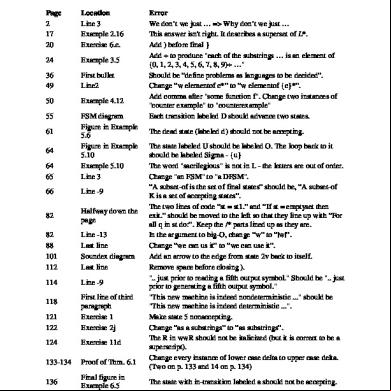

Abs Dynamic Positioning Systems-ppt 2013 451om

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Abs Dynamic Positioning Systems-ppt 2013 as PDF for free.

More details w3441

- Words: 4,757

- Pages: 75

ABS Guide for Dynamic Positioning Systems

Sue Wang Senior Managing Principal Engineer, Offshore Singapore 1 March 2013

ABS SEMINAR: ABS GUIDE FOR DYNAMIC POSITIONING SYSTEMS

Objective and Agenda

Introduce ABS Guide for DP systems to industry

Seek industry s and comments

Part 1: Overview of

DP system

ABS Guide for DP systems

Part 2: New optional Notations for

Enhanced DP system (EHS)

Station keeping performance (SKP)

2

2012 up

2011

2010

2009

2008

2007

2006

2004

2003

Advancement of technology

2002

2001

Wider range of application

2000

96-99

More complex field development

90-95

80s

Deep-water activity

upto 70s

2005

Rapid Expansion of DP Demand

3

Dynamic Positioning Applications

MODUs (drillships and semisubmersibles)

Offshore , installation and maintenance vessels

Pipe- and cable laying

Dredging

Offloading shuttle tankers

Cruise ships, large motor yachts

DP-assisted mooring

FPSOs in deepwater

Others

4

Basic DP Principles

A dynamic positioning (DP) control system automatically calculates the forces that the thrusters, propulsors and steering gear must produce in order to control the vessel’s position and heading

The DP control systems algorithm's will generate control signals to the thrusters, propulsors and steering gear to obtain the force and moment required for the requested position and heading control

5

What Do We Need for DP?

Power

Thrusters and rudders

Position measurement

Position filtering (LF)

Control algorithm (positive required force)

Thruster and rudder allocation

6

Elements of a DP System Human-Machine Interface Computer Operator Display Screen DP Operator

Position Reference Systems (PRS)

Sensors Com Wind Vertical Reference Draft Tension

DGPS Underwater Acoustics Laser Microwave Tautwire

DP Controller (DPC)

Power Syste m

Thrusters 7

7

Typical DP System Layout Operator Station

Controller Azimuth Thruster Hardwire or LAN

Tunnel Thruster Rudder Propulsion Thruster

8

How DP System Work

2

β = 0.05 β = 0.1

1.8

(- βω t)

1.6

1+e

1.4

X /X0 [ -]

EKF

1

o

β = 0.3

1.2

PID

β = 0.5 X0

β = 0.7 β=1

0.8 0.6

(-βω t)

1-e

0.4

o

0.2 0

Measured Position

VESSEL

0

1

2

3

4

5 time/ T0 [-]

6

7

8

9

10

(T,α)1..n ALLOC = f(Fx, Fy, Mz)

THRUST

Wind Waves Current 9

Basic Elements DP Control System

Power, Sensors, Position References

Thrusters 10

Common Position Measurement Equipment

Fan Beam (Laser Technique)

Taut Wire (Vertical Angle)

DGPS (Satellite)

HPR (Long and Short Base, Hydro-acoustic, Transponders)

Atriums (Radio Wave, Landmark, Specific-Site)

Others

11

DP System Vendors

Kongsberg Maritime

Converteam (GE)

L-3

Marine Technologies

Navis Engineering

Rolls-Royce

Nautronix

Others

12

Basic Elements of a Power System

13

Thrusters & Rudders

Main propellers

Bow and stern thrusters

Azimuthing thrusters

Retractable thrusters

Rudders

14

DP Guidelines from Related Organizations

IMO MSC Circular 645

IMO MODU Code

ISO 19901-7 Stationkeeping

US Coast Guard

Norwegian Maritime Directorate (NMD)

Flag State

International Marine Contractors Association (IMCA)

Marine Technology Society (MTS)

American Petroleum Institute (API)

Class Societies 15

IMO & ABS DP Equipment Class

IMO Class 1

For equipment class 1, loss of position may occur in the event of a single fault

ABS DPS-1

For vessels which are fitted with a dynamic positioning system which is capable of automatically maintaining the position and heading of the vessel under specified maximum environmental conditions having an independent centralized manual position control with automatic heading control

16

IMO & ABS DP Equipment Class

IMO Equipment Class 2

A loss of position is not to occur in the event of a single fault in any active component or system (generators, thrusters, switchboards, remote controlled valves, etc.) Normally static components will not be considered to fail

ABS DPS-2

For vessels which are fitted with a dynamic positioning system which is capable of automatically maintaining the position and heading of the vessel within a specified operating envelope under specified maximum environmental conditions during and following any single fault, excluding a loss of compartment or compartments

17

IMO & ABS DP Equipment Class

IMO Class 3

For equipment Class 3, a single failure includes items listed previous for Class 2, and any normally static component is assumed to fail All components in any watertight and fire protected compartment

ABS DPS-3

For vessels which are fitted with a dynamic positioning system which is capable of automatically maintaining the position and heading of the vessel within a specified operating envelope under specified maximum environmental conditions during and following any single fault, including complete loss of a compartment due to fire or flood

18

Selection of DP Equipment Class

DP equipment class governed by the type of operations

Norwegian Maritime Directorate (NMD) has specified

DP units of Class 1 should be used during operations where loss of position is not considered to endanger human lives, cause significant damage or cause more than minimal pollution DP units of Class 2 should be used during operations where loss of position could cause personnel injury, pollution or damage with great economic consequences DP units of Class 3 should be used during operations where loss of position could cause fatal accidents, severe pollution or damage with major economic consequences

19

Guidelines for DP Equipment Class

NORSOK

MTS

One Oil Company

Drilling Diving inside structures Diving in open water

3 3 2

2 2 2

3 3 3

Pipelay/umbilical lay Lifting Shuttle Offtake ROV (Open water) ROV (Close Proximity - Surface/Subsea) Floating Production (HC production)

2 2 2

2 2 2 1 2 2

3 3 2

1

2

3

2

1

2

2

3 3

Operation

Well intervention

2 3 2

Logistics Operations Subsea well workover Accomodation (ganway connection to installation) Accomodation (outside 500m safety zone) Construction activies inside 500m general Construction activies outside 500m general

