Acuson Aspen - Service Manual 4d4919

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Acuson Aspen - Service Manual as PDF for free.

More details w3441

- Words: 39,366

- Pages: 230

Acuson Aspen™ Ultrasound System - - - --------------------------------------

-- - - - - - - - - - - - - -

Service Manual

Acuson Corporation 1220 Charleston Road Mountain View, CA 94039 (415) 969-9112 (800) 4·ACUSON Part Number: 49881

COPYRIGHT

lop\'rit.:hl ({) 144/1 t'ly Acuson CorpoT,llion. All Nil p.ut 01 thi.. pUblic<1tion mny Pl' Tl"prllduCl'd, Ir'lJ1smitlc.'d, .. hlfl,d in rt'triL'\'ill ..,\,Sll'I11.. , or transl"kd into any I,mguagt.· or compull'r li1ngungl', in ,lOV form or hy ,lny J1lL'.m.... l'it'l"tmnh:, llll'ch.mit.".,1, m

tht' prior ",rjUl'" pl'rmission of AClIson Corporation. ACll ... nn CorrllT,lhon Tt>:-.eTVB thl' right tll rhangl'

Although Acustln Corporation has ilttempted to "Cnsure accuracy

thIS manual. Acu!>4.ln C(lrp

First Edition-Cctober]9%

TRADEMARKS

ACUSON, MultiHertz, RES, Vector, 128XP, XP and AEGIS are ed trademarks of Aruson Corporation. Aspen, CDE, CDV, Convergent Color Doppler, DELTA, DIMAQ, OTl, EE microCase, Multizone, NewView, ProtoCALL, QuantX, Quik-Clip. Sequoia. Solo, SpaceTime, SST and The Value of Vision are trademarks of Acuson Corporation. Cidex, Cidex Plus, and Cidex 7 are ed trademarks of Surgikos, Inc. K-Y Lubricating Gel a trademark oflohnson & Johnson Products, Jnc.IBM is a ed trademark of International Business Machines Corporation. Metricide is a trademark of Metrex Research Corporation. Omnicide is a trademark of Cottrell, Ltd. Panasonic is a trademark of Matsushita Electric Industrial Co. Ltd. Polaroid is a ed trademark of PolaTOid Corporation. 3M is a ed trademark of Minnesota Mining and Manufacturing. Apple, AppleTalk, EtherTalk, LocalTalk, Macintosh, MultiFinder, and LaserWriter are trademarks of Apple Computer, Inc. OOT is a ed trademark of Digital Optical Technoiogies. Pinnacle Micro Inc., Kodak, and Ektascan are ed trademarks of Eastman Kodak Company. PostScript is a ed trademark of Adobe Systems, Incorporated. Ricoh is a trademark. of Ricoh Company, Ltd. Sony is a ed trademark of Sony Corporation of America. Verbatim is a ed trademark of Verbatim Corporation. Tosoh is a trademark. of Tosoh Corporation. Multi-Imager is a trademark of lntemationallmaging Electronics. All other product names are trademarks of their respective companies.

CAUTION!

Federal Law restricts use of this device to or on the order of a physician.

LICENSE AGREEMENT

All computer programs copyright 1991)..1996 by Aeuson Corporation OR ITS SUPPUERS. Such programs are licensed under the follOWing software license agreement Acuson or its suppliers retain(s) ownership of and title to any computer program supp1ied \','ith the equipment and to the trade secrets embodied in such computer programs. Subject to the Buyer's acceptance and fulfillment of the obligations in this paragraph, Acuson grants the Buyer a personaL non-transferable, perpetual, non-exdusive license to use any computer program supplied with the Equipment that is necessary to operate the Equipment solely on the medium in which such program is delivered for the purpose of operating the Equipment in accordance with the instructions set forth in the operator's manuals supplied with the Equipment and for no other purpose whatsoever. Buyer may not reverse-assemble, reverse-compile or otherwise reverse-engineer such computer programs nor may Buyer make a copy of such program or apply any techniques to derive the trade secrets embodied therein. In the event of a failure by Buyer to comply with the of this license, the license granted by this paragraph shall terminate. Further, because unauthorized use of such computer programs will leave Acuson without an adequate remedy at law, Buyer agrees that injunctive or other equitable relief 'will be appropriate to restrain such use. threatened or actual. Buyer further agrees that (I) any of Acuson's suppliers of software is a direct and intended beneficiary of this end- sublicense and may enforce it directly against Buyer with respect to software supplied by such supplier, and (ii) NO SUPPLIER OF ACUSON SHALL BE LIABLE TO BUYER FOR ANY GENERAL, SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL, INCIDENTAL OR OTHER DAMAGES ARISING OLTT OF THE SUBLICENSE OF THE COMPUTER PROGRAMS SUPPLIED WITH THE EQUIPMENT,

ii

Acuson Aspen Ultrasound System

1096

Table of Contents - - - _... _._-_._. - ._-_._.

Preface

Chapter 1

.. -

xi xii xiii xiv xv

Introduction and System Requirements

1-1

System Architecture Ultrasound Basics System Architecture Theory of Operation Scanner Assemblies DIMAQ Integrated Ultrasound Workstation Theory of Operation 2D Data Path Spectral Doppler Data Path Color Doppler Data Path M-mode Data Path Cine Operation AEGIS System ECG and Physio Signal Processing Audio DlMAQ Workstation Assemblies

0796

_

About This Manual Organization Other Aspen System Manuals ing Acuson

Introduction to the Aspen System Reviewing System Requirements Using Input and Output Connectors Identifying PCB Type, Version, and Revision Following Basic Precautions Caring for the System Caring for Transducers Moving the System Attaching Peripherals

Chapter 2

_. .

Service Manual

]-2 ]-4

]-8 ]-]]

]-12 1-12 ]-14 1-15 1-15

2-1 2-3 2-3 2-6 2-]] 2-20 2-23 2-23 2-25 2-27 2-29 2-31 2-31 2-33 2-34 2-36

iii

Table of Contents

Chapter 3

Power Subsystem

3·1

Power Supply Architecture

Isolation Transformer Box

3-2 3-3 3-1 () 3-14

Removing and Replacing Field Replaceable Units (FRUs)

4-1

Introduction to Removing and Replacing FRUs Scan Converter

4-3 4-5 4-10 4-15 4-19

Theory of Operation

Power Sub Assemblies

Chapter 4

Scanner

Power Subsystem Monitor Assembly Interface Chapter 5

Chapter 6

Troubleshooting

5-1

System Troubleshooting Technical Assistance Symptom Type Quick Tips Common Symptoms and Fixes

5-2 5-3 5-5 5-6

System Diagnostics

6-1

Accessing Customer Menu The Customer Menu Emergency Diagnostics By Technical Assistance Chapter 7

Chapter 8

iv

4-20

5-2

6-2 6-2 6-6 6-6

Preventive Maintenance Preventive Maintenance Preliminaries Visual Inspection Mechanical Inspection Electrical Verification System Monitor Controls Operational Verification Customer Diagnostics

7-11

Parts List

8-1

Aspen System Acronym List Aspen System Parts List Cables and Wire Harnesses Chassis Hardware Monitor Assembly Peripheral Interface Cable Assemblies Power Supplies Printed Circuit Boards Mise. Parts

8-2

Acuson Aspen Ultrasound System

7-1

7-2 7-2 7-3 7-5 7-6

7-7 7-8

8-4 8-4

8-6 8-8 8-8 8-8 8-9

8-]0

0796

Table of Contents

Interface Assemblies

R-lO

Appendix A

System Drawings

A-l

Appendix B

Warranty and Service Warranty and Limitations of Liability

B-1

Preventive Maintenance Customer Service

Index

0796

B-2 B-6 B-6

Index-l

Service Manual

v

Figures

FIGURES Fif;ure 1-1. Aspen System - Front View

1-3

FiguTt'1-2. Circuit Breakers on Rear Figure 1-3. Circuit Breakers on Isolation Transformer Box

