents assembly, part handling, car assembly, final customer use, product end of life etc…) It applies to all products designed by and for Faurecia. After program is completed, the Design FMEA is updated every time there is a change in product design that could affect the validation of the product.

Property of Faurecia - Duplication prohibited

The Process FMEA identifies potential failures of the product due to the manufacturing process from raw material transformation up to customer use i.e. subcomponent manufacturing ( press, injection, machining etc…), subcomponents assembly, transportation, part handling, car assembly etc… It applies to all products manufactured inside or outside Faurecia. After program is completed, the process FMEA is updated every time there is a change in product or process that could affect quality of the product. 90

REDUCE THE COST OF MODIFICATIONS Tooling modifications

Property of Faurecia - Duplication prohibited

Drawing modifications

Slide version 02

91

The FMEA Types and Teams

Object

Design-FMEA (Product-FMEA)

Process-FMEA

Property of Faurecia - Duplication prohibited

Product Design

When

Responsible Product Design engineer or System architect

Product (System, Component)

Starts at End of Concept Phase

Production process

After first process definition

Process & Tool Engineer

Product Design

Quality

Quality

Teams Design-FMEA Team Functions

Validation Process Engineering

Process-FMEA Team Functions

Manufacturing

People with experience

Process Engineering 92

How to perform a FMEA

D-FMEA or P-FMEA

FMEA Number:

PROCESS

DESIGN

FMEA Date: Engineering level/index:

PILOT-leader :

EFFECT

MODE

S:

Severity

D : Detectability

Potential Cause of failure

O:

Design validation (D-FMEA) Process controls (P-FMEA) Prevention

Occurence

Detection

RPN :

RPN

(DFMEA)

Detection

(PFMEA)

Life situation (DFMEA):

POTENTIAL FAILURE

KCC nb

Product Function definition studied

Class

Part or Device or Item :

Process Step definition

Class can be S/R ( or "1") or "2" (function) or no value

Property of Faurecia - Duplication prohibited

Updated on :

Product :

KPC nb

N°

Drawing reference :

Severity

Line and Plant (PFMEA) :

Type of vehicle or device : FAU-f-DSG-4040/en

Occurrence

Design FMEA

Recommended Corrective Actions Responsible N°

Description

Target completion date

Forecasted new RPN Action taken S

O

D

RPN

RPN checked after actions implemented S

O

Risk Priority Number

1- Product function (DFMEA) or Process step (PFMEA) 2- Potential failure Mode 1- Potential cause of failure + occurence 3- Potential Effect 2- Key Characteristics number 4- Severity 3- Design Validation (DFMEA) 4- Process control (PFMEA) + Detection 5- RPN calculation 1- Recommended Corrective Actions 2- Responsible & target date 3- Action taken 4- Forecasted RPN 5- RPN checked after actions implemented 93

D

RPN

1st Step: Identify Failure mode (1/2) D-FMEA or P-FMEA

1- Which function to study (DFMEA) Process Step definition

Product Function definition studied

(PFMEA)

(DFMEA)

POTENTIAL FAILURE MODE

EFFECT

KPC nb

N°

Part or Device or Item : Class

Line and Plant (PFMEA) :

FAU-f-DSG-4040/en

Severity

(for each life situation)

Type of vehicle or device : Product :

Property of Faurecia - Duplication prohibited

2 - What can go wrong? - No function - Partial/over function or degraded over time - Intermittent function - Unintended function

3 - What are the worst effects for each failure mode?

4 – How bad is it ? Identify a severity rating

94

Property of Faurecia - Duplication prohibited

“S” : SEVERITY GRADING CHART (Design and Process)

95

2nd step: Evaluate Root cause and Current Controls (1/2)

PROCESS

DESIGN

Drawing reference : Engineering level/index:

Prevention

Detection

RPN

Design validation (D-FMEA) Process controls (P-FMEA)

Detection

Potential Cause of failure

KCC nb

Life situation (DFMEA): Occurrence

1- Identify the associated cause (first level and root) 2- The estimated occurrence

DFMEA

Property of Faurecia - Duplication prohibited

3- The actions already performed during Product design Prevention: Which checks have been made or standards used in order to make the design more robust Detection: Which checks or tests are currently included in the DVP design validation plan

4- Detection rating: How confindent are we with current definition of the DVP to detect a potential defect 5- RPN calculation 96

1st Step: Identify Failure mode (2/2) D-FMEA or P-FMEA Type of vehicle or device : Product :

1- Which process to study (PFMEA) Product Function definition studied

(PFMEA)

(DFMEA)

POTENTIAL FAILURE MODE

EFFECT

KPC nb

Process Step definition

Class

N°

Part or Device or Item : Severity

Line and Plant (PFMEA) :

FAU-f-DSG-4040/en

Property of Faurecia - Duplication prohibited

2 - What can go wrong? See below types of defects (for function consider degraded or intermittent due to process)

3 - What are the worst effects for each failure mode?

