Calculation Of Pitting Resistance Equivalent Numbers 1a282z

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Calculation Of Pitting Resistance Equivalent Numbers as PDF for free.

More details w3441

- Words: 1,805

- Pages: 7

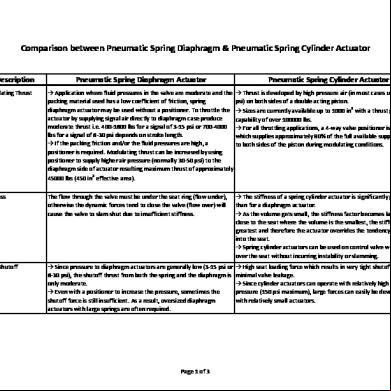

Calculation of pitting resistance equivalent numbers (PREN) Introduction Pitting resistance equivalent numbers (PREN) are a theoretical way of comparing the pitting corrosion resistance of various types of stainless steels, based on their chemical compositions. The PREN (or PRE) numbers are useful for ranking and comparing the different grades, but cannot be used to predict whether a particular grade will be suitable for a given application, where pitting corrosion may be a hazard. Actual or specified range compositions can be used and usually involve chromium, molybdenum and nitrogen in the calculations. Tungsten also appears in some versions of the calculation. In some industries, notably the oil and gas sector, specifications may place tighter restrictions on the PREN for specific grades than that implied by the minimum composition of the grade defined in EN or ASTM Standards.

Affect of alloying elements on pitting resistance These are 'linear' formulas, where the molybdenum and nitrogen levels are 'weighted' to take of their strong influence on pitting corrosion resistance. They typically take the form PREN = Cr + m Mo + n N where 'm' and 'n' are the factors for molybdenum and nitrogen. The most commonly used version of the formula is PREN = Cr + 3.3Mo + 16N Some formulas weight nitrogen more, with factors of 27 or 30, but as the actual nitrogen levels are quite modest in most stainless steels, this does not have a dramatic effect on ranking. Tungsten is also included in the molybdenum-rating factor to acknowledge its affect on pitting resistance in the tungsten bearing super-duplex types, for example 1.4501. A modified formula is then used: PREN = Cr + 3.3(Mo +0.5W) + 16N

Calculated pitting resistance numbers Nitrogen ranges are not specified in standards such as BS EN 10088-1 for all but specific grades, such as 1.4311 (304LN), 1.4406 (316LN) austenitics. In contrast all the duplex grades have specified nitrogen ranges. It can then be misleading to use just specified ranges as the residual nitrogen in commercially produced austenitics will benefit the pitting resistance. The table below shows a range of calculated PREN values for comparison. A full theoretical range is shown, using a combination of the lowest and highest specified values for a selection of ferritic, austenitic and duplex grades. The values are rounded for convenience of display. The PREN values for commercially available grades will of course lie somewhere between these minimum and maximum values and so commercially available steels in grades 1.4410, 1.4501 and 1.4507 are often stipulated to have actual PREN values over 40. Grades with a PREN of 40 or more are known as 'super' austenitics or 'super' duplex types, depending to which basic family they belong. PREN = Cr + 3.3Mo + 16N Tungsten (W) is known to have an effect on the pitting resistance and for some grades a modified formula is used:

PREN = Cr + 3.3(Mo +0.5W) + 16N Grade

Type

Cr

Mo

N

PREN

Ferritics 1.4003

-

10.5-12.5

NS

0.030 max

10.5-12.5

1.4016

430

16.0-18.0

NS

NS

16.0-18.0

1.4113

434

16.0-18.0

0.9-1.4

NS

19.0-22.6

1.4509

441

17.5-18.5

NS

NS

17.5-18.5

1.4521

444

17.0-20.0

1.8-2.5

0.030max

23.0-28.7

Austenitics 1.4301

304

17.5-19.5

NS

0.11max

17.5-20.8

1.4311

304LN

17.5-19.5

NS

0.12-0.22

19.4-23.0

1.4401/4

316/316L

16.5-18.5

2.0-2.5

0.11max

23.1-28.5

1.4435

316L (2.5% min Mo)