3 3 2 2 1

2

2

3

2

Remark 1

Vessels of lesser Class may be used with the appropriate structured risk identification and mitigation measures in place

2

Class 2 acceptable with extra fire watch and engine control watch routines

3

2

2

Class 3 for Norwegian Continental Shelf. For others, Class 2 accetable with Extra fire watch and engine control watch routines USCG: Class 2 or above for MODU according to IMO MODU Code

20

ABS DPS Rules & Guides & Notations

ABS Guide for Thrusters and Dynamic Positioning System (1994) was incorporated in the Rules for Building and Classing Steel Vessels, 4-3-5/15 in 2000

ABS Guide for Dynamic Positioning Systems (December 2012)

DPS Basic Notations

DPS-0, DPS-1, DPS-2, DPS-3 Inline with IMO Guidelines for Vessels with Dynamic Positioning Systems (1994)

Supplement Notations

EHS-P, EHS-C, EHS-F

SKP, SKP(a,b,c,d,e,f)

Incorporate new development

Provide flexibility 21

DPS Notations

Notation DPS-0

Most basic system

No redundancy

Centralized manual position control with automatic heading control (joystick)

Notation DPS-1

No redundancy

One automatic position and heading control computer

Independent manual position control with automatic heading control (joystick)

22

DPS Notations

Notation DPS-2

Redundancy design and able to maintain position and heading with a single fault Redundant(2) automatic position and heading control computers Independent manual position control with automatic heading control (joystick)

Notation DPS-3

Redundancy design with physical separation and able to maintain position and heading with a single fault and loss of a compartment due to fire or flood Redundant(3) automatic position and heading control computers Independent manual position control with automatic heading control (joystick)

23

Dynamic Positioning Systems Items Power System Power management UPS Thruster System Automatic Control Computers Manual Position Control with Auto heading Manual Independent Thruster Control at Bridge Position Reference Gyro Com MRU Wind Sensors Consequence Analyzer FMEA

0 No Redundancy No No No Redundancy 0

DPS Notation 1 2 No Redundancy Redundancy No Yes Yes Yes No Redundancy Redundancy 1 2

3 Redundancy Yes Yes Redundancy 3

1

1

1

1

Yes

Yes

Yes

Yes

1 1 0 1 No

2 2 2 2 No

3 3 3 3 Yes

3 3 3 3 Yes

No

No

Yes

Yes

24

Other ABS Rules Related to DP Components

ABS Steel Vessels Rules

ABS MODU Rules

Diesel Engines – Section 4-2-1 Gas Turbines – Section 4-2-3 Electric Motors and Motor Controllers – Section 4-8-3 Gears – Section 4-3-1 Shafting – Section 4-3-2 Propellers – Section 4-3-3 Piping System – Chapter 4-6 Thrusters 4-3-5 Control Equipment and Systems – Section 4-9-7 Pumps and Piping Systems – Chapter 4-2 Electrical Installation – Chapter 4-3 Rules for Equipment and Machinery Certification – Part 6 Surveys – Part 7

ABS Rules for Survey After Construction

Machinery Surveys – Chapter 7-6 Shipboard Automatic and Remote-control Systems – Chapter 7-8 Survey Requirements for Additional Systems and Services – Chapter 7-9 25

Guide Development Background

ABS updating Rules as routine process

Industry demanding

Wide range application of DP systems

Flexibility

Stationkeeping performance

Reflect industry advancement

Robust redundancy design concept

Enhanced generator protection technology

Rapid automatic blackout recovery

26

Innovation & New Technology

Robust redundancy concept

Advanced computing technology

Enhanced FMEA process

Advancement of sensor technology

Advanced generator protection

Advanced thruster control and protection

Quick black-out recovery

Comprehensive operation monitoring

27 27

Gap Analysis

Level of details

Lack of specifications

Closed bus design

Criteria for stationkeeping performance

Enhanced features

Advanced generator protection and control

Blackout prevention and automatic quick recovery

Robust redundancy concept

Fire and flood protection of machinery space (for DPS-2)

Higher availability and reliability of position reference systems and sensors

28

Overview DPS Guide Development

Major update for current ABS DPS Notations

DPS-1

DPS-2

DPS-3

Development of new optional notations

DP system enhancement notation (EHS)

Stationkeeping performance notation (SKP)

Objective

Reflect Industry advancement

Provide flexibility

Encourage higher design standards and consistent assessment

29

Highlight of DPS Guide

Definitions to form a common basis of understanding

Requirements on documentations for quality and completeness

Increased level of details on technical requirements

New enhanced system notations (EHS)

Recognition of design features beyond DPS-series notations

Encourage higher safe design standard

Provide flexibility to owners and operators

New stationkeeping performance notation (SKP)

Recognition of DP capability

Encourage robust design and consistent assessment

Increased level of details on testing

Vessel type and activity specifics 30

Content of DPS Guide

General

DP System Design

Power System

Thruster System

Control System

Marine Auxiliary System

Initial Test of DP System

Enhanced DP System

Stationkeeping Performance

Specific Vessel Types

Other Optional DP System Notations 31

Section 1-3: Definitions

Specified maximum environmental condition Specified operating envelope Single fault Dynamically positioned vessel Dynamic positioning system Industry mission Power system Thruster system DP control system Position reference system Joystick system Static component Active component Worst case failure Worst case failure design intent

Consequence analysis DP capability analysis Redundancy concept Critical redundancy Redundant groups Autonomous system Closed bus Common mod failure Single fault tolerance Independence Loss of position Stationkeeping

32

Section 1-4: Documentations

List of documentation (level of detail)

Dynamic positioning system

Power system

Thruster system

DP control system

Documentation type (level of detail)

R: Documentation for review I: Documentation for information and verification for consistency with related review OB: Documentation needs to be kept onboard

Added documents

Basic design of DP system redundancy (R DPS-2 and DPS-3)

Planned inspection and maintenance (I) 33

Section 2: Dynamic Positioning System Design

1 General

3 DP System Technical Requirements 3.1 Basic requirement 3.3 Redundancy design 3.5 Physical separation 3.7 DP system equipment requirements 3.9 Stationkeeping performance

5 Essential non-DP Systems 5.1 General 5.2 Emergency shut down system and DP redundancy 5.3 Fire protection and DP redundancy 5.4 Fuel quick closing valves and DP redundancy

7 Alarms and Instrumentation

9 Communications and DP Alter System 9.1 Communications 9.2 DP alter system

11 Failure Mode and Effects Analysis 11.1 Failure mode analysis 11.2 FMEA report

13 DP Operations Manual 34

Section 2: Dynamic Positioning System Design

Increased level of details for easy use

Content of documents

FMEA – Failure modes – FMEA analysis report – FMEA proving trial report

DP Operations Manual

Stationkeeping performance analysis

FMEA and Proving Trial Report (OB)