4 – How bad is it ? Identify a severity rating? Is it a KPC ?

97

Property of Faurecia - Duplication prohibited

“O” : OCCURRENCE GRADING CHART (Design & Process)

98

Property of Faurecia - Duplication prohibited

“D” : DETECTION GRADING CHART (Design)

99

2nd step: Evaluate Root cause and Current Controls (2/2)

PROCESS

DESIGN

Drawing reference : Engineering level/index:

Prevention

Detection

RPN

Design validation (D-FMEA) Process controls (P-FMEA)

Detection

Potential Cause of failure

KCC nb

Life situation (DFMEA): Occurrence

1- Identify the associated cause (first level and root) 2- The estimated occurrence

KCC identified as a contributor to achieve the KPC

PFMEA

Property of Faurecia - Duplication prohibited

3- The actions already performed during Process design Prevention: Which controls are included in the process in order to reduce the defect to occur Detection: Which controls are included in the process in order to detect the defect when it occurs

4- Detection rating: How confindent are we with current definition of the Process to detect a potential defect 5- RPN calculation 100

“D” : DETECTION GRADING CHART (Process)

Property of Faurecia - Duplication prohibited

If a later operation (same plant) can stop a defect like a double visual check, rating could be reduced by 1

101

Risk priority number ( or RPN)

Property of Faurecia - Duplication prohibited

RPN= : S x O x D

Severity or Probability that the failure will be serious

Probability that the cause/mode will occur

Probability that it won't be detected

Slide version 02

102

3rd step: Corrective Actions 1- Recommended Corrective Actions for Prevention and Detection: What can be done for - Design changes, - Standard changes, - Process changes - Special controls ?

FMEA Number: FMEA Date: Updated on : PILOT-leader :

Recommended Corrective Actions Responsible N°

Description

Target completion date

Forecasted new RPN Action taken S

O

D

RPN

RPN checked after actions implemented S

O

D

RPN

Property of Faurecia - Duplication prohibited

2- Responsible & target date

3- Forecasted new RPN Action taken ? Is action sufficient ?

4- When action has been taken ( if action is different from initial, please mention it) 5- New RPN after actions are implemented Is action sufficient ? 103

PREVENTIVE ACTIONS

Once critical failures are identified preventive or corrective actions are decided for the highes highest RPNs RPN > allowable limit (*) => ACTION

Property of Faurecia - Duplication prohibited

The future of our company depends on risk control

Once actions are in place the RPN should be recalculated it becomes: RPN' RPN' Faurecia urecia rules (*) may depend on customer requirement if more stringent than Fa Slide version 01

104

What have we learned on Design FMEA OUTPUTS

INPUTS

Design validation plan (product tests)

Product requirement Functional analysis Warranty, returns and rejects

Property of Faurecia - Duplication prohibited

modifications Programme goals (ppm, ppm, reliability, maintainability,… maintainability,…

Regulations

Formalise a critical examination of product design Ensure that the product design conforms to customer and legislative requirements

Design Poka Yoké Yoké Prototype control plan List of product special characteristics Corrective actions plan Measurement concepts, gages and instructions

FAU--S-PMFAU PM-3040 Slide version 02

105

What have we learned on Process FMEA Inputs

Outputs

DFMEA Process flow chart Process functional analysis Process assumptions Plant Lay out

Property of Faurecia - Duplication prohibited

Capitalization Warranty, returns and rejects Modifications Program goals (ppm, reliability, maintainability,…)

Formalise a critical examination of process design Ensure that the process design allows products made conforming to customer and legislative requirements ensure that products are not damaged in handling (transports, storage, …) including on and off site

Assembly and use instructions Serie control plan (included Process Poka Yoké) Corrective actions plan List of process special caracteristics Measurement and checking instructions FAU--S-PMFAU PM-3042 Slide version 02

