Black Max - Mud Motor - Operations Manual 1s1x

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Black Max - Mud Motor - Operations Manual as PDF for free.

More details w3441

- Words: 29,457

- Pages: 129

INTRODUCTION

The NQL Energy Services Operations Manual covers basic procedures and principals in the operation of BlackMax positive displacement mud motors, drilling jars and shock tools.This manual includes basic operating information, specifications and tool parameters and also provides general information for the to operate our equipment safely and effectively. As always, specific applications may dictate changes in procedures, therefore this manual is to be used as a guideline only. If there are any questions, please your nearest NQL Energy Services representative. This manual is divided into sections dealing with motors, jars and shock tools. It also includes basic engineering data for use at the rig. In addition, specifications for each motor power section are available to help the identify the proper power section for optimum drilling performance.

Printed in Canada Jan 2006

I N T R O D U C T I O N

Table of Contents FISHING DRAWINGS AND MEASUREMENTS

DRILLING TOOLS PRODUCT LINE BlackMax Mud Motors Specifications Optional Equipment Formulas Fluids Motor Shipping Weights Torque Connections Build Rates Setting Procedures for ABH

1 10 60 61 66 69 70 72 76

Mud Motor Fishing Dimensions

89

Shock Tool Fishing Dimensions

99

Drill Collar Weights

111

BlackMax Shock Tools

78

Annular Capacities

113

BlackMax Rayson Mechanical Jars

81

Hole Capacity

114

BlackMax Hydraulic Mechanical Jars

83

Drill Pipe Capacities

116

BlackMax Best Hitter Mechanical Jars

85

Drill Pipe Properties

117

BlackMax Rig Rattler Hydraulic Jars

87

Nozzle Flow Areas

118

Mechanical Jars Fishing Dimensions

103

Hydraulic Mechanical Jar Fishing Dimensions

105

HELPFUL TABLES AND INFORMATION Casing Dimensions

108

Rotary Connection Cross Reference

110

Mud Weights

120

Conversions

123

Locations

126

C O N T E N T S

NQL Energy Services Product Line

1

NQL's BlackMax line of quality drilling tools includes drilling motors, shock tools, two types of mechanical drilling jars, a hydraulic mechanical drilling jar, and a hydraulic drilling jar. In sizes ranging from 1 11/16" OD to 11 1/4" OD, NQL has a drilling tool for any application. BlackMax Mud Motors range in size from 1 11/16"OD to 11 ¼" OD. With over 80 different configurations, BlackMax Mud Motors provide our customers with the versatility to tailor the motor to a specific bit and drilling application. With our combinations of power sections, rugged drive shafts, and sealed thrust bearing assemblies BlackMax can build the exact tool to perform the job to the highest quality expected of their customers. BlackMax Mud Motors have drilled hundreds of thousands of feet of hole by marrying the power section you need with the bit required in the application. Black Max Shock Tools range in size from 2 7/8" OD to 11" OD. Designed to cushion heavy axial loading and reduce bit vibrations, BlackMax Shock Tools will extend drillstring component and bit life to help reduce drilling costs. BlackMax Shock Tools are sprung for compression and tension, are pressure balanced from hydrostatic pressures, and come in string or bottom hole configurations. BlackMax Rayson Mechanical Jars and Best Hitter Mechanical Jars are designed to create powerful mechanical jarring action to free drill strings that have become stuck. They are oil lubricated and are designed to work in the harshest of drilling environments. BlackMax Hydraulic Mechanical Jars have a mechanical latch feature that keeps the jar in the neutral position and prevents unexpected jarring while tripping in or out of the hole. The jars have a hydraulic valve that creates a time delay when the jar is in operation and the latch is disengaged. BlackMax "Rig Rattler" Jars are a hydraulic tool that jars up and has a mechanical "bump" down. The Rig Rattler has been a proven solution to stuck pipe in many applications, and provides a maximum jar action when needed most.

M U D M O T O R D E S I G N

M U D Bearing Assembly (A) Each BlackMax drilling motor comes equipped with a fully sealed, oil lubricated bearing system. Bearings are configured to accommodate high speed/low torque or low speed/high torque, without altering radial or axial loading.

Universal t Assembly (B) The BlackMax universal t is used to convert the eccentric motion of the motor (rotor) to a smooth concentric motion required by the bearing section. The design of sealed universal ts and a connecting rod, allows the motor to operate at high bent housing angles, yet still be able to handle high torque and speed.

Power Sections (D) BlackMax power sections are made up of a lobed rotor that fits inside an elestomer lined housing (stator). The rotor has one less lobe than the stator, creating a continuously sealing chamber. Drilling fluid or gas is forced through the motor, thereby turning the rotor and generating torque. Where drilling requirements call for circulation rates exceeding maximum recommended rates, rotors are jetted to allow excessive fluid to flow down a parallel path, thereby reducing damage to the elastomer in the stator.

Adjustable Bent Housing/Fixed Housing (C) BlackMax adjustable housings are available in 0°-3° settings, and include a specialized assembly for short radius drilling. The housing is easily adjustable and allows the operator to reset angles at the rig floor, eliminating the need to change assemblies or motors. Always follow the specifications for proper torquing of the assembly. (See pg. 75 - 76 for proper procedures)

Dump Valve/Blank Sub (E) optional (see your dealer for more details)

M O T O R D E S I G N

2

Introduction This section describes basic operating procedures, which are used in the field and will facilitate proper operation of BlackMax motors.

3

Bit Selection An important aspect of any planned downhole motor run, is properly matching the bit and hydraulics to the motor in order to achieve the desired results. Attention must be given to TFA (total flow area) to see that proper parameters are maintained with regard to pressure drop across bit, annular velocity needed for hole cleaning, maximum standpipe pressure, and adequate hole cleaning at the bit\formation interface. Keep in mind that stall pressure of a motor may approach pump relief valve limits in some cases. In larger hole sizes, a bored rotor may be necessary to accommodate fluid requirements mentioned above. Generally, all motor sizes have adequate torque to run any cone type bit. Abrassive PDC bits may cause stalling in rough and broken formations. If the purpose of the run is to build angle, or otherwise achieve significant deviation, gauge length on the bit is very important. Gauge protection is necessary if the motor is bent, since continual side loading occurs at the bit.

Surface Testing (& Orientation) The BlackMax motor is a sealed bearing motor, so it may be safely surface tested with or without a bit attached, since bit pressure drop is not necessary to cool the bearings. It is recommended that a bit not be attached if the motor is significantly bent, and needs to be positioned in the BOP's (blow-out preventers) or, below to accommodate testing of the dump valve. If the downhole motor is tested in this manner, be sure to remove the bit box thread protector before lowering the motor into the hole. When the downhole motor is equipped with a dump valve, attach the kelly and lower the ports just below the top of the bell nipple before starting the pump. Carefully observe the closing of the dump valve as the pump is eased up. After the valve is closed, ease up on the pump. Left-hand torque should be noted in the assembly. Vibration may be seen as flow rates increase, but is normal and no cause for concern. Before shutting the pump down, be sure that the dump valve is in position in the bell nipple. When the pump is shut down, if the pressure doesn't bleed off, open the fill-up line on the standpipe to relieve the pressure. When turning the bit box with tongs during the course of a coiled tubing operation, turn the box to the left, otherwise a back-off could occur. Pick the motor up, and attach the selected bit. If a bent housing adjustment is needed, lower the motor down to the adjustable housing, and make the

P R O C E D U R E S

needed change according to the accompanying setting procedure (see pg. 75 - 76). Upon completion of the setting procedure, mark the tool face, and slowly lower the motor into the hole, keeping tool face alignment as you go. At this point, you can align and test whatever steering device is to be used, and proceed on in the hole. Please note, motors are pre-tested in water and should be properly thawed before surface testing when operating in sub-zero temperatures.

Running In We recommend running a float valve with the downhole motor, especially if a dump valve assembly is used. This keeps trash out of the ID of the string. If no dump valve is used, the float will keep the motor from running backward as the pipe fills up. If heat is a factor, it is a good idea to break circulation once or twice as you approach bottom. Pumping should be at a slow rate and kept up long enough to move some cool mud down to the motor. Reciprocation of the drill string up and down during the pumping operation will keep casing wear to a minimum, and decrease the likelihood of leaving a ledge if the motor is in open hole. If the motor bend is extreme, keep running speeds slow to minimize the chance of ledging. Running speeds should also be slow when dealing with high mud weights and small liners, as pressure surges might knock the bottom out at the liner shoe. Drilling Drilling with a downhole motor is monitored mainly by changes in standpipe pressure. The amount of torque created at the bit face will be reflected by an increase in standpipe pressure over the "off bottom" reading. This difference in pressure is called “differential pressure”. The maximum motor differential pressure indicated in the downhole motor specifications is the total differential recommended. It takes from 10 to 15% of that total to turn the rotor in the off bottom position. The difference is the amount that is usable with WOB (weight-on-bit).