1-7 1-7 1-K

Fif;ure 1-4. Aspen SYstem Rear Connectors Fif;ure 1-5. Aspen System Front Connectors Fif;ure 1-6. Aspen System PCB Fif;ure 1-7. Air Filter Locations Fif;ure 2-1. Scanner Block Diagram Figure 2-2. Scanner Control and Setup . Figure 2-3. Scanner Transmit Block Diagram Figure 2-4. Scanner Reception Diagram Figure 2-5. Gain and Processing Block Diagram Figure 2-6. Scanner Doppler Processing Figure 2-7. Scanner Board Location Figure 2-8. DL-Connector (Plug and Figure 2-9. MP-Connector Figure 2-10. Basic Scan Conversion Principle Figure 2-11. DIMAQ Workstation Block Diagram Figure 2-12. 2-0 Data Path Figure 2-13. Spectral Doppler Data Path Figure 2-14. Color Doppler Data Path Figure 2-15. M-mode Data Path Figure 2-16. Aegis System Data Path Figure 2-17. Audio Data Path Figure 2-18. Scan Converter DIMAQ Workstation Board Layout Figure 3-1. AC Power Distribution Figure 3-2. DC Distribution Figure 3-3. Aspen System Power On/Off Sequence Figure 3-4. Main Power Supply Connector Descriptions Figure 3-5. The Main Power Supply (top and side views) Figure 3-6. Programmable Power Supply Figure 4-1. Aspen System - Front View Figure 4-2. Aspen System - Rear View Figure 4-3. Rear Air Filter Removal Figure 4-4. Right Cosmetic Side and Screw Location Figure 4-5. Scan Converter with Cover Figure 4-6. Scan Converter without Cover Figure 4-7. View of lOB from the Rear of Aspen System Figure 4-8. View of Scan Converter with All PCBs Removed Figure 4-9. View of Scanner with Cover On Figure 4-10. View of Scanner without Cover Figure 4-11. View of PPS and It's Location Figure 4-12. View of Main Power Supply Figure 4-13. AC Box Figure 4-14. Isolation Transfonner Figure 4-15. Monitor Assembly Screw and Connector Locations Figure 4-16. Monitor Tilt/Swivel Assy with Monitor Removed Figure 4-17. Interface and Mounting Screw Locations Figure 4-18. Interface Assembly without UI Bezel Figure 5-1. lOB 7-Segment Error Display and Ethernet LEOs Figure 5-2. lOB 7-Segment Error Codes and Ethernet LEOs Figure 6-1. Customer Menu

vi

Acuson Aspen Ultrasound System

1-10 1-11 1-B 2-5 2-6 2-7 2-9 2-10 2-10 2-11 2-17 2-18 2-21 2-22 2-24 2-26 2-28 2-30 2-32 2-35 2-36 3-4 3-7 3-8 3-11 3-12 3-13 4-4 4-4

4-5 4-5 4-6 4-6 4-8 4-9 4-11 4-11 4-15 4-16 4-17 4-18 4-19 4-20 4-21 4-22 5-6 5-11 6-2

0796

Figures

Figure 0-2. Keyboard Functionality Test 0-4 Figure 0-3. Power Up Diagnostic Coniigumtion 0-4 Figure 6-4. Test Patterns o-'i Figure 6-5. SMPTE RP 133-1980 Medical Diag imaging Pattern 6-5 Figure 6-6. Gray Ramp Pattern b-o Figure 7-1. Air Filter Removal 7-4 Figure A-1. System Cabling Diagram A-3 A-7 Figure A-2. Exploded View, Interface, DIMAQ Workstation Figure A-3. Exploded View, Disk! Audio Box, DIMAQ Workstation A-11 Figure A-4. Exploded View, Power Supply Bay A-15 Figure A-5. Exploded View, Scanner A-19 Figure A-6. Exploded View, Scan Converter, DIMAQ Workstation A-23 Figure A-7. Exploded View, System, Front A-27 Figure A-S. Exploded View, Casters A-31

0796

Service Manual

vii

Tables

TABLES Table 1-1. Input Power Values for Aspen System Table 1-2. Aspen System Rear Input and Output Connectors Table 1-3. Aspen System Front Input and Output Connectors Table 3-1. Scanner Power Supply Usage by Board Table 3-2. Power Supply Usage by Other Boards!FRU Table 5-1. Symptoms Types Definillon Table 5-2. Causes of Failures Table 5-3. Quick Tips Table 5-4. Normal Operations Table 5-5. Power Supply Troubleshooting Guide Table 5-6. System Powers Itself Down Table 5-7. lOB 7-Segment Error Codes and Ethernet LEDs Table 5-8. Video Failures Table 5-9. Format or Functional Problems Table 5-10. System Lock-up Problems Table5-11. ImageQualityProblems Table 5-12. Error Messages Table 5-13. Examples of Scanner Error Messages Table 5-14. Examples of DIMAQ Workstation Error Messages Table A-I. Interface, D1MAQ Workstation Table A-2. Disk! Audio Box, DIMAQ Workstation Table A-3. Power Supply Bay Table A-4. Scanner Table A-5. Scan Converter, DIMAQ Workstation Table A-6. System Front Table A-7. Casters

viii

Acuson Aspen Ultrasound System

1-6 1-'1 1-10 3-15 3,1 b 5-3 5-4 5-5 5-6 5-7 5-8 5-12 5-15 5-16 5-17 5-18 5-19 5-20 5-21 A-5 A-lO A-14 A-18 A-22 A-26 A-30

0796

Preface ._-- ---- ---- ---- ---- -._- ---- _._ ----

Acuson'" is pleased to welcome you to the Acuso n Aspen™ Ultraso und system . The Aspen system is a specia l-purpo se machin e design ed to help you perform general radiology, obstetrical, gynecologic, cardiac, and / or vascular exams. It gives you the operati ng modes and transdu cer formats throug h either standa rd features or option al upgrad es. Acuson system s have an exceptional record of depend ability and a custom er service networ k ready to respon d to your individ ual needs. For inform ation on Acuson 's service offerings, please consul t your Acuson Service Representative or call us at 1-(800) 9-ACUSON or 1-(415) 969-9112.

1096

Service Manual

ix

Preface

ABOUT THIS MANUAL The purpose of this manual is to familiarize service personnel with the basic operation of the Aspen ultrasound system for maintenance and troubleshooting. Service personnel are expected to be familiar with the use of basic test equipment (DVM, oscilloscope, etc.) as well as basic ultrasound theory. WARNING!

This manual is intended for use by trained service personnel. There are lethal volta!\es inside the Aspen ultrasound system. Bodily harm, possibly death, as well as damage to the system may result from untrained individuals openin!\ the system. This manual should be used only when servicing the Acuson Aspen ultrasound system. For service information about the Acuson Model 128 use service manual pin 19018 or 23151. For the 128XPor 128 upgraded to XP functionality use pin 25997. For the Sequoia 512 ultrasound system use pin 49726 and for Sequoia C256 echocardiography system use pin 48135.

x

Acuson Aspen Ultrasound Systam

1096

Organization

ORG ANIZ ATIO N This manua l contains the followinp; chapte rs:

1096

Chapter 1

•

Introdu ction and System Requir ements , introdu ces the Aspen system as well as some genera l guideli nes and system requirements.

Chapter 2

•

System Archite cture, explain s the major subsys tems and their functions.

Chapter 3

•

Power Subsys tem, explain s the power distrib ution, test points and introdu ces the power supplie s.

Chapter 4

•

Remov ing and Replac ing Field Replac eable Units, explain s how to access, remove , and replace major FRUs in the system .

Chapter 5

•

Troubl eshoot ing, explain s quick guide to faultfin ding as well as trouble shootin g the system.

Chapter 6

•

System Diagno stics, introdu ces the System Diagno stics.

Chapter 7

•

Preven tive Maintenance, provides a checklist which outlines the steps to follow when perform ing a preven tive mainte nance.

Chapter 8

•

Parts List, is a Jist of parts availab le from Acuson for servici ng the Aspen system.

Appendix A

•

System Drawi ngs, provid es explod ed view diagra ms of major Aspen system subass emblie s.

Appendix B

•

Warran ty and Service , provid es inform ation about your Aspen system 's warran ty and Acuson 's preven tive mainte nance progra m.

Service Manual

xi

Preface

Key Conventions

This manual uses several special symbols to refer to the controls on the svstem. The folloWing list shows the symbols and their descriptions. Symbol

Description

[LEFT]

Represents a soft key

CALC

Represents a key, knob, switch, or toggle control

CODE + SIZE

Means "Press the CODE key and press SIZE"

•

WARNING!

Represents a warning

IMPORTANT:

Represents an important statement

Indicates steps to follow to perform a procedurE'

Acuson provides special alphanumeric keys in different languages. This manual uses English labels for all keys and annotation tenns. To convert your system to another language, your Acuson Customer Service representative. For English and international keyboard layouts, see the Keyboard section of the manual.

OTHER ASPEN SYSTEM MANUALS In addition to this manual, the following manuals are also available for the Acuson Aspen system:

xii

•

Acuson Aspen Ultrasound System General Applications Manual with Cardiac Option The Manual provides infonnation that you use regularly as you perform ultrasound eXamS. It explains how to operate the standard and optional features of the Aspen system for rad iology, obstetrics, cardiology, gynecologic, and I or vascular exams. It also contains istrative and setup information that you use less frequently. The Manual addresses the reader who is familiar with ultrasound techniques; therefore, it does not include sonography training or clinical procedures.

•

Acuson Aspen Ultrasound System General Applications Transducer and Peripherals Manual with Cardiac Option The Transducer and Peripherals Manual explains the characteristics of the transducer types, transducer safety, and maintenance procedures. It proVides information on how to use special purpose transducers such as endocavity transducers, transesophageal transducers, and interoperative transducers. It explains how to use transducer needle guides to perfonn biopsies. It also provides specifications and power value tables for the Acuson transducers. In addition it contains information on setting up and operating peripheral devices with the Aspen system.

Acuson Aspen Ultrasound System

1096

ing Acuson

C O N TA C TI N G AC US O N For ad dit ion al inf orm ati on ab ou t the Ac us on sy ste m, co nta ct yo ur ne are st Acuson office. U.S.A.