17.0-19.0

2.5-3.0

0.11max

25.3-30.7

1.4406

316LN

16.5-18.5

2.0-2.5

0.12-0.22

25.0-30.3

1.4539

904L

19.0-21.0

4.0-5.0

0.15max

32.2-39.9

1.4563

Sanicro 28

24.0-26.0

3.0-4.0

0.11max

35.9-43.0

1.4547

254SMO

19.5-20.5

6.0-7.0

0.18-0.25

42.2-47.6

1.4529

1925hMo

19.0-21.0

6.0-7.0

0.15-0.25

41.2-48.1

1.4565

4565S

24.0-26.0

4.0-5.0

0.30-0.60

42.0-52.1

Duplex 1.4062

1

2202

22.0

0.4

0.20

26.5

1.4162

2101LDX

21.0-22.0

0.1-0.8

0.20-0.25

24.5-28.6

1.4362

SAF 2304

22.0-24.0

0.1-0.6

0.05-0.20

23.1-29.2

1.4462

21.0-23.0

2.5-3.5

0.10-0.22

30.8-38.1

2

24.0-26.0

3.0-4.0

0.24-0.35

> 402

1.45012

Zeron 1002

24.0-26.0

3.0-4.0

0.20-0.30

> 402

1.45072

Ferrinox 2552

24.0-26.0

3.0-4.0

0.20-0.30

> 402

1.4410

SAF 2205 2

SAF 2507

The nearest AISI grade is shown, where appropriate, otherwise a typical trade name used by some of manufacturers is shown. NS - Not specified 1 Typical composition only available 2 The “superduplex” steels in particular are subject to tighter restrictions on PREN than that implied by the minimum composition of the EN grade. For example, the equivalent ASTM grade or the specifications of the oil and gas industry e.g. NORSOK or NACE typically require a minimum of PREN =40. K03

ArcelorMittal Stainless UK Ltd

2101LDX

Outokumpu Ltd

904L

Outokumpu Ltd

254SMO 4565S

Outokumpu Ltd

SAF 2304, SAF 2205, SAF 2507, Sanicro 28

Sandvik Steel UK

Zeron 100

Rolled Alloys

http://www.bssa.org.uk/topics.php?article=111

Duplex stainless steels Typically twice the yield of austenitic stainless steels. Minimum Specified UTS typically 680 to 750N/mm2 (98.6 to 108ksi). Elongation typically > 25%. Superior corrosion resistance than a 316. Good Resistance to stress corrosion cracking in a chloride environment. Duplex materials have improved over the last decade; further additions of Nitrogen have been made improving weldability. Because of the complex nature of this material it is important that it is sourced from good quality steel mills and is properly solution annealed. Castings and possibly thick sections may not cool fast when annealed causing sigma and other deleterious phases to form. The material work hardens if cold formed; even the strain produced from welding can work harden the material particularly in multi welding. Therefore a full solution anneal is advantageous, particularly if low service temperatures are foreseen. The high strength of this material can make t fit up difficult. Usable temperature range restricted to, -50 to 280°C Used in Oil & Natural Gas production, chemical plants etc. Standard Duplex S31803 22Cr 5Ni 2.8Mo 0.15N PREn = 32-33 Super Duplex: Stronger and more corrosion resistant than standard duplex. S32760(Zeron 100) 25Cr 7.5Ni 3.5Mo 0.23N PREn = 40

Micro Of Standard Duplex Dark Areas:- Ferrite Light Areas:- Austenite

Duplex solidifies initially as ferrite, then transforms on further cooling to a matrix of ferrite and austenite. In modern raw material the balance should be 50/50 for optimum corrosion resistance, particularly resistance to stress corrosion cracking. However the materials strength is not significantly effected by the ferrite / austenite phase balance.