P R O C E D U R E S

When tagging bottom for the first time, keep in mind that a new bottom pattern needs to be established, especially if a different assembly or a different bend is employed. Higher differential pressures will be noted with less bit weight if PDC (drag) bits are used. Regular diamond bits will increase standpipe pressure slightly when bottom is tagged due to the reduction in flow area around the bit face. Whether the drilling operation is sliding or rotating, we recommend keeping differential at 60-75% of the maximum motor differential noted in the specifications. ROP (rate of penetration) is a function of rpm and bit geometry and formation.

4

Good weight transfer is normally accomplished with rotation of the drill string. Optimization of ROP can be attained with incremental changes of WOB. We recommend (for sections of hole where long rotation periods are anticipated) that bends be kept to a maximum of 1.5° (actual) and surface rotary speed be kept below 90 rpm.

5

Special precautions should be considered if high temperature is a factor in the well. The stator elastomer may swell and begin to fail. Pumps should be brought up to speed slowly to allow the rotar to begin turning, and then gradually increased to ease the shock loading of the swollen elastomer. Stall Indication/ Reaction A motor stall is indicated be a sudden increase in standpipe pressure while drilling. When a stall occurs, it is important to cut back pump strokes before lifting the motor off bottom. This reduces the pressure in the power section and will allow the driller to restart the motor. Pulling Out Care should be taken when pulling a bent housing motor through the BOP stack. A bent motor may damage the internal components of the stack. A check of the bearing stack oil should be made to determine if the motor should be re-run. Then procedure to check the oil is as follows:When picking the motor up to break the bit off, a water hose can be tied off in the top of the motor (if a hollow lift nipple is available). Place the bit in the bit breaker, put the lead tongs on the bearing housing to hold back up, and carefully bump the rotary intermittently to the right. If the bit output shaft is locked, lay the motor down. If the bit turns freely, engage the rotary and turn the bit slowly, turn the water on, and pump water through the downhole motor until it cleans up at the bit nozzles. Break the bit off the downhole motor. If a dump valve assembly is being used, be sure to flush the assembly thoroughly until clear water flows through the ports. If a re-run is being considered, a check of the oil left in the bearings is essential and can be described as follows:

P R O C E D U R E S

Above the bit box there is a large snap ring. Behind this ring is a piston assembly that moves away from the snap ring as oil seepage occurs. By measuring the distance from the bearing housing shoulder to the piston, and referring to the Piston Depth Chart below, the advisability of re-running the motor can be determined.

Tool Size 1 11/16” 2 1/16” 2 3/8” Short 2 7/8” Short 3 1/8” 3 3/8” 3 3/4” 4 1/8” 4 3/4” Short 5” 5” Series 3 5 1/2”

Piston Depth (in) “A” 9/16” 1” 1” 1 9/16” 1” 1 1/4” 7/8” 1 5/8” 2 1/8” 7/8” 7/8” 2 1/4”

Piston Depth (in) “A” 6” 1 7/8” 6 1/4” 1 3/8” 1 3/8” 6 1/2” & 6 1/2 S3 1 3/8” 6 3/4” & 6 3/4 S3 2 3/4” 7 1/2” & 7 1/2 S3 8” 3 1/2” 7/8” 8” Series 3 2 1/8” 9 5/8” 9 5/8” Series 3 3” 3 5/8” 11 1/4” Tool Size

P R O C E D U R E S

6

Motor Applications

7

NQL Energy Services now supplies one of the largest range of motor sizes available. It is this variety that allows us the flexibility to participate in almost any application with maximum performance. Performance\Straight Hole Drilling With the continued development of PDC bits and more powerful power sections, it has become cost effective to pair the two when long straight hole sections are to be drilled. NQL Energy Services offers a full line of motors that have proven themselves in very deep, hot, high mud weight, small hole applications. The savings recognized by operators due to reduced tubulars cost and savings in mud systems far outweighs the cost of conventional drilling at depth. Directional\Steerable Drilling NQL Energy Services motors offer a surface adjustable bent housing that provides directional drillers with flexibility in the planning and execution of any directional drilling project. The 3° adjustable housing allows the drilling of any conventional open hole kick-off or sidetrack operation.The motors can be oriented with single shot surveys, magnetic or gyroscopic wireline steering tools and measurement-while-drilling tools. If a steerable system is to be used, NQL Energy Services motors again display their versatility with the field replacable bearing housing stabilizer. Steerable systems are invaluable to wells that have multiple targets, or complex approach paths that are the result of geological constraints.The stabilization provided is normally 1/8 to 1/4 inch less than the hole gauge and can be tailored to the individual needs of the directional driller.

A P P L I C A T I O N S

Horizontal / Short Radius Drilling NQL Energy Services has a range of motor sizes suited to horizontal and short radius applications in various hole sizes. NQL Energy Services motors have performed medium radius projects with build rates ranging from 10°-45°/100'. Short radius (46°-95°/100 ft.) and ultra-short radius projects (96°-128°/100 ft.) are also becoming more commonplace. For angle building purposes, motors can be run with or without a near bit stabilizer and in many different configurations i.e. single bend, double bend, or with a flex t in place of a second bend at the top of the motor. The flex t allows limited rotation during the build section to fine tune the build rate. When rotating in the lateral section we recommend a bent housing maximum setting of 1.5°. This should be sufficient for minor course corrections as drilling proceeds.

Remedial\Workover Operations NQL Energy Services provides a wide variety of power section options and motor sizes that will accommodate almost any remedial need. Trying to rotate a small limber work string at depth with a power swivel is difficult in a deviated hole. Drilling out cement and guide shoes in small liners is efficiently and cost effectively accomplished by utilizing NQL Energy Services downhole motors.

Coiled Tubing NQL Energy Services motors have been used for years to provide a power source for coiled tubing remedial operations. Recently, NQL Energy Services motors have been used in the industry for drilling new holes. Torque restrictions in the coiled tubing so far have limited hole size applications, but drilling rates have been impressive, using both fluid and air as a circulating medium.

A P P L I C A T I O N S

8

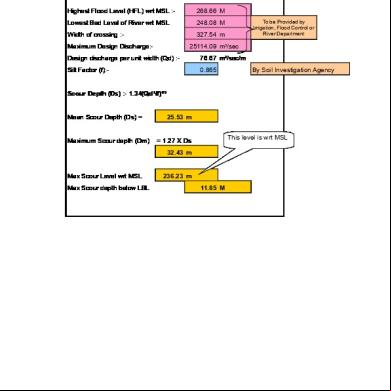

River Crossing\Utility Boring

9

NQL Energy Services is a recognized leader in the river crossing and utility boring industry. With crossing projects being undertaken in formations with considerable compressive strength, the addition of downhole motors with high torque deliverability and built in directional capabilities was inevitable. The sealed bearing assembly protects the bearing section when solids control is less than perfect. The wide range of rotor/stator configurations have proven to be invaluable to contractors who engage in the highly specialized crossing business. In a typical crossing operation, the bit enters the ground at an angle less than horizontal, proceeds down under the object to be crossed. It is then brought horizontal, and then back up to an exit point on the other side. The assembly is guided with a wireline steering tool, or a surface interactive instrument that can track the bit from above ground. The downhole motor is used on the pilot hole operation, with subsequent hole opening operations bringing the borehole to required diameter. Small diameter motors are being used more and more for utility boring operations in urban areas to install fiber optic cables and other utility conduits. The NQL Energy Services downhole motors have proven themselves to be cost-effective when compared to alternative horizontal boring methods. Guidance for these bores is similar to that described above.

A P P L I C A T I O N S

SPECIFICATIONS Horsepower: To determine the horsepower you must know the rpm and the torque at which you are running.

The performance graphs that accompany the specifications show maximum differential working (on/off bottom) pressure, torque, rpm, and horsepower as follows:

5252

=

133 × 1600 ft ⋅ lb 5252

320 280

2,400 2,100 1,800

200

1,500

{

rpm - 175 gpm

160

1,200

PRESS LOSS

120

900

rpm - 100 gpm

M O T O R S

600

PRESSURE DIFFERENTIAL psi

800

700

600

500

400

300

300

40

TO R

QU

E

PRESS LOSS

200

Rpm: To read rpm, find the line labeled 'rpm-175 gpm', and follow it to where it intersects the line labeled 'MAX. DIFF.'. Reading across the graph to the left, the rpm is 133 rpm.

80

100

It is offset to the left of the 'MAX. DIFF.' line by an amount equal to the pressure loss (75 psi). Reading this line across the graph to the right will give you a Torque reading. For this example, torque is 1600 ft-lb.