Great Britain

Ac us on Co rpo rat ion , U.S .A. Te lep ho ne : 1-(415) 969-9 112 1-800-4-ACUSON Fax: 1-(415) 964-8331 Asia PacifielLatin Am erica

Ac us on Asia Pa cif ic/ La tin America, US .A . Te lep ho ne : 1-(415) 969-9 112 1-8oo-4-ACUSON Fax: 1-(415) 965-9471 Australia

Ac us on Pty. Ltd. Te lep ho ne : (61) 2 201-7 777 Fax: (61) 2 869-1600 Belgium

Ac us on SA /N Y Telephone: (32) 2-229-22 77 Fax: (32) 2-217-4297

Canada

Acuson Ca na da Ltd. Telephone: 1-(416) 296-1 634 Fax: 1-(416) 296-1259 Denmark

Acuson AS Telephone: (45) 391799 91 Fax: (45) 39275521 Europe

Acuson EHQ. Telephone: (44) 1895-20 2960 Fax: (44) 1895-202965

Japan Ac us on Ni pp on , K.K. Te lep ho ne : (81) 3-3316-3 999 Fax: (81) 3-3316-7002

Ac us on Ltd., En gla nd Te lep ho ne : (44) 1895-25 1010 Fax: (44) 1895-202999 Finland

Ac us on OY Te lep ho ne : (358) 17-61 6-9007 Fax: (358) 17-653-3939

Ac us on S.A.R.L. Te lep ho ne : (33) 1-6929-8 110 Fax: (33) 1-6446-9840

Ac us on Gm bH Telephone: (49) 91-31-82 650 Fax: (49) 91-31-826565

Hong Kong

Ac us on Ho ng Ko ng , Lt d. Te lep ho ne : (852) 2574-79 89 Fax: (852) 2574-6945 Italy

Ac us on S.p.A. Te lep ho ne : (39) 2 982-5 91 Fax: (39) 2 982-41107

Latin America

Ac us on Latin Am eri ca , U S.A. Telephone: 1-(305) 596-3 148 Fax: 1-(305) 596-3149

Norway

Ac us on AS Te lep ho ne : (47) 67-58"()2 -oD Fax: (47) 67-58-15-30 Russia

Ac us on Int '! Sales Co rp. Mo sco w, Russia Te lep ho ne : (7) 095-9 56-0018 or (7) 095-956-0019 Fax: (7) 502-222-1269 Singapore

Ac us on Sin ga po re Pte , Lt d. Te lep ho ne : (65) 254-898 2 Fax: (65) 254-8952 Sweden

Ac us on AB Te lep ho ne : (46) 8-595-10 230 Fax: (46) 8-595-10222 Spain Ac us on Iberica S.A. Te lep ho ne : (34) 1-66305 04

Preface

Aspen™ Ultrasound System Service Manual

Introduction and System. Requirements

cc::uson

CHAPTER 1

Introduction and System Requirements

1096

Introduction to the Aspen System

1-2

Reviewing System Requirements

1-4

Reviewing Environmental Requirements Electrical Safety Requirements Reviewing Electrical Requirements Instrument Input Power Rating Isolated Accessory Outlets Leakage Current Limits System Circuit Breakers

1-4

Using Input and Output Connectors

1-8

1-';

1-5 1-6 1-6 1-6 1-7

Identifying PCB Type, Version and Revision

1-11 .

Following Basic Precautions

1-12

Caring for the System

1-12

Cleaning and Sanitizing the System Cleaning Air Filters

1-12 1-13

Caring for Transducers

1-14

Handling Transd ucers Inspecting Transducers About Transducer Manual

1-14 1-14 1-14

Moving the System

1-15

AttaChing Peripherals

1-15

Servico Manual

1-1

Chapter 1 - Introduction and System Requirements

INTRODUCTION TO THE ASPEN SYSTEM The Aspen ultrasound system is a mobile, self-contained ultrasound svstem specifically for medical applications. is based on the use of modular printed The Aspen system circuit boards (PCBs) and subassemblies known as field replaceable units (FRUs). This modularization simplifies on-site service and repair. No post-delivery adjustments or calibrations are required for equipment operation. In most cases, on-site maintenance is accomplished by removing and replacing the printed circuit boards

1-2

Acuson Aspen Ultrasound System

1096

Introduction to the Aspen System

Figure 1-1

1096

Aspen System. Front View

SeNice Manual

1-3

Chapter 1 - Introduction and System Requirements

IMPORTANT: WARNING!

I I

Read this chapter before you bep;in using the system. Federal law restricts this device to use by oron the order of a physician.

REVIEWING SYSTEM REQUIREMENTS Reviewing Environmental Requirements

The Aspen system is a stable, rugged device. However, it should receive the care given to any precision instrument. Make sure that the system's environment is free of fumes, dirt, and electrical interference, e.g., brush-type motors and large fields of RF energy. The systern is designed to operate within the following environmental limits: Acuson Aspen System Temperature Relative Humidity Heat dissipation Side Clearance Rear Clearance

Environmental Limits 15° to 33°C, 59° to 90°F up to 90% non-eondensing 5000 Btu per hour 15.0 em (6.0 inches) 30.0 em (12 inches)

and has the following physical characteristics:

1-4

Acuson Aspen System Height Depth Width Weight

135.64 em (53.4 in.) 116.80 em (46 in.) 62.90 em (24.8 in.)

Ground Clearance

6.35 em (2.5 inches)

Physical ChaT8cterstics

217 kg (477 lbs.)

Acuson Aspen Ultrasound System

1096

Reviewing System Requirements

Electrical Safety .Requirements

This section describes specific electrical and environmental characteristics lhat determine your system's facility requirements. If you have additional questions, your Acuson Customer Engineer. The Aspen system is classified in accordance with the system standard IEC 601-1 as follows:

WARNING!

60'-'

Standard

lEe

Type of protection against electric shock Degree of protection against electnc shock Degree of protection against ingress of water

Class I TypeBF Ordinary

Accessory equipment connected to the analog and digital interfaces must be certified according to the respective IEC standards (IEC 950 for data processing equipment and IEC 601-1 for medical equipment). Furthermore, all configurations shall comply with the system standard IEC 601-1-1. Any party who connects additional equipment to the signal input part or signal output part is considered to be configuring a medical system, and is therefore responsible that the system complies with the requirements of the system standard IEC 601-1-1. If you have additional questions, your Acuson Customer Engineer. This equipment has been tested and found to comply with the limits for medical devices to IEC 601-1-2:1993 (EN60601-1-2:1994) or the Electromagnetic Compatibility Directive 89/336/EEC. These limits are designed to provide reasonable protection against harmful interference in a typical medical installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions may cause harmful interference to other devices in the vicinity. However, there is no guarantee that the interference will not occur in a particular fashion. If this equipment does cause harmful interference to other devices, which can be determined by turning the equipment off and on, the is encouraged to try to correct the interference by one or more of the following measures:

Reviewing Electrical Requirements

•

Reorient or relocate the receiving device

•

Increase the separation between the equipment

•

Connect the equipment into an outlet on a different circuit from the other device(s)

•

Consult the manufacturer or field service technician for the help on other device

Acuson produces systems which operate with AC line voltages of 100, 115, and 230 VAC. The nameplate on the baCk of the system indicates the AC power required for your system. The 115 VAC systems usually require 15-A service; however, certain equipment options in certain countries notably Canada may require 2D-A service. These systems are equipped with 2D-A attachment plugs. Units configured for 230 VAC generally require 10-A service. For optimal system performance, use a dedicated, interference-free, well-grounded wall outlet. The 115 VAC Acuson systems are

1096

Service Manual

'-5

Chapter 1 - Inrroduction and System Requirements

equipped with a attachment To ensure grounding reliability, connect it to only an equivalent hospitalgrade socket. WARNING!

Before having your system installed by an Acuson Customer Engineer, ensure that the electrical service in your facility is adequate. Do not

modify the attachment plug or use an adapter; doing so may overload vour building's power circuits. Using an extension cord to provide power may cause your system to exceed leakage current requirements.

Instrument Input Power Rating

The instrument input.power rating has been established to clarify the maximum power requirement of your system with all accessories. Depending upon the accessories and options installed, your system may not draw the full amount of power listed on the serial plate. Table 1-1 shows input power values for various Acuson Aspen system input voltages. Table 1-1

Input Power Values for Aspen System

System Voltage VAC

Maximum Aspen Power Usage, VA

Isolated Accessory Power Available, VA

115 V (US.)

1380 VA 1725 VA'

250 VA Continuous 400 VA Intermittent

115 V (Canada)

1380 VA

350 VA

100 V (Japan)

1500 VA

165 VA

230 V

1725 VA

400 VA

• Requires a dedicated outlet for 15 A service. Some options require 2D-A service. must ensure adequate power is available.

Isolated Accessory Outlets

The Acuson Aspen system has a total of four isolated accessory outlets located on the rear of the system, to provide power to accessories. The system AUX ONIOFF standby switch controls power to these outlets. They are isolated to protect against chassis leakage currents from connected accessories. Plug only approved accessories into these outlets.

WARNING!