After completion of DP proving sea trials, the final version of DP FMEA and DP proving trial report, including final analysis and conclusions based on actual results from DP testing, are to be submitted Updated after major modifications

35

Section 3: Power System

1

General

3

Power Generation System

5

Power Distribution System

7

Power Management System

9

Uninterruptible Power Systems (UPS)

36

Section 3: Power System

Level of details for easy use

Closed bus tie breaker (DPS-2 and DPS-3)

Coordinated in relation to generator breakers to avoid total loss of main power (blackout) Two bus tie breakers are to be provided between bus sections

Closed bus for DPS-3

Capable of breaking the maximum short circuit current in the combined system

Consideration of EHS-P requirements

If all thrusters are direct diesel drive, no need for a power management system

37

Section 4: Thruster System

1

General

3

Thruster Capacity

5

Thruster Configuration

7

Thruster Auxiliary System

9

Thruster Control

11 Thruster Monitoring and Alarm

Level of details for easy use

38

Section 5: DP Control System

1

General

3

DP Control Station

5

DP Control System

7

Manual Position Control System

9

Control Mode Selection

11 Position Reference System and Environment Sensor

13 Consequence Analysis (For DPS-2/3)

15 Display and Monitoring

Level of details for easy use

39

Section 5: DP Control System

DP Control Station

Backup DP control station, a night vision, closed-circuit TV (CCTV) system is acceptable for viewing the external surrounding area

Data Communication Networks

Main DP control station with good viewing of the external surrounding area and all activities relevant to the DP operation

Communication network for DP control system is to be duplicated for DPS-2 and also separated for DPS-3 Manual position control system is not to share the same communication network with the DP control system

Control Mode Selection

Easy operational device to be provided in the DP control station for the selection of the thruster control modes Transfer of control to the backup DP control station to be initiated at backup control station and performed manually 40

Section 5/11: Position Reference System & Wind Sensor

One set of position reference system

GPS (others, position measurement devices)

Gyro (heading measurement device)

MRU (others, roll and pitch measurement for position correction)

MRU: where position reference systems are dependent on correction of roll and pitch effect, MRU or equivalent is to be provided

Position reference systems and wind sensors to be powered by UPSs and follow group redundancy concept

41

Section 6: Marine Auxiliary System (DPS 2/3)

1

General

3

Fuel Oil

5

Cooling Water

7

Compressed Air

9

Lubrication Oil Systems

11 HVAC and Ventilation

13 Piping

15 Pneumatic Systems

17

Level of details for easy use

Power Supply to Auxiliary Systems

42

Section 6: Marine Auxiliary System (DPS 2/3)

Auxiliary systems to be arranged in accordance with the redundancy concept

A single failure effect analysis for auxiliary systems to be included in the DP system FMEA

Fuel water content monitoring with remote alarms is to be installed

Power for auxiliary systems associated with DP systems is to be taken from within the redundancy group

43

Section 7: DP System Initial Test

1

General

3

DP System Performance Test

5

FMEA Proving Trial for DPS-2/DPS-3

Level of details

44

Section 7: System Performance Test

30 minute UPS Test

Position Reference Systems and Sensors

Manual Position Control System

Manual Thruster Control System

Thruster Emergency Stop

DP Control System

Control and Alarms

Standby Changeover

Protection equipment are to be tested if they are designed to provide essential redundancy of the DP system

6-hour Performance Endurance Test 45

Section 7: FMEA Proving Trial for DPS-2/DPS-3

FMEA tests to confirm the findings from FMEA analysis

Test procedures are to be developed in the FMEA analysis

Vessel is to operate in configurations analyzed in DP system FMEA

Submit final version of DP FMEA including conclusions from the testing

46

Section 8: Enhanced System

New Notations

EHS-P for enhanced power plant and thruster system

EHS-C for enhanced control system

EHS-F for fire and flood tolerance design

Supplement information for DPS-2/DPS-3 Notations

Provide three groups for flexibility and easy recognition

Can be combined as EHS-PC, etc.

Objective Improve reliability, operability and maintainability

Recognize safety features that beyond minimum requirements

Encourage higher safe design standard 47

Enhanced Propulsion System EHS-P

Applicable to DPS-2 and DPS-3 system

Features on power plant protection and quick blackout recovery

High safety measurement against closed bus operation

Targeting reduced consequence of failure

48

EHS-P Requirement

Enhanced generator protection

Failure detection and discrimination of failed components before a full or partial black-out situation occurs

Open bus-tie if the faulty generator fails to trip

One protection system per generator

Robust redundancy design

Autonomous generator sets

Autonomous thruster sets

Blackout prevention and automatic recovery (60s)

Power management system

Thruster phase back

System ride through capability (short circuit)

49

EHS-P Requirement

Autonomous

Control and automation – to be decentralized to the point that each item of main machinery (generators and thrusters) is capable of making itself ready for DP operations independently of any centralized control system Auxiliary – to be provided in a manner that makes the machinery (generators and thrusters) as independent as practical to minimize the number of failures that can lead to the loss of more than one main item of machinery

50

Enhanced Control System EHS-C

Applicable to DPS-2 and DPS-3 system

Aiming for higher availability and reliability of input data to the control system

Statistics point to the necessary of improvement

Encourage for higher design standard Incidents that led to loss of position 1994-2007

DP Computer Environment Power Generation Operator Error References Thruster Electrical Total

62 40 50 89 103 76 22 442

DP Computer Environment Power Generation Operator Error References Thruster Electrical

51

EHS-C Requirement

Three position reference systems and sensors available at any given time and location

Four position reference systems and four sensors with combination of different systems

Redundancy of relative reference system for offshore vessels

Three DP control computers (one backup)

Equipment from different suppliers or using different principles of operation

DP Data Logger

Integration of the centralized control system with sub-control systems 52

Fire & Flood Tolerance Design EHS-F

Applicable to DPS-2 system

Provide another level of measurement for fire and flood tolerance design

Focus on fire risk spaces

Flexibility for diversified market needs

53

EHS-F Requirement

DPS-3 automatically meets EHS-F requirements

A-0 separation along boundary of redundancy groups

No A-0 separation required between main and backup DP control station

A-60 separation for high fire risk spaces

The high fire risk area is the area defined by SVR 4-8-4/1.11 including Machinery spaces as defined by 4-7-1/11.15 and 4-7-1/11.17 Spaces containing fuel treatment equipment and other highly flammable substances

54

Summary of Enhanced DP Systems EHS-P

EHS-C

EHS-F

Autonomous Generator Set

2+1 Backup DP Control computers and controllers

Generators and Prime Movers

Bus Tie Breaker Wind Sensors redundantly configured 3 + 1 in back up control station between each bus segment

Separate compartments, A60 for high fire risk area. Watertight below damage waterline.