TORQUE ft lb

PRESS LOSS

{

SPEED rpm

240

M U D

= 40.5

{

rpm - 250 gpm

Working Pressure: Due to losses from friction, turbulence, and pressure, the Working Pressure will be less than the Maximum Pressure Differential: To determine the working pressure at 175 gpm, find the line marked 'rpm-175 gpm'. There is 75 psi indicated on the graph as 'Press. Loss'. This is the pressure loss through the motor at 175 gpm with no load on the bit. Therefore, Effective Pressure = 600 psi - 75 psi = 525 psi

rpm × torque

hp =

Maximum Pressure Differential: This is the maximum designed pressure dropped across the illustrated power section. It is indicated on the graph as 'MAX. DIFF.'. In this case, the pressure differential is 600 psi. For optimum performance and life, this pressure should not be exceeded.

MAX DIFF.

The following sections show specifications recommended for the proper operation of BlackMax motors.

10

1 11/16”

11

1 11/16” 1 11/16” 1-2, 3 Stage 40

MAX DIFF.

2,000 rpm - 35 gpm

1,750

35

Max Pressure Drop

10,342 kPa

450 psi

Max Diff. Pressure

3,103 kPa

86”

0/A Length

2,184 mm

For more information on our products see our Web site http://www.nql.com

30

1,500

25 20

1,000 rpm - 15 gpm

15 U

E

750 R TO

5

600

525

450

375

300

75

255

250

PRESSURE DIFFERENTIAL psi

Volume

Bit to Bend Length

Speed

Torque

(lpm)

(gpm)

(rpm)

(ft-lb)

57 95 132

15 25 35

534-797 9761,238

25 25 25

hp

2.5 4.6 7.1

22"

559

Bottom Connection

AW-ROD

Bearing Load (compression)

dynamic=2,500 lb

1,110 daN

static=6,000 lb

2,670 daN

Bearing Load (tension)

dynamic=2,500 lb

1,110 daN

static=6,000 lb

2,670 daN

Max. Overpull (for re-runs)

6,000 lb

2,670 daN

28,000 lb

12,455 daN

10

Q

500

TORQUE ft lb

rpm - 25 gpm

1,250

150

SPEED rpm

1500 psi

Absolute Overpull

M U D M O T O R S

3,302 mm

E

10

600

525

450

375

300

255

75

150

TO R

QU

125

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

57

15 30

100-212

62

114

310-430

57

170

45

540-645

50

hp

Bearing Load (compression)

dynamic=2,500 lb

1,110 daN

static=6,000 lb

2,670 daN

Bearing Load (tension)

dynamic=2,500 lb

1,110 daN

static=6,000 lb

2,670 daN

Max. Overpull (for re-runs)

6,000 lb

2,670 daN

28,000 lb

12,455 daN

MAX DIFF.

AW-ROD

rpm - 25 gpm

400 300 E

Bottom Connection

100

500

U

559

200

Q

20

22"

R

30

250 rpm - 15 gpm

Bit to Bend Length

120

80 60 40

TO

375

40

20

100

100

rpm - 30 gpm

SPEED rpm

MAX DIFF.

500

TORQUE ft lb

50

625

rpm - 35 gpm

600

rpm - 45 gpm

Volume

Speed

Torque

(gpm)

(rpm)

(ft-lb)

1.2

95

25

130-400

125

3.1

3.4

132

35

300-575

120

6.8

5.1

170

45

450-720

116

9.9

1 11/16”

M U D M O T O R S

PRESSURE DIFFERENTIAL psi

(lpm)

Absolute Overpull

TORQUE ft lb

0/A Length

140

700

800

130”

160

rpm - 45 gpm

700

2,438 mm

800

5,171 kPa

600

0/A Length

750 psi

10,342 kPa

Max Diff. Pressure

500

96”

60

750

3,103 kPa

PERFORMANCE 1 11/16” 1 11/16” 5-6, 5 Stage

400

450 psi

70

875

10,342 kPa

Max Diff. Pressure

Max Pressure 1500 psi Drop

300

80

1,000

SPEED rpm

Max Pressure 1500 psi Drop

200

1 11/16” 1 11/16” 5-6, 3 Stage

hp

12

1 11/16”

Stator Configuration 1 11/16” PERFORMANCE 1 11/16” 5-6, 5 Stage ML Volume (gpm) Speed (rpm) Torque (ft-lb) Bearing Assembly 125 - 400 1 11/16” 25 43 mm 125 Volume 290 - 560 121 35 25 - 45 gpm 95 - 170 lpm Speed 115 125 - 720 rpm 445 - 720 45 125 - 720 rpm Torque 169 N*m 125 ft - lb Max. Pressure Drop 1,500 psi 10,342 kPa Max. Diff. Pressure 5,171 kPa 750 psi Bit to Bend Length 22” 559 mm O/A Length 3,302 mm 130” 1 7/8” - 3” Hole Size 48 - 76 mm Top Connection AW - ROD AW - ROD Bottom Connection AW - ROD AW - ROD dynamic = 2,500 lb 1,110 daN Bearing Load (compression) static = 6,000 lb 2,670 daN dynamic = 2,500 lb 1,110 daN Bearing Load (tension) static = 6,000 lb 2,670 daN Max. Overpull 6,000 lb 2,670 daN (for re-runs)

Absolute Overpull

28,000 lb

12,455 daN

13

hp 3.0 6.7 9.7

M U D M O T O R S

2 1/16” 2 1/16” 1-2, 2 Stage 40

MAX DIFF.

1,600 1,400 rpm - 45 gpm

35

25 20

rpm - 25 gpm

15 QU

E

600

10

TO R

400

5

400

350

300

250

200

150

100

200

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

hp

(lpm)

(gpm)

(rpm)

(ft-lb)

95 132

25

575-683

25

2.7

35

852-960

25

4.1

170

45

1,111-1,219

25

5.3

TORQUE ft lb

rpm - 35 gpm

50

SPEED rpm

800

Max Pressure Drop

10,342 kPa

300 psi

Max Diff. Pressure

2,068 kPa

105”

0/A Length

2,667 mm

For more information on our products see our Web site http://www.nql.com

30

1,200 1,000

1500 psi

Bit to Bend Length

29"

Bottom Connection

AW-ROD

Bearing Load (compression)

dynamic=8,375 lb

3,725 daN

static=5,800 lb

2,580 daN

Bearing Load (tension)

dynamic=3,350 lb

1,490 daN

static=2,300 lb

1,025 daN

Max. Overpull (for re-runs)

2,300 lb

1,025 daN

Absolute Overpull

33,500 lb

14,900 daN

2 1/16”

737 mm

M U D M O T O R S

14

2 1/16”

Max Pressure Drop

10,342 kPa

155 psi

Max Diff. Pressure

1,069 kPa

300 psi

Max Diff. Pressure

2,068 kPa

350

82”

0/A Length

2,083 mm

110”

0/A Length

2,794 mm

300

Volume (lpm)

(gpm)

Speed

Torque

(rpm)

(ft-lb)

hp

AW-ROD

Bearing Load (compression)

dynamic=8,375 lb

3,725 daN

100

static=5,800 lb

2,580 daN

50

Bearing Load (tension)

dynamic=3,350 lb

1,490 daN

static=2,300 lb

1,025 daN

Max. Overpull (for re-runs)

2,300 lb

1,025 daN

Absolute Overpull

33,500 lb

14,900 daN

MAX DIFF.

80

150

60

rpm - 20 gpm

40

400

350

300

20

250

200

175

150

125

75

100

PRESSURE DIFFERENTIAL psi

Bottom Connection

737 mm

100

rpm - 35 gpm

200

E QU

50

TO R

10

29"

120

200

150

20

100

250

140

E

30

rpm - 50 gpm

Bit to Bend Length

160

QU

40

rpm - 20 gpm

400

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

76

20

92-118

52

0.9

76

20

100-123

110

2.2

132

35

187-213

43

1.5

132

35

190-213

108

3.9

189

50

277-303

39

2.0

189

50

285-308

98

5.3

TORQUE ft lb

1500 psi

100

50

150

50

10,342 kPa

50

60

rpm - 35 gpm

25

SPEED rpm

200

70

TORQUE ft lb

rpm - 50 gpm

300 250

Max Pressure Drop

SPEED rpm

MAX DIFF.

350

2 1/16” 2 1/16” 4-5, 2 Stage

1500 psi 80

400

15

TO R

Hot Hole 2 1/16” 2 1/16” 4-5, 1 Stage

M U D M O T O R S

2 3/8” 2 3/8” 1-2, 7 Stage

2 3/8” 2 3/8” 2-3, 4 Stage

90 rpm - 45 gpm

dynamic=3,525 lb

1,570 daN

static=2,650 lb

1,180 daN

2,650 lb

1,180 daN

hp

Max. Overpull (for re-runs) Absolute Overpull

40,500 lb

18,015 daN

375

45

MAX DIFF.