Leakage Current Limits

The total power available is indicated near the outlets and listed in Table 1-1. DO NOT overload these outlets as overloading can trip the circuit breaker of the system or the building circuit breakers. Failure to use isolated outlets for accessories can degrade image quality and compromise patient safety. Isolated accessory outlets let you connect approved accessories without increasing the system's leakage current. Connecting accessories powered from non-isolated sources may result in chassis leakage currents exceeding safe levels.

1-6

Acuson Aspen Ultrasound System

1096

Reviewing System Requirements

WARNING!

System Circuit Breakers

Plug only the proper connectors into tlll' input and output nmnt'ctor sockets. Fililurl' ttl do so can damilgl' the system ilnd destroy its dectricalsafety features. For complete description Set' U;:;;nx Illput and Oil/Flit Co/11leettlrs on the following page.

The Aspen system has two circuit breakers on the rear of the system 1-2. The circuit breakers provide the as shown in protection:

•

Mains input breaker: This breaker disconnects all parts of the svstem from both sides of the mains. It also serves as the mains switch. Note that a portion of the system is whenever the mains input breaker is on. Isolated accessory outlet breaker (AUX): This breaker protects the .isolated accessory outlets from physical damage due to

Figure 1"2' Circuit·Breakers on Rear P'lllel IsolationTransformer.circuit breakers: There are three circuit breakers o"n the lsolati@ Tiansfimner. The first in the primary disconnei:\S "the input to the isolaton transformer w!tile the other two, whi«;!t.are in series protect the system monitor"and the PrograIiuiiable .

Figure 1-3

1096

Circuit Breakers on Isolation Transformer Box

Service Manual

1-7

.Chapter 1 - IntroductIon and System Requirements

USING I.NPUT AND OUTPUT CONNECTORS Input and output connectors are located on the front and back of the system. Figure 1-4 shows the rear door for access to the rear connectors of the Acuson Aspen system. Table 1-2 describes the rear input and output connectors. Figure 1-5 shows the Aspen system front . Table 1-3 describes the front input and output connectors. WARNING!

Interconnection with other equipment may result in chassis leakage currents exceeding safe levels. For further information, your .....cuson Customer Engineer.

,. rr IJ13NOTUSEO

•

I'"::::" I

J1SSCSl

o

;:..a:':'-....

...

, OClDCCMla.-flll 1 oQX OWl VOL''''" l

• COOC""._'4(1

, sc..-.aoDlSOl_.aoo,... ,

STS11 .. CMIITI ....

...

I,',"'" "'

I I""", . 'I Imon>CA><"-l 00'"

UrNs

\

I

ca.;

J2:9

COLOR VIDEO

Figure 1-4 1-8

W fr'

'I

J30 Pill£!. CLOCK

OTEItNAL

J31

J3.

T1tIGG£fl

J3Z

J33

REMOTE

C-'/Il

8IW

EJI:POS£

VlDf.O

VUO

Aspen System Rear Connectors

Acuson Aspen Ultrasound System

1096

Using Input and Output Connectors

Table 1-2 No.

Aspen System Rear Input and Output Connectors

Connector Label

InputlOutput

Description

Interface Standard

Connector Type

Maximum

Voltage

2

Parallel Printer

Output

Centronics Printer Port Centronix

Dsub-25p

5V

3

External SCSI

Input/Output

External SCSI Interface SCSI 2 Type

SCSI2- SOp

5V

4

IOBaseT

Input/Output

Ethernet (For future use)

10BaseT

R)45

5V

5

External Ethernet AUI

Input/Output

External Ethernet (For future use)

AUI

D sub-15p

12V

6

Aux Serial B/C

Input/Output

Aux Serial Port

B= RS422

Dsub-26p

" 5V ,,12V

C = RS232 8

VCR

Input/Output

Interlaced Y-C, Stereo Proprietary (Line Level), Serial Port

Dsub-25p

" 12V

9

Betacam

Input/Output

Interlaced Y/C, Stereo Proprietary (Line Level), Serial Port

Dsub-25p

" 12V

10

AuxRGBln

Input

Interlaced RGB

MACn

Dsub-15p

-4V

11

AuxRGBOut

Output

Interlaced/ Progressive MAC II RGB

Dsub-15p

-4V

12

RGB Color Camera Input/Output

Interlaced RGB, Serial Port

Proprietary

Dsub-2Sp

" 12V

13

Y-Cln

Input

Interlaced Y-C

5VHS

Mini-DIN-4p IVpp

14

Y-COut

Output

Interlaced Y-C

SVHS

Mini-DIN-4p

IVpp

15

Color Video

Output

Interlaced Y-C

BNC

BNC

IVpp

16

Pixel Clock

Output

Digital Pixel clock

BNC

BNC

5V

17

External Trigger

Output

External Trigger For Aux. Device

BNC

SV

18

Remote Expose

Output

Camera Expose Control BNC

BNC

SV

19

Cam Video

Output

B/W video to Camera

BNC

BNC

IVpp

20

B/WVideo

Output

Interlaced Y (B /W)

BNC

BNC

IVpp

1096

Service Manual

1-9

Chapter 1 - Introduction and System Requirements

Figure 1-5

Table 1-3

Aspen System Front Connectors

Aspen System Front Input and Output Connectors

Connector Label Name

Description

Interface Standard

Connector Type

InputlOutput

Volt8ge

DL Transducer connector

Plug in Acuson DL Transducers

DL

Acuson DL

Input/Output

+150V

MP Transducer Plug in Acuson MP connector Transducers

MP

Input/Output

+150V

Maximum

Custom Design AcusonMP Custom Design

Headphone

Audio output for use with headphones

Stereo phone jack

Output

IVpp

Microphone

Connection for external microphone

Mon. phone jack

Input

5Vpp

Footswitch

Connection for lootswitch

6-pin]ones

Input/Output

5V

AUXCW (optional)

Acuson Auxiliary CW Transducer

proprietary

IG-pin circular

Input/Output

Use only Acuson AuxCW Transducers

ECG

ECG trace

AAMIECGC

AAMIECGC

Input/Output

",5 V

AUX

DC input

1/4" Phone

Input

",5 V

Phona

Heartsound trace

1/4" Phone

Input/ Output

",5 V

Pulse/ Respiration

Pulse trace

1/4" Phone

Input

",5 V

1·10

Respiratory trace

Acuson Aspen Ultrasound System

1096

Identifying PCB Type, Version, and Revision

IDENTIFYING

PCB TYPE, VERSION, AND REVISION Printed circuit boards are identified by board type, version and revision level. The board type indicates the board's major function. The type is abbreviated into a two or three-letter acronym, such as VPB for the Video Processor Board. Version numbers are used to distinguish Significant design changes of a board type. The new version is distinguished from the old by appending a number to the three-letter type identifier. In case of VPB board, the earlier boards were called VPB. Later changes produced VPB2. All these versions refer to generally as VPB boards. Except when indicated, newer version boards may always be used in place of older versions. The type and version identifiers are etched in the board's copper foil. Occasionally a number is appended to an alphabetic revision to indicate a revision level in between two alphabetic revision levels. For example, revision ''Dl is between revisions un" and U

Revision levels are hand written on the board in indelible ink and / Or marked on one of the PCB ejectors. The board assembly level should not be confused with the PCB fabrication (bare board) revision level, which is marked in the copper etch or silkscreen.

Board Type Acronym - Rev. Level

Part Number - Serial Number

Figure 1-6

1096

Version Number

Aspen System PCB

service Manual

1-11

Chapter 1 . Introduction and System Requirements

FOLLOWING BASIC PRECAUTIONS The following safety precautions should be observed when servicing the Acuson Aspen system: Servicing the Aspen system shall only be conducted by Acuson trained Aspen system service provider. Lethal voltages (up to 300 VDC) are present inside the Aspen system. Use caution when opening the unit. Under certain fault conditions the high voltage bus may remain charged even when"the system is unplugged from the wall outlet. Furthermore, the operating temperature of some components can cause bums.

WARNING!!

Always consult the Mnnual pin 47881 for proper operation and use of this system. Also refer to the Basic Safety Precautions section of the Manual for detailed list of basic precautions. The Aspen system employs a software power-on/ off circuit. This means that there are live voltages present in the system even with the power off. Always unplug the system to perform any cleaning or maintenance.

WARNING!

CARING FOR THE SYSTEM The Aspen system requires proper care and cleaning. IMPORTANT:

I

Improper system care will void your warranty. System care includes inspecting and cleaning air filters weekly, cleaning and sanitizing the system, and inspecting the illuminating keys. For detailed information on caring for your system, consult the Mnnual.

Ultrasound systems are sometimes used in an environment in which they are exposed to pathogens which pose a potential health hazard to persons handling the system. For health reasons, always thoroughly clean, sanitize, and/or sterilize the system and its transducers prior to performing maintenance.

IMPORTANT:

Cleaning and Sanitizing the System

WARNING!

'-'2

•

1 2

I

To clean or sanitize the system: Switch the system off and unplug it from the power outlet. Dean the system cabinet, transducer holders, and storage bay with a damp cloth soaked in mild soap and water, or sanitize it using isopropyl alcohol.

DO NOT drip any liquid into the system or onto the keyboard.