106

Property of Faurecia - Duplication prohibited

8 Quality Basics in Development Group owners & PG Referent / Experts

March 18th, 2011

7 Basics

FAS

FIS

FAE

FECT

Group

Key characteristics

L.Klingauf

Ph.Lalaguë

P.Renoit/ R.Mary

F.Lueder

P.Mesnard

FMEA

M.Jordan

C.Desplanque

F.Selb/R.Mary/M. Stefan-Weber

V.Gosatti

PL. Soula

Strict Control Plans

TBD

P.Mesnard

Y.Schneider/ JF.Wyrwas

V.Gosatti

E.Jacquot

Validated Engg changes

TBD

R.Hilpert

JP.Gehin/ M.Kherbache

F.Abadie

E.Jacquot

QRCI

L.Klingauf

P.Mesnard

Y.Schneider/ JF.Wyrwas

E.Jacquot

L.Klingauf

Funct Milestone Program Stg & Gate Reviews

J.Ygout

E.Brogniart

MN.Rothan

Ch.Majchrowicz

PL. Soula

Ph.Lalaguë

F.Selb/ M.StefanWeber

Ch.Sarda

P.Mesnard

A. Selbach/ M.Schafbauer

Th.Rochard

J.Burke

Cap & Trans

TBD

Supplier Quality

Ph.Cossonnièr e

J.Robineau

107

Workshop on P-FMEA – 20 mn

1. Choose 3 failure modes 2. Establish a P-FMEA for these 3 failure modes 3. Each group to report D-FMEA or P-FMEA

FMEA Number:

PROCESS

DESIGN

FMEA Date: Engineering level/index:

EFFECT

MODE

S:

Severity

D : Detectability

PILOT-leader :

O:

Design validation (D-FMEA) Process controls (P-FMEA) Prevention

Occurence

Detection

RPN :

RPN

Potential Cause of failure

Detection

(DFMEA)

Life situation (DFMEA):

POTENTIAL FAILURE

Occurrence

(PFMEA)

Class can be S/R ( or "1") or "2" (function) or no value

108

Drawing reference :

Product :

Class

N°

Product Function definition studied

Updated on :

Type of vehicle or device : FAU-f-DSG-4040/en Part or Device or Item :

Process Step definition

KPC nb

Line and Plant (PFMEA) :

KCC nb

Design FMEA

Severity

Property of Faurecia - Duplication prohibited

Nut and L-profile assembly by resistance welding

Recommended Corrective Actions Responsible N°

Description

Target completion date

Forecasted new RPN Action taken S

O

D

RPN

RPN checked after actions implemented S

O

D

RPN

Risk Priority Number

Slide version 02

108

Nut & L-profile assembly by resistance welding

L-profile

Property of Faurecia - Duplication prohibited

Nut M10

After electrical welding

109

Nut & L-profile assembly by resistance welding

D-FMEA or P-FMEA

Engineering level/index:

G

PILOT-leader :

ME / YOKE P.

Part or Device or Item :

Nut and L-Profile assembly

Life situation (DFMEA):

-

POTENTIAL FAILURE MODE

EFFECT

Missing NUT

No welding possible, machine stop, fastening operation stopped if by , process interuption

Property of Faurecia - Duplication prohibited

1

8

Potential Cause of failure NUT forgotton to insert (Operator failure)

4

Design validation (D-FMEA) Process controls (P-FMEA) Prevention

Detection

Operator qualification level L Automatic machine stop or higher during clamping operation (Poka Yoke no. J84/27)

RPN

Resistance welding of NUT on L-PROFILE

Rear Seat Metal Structure

KCC nb

(DFMEA)

16/03/2010

Product :

O c c u rre n c e

(PFMEA)

Updated on :

C la s s

Product Function definition studied

15/07/2004

5155436/38

D e t e c t io n

40

Process Step definition

J84-P-RSS-G

FMEA Date: Drawing reference :

KPC nb

N°

FMEA Number:

Type of vehicle or device : J84 Renault Megane Scenic

S e v e r ity

Line and Plant (PFMEA) : UAP 3 / Nogent

PROCESS

DESIGN

1

32

Recommended Corrective Actions Responsible N°

Description

RPN checked after Forecasted new RPN Target completion actions implemented Action taken date S O D RPN S O D RPN

110

Nut & L-profile assembly by resistance welding

Resistance welding of NUT on L-PROFILE

Part or Device or Item :

Life situation (DFMEA):

-

POTENTIAL FAILURE MODE

EFFECT

Missing NUT

No welding possible, machine stop, fastening operation stopped if by , process interuption

1 Missing L-PROFILE

1 Wrong NUT (material, diameter, threat,....)

2 Wrong PROFILE (LH/RH)

2 NUT turned by a few degrees

3

8

No welding possible, machine stop, process interuption

6

No Belt Buckle fastening possible (threat diameter too small)

8

Wrong assembly reference produced but part is Ok

6

Insufficient torque resistance, risk of stability loss during final assembly and endurance

10

Machine stop, no welding possible

6

Insufficient torque resistance, risk of stability loss during final assembly and endurance

10

NUT forgotton to insert (Operator failure)

1 2

2 1

To be confirmed NUT assembled from wrong side

4 Bad welding connection (insufficient penetration)

1

3

5 5

Threat of NUT or PROFILE damaged

No Belt Buckle assembly possible

8

2

4

Welding spatters in threat of NUT

No Belt Buckle assembly possible

Property of Faurecia - Duplication prohibited

NUT not correctly clamped Insufficient torque resistance, / gap between nut and risk of stability loss during final profile assembly and endurance 7