The main problem with Duplex is that it very easily forms brittle intermetalic phases, such as Sigma, Chi and Alpha Prime. These phases can form rapidly, typically 100 seconds at 900°C. However shorter exposure has been known to cause a drop in toughness, this has been attribute to the formation of sigma on a microscopic scale. Prolonged heating in the range 350 to 550°C can cause 475°C temper embrittlement. For this reason the maximum recommended service temperature for duplex is about 280°C. Sigma (55Fe 45Cr) can be a major problem when welding thin walled small bore pipe made of super duplex, although it can occur in thicker sections. It tends to be found in the bulk of the material rather than at the surface, therefore it probably has more effect on toughness than corrosion resistance. Sigma can also occur in thick sections, such as castings that have not been properly solution annealed (Not cooled fast enough).

However most standards accept that deleterious phases, such as sigma, chi and laves, may be tolerated if the strength and corrosion resistance are satisfactory. Nitrogen is a strong austenite former and largely responsible for the balance between ferrite and austenite phases and the materials superior corrosion resistance. Nitrogen can’t be added to filler metal, as it does not transfer across the arc. It can also be lost from molten parent metal during welding. Its loss can lead to high ferrite and reduced corrosion resistance. Nitrogen can be added to the shielding gas and backing gas, Up to about 10%; however this makes welding difficult as it can cause porosity and contamination of the Tungsten electrode unless the correct welding technique is used. Too much Nitrogen will form a layer of Austenite on the weld surface. In my experience most duplex and super duplex are TIG welded using pure argon. Backing / purge gas should contain less than 25ppm Oxygen for optimum corrosion resistance. Fast cooling from molten will promote the formation of ferrite, slow cooling will promote austenite. During welding fast cooling is most likely, therefore welding consumables usually contain up to 2 - 4% extra Nickel to promote austenite formation in the weld. Duplex should never be welded without filler metal, as this will promote excessive ferrite, unless the welded component is solution annealed. Acceptable phase balance is usually 30 – 70% Ferrite Duplex welding consumables are suitable for ing duplex to austenitic stainless steel or carbon steel; they can also be used for corrosion resistant overlays. Nickel based welding consumables can be used but the weld strength will not be as good as the parent metal, particularly on super duplex.

Low levels of austenite: - Poor toughness and general corrosion resistance.

High levels of austenite: - Some Reduction in strength and reduced resistance to stress corrosion cracking.

Good impact test results are a good indication that the material has been successfully welded. The parent metal usually exceeds 200J. The ductile to brittle transition temperature is about –50°C. The transition is not as steep as that of carbon steel and depends on the welding process used. Flux protected processes, such as MMA; tend to have a steeper transition curve and lower toughness. Multi run welds tend to promote austenite and thus exhibit higher toughness Tight controls and the use of arc monitors are recommended during welding and automatic or mechanised welding is preferred. Repair welding can seriously affect corrosion resistance and toughness; therefore any repairs should follow specially developed procedures. See BS4515 Part 2 for details. Production control test plates are recommended for all critical poduction welds. Welding procedures should be supplemented by additional tests, depending on the application and the requirements of any application code:-

A ferrite count using a Ferro scope is probably the most popular. For best accuracy the ferrite count should be performed manually and include a check for deleterious phases.

Good impact test results are also a good indication of a successful welding procedure and are mandatory in BS4515 Part 2.