Acuson Aspen Ultrasound System

1096

Caring for the System

Cleaning Air Filters

The Acuson Aspen system has three air filters. Air filters are located on the right rear, left rear, and front side of the system. Refer to the Figure 1-7. Remove, inspect, and clean the air filters each week. •.

To remove and clean the air filters:

,

Unplug the system from the power outlet.

2

To remove the air filters located on the right rear and left rear of the system, use the tab on each filter to slide it out and remove the filter.

3

To remove third air filter located on the left front side of the system, pull at the top of the air filter grill.

4

Wash the filters in water with mild detergent and dry them, or clean them with a hand-held vacuum cleaner.

S

Replace the filters.

Figure 1·7

1096

Air Filter Locations

Servic6 Manual

1·13

Chapter 1 - Introduction and System Requirements

CARING FOR TRANSDUCERS Transducers require proper handling, care, and cleaning. IMPORTANT:

I

Improper transducer care will void your warranty. Transducer care includes daily inspection, daily cleaning, disinfecting and sterilization whenever necessary. It is important to handle transducers properly:

Handling Transducers

•

00 NOT drop the transducer. Dropping or striking a transducer against a hard surface can damage the transducer elements and acoustic lens and damage the electrical safety features.

•

00 NOT use a cracked or broken transducer. Damaged transducers present a danger of electric shock. If a transducer cracks or breaks, your Acuson Customer Engineer immediately. 00 NOT pinch or kink the transducer cable. If the transducer housing becomes cracked or broken or if there are cuts or openings in the cable, the electrical safety features of the transducer could be compromised. 00 NOT immerse the external transducer in any liquid beyond the first ridge. The transducer is not watertight. Immersing it beyond the first ridge can destroy its electrical safety features. For an explanation and illustration of the proper immersion technique see the Transducer and Peripherals Manual.

•

•

•

WARNING!

Use only recommended ultrasound coupling gels and cleaning agents and do not use those containing components described in the Transducer and Peripherals Manual. Improper transducer care will void your warranty. For specific information, see the Transducer and Peripherals Manual.

00 NOT use a transducer that has been dropped or subjected to a severe collision until it has been inspected by an Acuson Customer Engineer. Cracks or other damage to the transducer and cuts or openings in the transducer cable can damage the electrical safety features of the transducer.

Inspecting Transducers

Inspect the transducer lens, case, and cable each day. Check for cracks or other damage that may allow liquids to enter the transducer. If you find any damage, have the transducer replaced by Acuson Customer Service.

About the Transducer Manual

For transducer specifications and transducer power values refer to the Acuson Aspl'1l System Transducer aM Peripherals Manual pin 47882. Your transducer manual contains important transducer safety and reference information. It also provides information on how to use special purpose transducers such as endovaginal and transesophageal transducers. The transducer manual also includes lists of Acuson tested coupling gels, Acuson compatible disinfecting and sterilizing solutions, and lists of manufacturers of transducer supplies.

1-14

Acuson Aspen Ultrasound System

1096

Moving the System

MOVING THE SYSTEM When you move the system, do so carefully. Be especially careful when moving it along inclined ages. •

Observe the following precautions when moving the system: o

Eject the magneto-optical disk from that disk drive.

o

Tum the system off, disconnect the power cord, and disconnect any other cords. Store the power cord on the holders on the back of the system.

o

Clamp the transducer connectors in the transducer storage ports and store the transducer in one of the transducer holders on either side of the system.

o

Make sure that transducer cables are away from the wheels before moving the system. Loop the transducer cable through one of the cable hooks under the keyboard.

o

Make sure the monitor is in the locked position.

o

Unlock the wheels before moving the system. Use the caster locking mechanism located on the caster.

o

Make sure that the peripherals are strapped securely in place.

•

Use the front or rear handle grips to move the system.

•

DO NOT allow the system to strike walls or door frames.

o

Use care when moving the system off ramps, or elevators. Jarring the system by sudden drops can cause structural damage to the frame of the system.

•

Lock the wheels, once you reach your destination.

ATTACHING PERIPHERALS IMPORTANT:

1096

I

Your Acuson Customer Engineer must install the peripheral devices to the system for you. For detailed infonnation on peripheral devices refer to the Acuson Aspen Ultrasound System Transducer and Peripheral Manual pin 47882.

Service Manual

'-'5

Chapter 1 - Introduction and System Requirements

'·16

Acuson Aspen Ultrasound System

1096

Aspen™

lfltrasound System Service Manual

System Architecture

cc:uson

CHAPTER 2

System Architecture

Ultrasound Basics

2-3

Amplitude Frequency

2-3 2-3

System Architecture

2-3

Scanner Theory of Operation

2-6

Scanner Control Transmission

Reception Gain and Processing Doppler Processing Scanner Assemblies

1096

2-3 2-6 2-7 2-8 2-10 2-10

2-11

APD - Apodizer Board AUX -Auxiliary Continuous Wave Doppler Board BBQ - Baseband Quadrature Board DBL - Distribution Board Lower DeC - Dual Channel Controller Board IFD - Intermediate Frequency Detector Board IGD - Interpolating Gain Driver Board MEX - Memory Expansion Board MXK - Mixer Oock Board RCV - Receiver Board SOL - Summing Delay Line Board STG - Scanner Timing Generator Board TRM - Terminator Board VDT - Video Detector Board XDY - Transmit Delay Board XMT- Transmitter Board ZDL - Transducer Interconnect Board DL ZIP - Transducer Interconnect Board MP ZDT - Distribution Board Top ZS - Scanner Control Processor Board

2-12 2-12 2-12 2-13

DIMAQ Integrated Ultrasound Workstation

2·20

Scan Converter

2-21

Service Manual

2-13 2-13 2-13 2-14 2-14 2-14 2-14 2-15 2-15 2-15 2-16 2-16 2-17 2-18 2-18 2-19

2-1

Chapter 2 - System Architecture

2-2

Theory of Operation

2-23

20 Data Path

2-23

Spectral Doppler Data Path

2-25

Color Doppler Data Path

2·27

M-mode Data Path

2-29

Cine Operation

2·31

AEGIS system

2-31

ECG and Physio Signal Processing

2-33

Audio

2·34

Interface

2-35

DIMAQ Workstation Assemblies

2·36

AQP - Acquisition Processor Board CDM - Cine Data Memory Board CRr - Color Reconstruction Processor Board DAQ - Doppler Acquisition Board DSP - Doppler Spectral Processor Board ECG/ Physio Module FEe- Flow Estimator Calculator Board lOB - Input Out put Board MSE - Monitor Speaker Equilizer Board Rr - Reconstruction Processor Board SVC - Syscon Video Controller Board VIC - Interface Controller VPB - Video Processor Board WFP - Waveform Processor Board ZAP - Audio Processor Board ZFEB - Flow Estimator Buffer Board

2-37 2-37 2-37 2-38 2-38 2-38 2-39 2-39 2-39 2-39

Acuson Aspen Ultrasound System

2-40 2-40 2-40

2-41 2-41 2-41

1096

Ultrasound Basics

ULTRASOUND BASICS Ultrasound imaging is a method of viewing the anatomy by displaying the reflections of ultrasound waves on a video monitor. An ultrasound image is made up of a large numbers of discrete lines of echo information. A pulse of ultrasound energy is transmitted into the body by a transducer. Echoes are created when the sound wave propagates through tissues of different acoustic impedance. After the ultrasound pulse is transmitted, the transducer receives the echoes from the tissues. The quality of the image is determined by the precision with which the ultrasound beam is focussed in both transmit and receive modes. Echoes contain several kinds of information:

Amplitude

The strength of a reflected echo is proportional to relative changes in the acoustic impedance of the tissue being examined.

Frequency

Just as a train whistle has a higher pitch when it is approaching than it does when receding, echoes from a moving target are also shifted in frequency by the Doppler effect. By measuring the difference in frequency between the transmit pulse and the echo, velocities of blood or other structures may be determined.

SYSTEM ARCHITECTURE The Acuson Aspen system may be divided into three major operational subsystems:

Scanner

•

Scanner

•

DIMAQ Integrated Ultrasound Workstation

•

Power Subsystem (refer to Chapter 3)

The Scanner is the front end of the Aspen system. It contains the hybrid analogI digital computer which controls timing, phase, and amplitude for each of the 128 transmit and receive channels. Controlling these parameters allows the Aspen system to transmit a tightly focused pulse of ultrasound energy from the transducer. During the receive cycle the Scanner adjUSts these parameters in real time. As the ultrasound pulse penetrates the body, the Scanner continuously maintains focus at successively deeper points along the scan line. Information about the ultrasound line number, depth of scan, etc. is ed along with the analog echo signal to the Scan Converter within the DIMAQ integrated ultrasound workstation. The Scanner is made up of a card cage capable of containing up to 67 circuit boards which plug directly into the Scanner motherboard. It is located on the left side of the Aspen system. Transducers are plugged directly into the Scanner via the ZDL, in the case of DL Transducers, or the ZIP, in the case of MP

1096

ServiCE: Manual

2·3

Chapter 2 - System Architecture

Transducers. Althou/lh both types of transducers can be plugged in to the Aspen system simultaneously, only one port can be activated at a time. Digital communication between the Scanner and Scan Converter is accomplished via a dual-port RAM located on the ZDT. Analog signals are transferred to the Scan Converter via the DBL. Power is supplied to the Scanner from the power supplies located on the right side front of the system. Power connections are made via connectors on the back and at the rear of the motherboard. Voltages used in the Scanner are: 15 VDC, :7.5 VDC, :5 VDC, : 12 VDC and 30-150 VDC (programmable). See the section on the Power Subsystem for more detail.