Bearing Load (tension)

3,915 daN

60 rpm - 20 gpm

250 UE

30

RQ

125

15

TO

600

889 mm

525

35"

75

500

M U D M O T O R S

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(lpm)

(gpm)

(rpm)

(ft-lb)

hp

76

20

400-549

85

6.5

76

20

168 - 287

95

132

35

815-963

85

13.2

170

45

534 - 634

93

9.5

189

50

1,215-1,363

85

19.6

246

65

814 - 912

91

14.1

2 3/8”

TORQUE ft lb

105

750

450

1,050

900

750

600

450

(ft-lb)

Bit to Bend Length

2,960 daN

E

(rpm)

875

625

static=6,650 lb

QU

(gpm)

3,658 mm

BW-ROD

TO R

300

(lpm)

0/A Length

dynamic=8,800 lb

PRESSURE DIFFERENTIAL psi

Torque

144”

3,820 kPa

Bearing Load (compression)

30

Speed

4,343 mm

Max Diff. Pressure

Bottom Connection

15

Volume

554 psi

1,200

45

0/A Length

6,067 kPa

375

MAX DIFF.

rpm - 20 gpm

400 200

60

Max Diff. Pressure

300

75

TORQUE ft lb

171” rpm - 35 gpm

800 600

880 psi

120 rpm - 65 gpm

225

1,200

90

10,342 kPa

150

105

10,342 kPa

1000

75

1,400

150

SPEED rpm

rpm - 50 gpm

Max Pressure 1500 psi Drop

SPEED rpm

1,600

1,000

Max Pressure 1500 psi Drop

120

3.0

16

2 3/8”

Torque

(rpm)

(ft-lb)

10

79-99

97

15

129-149

96

25

227-247

95

38 57 95

2,870 mm

hp

525

Bit to Bend Length

35"

Bottom Connection

BW-ROD

Bearing Load (compression)

dynamic=8,800 lb

3,915 daN

static=6,650 lb

2,960 daN

Bearing Load (tension)

dynamic=3,525 lb

1,570 daN

static=2,650 lb

1,180 daN

Max. Overpull (for re-runs)

2,650 lb

1,180 daN

Absolute Overpull

40,500 lb

18,015 daN

889 mm

450 375

175 150 125

rpm - 50 gpm

100

300 rpm - 35 gpm

75

225 rpm - 20 gpm

150 75

50 25

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(rpm)

(ft-lb)

hp

(lpm)

(gpm)

1.5

76

20

96-138

115

2.1

2.4

132

35

201-243

100

3.8

4.1

189

50

303-345

90

5.2

TORQUE ft lb

0/A Length

600

113”

525

2,896 mm

450

0/A Length

MAX DIFF.

114”

200

375

2,565 kPa

300

600

525

450

375

300

225

75

Speed

(gpm)

Max Diff. Pressure

25

PRESSURE DIFFERENTIAL psi

Volume

372 psi

225

E

QU

R TO

(lpm)

2,958 kPa

E

50

80 40

Max Diff. Pressure

U

75

rpm -10 gpm

600

150

120

100

2 3/8” 2 3/8” 5-6, 2.5 Stage

10,342 kPa

Q

rpm - 15 gpm

160

Max Pressure Drop

R

125

200

150

SPEED rpm

150

1500 psi

429 psi 175

TORQUE ft lb

rpm - 25 gpm

240

10,342 kPa

TO

MAX DIFF.

280

Max Pressure Drop

75

1500 psi 200

320

17

SPEED rpm

LOW FLOW 2 3/8” 2 3/8” 4-5, 3 Stage

M U D M O T O R S

2 7/8” 2 7/8” 2-3, 7 Stage

2 7/8” 2 7/8” 1-2, 5.2 Stage

U

Q

30

R

800

700

600

500

400

300

200

TO

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

4,699 mm

158”

0/A Length

4,013 mm 625

Bit to Bend Length

40"

Bottom Connection

2 3/8 Reg., N-Rod

Bearing Load (compression)

dynamic=13,650 lb static=10,750 lb

4,780 daN

Bearing Load (tension)

dynamic=5,450 lb

2,425 daN

static=4,300 lb

1,915 daN

Max. Overpull (for re-runs)

4,300 lb

1,915 daN

Absolute Overpull

1,016 mm

150 rpm - 40 gpm

500 375

90

250

UE

6,070 daN

RQ

TO

125

27,580 daN

60 30

Speed

Torque

(lpm)

(gpm)

(rpm)

(ft-lb)

M O T O R S

hp

76

20

145-220

153

4.2

151

40

369 - 495

182

12.7

170

45

425-570

153

12.4

208

55

539 - 668

182

18.6

265

70

715-780

153

20.8

265

70

719 - 845

180

24.6

2 7/8”

M U D

PRESSURE DIFFERENTIAL psi

Volume

62,000 lb

120

TORQUE ft lb

0/A Length

180

rpm - 55 gpm

MAX DIFF.

60

E

185”

210

1,000

rpm - 20 gpm

125

750

875

90

875

6,688 kPa

750

375

Max Diff. Pressure

625

120

970 psi

500

500

4,482 kPa

240 rpm -70 gpm

375

rpm - 45 gpm

Max Diff. Pressure

10,342 kPa

250

150

250

650 psi

180

625

100

SPEED rpm

750

210

TORQUE ft lb

rpm - 70 gpm

10,342 kPa

1,000

125

MAX DIFF.

875

240

Max Pressure 1500 psi Drop

SPEED rpm

1,000

Max Pressure 1500 psi Drop

18

2 7/8”

3,778 kPa

517 psi

Max Diff. Pressure

3,565 kPa

121”

0/A Length

3,073 mm

123”

0/A Length

3,124 mm

6,070 daN

static=10,750 lb

4,780 daN

Bearing Load (tension)

dynamic=5,450 lb

2,425 daN

static=4,300 lb

1,915 daN

Max. Overpull (for re-runs)

4,300 lb

1,915 daN

Absolute Overpull

62,000 lb

27,580 daN

600

525

450

375

300

225

150

25

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(rpm)

(ft-lb)

10

50-75

143

25

172-197

142

40

290-320

141

(lpm)

(gpm)

38 95 151

hp

160

rpm - 50 gpm

225 150

120

rpm - 20 gpm

75

80 40

800

dynamic=13,650 lb

300

700

2 3/8 Reg., N-Rod

Bearing Load (compression)

200

375

MAX DIFF.

Bottom Connection

1,016 mm

E

40"

240

rpm - 80 gpm

600

50

50

Bit to Bend Length

450

500

100 rpm - 10 gpm

75

280

525

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(rpm)

(ft-lb)

20

65-105

190

50

225-265

183

7.8

80

377-417

167

12.0

(lpm)

(gpm)

1.4

76

4.7

189

7.8

303

hp 2.4

TORQUE ft lb

Max Diff. Pressure

400

RQ

TO

320

600

QU

UE

150

100

MAX DIFF.

200

2 7/8” 2 7/8” 5-6, 3.3 Stage

10,342 kPa

TO R

125 rpm - 25 gpm

TORQUE ft lb

250

75

SPEED rpm

150

Max Pressure Drop

548 psi 175

300

1500 psi

300

350

10,342 kPa

200

200 rpm - 40 gpm

Max Pressure Drop

100

1500 psi 400

19

SPEED rpm

LOW FLOW 2 7/8” 2 7/8” 3-4, 4 Stage

M U D M O T O R S

2 7/8” 2 7/8” 7-8, 2.5 Stage 600

600

525

525 rpm - 110

300

450

rpm - 90 gpm

375

rpm - 70 gpm

300

225

150

800

700

600

75

500

400

300

75

200

TO

RQ

UE

150

MAX DIFF.

225

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

hp

(lpm)

(gpm)

(rpm)

(ft-lb)

265

70

198-257

250

341

90

256-335

215

11.3

416

110

378-423

180

12.9

9.4

TORQUE ft lb

375

100

SPEED rpm

450

1500 psi

Max Pressure Drop

10,342 kPa

490 psi

Max Diff. Pressure

3,378 kPa

115”

0/A Length

2,921 mm

For more information on our products see our Web site http://www.nql.com

Bit to Bend Length

40"

Bottom Connection

2 3/8 Reg., N-Rod

Bearing Load (compression)

dynamic=13,650 lb

6,070 daN

static=10,750 lb

4,780 daN

Bearing Load (tension)

dynamic=5,450 lb

2,425 daN

static=4,300 lb

1,915 daN

Max. Overpull (for re-runs)

4,300 lb

1,915 daN

Absolute Overpull

62,000 lb

27,580 daN

2 7/8”

1,016 mm

M U D M O T O R S

20

3 1/8”

600 psi

Max Diff. Pressure

4,137 kPa

156”

0/A Length

3,962 mm

Volume

Speed

Torque

(gpm)

(rpm)

(ft-lb)

303

80

122-141

665

416

110

170-189

560

530

140

230-249

440

(lpm)

hp

450

rpm - 110

375

375

rpm - 90 gpm

300

300

rpm - 70 gpm

2 3/8 Reg.