A corrosion test, such as the G48 test, is highly recommended. The test may not model the exact service corrosion environment, but gives a good qualative assessment of the welds general corrosion resistance; this gives a good indication that the welding method is satisfactory. G48 test temperature for standard duplex is typically 22°C, for super duplex 35°C

Typical Welding Procedure For Zeron 100 (Super Duplex) Pipe 60mm Od x 4mm Thick Maximum Inter 100°C 1.6mm Filler Wire

Temperature at the end of welding < 250°C

85 amps 2 weld runs (Root and Cap)

Arc energy 1 to 1,5 KJ/mm

Recommended Testing

Position 6G

Travel speed 0.75 to 1 mm/sec

1. Ferric Chloride Pitting Test To ASTM G48 : Method A 2. Chemical analysis of root 3. Ferrite count http://www.gowelding.com/met/duplex.html

Affect of alloying elements on pitting resistance These are 'linear' formulas, where the molybdenum and nitrogen levels are 'weighted' to take of their strong influence on pitting corrosion resistance. They typically take the form PREN = Cr + m Mo + n N where 'm' and 'n' are the factors for molybdenum and nitrogen. The most commonly used version of the formula is PREN = Cr + 3.3Mo + 16N Some formulas weight nitrogen more, with factors of 27 or 30, but as the actual nitrogen levels are quite modest in most stainless steels, this does not have a dramatic effect on ranking. Tungsten is also included in the molybdenum-rating factor to acknowledge its affect on pitting resistance in the tungsten bearing super-duplex types, for example 1.4501. A modified formula is then used: PREN = Cr + 3.3(Mo +0.5W) + 16N

Calculated pitting resistance numbers Nitrogen ranges are not specified in standards such as BS EN 10088-1 for all but specific grades, such as 1.4311 (304LN), 1.4406 (316LN) austenitics. In contrast all the duplex grades have specified nitrogen ranges. It can then be misleading to use just specified ranges as the residual nitrogen in commercially produced austenitics will benefit the pitting resistance. The table below shows a range of calculated PREN values for comparison. A full theoretical range is shown, using a combination of the lowest and highest specified values for a selection of ferritic, austenitic and duplex grades. The values are rounded for convenience of display. The PREN values for commercially available grades will of course lie somewhere between these minimum and maximum values and so commercially available steels in grades 1.4410, 1.4501 and 1.4507 are often stipulated to have actual PREN values over 40. Grades with a PREN of 40 or more are known as 'super' austenitics or 'super' duplex types, depending to which basic family they belong. PREN = Cr + 3.3Mo + 16N Tungsten (W) is known to have an effect on the pitting resistance and for some grades a modified formula is used:

PREN = Cr + 3.3(Mo +0.5W) + 16N Grade

Type

Cr

Mo

N

PREN

Ferritics 1.4003

-

10.5-12.5

NS

0.030 max

10.5-12.5

1.4016

430

16.0-18.0

NS

NS

16.0-18.0

1.4113

434

16.0-18.0

0.9-1.4

NS

19.0-22.6

1.4509

441

17.5-18.5

NS

NS

17.5-18.5

1.4521

444

17.0-20.0

1.8-2.5

0.030max

23.0-28.7

Austenitics 1.4301

304

17.5-19.5

NS

0.11max

17.5-20.8

1.4311

304LN

17.5-19.5

NS

0.12-0.22

19.4-23.0

1.4401/4

316/316L

16.5-18.5

2.0-2.5

0.11max

23.1-28.5

1.4435

316L (2.5% min Mo)