2-4

Acuson Aspen Ultrasound System

1096

ZOL

ULTRASOUND VIDEO

144-

LXDCR ZIP

I/Q

+

+

DRL

or.

'Tl

l' t'" ::J

§.

SYSTEM TIMING

JoMK

XMT

Rey

XOY --,

t

...':-' w .

US VIDEO

STG XDV BUS

r-

f•

I

2:

-

o

l'

5l'" a.

-

0

BBUS

APD

I VGAIN

JoMK

1

1

L r

YOT

fA

IIRQ

r.

AVX

I

t

VIDEO GAIN

•

IF FIL

IGO

TRM

•

DBUS

MEX

T

:D

AUX CARR

VXMT

CBUS

Dee

IfO

I/Q

Via ZDL

•

MXK

A BUS

DeC

OUTSE

APOD .....

BUS

o

SOL

1

1

PXDCR NXMT

""

AUXCW xoeR

I

r

ZOT

LINENO TYPE SCANADR SCAN DATA

SCM/CONVERTER INTERFACE 1i)

I

3

l>

il 2:

1i) II>

0,

iil

Chapter 2 - System Architecture

THEORY OF OPERATION The scanner sequence can be divided into four major operations:

Scanner Control

•

Scanner Control

•

Transmission

•

Reception

•

Gain and Processing

All Scanner orerations are controlled by the Scanner Control Processor CZS) board. The ZS communicates to the digital control boards via the P bus.The Distribution Board Top CZDT) provides the data and communication link between the ZS and the Scan Converter within the DIMAQ workstation. Two Dual Channel Controller boards are used to drive the four digital buses. DeCO drives the A and B buses while DeCl, drives the C and D buses. A 4O-MHz master clock is located on the Scanner Timing Generator CSTG). Scanner operations and some of the Scan Converter operations are synchronized to this master clock signal. The control data, called microcode, for each particular transducer is stored on the Memex boardCs). A scanner accommodates up to three Memex boards to the selected transducers.

MEX

ZS

Scanner P Bus

STG

MXK Bus

XDY Bus

Timing Stgnals To Scanner

DCCO

DCC1

ABus BBus

CBus

ZDT

Scan Converter Interface

DBus

To lOS

Figure 2·2

2-6

Scanner Control and Setup

Acuson Aspen Ultrasound System

1096

Theory or Operarion

Transmission

During the transmission cycle, the following steps occurs: •

The gain and control information from the front is ed from the D1MAQ workstation to the Scanner.

•

The type and number of the lines to be fired are determined.

•

The control data needed to configure the beamformers, beamformer drivers, and gain/video subsystems are the outputs from the DCC boards via the A, B, C, and D buses for the particular line being fired.

After the setup data has configured the Scanner for a particular ultrasound line, a signal from the Z5 causes the Transmit Delay boards to output the phased transmit signals to the Transmitter boards. The Transmitter boards then output the high energy pulses required to drive the transducer elements to produce an ultrasound wave at the transducer face.

... ... <>

"""'" $" e..

:2:

<>

ZIP TIR 0-127

"""'"

$ -' 0

XMT

NXMT 0-127

XDY

XDY Bus

ZDL A Bus B Bus

e Bus

DCCO

Figure 2-3

1096

DCC1

STG

Scanner Transmit Block Diagram

Service Manual

2-7

Chapter 2 . System Architecture

Reception

After the transmit pulses are sent, echoes return to the transducer and are transformed into low-level electrical Signals. Signal flow through the Scanner during reception is as follows: Signals travel from the transducer elements through the transducer cable and enter the Scanner via the ZIP or the ZDL boards. The ZIP or ZDL sends the signals to the backplane, which routes them to the Receiver boands. The Receiver boards amplify the low-level signals and convert them to an intermediate frequency using mixer signals from the Mixer Clock boards. Signals from the Apodizer boards (APD), Mixer Clock boards (MXK), and Interpolating Gain Driver boand (IGD) control the gain of the Receiver boards (RCV) to compensate for attenuation due to depth and adjust the aperture of the array during reception. Refer to Figure 2-4 and 2-5. The Receiver boands output the IF signal to the Summing Delay Line boards (SDL). The eight SDL boards properly sum the signals from the sixteen Receiver boards, and output the IF signal to the Distribution Boand Lower (DBU. The DBL sums the signals from the SDL boards into one signal called lFSUM. This signal is then sent to the IFD boand for IF filtering. The IFD then routes the IFSUM to the Video Detector board for processing. The Video Detector board converts the received IFSUM signal to an ultrasound video signal. It also amplifies and performs Special processing to the ultrasound video signal and outputs it to the DBL. The DBL buffers the ultrasound video signal and outputs it to the Scan Converter within the DIMAQ workstation via connector }9 on the DBL.

2-8

Acuson Aspen Ultrasound System

1096

Theory of Operation

ZIP "

DL Transducer

Ultrasound Video

to Scan Conver1er

TIR 0-'27

us VIDEO

ReV

SDl

(16) 128 Ch.

(8)

DBl

MXK Bus

IFDIF

AP 0·127

MXK 0-127

STG

VDT

OUT 0·7

I .MXK

IF SUM

IFD

APD (4)

(4)

128Ch.

128 Ch.

B Bus

Dee 0

A Bus

:::: Bus

Dee 1

o Bus Figure 2-4

1096

Scanner Reception Diagram

Service Manual

2-9

Chapter 2 - System Architecture

Gain and Processing

The IGD is used to set the gain levels in the Scanner. II provides gain signals for transmit power, receiver gain, receiver bias, apodizer bias, and the ultrasound (US) video gain levels.The gain curve is determined by the microcode for each transducer and the settings of the master gain control and the DGC pots. Also included here is the IFD which filters the IF and the VDT which performs log compression, detection and filtering operations.

ToTransducer

T!R()..l27

I

I

XMT

ReV

IB) 128Ch.

APO-127

(16)

'28 Ch.

APD (4)

128Ch.

t

VXMT

EJ VD

V GAIN V BIAS

IGO

VA BIAS

VA FIEF

.

VIDEO GAIN

DBus

Figure 2-5

Doppler Processing

Gain and Processing Block Diagram

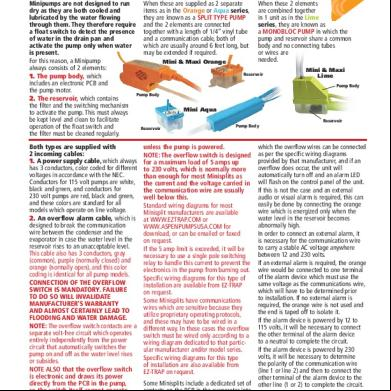

Two boards are used to provide the preliminary processing of Doppler signals in the Scanner. The BBQ board converts the IF FIL signal from the VDT into I & Q signals for PW and Color Doppler. In cardiology systems it processes the AUX CARR signal from the AUX board for imaging CW or auxiliary CW Doppler.

I

VOT

IF FIL SIGNAL

BBQ AUX

I&OSIGNAL

AUX CARR SIGNAL

Figure 2-6

I&OSIGNAL

OBL

TO SCAN CONVERTER

Scanner Doppler Processing

The I & Q signal from BBQ is then routed via DBL to the Scan Converter within the DIMAQ Integrated Workstation where further processing of the I & Q signals is done. For more detailed information refer to the DIMAQ Workstation section of this chapter.

2-10

Acuson Aspen Ultrasound System

1096

Scanner AssembJies

SCANNER ASSEMBLIES The following pages describe the circuit board descriptions. These are arranged alphabetically by the two or three letter acronym of each board. A brief functional description of each board is provided. See the DIMAQ Works/a/ion Assemblies section for information about the boards in DIMAQ workstation. The following figure shows the locations of the scanner boards. The numbers that follow the Board acronym denote the channel.

--

lOT

ZSCI' MEX(l)

occo

MEX(2)

!lCC' MEX(3) STG

XDY 1&31

SOLQ-15 RCVo-7 XMTQ-15 RCV&-15 SOl. 16-31 RCV 16-23 XMT 16-31 RCV24-31 SOL. 32-47 RCV32·39 XMT32-47

ZIP

APDQ-31 XDY32"'7 MXK 32-63 XDY48-63

SOL 48-& RCV48-55 XMT48-&

APe 32-63

RCV .....

SOL 64-79

XDY64-79 MXK 64-95

XDY80-S5 XDY96-111

RCV84-71 XMT84-79 ACV72·79 APO 64-95 SOL Bo-95 MXK 95-127 ReV 80-87 XMTBo-95 RCV_ SDU&111 RCV86-103 XMT96-111 AUXCW Rev 104-111 B8Q SOL 112·127 RCV 112·119 'FD XMT 112·127 Rev 119-127 VOT

IGO

zoe

OBI.