225

225

Bearing Load (compression)

dynamic=12,000 lb

5,340 daN

150

150

static=36,000 lb

16,015 daN

75

Bearing Load (tension)

dynamic=12,000 lb

5,340 daN

static=36,000 lb

16,015 daN

Max. Overpull (for re-runs)

36,000 lb

16,015 daN

Absolute Overpull

68,000 lb

30,250 daN

MAX DIFF.

Bottom Connection

75

800

700

600

800

700

600

500

400

300

200

100

PRESSURE DIFFERENTIAL psi

813 mm

525

450

500

QU

150

TO R

40

32"

525

400

300

3,150 mm

300

450

80 E

120

Bit to Bend Length

0/A Length

E

600

124”

600

U

750

rpm - 80 gpm

160

5,171 kPa

Q

200

Max Diff. Pressure

R

rpm - 110

750 psi

600

200

900

10,342 kPa

TO

1,050

TORQUE ft lb

rpm - 140

240

3 1/8” 3 1/8” 7-8, 4 Stage

Max Pressure Drop

1500 psi

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

13.8

265

70

198-250

422

15.9

18.1

341

90

276-328

395

20.8

19.3

416

110

348-400

355

23.5

TORQUE ft lb

10,342 kPa

100

MAX DIFF.

280

SPEED rpm

Max Pressure Drop

1500 psi 1,200

320

21

SPEED rpm

PERFORMANCE 3 1/8” 3 1/8” 7-8, 3 Stage

M U D M O T O R S

3 3/8” 3 3/8” 1-2, 5 Stage

3 3/8” 3 3/8” 4-5, 5 Stage

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

hp

Bit to Bend Length

51"

1,295 mm

Bottom Connection 2 3/8 Reg., 2 7/8 Reg. Bearing Load (compression)

dynamic=26,525 lb

Bearing Load (tension)

dynamic=13,250 lb

5,895 daN

static=36,650 lb

16,300 daN

Max. Overpull (for re-runs)

36,650 lb

16,300 daN

Absolute Overpull

95,000 lb

42,255 daN

static=73,325 lb

11,800 daN 32,615 daN

rpm - 75 gpm

150 100

rpm - 30 gpm

300 225 150

50

75

M U D M O T O R S

PRESSURE DIFFERENTIAL psi

Volume

(lpm)

(gpm)

(rpm)

(ft-lb)

454

120

490-640

320

29.6

568

150

636-786

320

38.8

681

180

783-933

320

47.7

454

3 3/8”

375

200

TORQUE ft lb

450

250

MAX DIFF.

4,928 mm

800

0/A Length

525

300

700

194”

4,654 kPa

600

1,000

50

6,579 mm

600

rpm - 120 gpm

350

500

MAX DIFF.

100

875

625

500

375

750

E

150

250

TO R

QU

300

150

5,171 kPa

400

400

450

675 psi

Max Diff. Pressure

10,342 kPa

300

200

0/A Length

Max Pressure Drop

UE

rpm - 120

600

TORQUE ft lb

250

750 psi 259”

rpm - 150

750

125

SPEED rpm

300

1500 psi

200

rpm - 180

900

Max Diff. Pressure

10,342 kPa

RQ

350

Max Pressure Drop

TO

1,050

1500 psi

100

400

SPEED rpm

1,200

Speed

Torque

(rpm)

(ft-lb)

30

66-86

435

5.5

75

206-226

430

16.9

120

346-366

415

27.4

(lpm)

(gpm)

114 284

hp

22

3 3/8”

562 psi

Max Diff. Pressure

3,875 kPa

194”

0/A Length

4,928 kPa

1,050

Volume

Speed

Torque

(rpm)

(ft-lb)

60

74-95

764

90

120-143

660

120

159-180

540

(lpm)

(gpm)

227 341 454

hp

250

700 600 500

rpm - 90 gpm

400

200 rpm - 60 gpm

150

300

Bearing Load (compression)

dynamic=26,525 lb

11,800 daN

100

200

static=73,325 lb

32,615 daN

50

Bearing Load (tension)

dynamic=13,250 lb

5,895 daN

static=36,650 lb

16,300 daN

Max. Overpull (for re-runs)

36,650 lb

16,300 daN

Absolute Overpull

95,000 lb

42,255 daN

100

800

700

600

500

150

PRESSURE DIFFERENTIAL psi

1,295 mm

Bottom Connection 2 3/8 Reg., 2 7/8 Reg.

300

400

525

450

375

300

75

225

TO

51"

rpm - 120 gpm

300

25

600

UE

RQ

3,378 mm

M U D

E

300

0/A Length

U

450

50

MAX DIFF.

75

133”

800

350

Q

600

4,426 kPa

R

rpm - 60 gpm

100

Bit to Bend Length

Max Diff. Pressure

TO

750

125

TORQUE ft lb

900

rpm - 90 gpm

150

SPEED rpm

150

642 psi

3 3/8” 3 3/8” 9-10, 3 Stage 400

200

175

10,342 kPa

100

rpm - 120 gpm

Max Pressure Drop

1500 psi

TORQUE ft lb

10,342 kPa

1,200

MAX DIFF.

Max Pressure Drop

1500 psi 200

23

SPEED rpm

3 3/8” 3 3/8” 7-8, 3 Stage

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

10.8

227

60

125-159

475

11.3

15.1

341

90

203-234

420

16.2

16.3

454

120

283-317

345

18.6

M O T O R S

3 3/4” 3 3/8” 4-5, 5 Stage

187”

0/A Length

4,750 mm

PRESSURE DIFFERENTIAL psi

Speed

Torque

(rpm)

(ft-lb)

hp

Bit to Bend Length

39"

965 MM

Bottom Connection

2 7/8 Reg.

Bearing Load (compression)

dynamic=20,575 lb static=67,500 lb

30,025 daN

Bearing Load (tension)

dynamic=20,575 lb

9,150 daN

static=67,500 lb

30,025 daN

Max. Overpull (for re-runs)

67,500 lb

30,025 daN

Absolute Overpull

150,000 lb

66,720 daN

9,150 daN

150

900

rpm - 90 gpm

750

125 rpm - 60 gpm

100

600

75 50 UE

RQ

25

450 300 150

TO

M U D M O T O R S

PRESSURE DIFFERENTIAL psi

Volume (lpm)

(gpm)

Speed

Torque

(rpm)

(ft-lb)

hp

114

30

66-86

435

5.5

227

60

74-95

764

10.8

284

75

206-226

430

16.9

341

90

120-143

660

15.1

454

120

346-366

415

27.4

454

120

159-180

540

16.3

3 3/4”

TORQUE ft lb

4,750 mm

MAX DIFF.

0/A Length

600

800

700

600

500

400

300

200

100

187”

1,050

525

200 100

(gpm)

3,875 kPa

450

300

75

(lpm)

Max Diff. Pressure

375

TO

rpm - 30 gpm

Volume

562 psi

300

rpm - 75 gpm

150

400

U RQ

225

4,654 kPa

225

E

300

175

Max Diff. Pressure

1,200

rpm - 120 gpm

150

500

TORQUE ft lb

rpm - 120 gpm

10,342 kPa

675 psi 600

375

10,342 kPa

200

75

450

700

Max Pressure 1500 psi Drop

SPEED rpm

525

SPEED rpm

3 3/4” 3 3/8” 7-8, 3 Stage Max Pressure 1500 psi Drop

800

MAX DIFF.

600

24

3 3/4”

440 psi

Max Diff. Pressure

3,034 kPa

108”

0/A Length

2,743 mm

rpm - 120 gpm

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

227

60

125-159

310

341

90

207-239

260

454

120

287-317

185

10.1

rpm - 120 gpm

300 250

700 600 500

rpm - 90 gpm

Bit to Bend Length

39"

Bottom Connection

2 7/8 Reg.

150

300

Bearing Load (compression)

dynamic=20,575 lb

9,150 daN

100

200

static=67,500 lb

30,025 daN

50

Bearing Load (tension)

dynamic=20,575 lb

9,150 daN

static=67,500 lb

30,025 daN

Max. Overpull (for re-runs)

67,500 lb

30,025 daN

Absolute Overpull

150,000 lb

66,720 daN

400

200 rpm - 60 gpm

100

800

700

965 MM

600

600

50

3,048 mm

500

MAX DIFF.