Gyros 3 + 1 in backup control station

Power Distribution System A0 between redundant groups. Watertight below damage waterline.

Enhanced Power Management

MRU 3 + 1 in backup control station

Thruster System A0 between redundant groups. Watertight below damage waterline.

Autonomous Thruster Set

Position Reference Systems 3 + 1 in backup control station

Controller Space A0 between redundant groups.

Enhanced Generator Protection

55

Closed Bus

Enhanced system design (EHS-P)

Improvement of active redundancy

Reduce consequence after failure

At least two or more generators running and they are connected to two or more sections of the main bus

The worst case failure of the configuration is not to result to a blackout

Spinning reserve is to be able to make up at least 50% lost capacity after the worst case failure of the operating mode in consideration

Other 50% lost capacity can be provided from the standby units

56

Standby Start

Changeover is to be automatic

Position and heading of the vessel are within the specified limits and DP performance is not degrading

Maximum allowed changeover time is 45s

Single fault does not cause total blackout including loss of entire compartment for DPS-3

A failure in one redundancy group is not to cause failure of more than one redundancy groups

A failure in the system being changed over to is not to cause failure of more than one redundancy groups

Changeover is not to cause failure of the redundancy group that is being connected to

At least, one standby generator is to be considered not available when needed 57

FMEA & Test (EHS)

Operation of protection systems (breakers, bus ties, etc.) related to short circuit

Severe voltage dips associated with short circuit faults in power plant configured as a common power system

Failure to excess and insufficient fuel

Over and under-excitation

Governor and AVR failure modes

Failure modes related to standby start and changeover

Power management failure on load sharing, malfunction, etc.

Phase back thrust and large load

Blackout recovery 58

Documentation (EHS)

Description of protection design philosophy and protection systems the redundancy concept of DP system depends on

Analysis of effects of severe voltage transients on power system stability

Short circuit analysis

Simulation of severe over/under voltage and over/under frequency

Protection coordination analysis

Protection settings

Description of automatic blackout recovery

59

Section 9: Stationkeeping Performance

New notations

SKP: verification for given design environmental conditions through analysis SKP(a,b,c,d,e,f): determine limiting environments for a given environment site through analysis

Supplement for DPS-series notations

Objective

Recognition of DP capability

Encourage robust design and consistent assessment

60

SKP Notation

Owner specify design environment conditions

Design wind speed and directions

Design wave height, related period and directions

Design current speed and directions

Station keeping performance assessment

Environmental load calculation Available thrust calculation including effect due to thruster interference with others

Analysis results demonstrate the capability of stationkeeping for the specified environment conditions

61

Result Presentation for SKP

Total Thrust Utilization Plot for given Environment Condition 62

Environmental Load

Wind and current

1-minute mean wind speed at 10-meter above water surface

Model test data to be used whenever possible

For non-ship shape unit, wind and current forces according to ABS Rules for MODU, FPI or API 2SK For a ship shape unit, wind and forces according to ABS Rules for MODU, FPI, API RP 2SK or OCIMF publication

Wave

Significant wave heights and characteristic periods (frequencies)

JONSWAP for North Sea and locations with limited fetch

Bretschneider for open seas

Model test data for wave drift force if available

Drift force calculation using appropriate hydrodynamic analysis computer program 63

Available Thrust

Manufacturer’s test data of full scale or suitable model test for the thrust output of thrusters to be used

This Guide provides method for determining available thrust

Thruster-Thruster Interaction

Thruster-Hull Interaction

Thruster-Current Interaction

64

DP Capability

Real Capability

Predicted Capability Courtesy: MTS/Shell

65

SKP(a,b,c,d,e,f) Notation

a: the probability that the vessel can remain on station with all thrusters operating for location f and current speed e

b: the probability that the vessel can remain on station with the failure of minimum effect of single thruster for location f and current speed e

c: the probability that the vessel can remain on station with the failure of maximum effect single thruster for location f and current speed e

d: the probability that the vessel can remain on station with the worst case failure condition for location f and current speed e

e: current speed in knot (owner specify or typical 1.5 kt)

f: environment location (owner specify or typical North Sea) 66

SKP(a,b,c,d,e,f) Notation

Same analysis procedures for load and thrust calculation

May cover SKP if design environments are given and are within the limit

Require for the relationship between wind speeds and wave heights

Require probability of non-exceedance of wind speed

67

Wind & Wave Relationship (North Sea)

68

Result Presentation for SKP(a,b,c,d)

Typical DP Capability Plot 69

Section 9: Sub-sections

1 General

9 Other External Load

1.1 Definition

11 Available Thrust

1.1.1 SKP

11.1 Available Thrust for Thrusters

1.1.2 SKP (a,b,c,d)

11.3 Thruster-Thruster Interaction

1.1.3 Normal Operation Condition

11.5 Thruster-Hull Interaction

1.1.4 Standby Condition

11.7 Thruster-Current Interaction

11.9 Available Thrust for Transverse Tunnel Thrusters

3 Environmental Condition

3.1 Wind

3.3 Wave

13 Rudder Force

3.5 Current

15 SKP Calculation

3.7 Environment for SKP

15.1 SKP Notation

3.9 Environment for SKP (a,b,c,d)

15.3 SKP (a,b,c,d) Notation

5 Analysis Conditions

5.1 DP System Configurations

5.3 Operation Conditions

17 Documentation

7 Environmental Load Calculation

7.1 Wind and current force

7.3 Wave force 70

Documentation

Where the DP system is to be supplemented with a stationkeeping performance notation, the following information is to be submitted for review

General arrangement and lines plan

Thruster arrangement

Thruster power and thrust

Thruster interactions

Analysis procedures

Capability plots

Documentation on the environment conditions long term distribution (any area for intended service) Owner specified limiting environments

71

Section 10: Specific Vessel Types

1 Introduction

3 Mobile Offshore Drilling Units

Effect of drilling

Effect of emergency shutdown system

Effect of emergency disconnect system

Maintenance plan

5 Project or Construction Vessels

Suitable DP Control modes

Redundancy of relative position reference system

7 Logistics Vessels

Redundancy of relative position reference system

72

DPS Guide Development Milestones Jan 2012

Project Kickoff Divisions Technology TBDs Previous DP Consultant work

Jun 2012

Aug 2012

Oct 2012

Dec 2012

Review Initial development work

Project Plan

DPS draft guide development

Industry workshop

Consultant

DPS Guide Internal and external review

Rough Draft for DP consultants review and improvement 73

Summary

DPS Guide to reduce the gaps between industry practices and class requirements

New notations for enhanced system (EHS) and stationkeeping performance (SKP)