Class can be S/R ( or "1") or "2" (function) or no value

S:

Severity

7

10

2

1

4

L-PROFILE forgotton to insert (Operator failure)

2

Wrong NUT reference at welding station (Logistical failure)

2

Wrong welding fixation plate used (Tool change failure)

Detection

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

32

Recommended Corrective Actions Responsible N°

Description

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

12

1st piece OK check

2

32

4

Operator qualification level L or higher

1st piece OK check

2

48

NUT incorrect inserted in fixation plate (Operator failure)

4

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

40

Preventive Maintenance plan no. J84/40)

1st piece OK check

2

40

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

24

To be confrimed

Restricted machine & parameter access, parameter change documentation

1st piece OK check (resistance torque measurement)

2

40

Do we need to do something else can we let Firs part Ok at 1 JY Loreau what can vwe do more ?

Preventive Maintenance plan no. J84/40)

1st piece OK check

2

40

Yearly supplier part requalification

1st piece OK check (resistance torque measurement)

4

160

Preventive Maintenance plan no. J84/40)

1st piece OK check

2

32

Yearly supplier part requalification

1st piece OK check (resistance torque measurement)

4

128

Preventive Maintenance plan no. J84/40)

1st piece OK check

2

14

Do we keep it or not ?

Preventive Maintenance plan no. J84/40)

1st piece OK check

2

40

Defect on part geometry considered ?

Tooling damaged / worn out (Maintenance failure)

2

NUT incorrect inserted in L-PROFILE (Operator failure)

4

Wrong welding parameter (technician failure)

2

Machine defect or tooling defect ( tips not Ok) (Equipment failure)

2

Changed material properties (Supplier failure)

4

Machine defect (Equipment failure)

2 4

4

Machine defect (Equipment failure)

1

3

Machine defect (Equipment failure)

2

D : Detectability

Design validation (D-FMEA) Process controls (P-FMEA) Prevention

Label scan of every new box with NUTs at welding station

Damaged delivered part (Supplier failure)

6

6 (defect for example)

Potential Cause of failure

Need to have a picture of the machine and how it works

FMEA Number:

J84-P-RSS-G

FMEA Date:

15/07/2004

Updated on :

16/03/2010

PILOT-leader :

ME / YOKE P.

er Jean-Yves Loreau

KCC nb

Nut and L-Profile assembly

Occurrence

(DFMEA)

G

Class

Product Function definition studied

(PFMEA)

5155436/38

Engineering level/index:

RPN

40

Process Step definition

Drawing reference :

KPC nb

N°

Type of vehicle or device : J84 Renault Megane Scenic Product : Rear Seat Metal Structure

Severity

Line and Plant (PFMEA) : UAP 3 / Nogent

PROCESS

DESIGN

Detection

D-FMEA or P-FMEA

1

2

3, 4, 5

6, 7

8

9

O:

Occurence

RPN :

Target completion date

Forecasted new RPN Action taken

RPN checked after actions implemented

S

O

D

RPN

S

O

D

RPN

To be confirmed

Jean-Yvs is it Ok ?

40-1

Check of Supplier measurement protocols (material properties) for every NUT and L-PROFILE batch within incoming inspection

Q / SERIOUS V.

18/09/2004

100% protocol 10 check for NUT and L-PROFILE integrated in J84RSS-G at 20.09.2004

2

2

40

10

2

2

40

40-1

Check of Supplier measurement protocols (material properties) for every NUT batch within incoming inspection

Q / SERIOUS V.

18/09/2004

100% protocol check for NUT integrated in J84RSS-G at 20.09.2004

2

2

28

7

2

2

28

Risk Priority Number

7

111

RPN

4

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

32

Transfer the detection on machine stop

No welding possible, machine stop, process interruptionframe cannot be assembled

6

L-PROFILE forgotten to insert (Operator failure)

2

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

12

Transfer the detection on machine stop

No Belt Buckle fastening possible (threat diameter too small)

8

Wrong NUT reference at welding station (Logistical failure)

2

1st piece OK check

5

80

Label scan of every new box with NUTs at welding station

Wrong assembly reference produced but part is Ok

6

Wrong welding fixation plate used (Tool change failure)

4

Operator qualification level L or higher

1st piece OK check

2

48

Insufficient torque resistance, risk of stability loss during final assembly and endurance

10

NUT incorrect inserted in fixation plate (Operator failure)

4

Operator qualification level L or higher

Automatic machine stop during clamping operation (Poka Yoke no. J84/27)

1

40