Figure 2-7 Scanner Board Location

7096

Service Manual

2-11

Chapter 2 - System Architecture

APD

Apodizer Board, PIN 10332

Function

The Scanner has four Apodizer boards, each with 32 apodizer channels, proViding a total of 128 apodizer channels. The function of the apodizer channels is to adjust the aperture of the transducer array. The output of an apodizer channel drives the apodizing amplifier section of an associated Receiver channel. The Apodizer boards are control1ed by microcode on DeCO via the Bbus.

AUX

Auxiliary Continuous Wave Doppler Board, PIN 17332

Function

The Auxiliary Continuous Wave Doppler board operates in one of two modes depending upon the type of CW function being used. In the first mode, an Auxiliary Continuous Wave Transducer is used. This transducer has a single piezoelectric transducer element for transmitting and a second element for receiving. In this mode the AUX board generates the transmit puises which drive the transducer. These puises are ed to the transducer via the ZDL. The receive signal enters the Scanner via the ZDL also. The AUX board then filters out the carrier/clutter component of the return signal and outputs the AUX CARR signal to the BBQ·board. In the second mode, an Aeuson imaging transducer is used. A number of the transducer elements are continuously transmitting while others are continuously receiving. Actually, the process is more or less continuous since it is possible to update the 2-D image periodicalIy. The format for transmit and receive is configured by the Scanner and the signal processing is similar to normal Doppler operation with the following exception: the IF FIL signal from the VDT is ed to the AUX board for processing rather than being processed by the BBQ directly. After the AUX board has separated the Doppler signal it es the Doppler signal to the BBQ. Once at the BBQ, the signal is processed in the usual manner.

BBO

Baseband Quadrature Board, PIN 32272

Function

The Baseband Quadrature Board is active only when in Doppler modes. It converts the IF FIL signal from the VDT to an "I" signal (in phase) and a "Q" signal (quadrature). The 1& Q signals preserve amplitude, frequency, and phase information for subsequent processing by the DAQ and DSP. When using continuous wave Doppler, the AUX CARR signal is processed rather than the IF FIL signal.

2·12

Acuson Aspen Ultrasound System

1096

Scanner Assemblies

DBl

Distribution Board Lower, PIN 34602

Function

The Distribution Board Lower performs the following functions: •

Interfaces the analog ultrasound video signal to the Scan Converter within the DlMAQ Workstation.

•

Signal routing of the SDL outputs

•

Terminating the A and D bus

•

Buffering the test point outputs and analog outputs

•

Carrying probe temperature information from VIC to Scanner

The DBL is controlled by microcode on DCC 1 via the D bus.

Dee

Dual Channel Controller Board, PIN 21552

Function

The purpose of the Dual Channel Controller board is to provide high speed data transfer to control the functions of the Scanner. The DCC is basically a high speed memory board that drives two digital buses: an 8-bit data bus, and a 16-bit data bus. Both buses have an 8bit address bus. Two DCC boards are used in the Scanner. The DCC nearest the top side of the Scanner, DCCO, drives the A and B buses. The other, DCC1, drives the C and D buses. The A, B, C, and D buses carry control information to the beamformer drive and video gain processing sections of the Scanner. During the scanning cycles, the DCCs output the necessary control information onto the A, B, C, and D buses.

IFD

Intermediate Frequency Detector board, PIN 30242

Function

The Intermediate Frequency Detector board provides IF frequencies, fixed response filters, and programmable magnitude equalizers to shape and optimize frequency response for IF SUM. Extends autocal to multiple IF frequencies.

IGD

Interpolating Gain Driver Board, PIN 26442

Function

The Interpolating Gain Driver board performs a high speed interpolation of the control words sent on the D bus. The control words configure the IGD for a particular gain format. Five AID convertors proVide the follOWing gain signals for use by the Scanner: •

Receiver Gain

•

Receiver Bias

•

Transmit Power

•

VideoGain

•

Apodizer Bias

The apodizer reference level is also generated on the IGD board.

1096

Service Manual

2·13

Chapter 2 . System Architecture

The IGD monitors the thermal sense line and provides a fail-safe shutdown of XMT boards.

MEX

Memory Expansion Board, PIN 26142

Function

The Memory Expansion board is used as a storage area for control data (microcode) for various transducers. The data set for a particular transducer is programmed into a set of PROMs and then placed in sequential order on the MEX. When that particular transducer is connected to the system, its ID code is read and data from the corresponding microcode set is loaded into the DeCs. Data exits the MEX via the P bus. All the PROMs in a set must be adjacent to one another and arranged in ascending order. Additional boards may be installed in the system by setting the address jumper (BDO, BDl, BD2) as appropriate for that board.

MXK

Mixer Clock Board, PIN 17932

Function

The Scanner has four Mixer Clock boards, with 32 channels each, providing a total of 128 channels. The purpose of the Mixer Clock is to generate a phased local oscillator signal to mix with the received ultrasound signal to produce an intermediate frequency (IF). The output of each mixer clock channel is used to drive the mixer section of each associated receiver channel. The mixer clock frequency changes with different transducer types. The MXK boards are controlled by microcode ed to the DeC1 via the C bus. Logic on the MXK board buffers and latches control words from the C bus to configure the MXK boards for a particular ultrasound line. Addresses for the MXK boards are encoded into the motherboard connectors to identify each of the four MXK boards in the Scanner.

Rev

Receiver Board, PIN 17912

Function

The function of the Receiver board is to amplify the low level signal from the transducer elements and to convert the received signal to an intermediate frequency (IF) for further processing in the Scanner. Gain signals from the Apodizer boards and the Interpolating Gain Driver control the output level of the Receiver. The local oscillator frequency used to produce the IF signal is generated on the STG

board. There are 16 Receiver boards in the Scanner and 8 receiver cells on each board, thus giving 128 total cells. SOL

Summing Delay Line Board, PIN 18132

Function

There are eight Summing Delay Line Board boards in the Scanner. Each board has eight summing delay line cells providing a total of 64 cells.

2-14

Acuson Aspen Ultrasound System

1096

Scanner Assemblies Each Receiver pair IF output is connected to one SDL channel input and is carried on lines IF 0 • 7. Each SDL channel is associated with two receiver channels, thus the entire board services 16 receiver channels. The output of each SDL board is sent to the Distribution Board Lower (DBLl, where all eight SDL board outputs are summed together. The SDL boards are controlled by OCCO via the A bus. Logic on the SDL board buffers and latches the control words from the A bus to configure the SDL for a particular ultrasound line. Addresses for the SDL boards are encoded into the connectors in the motherboard to identify each of the eight SDL boards in the Scanner.

STG

Scanner Timing Generator Board, PIN 35412

Function

The Scanner Timing Generator board generates all of the timing signals used in the Scanner. The heart of the STG is a 120 MHz crystal oscillator which feeds a divider network and generates the 10 MHz REFCLK signal to which all timing in the Scanner and parts of Scan Converter are synchronized. A programmable timing generator located on the STG generates the following signals: •

SOL - Start of Line

•

SOT - Start of Transmit

•

VSOT - Virtual Start of Transmit

•

VSOR • Virtual Start of Receive

The period of each of these signals is programmed by the ZS, and is dependent upon the depth of field to which the image is set.The STG has two networks which generate the local oscillator clocks and transmit delay clocks. The STG is controlled by firmware on the ZS via the P bus. Control words are buffered and latched by logiC on the STG.

TRM

Terminator Board, PIN 10412

Function

The Terminator board is used to terminate the Band C bus and also terminate the mixer phase and transmit phase buses, all of which are digital buses.

VOT

Video Detector Board, PIN 47%2

Function

The Video Detector board is used to process the summed ultrasound IF signal and convert it to an A-mode ultrasound video signal. Signal processing functions such as IF filtering, log detection, video filtering, and video preprocessing are also performed on the Video Detector.

1096

Servicg Manual

2-15

Chapter 2 - System Architecture

The VDT is controlled by microcode on the DeC ] via the 0 bus. Logic on the VDT buffers and latches control words from the 0 bus to configure the Video Detector for a particular setup formal.

XDY

Transmit Delay Board, PIN 16942

Function

The Transmit Delay board contains ]6 individual transmit delay channels. The output of each channel is used to drive the input· section of each associated transmitter channel which is carried via line 00 through ] 5. Each has the function of processing the amount of delay needed to properly phase the transmit signal for any particular ultrasound line. The Transmit Delay board also outputs the selected number of transmit pulses required to aid in the power delivered from the transducer during the transmit cycle. The Transmit Delay boards are controlled by microcode on DeCO or DeC], depending on the boards location. The information is carried over the B or C bus. DeCO and the B bus control Transmit Delay board 0, ], 6 and 7. DeCl and the C bus control Transmit Delay boards 2, 3, 4 and 5. Logic on the Transmit Delay board buffers and latches control words from the B or C bus to configure the Transmit Delay board for a particular ultrasound line. Addresses for the Transmit Delay boards are encoded into the motherboard connectors to identify each of the eight XDY boards in the Scanner.