Provide systematic measurement

Provide more flexibility for owners and operators

Need industry s for further improvement

Shipbuilder Classification Society

Charterer

SHIP OWNER Shipping Financier

Underwriter

Flag State

Port State

74

www.eagle.org

Sue Wang Senior Managing Principal Engineer, Offshore Singapore 1 March 2013

ABS SEMINAR: ABS GUIDE FOR DYNAMIC POSITIONING SYSTEMS

Objective and Agenda

Introduce ABS Guide for DP systems to industry

Seek industry s and comments

Part 1: Overview of

DP system

ABS Guide for DP systems

Part 2: New optional Notations for

Enhanced DP system (EHS)

Station keeping performance (SKP)

2

2012 up

2011

2010

2009

2008

2007

2006

2004

2003

Advancement of technology

2002

2001

Wider range of application

2000

96-99

More complex field development

90-95

80s

Deep-water activity

upto 70s

2005

Rapid Expansion of DP Demand

3

Dynamic Positioning Applications

MODUs (drillships and semisubmersibles)

Offshore , installation and maintenance vessels

Pipe- and cable laying

Dredging

Offloading shuttle tankers

Cruise ships, large motor yachts

DP-assisted mooring

FPSOs in deepwater

Others

4

Basic DP Principles

A dynamic positioning (DP) control system automatically calculates the forces that the thrusters, propulsors and steering gear must produce in order to control the vessel’s position and heading

The DP control systems algorithm's will generate control signals to the thrusters, propulsors and steering gear to obtain the force and moment required for the requested position and heading control

5

What Do We Need for DP?

Power

Thrusters and rudders

Position measurement

Position filtering (LF)

Control algorithm (positive required force)

Thruster and rudder allocation

6

Elements of a DP System Human-Machine Interface Computer Operator Display Screen DP Operator

Position Reference Systems (PRS)

Sensors Com Wind Vertical Reference Draft Tension

DGPS Underwater Acoustics Laser Microwave Tautwire

DP Controller (DPC)

Power Syste m

Thrusters 7

7

Typical DP System Layout Operator Station

Controller Azimuth Thruster Hardwire or LAN

Tunnel Thruster Rudder Propulsion Thruster

8

How DP System Work

2

β = 0.05 β = 0.1

1.8

(- βω t)

1.6

1+e

1.4

X /X0 [ -]

EKF

1

o

β = 0.3

1.2

PID

β = 0.5 X0

β = 0.7 β=1

0.8 0.6

(-βω t)

1-e

0.4

o

0.2 0

Measured Position

VESSEL

0

1

2

3

4

5 time/ T0 [-]

6

7

8

9

10

(T,α)1..n ALLOC = f(Fx, Fy, Mz)

THRUST

Wind Waves Current 9

Basic Elements DP Control System

Power, Sensors, Position References

Thrusters 10

Common Position Measurement Equipment

Fan Beam (Laser Technique)

Taut Wire (Vertical Angle)

DGPS (Satellite)

HPR (Long and Short Base, Hydro-acoustic, Transponders)

Atriums (Radio Wave, Landmark, Specific-Site)

Others

11

DP System Vendors

Kongsberg Maritime

Converteam (GE)

L-3

Marine Technologies

Navis Engineering

Rolls-Royce

Nautronix

Others

12

Basic Elements of a Power System

13

Thrusters & Rudders

Main propellers

Bow and stern thrusters

Azimuthing thrusters

Retractable thrusters

Rudders

14

DP Guidelines from Related Organizations

IMO MSC Circular 645

IMO MODU Code

ISO 19901-7 Stationkeeping

US Coast Guard

Norwegian Maritime Directorate (NMD)

Flag State

International Marine Contractors Association (IMCA)

Marine Technology Society (MTS)

American Petroleum Institute (API)

Class Societies 15

IMO & ABS DP Equipment Class

IMO Class 1

For equipment class 1, loss of position may occur in the event of a single fault

ABS DPS-1

For vessels which are fitted with a dynamic positioning system which is capable of automatically maintaining the position and heading of the vessel under specified maximum environmental conditions having an independent centralized manual position control with automatic heading control

16

IMO & ABS DP Equipment Class

IMO Equipment Class 2

A loss of position is not to occur in the event of a single fault in any active component or system (generators, thrusters, switchboards, remote controlled valves, etc.) Normally static components will not be considered to fail

ABS DPS-2

For vessels which are fitted with a dynamic positioning system which is capable of automatically maintaining the position and heading of the vessel within a specified operating envelope under specified maximum environmental conditions during and following any single fault, excluding a loss of compartment or compartments

17

IMO & ABS DP Equipment Class

IMO Class 3

For equipment Class 3, a single failure includes items listed previous for Class 2, and any normally static component is assumed to fail All components in any watertight and fire protected compartment

ABS DPS-3

For vessels which are fitted with a dynamic positioning system which is capable of automatically maintaining the position and heading of the vessel within a specified operating envelope under specified maximum environmental conditions during and following any single fault, including complete loss of a compartment due to fire or flood

18

Selection of DP Equipment Class

DP equipment class governed by the type of operations

Norwegian Maritime Directorate (NMD) has specified

DP units of Class 1 should be used during operations where loss of position is not considered to endanger human lives, cause significant damage or cause more than minimal pollution DP units of Class 2 should be used during operations where loss of position could cause personnel injury, pollution or damage with great economic consequences DP units of Class 3 should be used during operations where loss of position could cause fatal accidents, severe pollution or damage with major economic consequences

19

Guidelines for DP Equipment Class

NORSOK

MTS

One Oil Company

Drilling Diving inside structures Diving in open water

3 3 2

2 2 2

3 3 3

Pipelay/umbilical lay Lifting Shuttle Offtake ROV (Open water) ROV (Close Proximity - Surface/Subsea) Floating Production (HC production)

2 2 2

2 2 2 1 2 2

3 3 2

1

2

3

2

1

2

2

3 3

Operation

Well intervention

2 3 2

Logistics Operations Subsea well workover Accomodation (ganway connection to installation) Accomodation (outside 500m safety zone) Construction activies inside 500m general Construction activies outside 500m general

3 3 2 2 1

2

2

3

2

Remark 1

Vessels of lesser Class may be used with the appropriate structured risk identification and mitigation measures in place

2

Class 2 acceptable with extra fire watch and engine control watch routines

3

2

2

Class 3 for Norwegian Continental Shelf. For others, Class 2 accetable with Extra fire watch and engine control watch routines USCG: Class 2 or above for MODU according to IMO MODU Code