100

525

450

375

300

225

50

150

TO R

QU

E

100

0/A Length

400

150

120”

800

350

300

rpm - 60 gpm

150

4,413 kPa

UE

200

200

Max Diff. Pressure

RQ

250

rpm - 90 gpm

75

SPEED rpm

250

TORQUE ft lb

300

300

642 psi

3 3/4” 3 3/8” 9-10, 3 Stage 400

TO

350

10,342 kPa

200

350

Max Pressure Drop

1500 psi

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

7.5

227

60

125-159

475

11.3

10.0

341

90

203-234

420

16.2

454

120

283-317

345

18.6

TORQUE ft lb

10,342 kPa

100

400

MAX DIFF.

Max Pressure Drop

1500 psi 400

25

SPEED rpm

3 3/4” 3 3/8” 9-10, 2 Stage

M U D M O T O R S

580 545 460

M U D

786 N*m 3 3/4” 3 3/4” 5-6, 3.8 Stage 800

600

700

525 rpm - 200 gpm

375

500

rpm - 150 gpm

400

300 rpm - 100 gpm

300

M O T O R S

200

800

100

700

500

400

300

600

E QU

200

100

75

TO R

150

MAX DIFF.

225

TORQUE ft lb

600

450

SPEED rpm

580 ft-lb

18.2 29.1 34.6

PRESSURE DIFFERENTIAL psi

3 3/4”

26

3 3/4”

27

3 3/4” 3 3/4” 4-5, 3.5 Stage

3 3/4” 3 3/4” 7-8, 2.3 Stage

Max Diff. Pressure

3,427 kPa

428 psi

Max Diff. Pressure

2,951 kPa

204”

0/A Length

5,182 mm

204”

0/A Length

5,182 mm

rpm - 160 gpm

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(rpm)

(ft-lb)

hp

(lpm)

(gpm)

379

100

114-146

680

14.8

492

130

159-191

650

19.7

606

160

204-236

625

24.3

9,150 daN

static=67,500 lb

30,025 daN

Bearing Load (tension)

dynamic=20,575 lb

9,150 daN

static=67,500 lb

30,025 daN

Max. Overpull (for re-runs)

67,500 lb

30,025 daN

Absolute Overpull

150,000 lb

66,720 daN

40 20

400 200

600

dynamic=20,575 lb

600 MAX DIFF.

2 7/8 Reg.

Bearing Load (compression)

800

rpm - 100 gpm

60

525

800

700

600

500

400

300

200

100

100

50

Bottom Connection

80

450

TO R

QU

E

200

965 MM

1,000

375

300

39"

rpm - 130 gpm

100

300

150

Bit to Bend Length

1,200

120

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

379

100

60-76

1,125

12.9

492

130

83-98

950

15.0

606

160

106-121

725

14.6

TORQUE ft lb

497 psi

E

rpm - 100 gpm

100

400

MAX DIFF.

200

1,400

140

SPEED rpm

500

rpm - 130 gpm

TORQUE ft lb

rpm - 160 gpm

1,600

160

10,342 kPa

225

Max Pressure Drop

QU

1500 psi

TO R

10,342 kPa

600

300

SPEED rpm

Max Pressure Drop

150

700

350

250

1500 psi

75

800

400

M U D M O T O R S

1500 1390 1280

M U D

2,034 N*m 3 3/4” 3 3/4” 7-8, 6.7 Stage 1600

400

1400

350

250 200

rpm - 160 gpm

1200 1000

rpm - 130 gpm

800

rpm - 100 gpm

600

M O T O R S

400

1600

200

1400

800

1000

600

1200

E QU

400

200

50

TO R

100

MAX DIFF.

150

TORQUE ft lb

300

SPEED rpm

1500 ft-lb

37.1 47.6 58.5

PRESSURE DIFFERENTIAL psi

3 3/4”

28

4 1/8”

1500 psi

Max Pressure Drop

10,342 kPa

1,400

580 psi

Max Diff. Pressure

4,000 kPa

420 psi

Max Diff. Pressure

2,896 kPa

1,200

187”

0/A Length

4,750 mm

187”

0/A Length

4,750 mm

PRESSURE DIFFERENTIAL psi

Volume (lpm)

(gpm)

Speed

Torque

(rpm)

(ft-lb)

hp

75 60

Bottom Connection

2 7/8 Reg.

Bearing Load (compression)

dynamic=34,000 lb

15,130 daN

30

static=123,000 lb

54,750 daN

15

Bearing Load (tension)

dynamic=17,000 lb

7,565 daN

static=61,500 lb

27,375 daN

Max. Overpull (for re-runs)

61,500 lb

27,375 daN

Absolute Overpull

150,000 lb

66,765 daN

1,250 1,000

rpm - 100 gpm

750 MAX DIFF.

45

500

600

525

250

450

375

300

1,245 mm

225

800

700

500

400

300

200

600

QU TO R

200

100

25

400

MAX DIFF.

E

600

49"

1,500

rpm - 130 gpm

E

rpm - 80 gpm

50

Bit to Bend Length

rpm - 160 gpm

90

QU

800

1,750

105

150

1,000

rpm - 140 gpm

100

2,000

120

75

125

PERFORMANCE 4 1/8” 3 7/8” 7-8, 2 Stage

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

303

80

51-65

1250

16

379

100

45-55

1,550

13.3

530

140

96-110

1060

22

492

130

63-73

1,325

15.9

757

200

146-160

850

26

606

160

78-90

1,050

15.6

TORQUE ft lb

10,342 kPa

SPEED rpm

rpm - 200 gpm

150

SPEED rpm

Max Pressure Drop

TORQUE ft lb

175

75

1500 psi

1,600

200

29

TO R

PERFORMANCE 4 1/8” 3 7/8” 6-7, 3 Stage

M U D M O T O R S

4 3/4” 4 3/4” 1-2, 3 Stage

4 3/4” 4 3/4” 4-5, 3.5 Stage

Volume

Speed

Torque

hp

(lpm)

(gpm)

(rpm)

(ft-lb)

379

100

172-220

440

14.4

568

150

289-337

440

24.2

757

200

402-450

440

33.7

81,045 daN

Bearing Load (tension)

dynamic=25,125 lb

16,700 daN

static=20,050 lb

56,045 daN

Max. Overpull (for re-runs)

20,050 lb

56,045 daN

Absolute Overpull

143,000 lb

63,605 daN

600

120 rpm - 100 gpm

450

80 40

150

M O T O R S

PRESSURE DIFFERENTIAL psi

Volume

4 3/4”

300

TORQUE ft lb

static=60,175 lb

30,815 daN

160

800

dynamic=75,400 lb

750

rpm - 175 gpm

700

3 1/2 Reg.

Bearing Load (compression)

900

MAX DIFF.

Bottom Connection

200

600

800

700

600

500

400

300

200

100

PRESSURE DIFFERENTIAL psi

1,829 mm

240

500

RQ

150

TO

75

52"

5,182 mm

400

300

UE

150

Bit to Bend Length

0/A Length

M U D

1,050 rpm - 250 gpm

300

450

204”

1,200

E

rpm - 100 gpm

225

5,715 mm

3,378 kPa

280

200

600

300

0/A Length

490 psi

320

QU

750

rpm - 150 gpm

TORQUE ft lb

225” 375

2,620 kPa

10,342 kPa

Max Diff. Pressure

TO R

380 psi 900

10,342 kPa

Max Diff. Pressure

100

rpm - 200 gpm

450

1,050

Max Pressure 1500 psi Drop

SPEED rpm

MAX DIFF.

525

SPEED rpm

Max Pressure 1500 psi Drop

1,200

600

Speed

Torque

(rpm)

(ft-lb)

100

60-91

1,020

11.7

175

132-164

1,000

25.1

250

204-236

950

36.9

(lpm)

(gpm)

379 662 946

hp

30

4 3/4”

Volume

Speed

Torque

(rpm)

(ft-lb)

100

81-85

850

175

146-151

825

250

211-216

750

(lpm)

(gpm)

379 662 946

hp

1,500

120

52"

Bottom Connection

3 1/2 Reg.

Bearing Load (compression)

dynamic=75,400 lb

30,815 daN

40

static=60,175 lb

81,045 daN

20

Bearing Load (tension)

dynamic=25,125 lb

16,700 daN

static=20,050 lb

56,045 daN

Max. Overpull (for re-runs)

20,050 lb

56,045 daN

Absolute Overpull

143,000 lb

63,605 daN

rpm - 175 gpm

1,250

60

1,000

MAX DIFF.