XMT

Transmitter Board, PIN 20992

Function

The function of the Transmitter board is to produce a negative polarity, high energy pulse burst to drive the transducer elements and produce an ultrasound wave. Each transmitter board contains 16 individ uai transmitter channels. The output of each channel is connected to one transducer element via lines 0 - 15. Lines 0 - 15 are also connected to the input of the receiver channels. The pulses which drive the transmitters are generated on the Transmit Delay board. The output amplitude of all 128 transmitter channels is controlled by the Interpolating Gain Driver via line VXMT. The Transmitter boards are controlled by DeC-o via the A bus. Logic on the Transmitter board buffers·and latches control words from the A bus to configure the transmitter pulse amplitudes for a particular ultrasound line. Addresses for the Transmitter boards are encoded into the connectors in the motherboard to identify each of the eight Transmitter boards in the Scanner. There are eight Transmitter boards in the Scanner and 16 transmitter channels on each Transmitter board, providing a total of 128 transmitter channels in the Scanner.

2·16

Acuson Aspen Ultrasound System

1096

Scanner Assemblies

ZOL

DL Transducer Interconnect Board PIN 46602

Function

The DL Transducer Interconnect board is located along the front left side of the Scanner card cage. DL connectors mounted on the ZDL protrude through the opening at the front of the Acuson Aspen system and provide a receptacle to which DL transducers are connected. Two transducers may be connected at a time; however, only one transducer port may be active at a time. Active port selection is under operator control using the TflANSDUCER key. The function of the ZDL is to carry electrical signals to and from the DL Transducer to the Scanner motherboard.

I I I I -0-

Figure 2-8

1096

o

DL-Connector (Plug and Receptacle)

Service Manual

2-17

Chapter 2 . System Architecture

ZIP . Function

MP Transducer Interconnect Board, PIN 38072 The MP Transducer Interconnect board is located along the fronl right side of the Scanner card cage. An MP connector mounted on the ZIP, protrudes through the opening at the front of the Aspen system and connects 10 the transducer. Active port selection between the MP and DL Transducers is under operator control using the Transducer Swilch option. The function of the ZIP is to carry electrical signals to and from the MP Transducer to' the Scanner motherboard. . ...

UIBnl nllnl nOli I_H_J ....... Figure 2-9

MP-Conneclor

ZDT

Distribution Board Top, PIN 41172

Function

ZDT board has following functions:

2-18

•

Z Bus Interface-Interfaces between the ZIP, ZDL, and the Pbus.

•

PPS the Programmable Power Supply's generation of the transmit voltages.

•

Allows interrupts between the Scanner and Scan Converter

•

Communicates real-time line scanning controJ.jnformation between the Scanner and Scan Converter. .'.

•

Allows the ZS processor access to the resources and interfaces of the ZDT for generic ZDT control by the ZS.

•

Provides A bus Interface between the Scanner Digital Subsection and the Xmit and SDLs of the Beamformer.

•

Provides the Start Of Frame signal.

•

Distributes a number of system-wide synchronization signals.

•

Terminates the P Bus.

•

Generates the power-on reset for the rest of the Scanner.

Acuson Aspen Ultrasound System

1096

Scanner Assemblies

ZS

Scanner Control Processor Board, PIN 46212

Function

The ZSC:Ps function is to control the operation of the Scanner. The heart of the ZSC:P is a 386 microprocessor and related devices. The microprocessor is driven by the 40 MHz clock generated on the STG board. The ZSC:P software is ed from the DIMAQ integrated ultrasound workstation by F1ashresident firmware on the SVc. This allows the Scanner operating system to be upgraded with the rest of the system software. The S communicates to the other digital control boards via the Pbus.

1096

Service Manual

2-19

Chapter 2 - System Architecture

DIMAQ INTEGRATED ULTRASOUND WORKSTATION The Aspen system utilizes a D1MAQ Integrated Ultrasound Workstation. The primary functions of the DIMAQ workstation is the display of data received from the Scanner. In addition to this, the DIMAQ workstation incorporates a number of other functions. These are to process ultrasound 2-D and Doppler data, to perform calculations and to interface the system to various input and output devices including the controls. Overall control of the system is the job of a processor located on the Syscon/Video Controller (SVC) in the DIMAQ workstation. Major Functions

Usted below are the major functions which can be performed by the DIMAQ workstation. These are grouped together according to the capability they give the system. •

Scan Conversion

•. Video image storage for Cine review

2·20

•

Alphanumeric and graphic overlays

•

Video conversion to and from several standard video formats

•

Integrated Aegis system

•

Stress echo applications

•

Interface

•

ECG and Physio processing

•

Audio Processing

•

Interface to local display and recording devices

Acuson Aspen Ultrasound System

1096

DIMAO Integrated Ultrasound Workstation

Scan Converter

The Scan Converter subsystem within the DIMAQ workstation derives its name from one of its primary functions, namely to convert the scan format of data received from the Scanner. Ultrasound data can be obtained in one of four formats, linear, sector, curved or VectOTCi> wide view array. None of these formats is similar to the video raster format, therefore a conversion process must take place in order to display the ultrasound data on a video monitor.

The Scan Converter performs reformatting of Ultrasound Video line data into TV Raster line data. Figure 2-10 shows a Simplified diagram of the process.

TV Raster Video Format

Ultrasound Video Format

Scan Conversion

Linear

Sector

Figure 2·10 Basic Scan Conversion Principle In addition to basic Scan Conversion, this subsystem performs other signal processing such as ffitering, and interpolation to improve image aesthetics. Listed below are the major functions which are performed by the Scan Converter:

1096

•

Digitization of the analog ultrasound video

•

Image enhancement through signal processing

•

Conversion from ultrasound scan format to video scan format

Service Manual

2·21

'" DIGITAL 1&0

lOB

COLOR IMAGE

FEC f---+ ZFEB

r+

CRP

......

--.

DAQ 'T1

l>

g

ig

"l>

{g

l\)

"

!;::

'c:0" "Cl.

'"

tb :3

l'... 0

3:

>

iO

..

AUDIO 1&0

DSP

VIA UIC---::

SVC

SPECTRAL

ADORES

M-mode

:,

"Tl

o !ij

!JPEGI

VIA 101

,,

= o ::

-

INITIAnO

0 ::I

OJ 0

0

e

3:

C 1JI

ECGI

WFP

-

.CltFEIl

':' SETUi

r

vVJlEl

'-+- AQP

:FO'"

RP

2-D M-modo SPECTRAL

COLOR PRINTER

PHYSic

::D

::t.

l>

il PRINTE R

AUDIO

ZAP

M·mode :

IlO

lOB

J

•

•

DCI l -

BIW

DIGITAL 1&0

:::•

-

I--

f'"

SCSI CABLE

COM

SYSTE IMAGE

,. VPB l -

f-

ONITO

I-

UIC

2-D M-mod. SPECTRAL

(

• UI

"

Theory of Opera/ion

THEORY OF OPERATION This section describes the D1MAQ Integrated Ultrasound Workstation in detail. First, the 2-D data path is discussed. Following this, each of the other modalities, Spectral Doppler, Color Doppler, M-mode, and Aegis Digital Image and Data Management System will be discussed in succession.

20

DATA PATH The following boards are responsible for 2-D scan conversion and digital image and data management and display in the Aspen system: •

Acquisition Processor (AQP)

•

Reconstruction Processor (RP)

•

Cine Data Memory (COM)

•

Syscon Vide<'> Controller (SVC)

•

Video Processor Board (\/PB)

•

Input/Output Board (lOB)

The analog to digital conversion of the ultrasound video data from the Scanner is performed by the AQP board. Transmit zone crossfading and signal filtering are also performed by the AQP. The AQPs digitized output is then ed on to the RP board. The RP interpolates the incoming data, and generates image memory addresses for storage of its output by the COM. The COM temporally filters, (i.e., persists) the incoming data and stores it in image and Cine memory. Data from the CDMs image memory is read out in serial form and laterally interpolated. The fundamental scan conversion is accomplished by the transfer of data from the CDM, which is controlled by the RP. The CDMs system image is sent to the SVC in video raster format. The SVC generates 20 graphics, overlays it on the image, and sends the system video image to the VPB. The VPB performs a digital-toanalog conversion, and sends its output to the lOB. The lOB buffers the incoming video. The system image is now complete and available at the lOB's output, ready to be presented to the monitor for display.

1096

Service Manual

2·23

Chapter 2 - System Architecture

o 5

14--15

...

w

III

"'"iii

--

c.

CJ0

Il:

0>

0

wif

a:

.8'" a:l

w II.

'"

;;

C.

C.

II.

3=

N

N

.

go

Q

",-

:!

....

'"

a: t-

.'"

"w

C. CIl

O

W

0

II.

... 0"

5-

... S:!

-1-·-

i

··lffi-"sa: a:",

wE

0

US VIDEO Figure 2-12

2-24

2-D Data Path

Acuson Aspen Ultrasound System

1096

Spectral Doppler Data Path

SPECTRAL DOPPLER DATA PATH The following DIMAQ workstation boards Spectral Doppler: •

Doppler Acquisition board (DAQ)

•

Doppler Spectral Processor (OSP)

•

Waveform Processor (WFP)

•

Audio Processor (ZAP)