20

ABS DPS Rules & Guides & Notations

ABS Guide for Thrusters and Dynamic Positioning System (1994) was incorporated in the Rules for Building and Classing Steel Vessels, 4-3-5/15 in 2000

ABS Guide for Dynamic Positioning Systems (December 2012)

DPS Basic Notations

DPS-0, DPS-1, DPS-2, DPS-3 Inline with IMO Guidelines for Vessels with Dynamic Positioning Systems (1994)

Supplement Notations

EHS-P, EHS-C, EHS-F

SKP, SKP(a,b,c,d,e,f)

Incorporate new development

Provide flexibility 21

DPS Notations

Notation DPS-0

Most basic system

No redundancy

Centralized manual position control with automatic heading control (joystick)

Notation DPS-1

No redundancy

One automatic position and heading control computer

Independent manual position control with automatic heading control (joystick)

22

DPS Notations

Notation DPS-2

Redundancy design and able to maintain position and heading with a single fault Redundant(2) automatic position and heading control computers Independent manual position control with automatic heading control (joystick)

Notation DPS-3

Redundancy design with physical separation and able to maintain position and heading with a single fault and loss of a compartment due to fire or flood Redundant(3) automatic position and heading control computers Independent manual position control with automatic heading control (joystick)

23

Dynamic Positioning Systems Items Power System Power management UPS Thruster System Automatic Control Computers Manual Position Control with Auto heading Manual Independent Thruster Control at Bridge Position Reference Gyro Com MRU Wind Sensors Consequence Analyzer FMEA

0 No Redundancy No No No Redundancy 0

DPS Notation 1 2 No Redundancy Redundancy No Yes Yes Yes No Redundancy Redundancy 1 2

3 Redundancy Yes Yes Redundancy 3

1

1

1

1

Yes

Yes

Yes

Yes

1 1 0 1 No

2 2 2 2 No

3 3 3 3 Yes

3 3 3 3 Yes

No

No

Yes

Yes

24

Other ABS Rules Related to DP Components

ABS Steel Vessels Rules

ABS MODU Rules

Diesel Engines – Section 4-2-1 Gas Turbines – Section 4-2-3 Electric Motors and Motor Controllers – Section 4-8-3 Gears – Section 4-3-1 Shafting – Section 4-3-2 Propellers – Section 4-3-3 Piping System – Chapter 4-6 Thrusters 4-3-5 Control Equipment and Systems – Section 4-9-7 Pumps and Piping Systems – Chapter 4-2 Electrical Installation – Chapter 4-3 Rules for Equipment and Machinery Certification – Part 6 Surveys – Part 7

ABS Rules for Survey After Construction

Machinery Surveys – Chapter 7-6 Shipboard Automatic and Remote-control Systems – Chapter 7-8 Survey Requirements for Additional Systems and Services – Chapter 7-9 25

Guide Development Background

ABS updating Rules as routine process

Industry demanding

Wide range application of DP systems

Flexibility

Stationkeeping performance

Reflect industry advancement

Robust redundancy design concept

Enhanced generator protection technology

Rapid automatic blackout recovery

26

Innovation & New Technology

Robust redundancy concept

Advanced computing technology

Enhanced FMEA process

Advancement of sensor technology

Advanced generator protection

Advanced thruster control and protection

Quick black-out recovery

Comprehensive operation monitoring

27 27

Gap Analysis

Level of details

Lack of specifications

Closed bus design

Criteria for stationkeeping performance

Enhanced features

Advanced generator protection and control

Blackout prevention and automatic quick recovery

Robust redundancy concept

Fire and flood protection of machinery space (for DPS-2)

Higher availability and reliability of position reference systems and sensors

28

Overview DPS Guide Development

Major update for current ABS DPS Notations

DPS-1

DPS-2

DPS-3

Development of new optional notations

DP system enhancement notation (EHS)

Stationkeeping performance notation (SKP)

Objective

Reflect Industry advancement

Provide flexibility

Encourage higher design standards and consistent assessment

29

Highlight of DPS Guide

Definitions to form a common basis of understanding

Requirements on documentations for quality and completeness

Increased level of details on technical requirements

New enhanced system notations (EHS)

Recognition of design features beyond DPS-series notations

Encourage higher safe design standard

Provide flexibility to owners and operators

New stationkeeping performance notation (SKP)

Recognition of DP capability

Encourage robust design and consistent assessment

Increased level of details on testing

Vessel type and activity specifics 30

Content of DPS Guide

General

DP System Design

Power System

Thruster System

Control System

Marine Auxiliary System

Initial Test of DP System

Enhanced DP System

Stationkeeping Performance

Specific Vessel Types

Other Optional DP System Notations 31

Section 1-3: Definitions

Specified maximum environmental condition Specified operating envelope Single fault Dynamically positioned vessel Dynamic positioning system Industry mission Power system Thruster system DP control system Position reference system Joystick system Static component Active component Worst case failure Worst case failure design intent

Consequence analysis DP capability analysis Redundancy concept Critical redundancy Redundant groups Autonomous system Closed bus Common mod failure Single fault tolerance Independence Loss of position Stationkeeping

32

Section 1-4: Documentations

List of documentation (level of detail)

Dynamic positioning system

Power system

Thruster system

DP control system

Documentation type (level of detail)

R: Documentation for review I: Documentation for information and verification for consistency with related review OB: Documentation needs to be kept onboard

Added documents

Basic design of DP system redundancy (R DPS-2 and DPS-3)

Planned inspection and maintenance (I) 33

Section 2: Dynamic Positioning System Design

1 General

3 DP System Technical Requirements 3.1 Basic requirement 3.3 Redundancy design 3.5 Physical separation 3.7 DP system equipment requirements 3.9 Stationkeeping performance

5 Essential non-DP Systems 5.1 General 5.2 Emergency shut down system and DP redundancy 5.3 Fire protection and DP redundancy 5.4 Fuel quick closing valves and DP redundancy

7 Alarms and Instrumentation

9 Communications and DP Alter System 9.1 Communications 9.2 DP alter system

11 Failure Mode and Effects Analysis 11.1 Failure mode analysis 11.2 FMEA report

13 DP Operations Manual 34

Section 2: Dynamic Positioning System Design

Increased level of details for easy use

Content of documents

FMEA – Failure modes – FMEA analysis report – FMEA proving trial report

DP Operations Manual

Stationkeeping performance analysis

FMEA and Proving Trial Report (OB)

After completion of DP proving sea trials, the final version of DP FMEA and DP proving trial report, including final analysis and conclusions based on actual results from DP testing, are to be submitted Updated after major modifications

35

Section 3: Power System

1

General

3

Power Generation System

5

Power Distribution System

7

Power Management System

9

Uninterruptible Power Systems (UPS)