80 rpm - 250 gpm

750 500 250

600

100

Bit to Bend Length

1,829 mm

1,750

rpm - 250 gpm

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

13.1

379

100

45-53

1,660

14.2

22.9

662

175

90-98

1,450

24.9

30.1

946

250

122-130

1,150

26.7

TORQUE ft lb

5,182 mm

525

400

350

300

250

200

150

100

PRESSURE DIFFERENTIAL psi

0/A Length

2,000

450

E QU

150

TO R

40

204”

140

375

300

3,886 mm

2,758 kPa

300

rpm - 100 gpm

80

0/A Length

Max Diff. Pressure

225

450

120

153”

400 psi

E

600

2,068 kPa

4 3/4” 4 3/4” 7-8, 2.2 Stage 160

QU

160

rpm - 175 gpm

Max Diff. Pressure

10,342 kPa

150

750

TORQUE ft lb

900

rpm - 250 gpm

300 psi

Max Pressure Drop

1500 psi

TO R

1,050

200

50

SPEED rpm

240

10,342 kPa

75

280

Max Pressure Drop

1500 psi

1,200

MAX DIFF.

320

31

SPEED rpm

4 3/4 5” 5-6, 2 Stage

M U D M O T O R S

5” S3 4 3/4” 1-2, 3 Stage

5” S3 4 3/4” 4-5, 3.5 Stage

Volume

Speed

Torque

hp

(lpm)

(gpm)

(rpm)

(ft-lb)

379

100

172-220

440

14.4

568

150

289-337

440

24.2

757

200

402-450

440

33.7

0/A Length

5,918 mm

212”

0/A Length

900

5,385 mm 200

3 1/2 Reg.

Bearing Load (compression)

dynamic=79,625 lb

35,415 daN

static=224,950 lb

100,060 daN

Bearing Load (tension)

dynamic=34,625 lb

15,400 daN

static=91,100 lb

40,520 daN

Max. Overpull (for re-runs)

91,100 lb

40,520 daN

Absolute Overpull

210,000 lb

93,410 daN

120 rpm - 100 gpm 80 40

300 150

M U D M O T O R S

PRESSURE DIFFERENTIAL psi

Volume

5”

450

800

Bottom Connection

600

700

1,651 mm

MAX DIFF.

65"

600

Bit to Bend Length

750

rpm - 175 gpm

160

TORQUE ft lb

233”

1,050 rpm - 250 gpm

500

800

700

600

500

400

300

200

PRESSURE DIFFERENTIAL psi

240

400

E U Q R

150

TO

75

3,378 kPa

300

300

150

Max Diff. Pressure

E

450

490 psi

1,200

280

200

rpm - 100 gpm

225

2,620 kPa

320

10,342 kPa

QU

600

300

Max Diff. Pressure

10,342 kPa

100

750

rpm - 150 gpm

100

SPEED rpm

375

380 psi 900

TORQUE ft lb

rpm - 200 gpm

450

1,050

Max Pressure 1500 psi Drop

SPEED rpm

MAX DIFF.

525

Max Pressure 1500 psi Drop

TO R

1,200

600

Speed

Torque

(rpm)

(ft-lb)

100

60-91

1,020

11.7

175

132-164

1,000

25.1

250

204-236

950

36.9

(lpm)

(gpm)

379 662 946

hp

32

5” PERFORMANCE 5” S3 4 3/4” 4-5, 6.3 Stage

2,400

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(rpm)

(ft-lb)

100

40-91

1,870

175

110-161

1,835

250

185-236

1,790

(lpm)

(gpm)

379 662 946

hp

6,116 kPa

400 psi

Max Diff. Pressure

2,758 kPa

298”

0/A Length

7,569 mm

214”

0/A Length

5,436 mm

140

1,750

rpm - 250 gpm

1,500

120

1,250

80

1,000

65"

Bottom Connection

3 1/2 Reg.

Bearing Load (compression)

dynamic=79,625 lb

35,415 daN

40

static=224,950 lb

100,060 daN

20

Bearing Load (tension)

dynamic=34,625 lb

15,400 daN

static=91,100 lb

40,520 daN

Max. Overpull (for re-runs)

91,100 lb

40,520 daN

Absolute Overpull

210,000 lb

93,410 daN

60

rpm - 100 gpm

750

M U D

500

480

420

250

360

1,651 mm

MAX DIFF.

100

Bit to Bend Length

TORQUE ft lb

rpm - 175 gpm

300

1,600

1,400

1,200

1,000

800

600

400

400

Max Diff. Pressure

240

E QU TO R

40

887 psi

180

800

80

2,000

160

E

1,200

rpm - 100 gpm

5” S3 4 3/4” 7-8, 2.2 Stage

10,342 kPa

QU

120

Max Pressure Drop

120

1,600

1500 psi

TO R

rpm - 175 gpm

160

10,342 kPa

60

2,000

200

Max Pressure Drop

SPEED rpm

rpm - 250 gpm

200

SPEED rpm

240

2,800

TORQUE ft lb

280

1500 psi

3,200

MAX DIFF.

320

33

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)

Volume (gpm)

(rpm)

(ft-lb)

hp

14.2

379

100

45-53

1,660

14.2

38.4

662

175

90-98

1,450

24.9

63.1

946

250

122-130

1,150

26.7

M O T O R S

PERFORMANCE 5” S3 4 3/4” 7-8, 2 Stage

6,833 mm

E QU

500

600

525

450

375

300

225

150

TO R

15

3 1/2 Reg.

Bearing Load (compression)

dynamic=79,625 lb

35,415 daN

static=224,950 lb

100,060 daN

Bearing Load (tension)

dynamic=34,625 lb

15,400 daN

static=91,100 lb

40,520 daN

Max. Overpull (for re-runs)

91,100 lb

40,520 daN

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(lpm)

(gpm)

(rpm)

(ft-lb)

379

100

21-29

2,650

10.6

662

175

43-51

2,350

19.2

946

250

66-74

1,680

Absolute Overpull

2,000

60

1,500

40

1,000

20

210,000 lb

21.1

5”

93,410 daN

500

M O T O R S

PRESSURE DIFFERENTIAL psi

Volume

hp

2,500

rpm - 150 gpm

80

E

Bottom Connection

3,000

QU

1,000

30

1,651 mm

rpm - 200 gpm

100

TO R

1,500 rpm - 100 gpm

120

TORQUE ft lb

0/A Length

800

269”

MAX DIFF.

6,909 mm

700

0/A Length

600

272”

500

3,000

M U D

3,500

400

4,240 kPa

300

Max Diff. Pressure

200

615 psi

65"

4,000 rpm - 250 gpm

140

2,579 kPa

Bit to Bend Length

160

10,342 kPa

Max Diff. Pressure

2,000

45

Max Pressure Drop

374 psi

2,500

rpm - 175 gpm

1500 psi

100

60

10,342 kPa

SPEED rpm

rpm - 250 gpm

75

75

SPEED rpm

90

Max Pressure Drop

3,500

TORQUE ft lb

105

1500 psi

4,000

MAX DIFF.

120

PERFORMANCE 5” S3 4 3/4” 7-8, 3.8 Stage

Speed

Torque

(rpm)

(ft-lb)

150

62-78

2,500

29.5

200

88-104

2,300

38.5

250

112-128

2,050

43.7

(lpm)

(gpm)

568 757 946

hp

34

5”

Volume

Speed

Torque

(rpm)

(ft-lb)

100

67-84

1,700

175

133-150

1,640

250

200-217

1,550

(lpm)

(gpm)

379 662 946

hp

Bearing Load (compression)

dynamic=79,625 lb

2,000 rpm - 250 gpm

1,600

200 150

35,415 daN

100

static=224,950 lb

100,060 daN

50

Bearing Load (tension)

dynamic=34,625 lb

15,400 daN

static=91,100 lb

40,520 daN

Max. Overpull (for re-runs)

91,100 lb

40,520 daN

Absolute Overpull

210,000 lb

93,410 daN

1,200

rpm - 150 gpm

Volume

400

Speed

Torque

(rpm)

(ft-lb)

150

96-130

2,750

250

181-215

2,550

87.9

350

266-300

2,350

119.0

(gpm)

21.7

568

41.5

946

59.0

1325

M U D

800

PRESSURE DIFFERENTIAL psi

(lpm)

TORQUE ft lb

3 1/2 Reg.

2,400

250

MAX DIFF.