36

Section 3: Power System

Level of details for easy use

Closed bus tie breaker (DPS-2 and DPS-3)

Coordinated in relation to generator breakers to avoid total loss of main power (blackout) Two bus tie breakers are to be provided between bus sections

Closed bus for DPS-3

Capable of breaking the maximum short circuit current in the combined system

Consideration of EHS-P requirements

If all thrusters are direct diesel drive, no need for a power management system

37

Section 4: Thruster System

1

General

3

Thruster Capacity

5

Thruster Configuration

7

Thruster Auxiliary System

9

Thruster Control

11 Thruster Monitoring and Alarm

Level of details for easy use

38

Section 5: DP Control System

1

General

3

DP Control Station

5

DP Control System

7

Manual Position Control System

9

Control Mode Selection

11 Position Reference System and Environment Sensor

13 Consequence Analysis (For DPS-2/3)

15 Display and Monitoring

Level of details for easy use

39

Section 5: DP Control System

DP Control Station

Backup DP control station, a night vision, closed-circuit TV (CCTV) system is acceptable for viewing the external surrounding area

Data Communication Networks

Main DP control station with good viewing of the external surrounding area and all activities relevant to the DP operation

Communication network for DP control system is to be duplicated for DPS-2 and also separated for DPS-3 Manual position control system is not to share the same communication network with the DP control system

Control Mode Selection

Easy operational device to be provided in the DP control station for the selection of the thruster control modes Transfer of control to the backup DP control station to be initiated at backup control station and performed manually 40

Section 5/11: Position Reference System & Wind Sensor

One set of position reference system

GPS (others, position measurement devices)

Gyro (heading measurement device)

MRU (others, roll and pitch measurement for position correction)

MRU: where position reference systems are dependent on correction of roll and pitch effect, MRU or equivalent is to be provided

Position reference systems and wind sensors to be powered by UPSs and follow group redundancy concept

41

Section 6: Marine Auxiliary System (DPS 2/3)

1

General

3

Fuel Oil

5

Cooling Water

7

Compressed Air

9

Lubrication Oil Systems

11 HVAC and Ventilation

13 Piping

15 Pneumatic Systems

17

Level of details for easy use

Power Supply to Auxiliary Systems

42

Section 6: Marine Auxiliary System (DPS 2/3)

Auxiliary systems to be arranged in accordance with the redundancy concept

A single failure effect analysis for auxiliary systems to be included in the DP system FMEA

Fuel water content monitoring with remote alarms is to be installed

Power for auxiliary systems associated with DP systems is to be taken from within the redundancy group

43

Section 7: DP System Initial Test

1

General

3

DP System Performance Test

5

FMEA Proving Trial for DPS-2/DPS-3

Level of details

44

Section 7: System Performance Test

30 minute UPS Test

Position Reference Systems and Sensors

Manual Position Control System

Manual Thruster Control System

Thruster Emergency Stop

DP Control System

Control and Alarms

Standby Changeover

Protection equipment are to be tested if they are designed to provide essential redundancy of the DP system

6-hour Performance Endurance Test 45

Section 7: FMEA Proving Trial for DPS-2/DPS-3

FMEA tests to confirm the findings from FMEA analysis

Test procedures are to be developed in the FMEA analysis

Vessel is to operate in configurations analyzed in DP system FMEA

Submit final version of DP FMEA including conclusions from the testing

46

Section 8: Enhanced System

New Notations

EHS-P for enhanced power plant and thruster system

EHS-C for enhanced control system

EHS-F for fire and flood tolerance design

Supplement information for DPS-2/DPS-3 Notations

Provide three groups for flexibility and easy recognition

Can be combined as EHS-PC, etc.

Objective Improve reliability, operability and maintainability

Recognize safety features that beyond minimum requirements

Encourage higher safe design standard 47

Enhanced Propulsion System EHS-P

Applicable to DPS-2 and DPS-3 system

Features on power plant protection and quick blackout recovery

High safety measurement against closed bus operation

Targeting reduced consequence of failure

48

EHS-P Requirement

Enhanced generator protection

Failure detection and discrimination of failed components before a full or partial black-out situation occurs

Open bus-tie if the faulty generator fails to trip

One protection system per generator

Robust redundancy design

Autonomous generator sets

Autonomous thruster sets

Blackout prevention and automatic recovery (60s)

Power management system

Thruster phase back

System ride through capability (short circuit)

49

EHS-P Requirement

Autonomous

Control and automation – to be decentralized to the point that each item of main machinery (generators and thrusters) is capable of making itself ready for DP operations independently of any centralized control system Auxiliary – to be provided in a manner that makes the machinery (generators and thrusters) as independent as practical to minimize the number of failures that can lead to the loss of more than one main item of machinery

50

Enhanced Control System EHS-C

Applicable to DPS-2 and DPS-3 system

Aiming for higher availability and reliability of input data to the control system

Statistics point to the necessary of improvement

Encourage for higher design standard Incidents that led to loss of position 1994-2007

DP Computer Environment Power Generation Operator Error References Thruster Electrical Total

62 40 50 89 103 76 22 442

DP Computer Environment Power Generation Operator Error References Thruster Electrical

51

EHS-C Requirement

Three position reference systems and sensors available at any given time and location

Four position reference systems and four sensors with combination of different systems

Redundancy of relative reference system for offshore vessels

Three DP control computers (one backup)

Equipment from different suppliers or using different principles of operation

DP Data Logger

Integration of the centralized control system with sub-control systems 52

Fire & Flood Tolerance Design EHS-F

Applicable to DPS-2 system

Provide another level of measurement for fire and flood tolerance design

Focus on fire risk spaces

Flexibility for diversified market needs

53

EHS-F Requirement

DPS-3 automatically meets EHS-F requirements

A-0 separation along boundary of redundancy groups

No A-0 separation required between main and backup DP control station

A-60 separation for high fire risk spaces

The high fire risk area is the area defined by SVR 4-8-4/1.11 including Machinery spaces as defined by 4-7-1/11.15 and 4-7-1/11.17 Spaces containing fuel treatment equipment and other highly flammable substances

54

Summary of Enhanced DP Systems EHS-P

EHS-C

EHS-F

Autonomous Generator Set

2+1 Backup DP Control computers and controllers

Generators and Prime Movers

Bus Tie Breaker Wind Sensors redundantly configured 3 + 1 in back up control station between each bus segment

Separate compartments, A60 for high fire risk area. Watertight below damage waterline.

Gyros 3 + 1 in backup control station

Power Distribution System A0 between redundant groups. Watertight below damage waterline.

Enhanced Power Management

MRU 3 + 1 in backup control station

Thruster System A0 between redundant groups. Watertight below damage waterline.

Autonomous Thruster Set

Position Reference Systems 3 + 1 in backup control station

Controller Space A0 between redundant groups.

Enhanced Generator Protection

55

Closed Bus

Enhanced system design (EHS-P)

Improvement of active redundancy

Reduce consequence after failure

At least two or more generators running and they are connected to two or more sections of the main bus

The worst case failure of the configuration is not to result to a blackout

Spinning reserve is to be able to make up at least 50% lost capacity after the worst case failure of the operating mode in consideration

Other 50% lost capacity can be provided from the standby units

56

Standby Start

Changeover is to be automatic

Position and heading of the vessel are within the specified limits and DP performance is not degrading

Maximum allowed changeover time is 45s

Single fault does not cause total blackout including loss of entire compartment for DPS-3

A failure in one redundancy group is not to cause failure of more than one redundancy groups

A failure in the system being changed over to is not to cause failure of more than one redundancy groups

Changeover is not to cause failure of the redundancy group that is being connected to

At least, one standby generator is to be considered not available when needed 57

FMEA & Test (EHS)

Operation of protection systems (breakers, bus ties, etc.) related to short circuit

Severe voltage dips associated with short circuit faults in power plant configured as a common power system

Failure to excess and insufficient fuel

Over and under-excitation

Governor and AVR failure modes

Failure modes related to standby start and changeover

Power management failure on load sharing, malfunction, etc.

Phase back thrust and large load

Blackout recovery 58

Documentation (EHS)

Description of protection design philosophy and protection systems the redundancy concept of DP system depends on

Analysis of effects of severe voltage transients on power system stability

Short circuit analysis

Simulation of severe over/under voltage and over/under frequency

Protection coordination analysis

Protection settings

Description of automatic blackout recovery

59

Section 9: Stationkeeping Performance

New notations

SKP: verification for given design environmental conditions through analysis SKP(a,b,c,d,e,f): determine limiting environments for a given environment site through analysis

Supplement for DPS-series notations

Objective

Recognition of DP capability

Encourage robust design and consistent assessment

60

SKP Notation

Owner specify design environment conditions

Design wind speed and directions

Design wave height, related period and directions

Design current speed and directions

Station keeping performance assessment

Environmental load calculation Available thrust calculation including effect due to thruster interference with others

Analysis results demonstrate the capability of stationkeeping for the specified environment conditions

61

Result Presentation for SKP

Total Thrust Utilization Plot for given Environment Condition 62

Environmental Load

Wind and current

1-minute mean wind speed at 10-meter above water surface

Model test data to be used whenever possible

For non-ship shape unit, wind and current forces according to ABS Rules for MODU, FPI or API 2SK For a ship shape unit, wind and forces according to ABS Rules for MODU, FPI, API RP 2SK or OCIMF publication

Wave

Significant wave heights and characteristic periods (frequencies)

JONSWAP for North Sea and locations with limited fetch

Bretschneider for open seas

Model test data for wave drift force if available

Drift force calculation using appropriate hydrodynamic analysis computer program 63

Available Thrust

Manufacturer’s test data of full scale or suitable model test for the thrust output of thrusters to be used

This Guide provides method for determining available thrust

Thruster-Thruster Interaction

Thruster-Hull Interaction

Thruster-Current Interaction

64

DP Capability

Real Capability

Predicted Capability Courtesy: MTS/Shell

65

SKP(a,b,c,d,e,f) Notation

a: the probability that the vessel can remain on station with all thrusters operating for location f and current speed e

b: the probability that the vessel can remain on station with the failure of minimum effect of single thruster for location f and current speed e

c: the probability that the vessel can remain on station with the failure of maximum effect single thruster for location f and current speed e

d: the probability that the vessel can remain on station with the worst case failure condition for location f and current speed e

e: current speed in knot (owner specify or typical 1.5 kt)

f: environment location (owner specify or typical North Sea) 66

SKP(a,b,c,d,e,f) Notation

Same analysis procedures for load and thrust calculation

May cover SKP if design environments are given and are within the limit

Require for the relationship between wind speeds and wave heights

Require probability of non-exceedance of wind speed

67

Wind & Wave Relationship (North Sea)

68

Result Presentation for SKP(a,b,c,d)

Typical DP Capability Plot 69

Section 9: Sub-sections

1 General

9 Other External Load

1.1 Definition

11 Available Thrust

1.1.1 SKP

11.1 Available Thrust for Thrusters

1.1.2 SKP (a,b,c,d)

11.3 Thruster-Thruster Interaction

1.1.3 Normal Operation Condition

11.5 Thruster-Hull Interaction

1.1.4 Standby Condition

11.7 Thruster-Current Interaction

11.9 Available Thrust for Transverse Tunnel Thrusters

3 Environmental Condition

3.1 Wind

3.3 Wave

13 Rudder Force

3.5 Current

15 SKP Calculation

3.7 Environment for SKP

15.1 SKP Notation

3.9 Environment for SKP (a,b,c,d)

15.3 SKP (a,b,c,d) Notation

5 Analysis Conditions

5.1 DP System Configurations

5.3 Operation Conditions

17 Documentation

7 Environmental Load Calculation

7.1 Wind and current force

7.3 Wave force 70

Documentation

Where the DP system is to be supplemented with a stationkeeping performance notation, the following information is to be submitted for review

General arrangement and lines plan

Thruster arrangement

Thruster power and thrust

Thruster interactions

Analysis procedures

Capability plots

Documentation on the environment conditions long term distribution (any area for intended service) Owner specified limiting environments

71

Section 10: Specific Vessel Types

1 Introduction

3 Mobile Offshore Drilling Units

Effect of drilling

Effect of emergency shutdown system

Effect of emergency disconnect system

Maintenance plan

5 Project or Construction Vessels

Suitable DP Control modes

Redundancy of relative position reference system

7 Logistics Vessels

Redundancy of relative position reference system

72

DPS Guide Development Milestones Jan 2012

Project Kickoff Divisions Technology TBDs Previous DP Consultant work

Jun 2012

Aug 2012

Oct 2012

Dec 2012

Review Initial development work

Project Plan

DPS draft guide development

Industry workshop

Consultant

DPS Guide Internal and external review

Rough Draft for DP consultants review and improvement 73

Summary

DPS Guide to reduce the gaps between industry practices and class requirements

New notations for enhanced system (EHS) and stationkeeping performance (SKP)

Provide systematic measurement

Provide more flexibility for owners and operators

Need industry s for further improvement

Shipbuilder Classification Society

Charterer

SHIP OWNER Shipping Financier

Underwriter

Flag State

Port State

74

www.eagle.org