Bottom Connection

1,651 mm

300

1,200

65"

5,893 mm

rpm - 350 gpm

900

Bit to Bend Length

0/A Length

2,800

350

1,050

276”

5,893 mm

3,200

400

750

7,198 kPa

E

1,044 psi

600

800

700

600

500

400

300

200

PRESSURE DIFFERENTIAL psi

10,342 kPa

Max Diff. Pressure

450

300

TO R

40

600

Max Pressure Drop

QU

QU

E

80

900

4,454 kPa

1500 psi

300

MAX DIFF.

rpm - 100 gpm

0/A Length

10,342 kPa

TO R

1,200

160

TORQUE ft lb

1,500 rpm - 175 gpm

100

SPEED rpm

646 psi

Max Diff. Pressure

232”

1,800

rpm - 250 gpm

200

120

Max Pressure Drop

150

2,100

280 240

1500 psi 2,400

320

SPEED rpm

PERFORMANCE 5” S3 5” 5-6, 4 Stage

35 PERFORMANCE 5” S3 5” 6-7, 6 Stage

hp 50.3

M O T O R S

5 1/2” 5 1/2” 7-8, 3 Stage

5 1/2” 5 1/2” 9-10, 3.2 Stage

Volume (lpm)

(gpm)

Speed

Torque

(rpm)

(ft-lb)

hp

0/A Length

6,452 mm 2,500

100

dynamic=84,125 lb

37,420 daN

static=247,450 lb

110,065 daN

Bearing Load (tension)

dynamic=42,050 lb

18,705 daN

static=123,700 lb

55,020 daN

Max. Overpull (for re-runs)

123,700 lb

55,020 daN

Absolute Overpull

214,000 lb

95,190 daN

1,500

rpm - 100 gpm

40

1,000

20

500

800

4 1/2 Reg.

Bearing Load (compression)

60

700

Bottom Connection

2,000

600

2,159 mm

500

85"

rpm - 200 gpm

400

Bit to Bend Length

80

300

600

525

450

375

300

225

150

PRESSURE DIFFERENTIAL psi

254”

3,000

E

QU TO R

400

75

30

6,375 mm

3,500

QU

800

E

60

1,200

0/A Length

rpm - 300 gpm

200

90

3,965 kPa

100

rpm - 200 gpm

1,600

Max Diff. Pressure

SPEED rpm

MAX DIFF.

rpm - 275 gpm

120

TORQUE ft lb

2,000

575 psi

4,000

M U D M O T O R S

PRESSURE DIFFERENTIAL psi

Volume

Speed

Torque

(lpm)

(gpm)

(rpm)

(ft-lb)

hp

757

200

70-92

2,622

34.9

379

100

35-45

2,700

17.9

1041

275

98-120

2,400

44.8

757

200

68-79

2,450

31.7

1325

350

135-160

2,050

52.7

1136

300

105-118

1,900

38.0

5 1/2”

TORQUE ft lb

251”

rpm - 350 gpm

150

3,103 kPa

140 120

2,400

180

Max Diff. Pressure

10,342 kPa

160

MAX DIFF.

450 psi

10,342 kPa

Max Pressure 1500 psi Drop

TO R

2,800

210

SPEED rpm

Max Pressure 1500 psi Drop

3,200

240

36

6 1/2” 6 3/4”

Volume (lpm)

(gpm)

dynamic=154,750 lb

68,835 daN

static=467,900 lb

208,120 daN

Bearing Load (tension)

dynamic=77,375 lb

34,415 daN

static=234,000 lb

104,085 daN

Max. Overpull (for re-runs)

234,000 lb

104,085 daN

800

700

600

500

300

400

Speed

Torque

(rpm)

(ft-lb)

hp

Absolute Overpull

3,500 rpm - 400 gpm

3,000

125 100 75

2,500 rpm - 300 gpm

rpm - 200 gpm

50 25

122,320 daN

1,500

PRESSURE DIFFERENTIAL psi

(lpm)

(gpm)

M U D

1,000 500

Volume

275,000 lb

2,000

TORQUE ft lb

4 1/2 Reg.

Bearing Load (compression)

150

800

E QU

200

100

PRESSURE DIFFERENTIAL psi

2,235 mm

Bottom Connection

400

TO R

40

88"

175

700

800

80

6,198 mm

MAX DIFF.

1,200

Bit to Bend Length

0/A Length

600

MAX DIFF.

rpm - 150 gpm

120

1,600

244”

4,000

500

2,000

160

6,528 mm

200

400

200

3,448 kPa

300

0/A Length

500 psi

E

rpm - 275 gpm

TORQUE ft lb

2,400

240

4,309 kPa

200

257”

2,800

10,342 kPa

Max Diff. Pressure

QU

rpm - 400 gpm

280

Max Pressure Drop

TO R

625 psi

Max Diff. Pressure

1500 psi

10,342 kPa

100

Max Pressure Drop

3,200

320

SPEED rpm

1500 psi

37 6 1/2”-6 3/4” 6 1/4” 7-8, 2.8 Stage

SPEED rpm

6 1/2”-6 3/4” 6 1/4” 4-5, 4.3 Stage

Speed

Torque

(rpm)

(ft-lb)

hp

568

150

65-105

2,300

28.4

757

200

10-65

3,400

6.5

1040

275

145-180

2,200

60.7

1136

300

45-100

3,200

27.4

1514

400

230-265

2,150

94.1

1514

400

97-135

2,6500

48.9

M O T O R S

6 1/2”-6 3/4” S3 6 1/4” 4-5, 4.3 Stage

rpm - 400 gpm

280

Max Pressure Drop

10,342 kPa

625 psi

Max Diff. Pressure

4,309 kPa

240”

0/A Length

6.096 mm

2,800

200

2,000

rpm - 275 gpm

1,600

160 MAX DIFF.

rpm - 150 gpm

120

QU

E

80

800

800

700

600

500

400

300

200

100

PRESSURE DIFFERENTIAL psi

Volume (lpm)

(gpm)

Speed

Torque

(rpm)

(ft-lb)

hp

568

150

65-105

2,300

28.4

1040

275

145-180

2,200

60.7

1514

400

230-265

2,150

94.1

For more information on our products see our Web site http://www.nql.com

Bit to Bend Length

71"

Bottom Connection

4 1/2 Reg.

Bearing Load (compression)

dynamic=130,000 lb

57,825 daN

static=400,500 lb

178,140 daN

Bearing Load (tension)

dynamic=65,000 lb

28,910 daN

static=200,250 lb

89,070 daN

Max. Overpull (for re-runs)

200,250 lb

89,070 daN

Absolute Overpull

289,000 lb

128,550 daN

400

TO R

40

1,200

TORQUE ft lb

2,400

240

SPEED rpm

1500 psi 3,200

320

6 1/2” 6 3/4”

1,803 mm

M U D M O T O R S

38

6 1/2” 6 3/4”

39 PERFORMANCE 6 1/2”-6 3/4” S3 6 1/4 7-8, 4.8 Stage

Volume (lpm)

(gpm)

Speed

Torque

(rpm)

(ft-lb)

hp

757

200

10-65

3,400

6.5

1136

300

45-100

3,200

27.4

1514

400

97-135

2,650

48.9

Bit to Bend Length

71"

Bottom Connection

4 1/2 Reg.

Bearing Load (compression)

dynamic=130,000 lb

57,825 daN

static=400,500 lb

178,140 daN

Bearing Load (tension)

dynamic=65,000 lb

28,910 daN

static=200,250 lb

89,070 daN

Max. Overpull (for re-runs)

200,250 lb

89,070 daN

Absolute Overpull

289,000 lb

1,803 mm

150

6,000 5,000

125 rpm - 300 gpm

4,000

100 75

rpm - 200 gpm

50

128,550 daN

25

3,000

1,000

PRESSURE DIFFERENTIAL psi

Volume (lpm)

(gpm)

M U D

2,000

1200

800

700

600

500

400

300

200

PRESSURE DIFFERENTIAL psi

8,052 mm

MAX DIFF.

E QU

500

TO R

25

0/A Length

7,000 rpm - 400 gpm

900

1,000

50

317”

5,998 kPa

1050

1,500

6,198 mm

Max Diff. Pressure

750

rpm - 200 gpm

0/A Length

870 psi

600

75

MAX DIFF.

100

2,000

3,448 kPa

175

450

rpm - 300 gpm

244”

Max Diff. Pressure

8,000

200

10,342 kPa

E

2,500

TORQUE ft lb

rpm - 400 gpm

125

100

SPEED rpm

500 psi

Max Pressure Drop

QU

150

3,000

1500 psi

300

3,500

10,342 kPa

TO R

175

Max Pressure Drop

150

1500 psi

SPEED rpm

4,000

TORQUE ft lb

6 1/2”-6 3/4” S3 6 1/4 7-8, 2.8 Stage 200

Speed

Torque

(rpm)

(ft-lb)

hp

757

200

13-63

5800

14.4

1136

300

45-104

5500

47.1

1514

400

87-130

5200

86.1

M O T O R S

6 1/2”-6 3/4” 6 1/2”-6 3/4” 1-2, 4 Stage rpm - 500 gpm

rpm - 350 gpm MAX DIFF.

225

10,342 kPa

1,400

474 psi

Max Diff. Pressure

3,268 kPa

1,200

324”

0/A Length

8,230 mm

1,000

300 rpm - 200 gpm

800 600 400

800

700

600

500

400

300

200

200

75

TO R

QU

E

150

100

SPEED rpm

450 375

Max Pressure Drop

PRESSURE DIFFERENTIAL psi

Speed

Torque

(lpm)