17.0-19.0

2.5-3.0

0.11max

25.3-30.7

1.4406

316LN

16.5-18.5

2.0-2.5

0.12-0.22

25.0-30.3

1.4539

904L

19.0-21.0

4.0-5.0

0.15max

32.2-39.9

1.4563

Sanicro 28

24.0-26.0

3.0-4.0

0.11max

35.9-43.0

1.4547

254SMO

19.5-20.5

6.0-7.0

0.18-0.25

42.2-47.6

1.4529

1925hMo

19.0-21.0

6.0-7.0

0.15-0.25

41.2-48.1

1.4565

4565S

24.0-26.0

4.0-5.0

0.30-0.60

42.0-52.1

Duplex 1.4062

1

2202

22.0

0.4

0.20

26.5

1.4162

2101LDX

21.0-22.0

0.1-0.8

0.20-0.25

24.5-28.6

1.4362

SAF 2304

22.0-24.0

0.1-0.6

0.05-0.20

23.1-29.2

1.4462

21.0-23.0

2.5-3.5

0.10-0.22

30.8-38.1

2

24.0-26.0

3.0-4.0

0.24-0.35

> 402

1.45012

Zeron 1002

24.0-26.0

3.0-4.0

0.20-0.30

> 402

1.45072

Ferrinox 2552

24.0-26.0

3.0-4.0

0.20-0.30

> 402

1.4410

SAF 2205 2

SAF 2507

The nearest AISI grade is shown, where appropriate, otherwise a typical trade name used by some of manufacturers is shown. NS - Not specified 1 Typical composition only available 2 The “superduplex” steels in particular are subject to tighter restrictions on PREN than that implied by the minimum composition of the EN grade. For example, the equivalent ASTM grade or the specifications of the oil and gas industry e.g. NORSOK or NACE typically require a minimum of PREN =40. K03

ArcelorMittal Stainless UK Ltd

2101LDX

Outokumpu Ltd

904L

Outokumpu Ltd

254SMO 4565S

Outokumpu Ltd

SAF 2304, SAF 2205, SAF 2507, Sanicro 28

Sandvik Steel UK

Zeron 100

Rolled Alloys

http://www.bssa.org.uk/topics.php?article=111

Duplex stainless steels Typically twice the yield of austenitic stainless steels. Minimum Specified UTS typically 680 to 750N/mm2 (98.6 to 108ksi). Elongation typically > 25%. Superior corrosion resistance than a 316. Good Resistance to stress corrosion cracking in a chloride environment. Duplex materials have improved over the last decade; further additions of Nitrogen have been made improving weldability. Because of the complex nature of this material it is important that it is sourced from good quality steel mills and is properly solution annealed. Castings and possibly thick sections may not cool fast when annealed causing sigma and other deleterious phases to form. The material work hardens if cold formed; even the strain produced from welding can work harden the material particularly in multi welding. Therefore a full solution anneal is advantageous, particularly if low service temperatures are foreseen. The high strength of this material can make t fit up difficult. Usable temperature range restricted to, -50 to 280°C Used in Oil & Natural Gas production, chemical plants etc. Standard Duplex S31803 22Cr 5Ni 2.8Mo 0.15N PREn = 32-33 Super Duplex: Stronger and more corrosion resistant than standard duplex. S32760(Zeron 100) 25Cr 7.5Ni 3.5Mo 0.23N PREn = 40

Micro Of Standard Duplex Dark Areas:- Ferrite Light Areas:- Austenite

Duplex solidifies initially as ferrite, then transforms on further cooling to a matrix of ferrite and austenite. In modern raw material the balance should be 50/50 for optimum corrosion resistance, particularly resistance to stress corrosion cracking. However the materials strength is not significantly effected by the ferrite / austenite phase balance.

The main problem with Duplex is that it very easily forms brittle intermetalic phases, such as Sigma, Chi and Alpha Prime. These phases can form rapidly, typically 100 seconds at 900°C. However shorter exposure has been known to cause a drop in toughness, this has been attribute to the formation of sigma on a microscopic scale. Prolonged heating in the range 350 to 550°C can cause 475°C temper embrittlement. For this reason the maximum recommended service temperature for duplex is about 280°C. Sigma (55Fe 45Cr) can be a major problem when welding thin walled small bore pipe made of super duplex, although it can occur in thicker sections. It tends to be found in the bulk of the material rather than at the surface, therefore it probably has more effect on toughness than corrosion resistance. Sigma can also occur in thick sections, such as castings that have not been properly solution annealed (Not cooled fast enough).

However most standards accept that deleterious phases, such as sigma, chi and laves, may be tolerated if the strength and corrosion resistance are satisfactory. Nitrogen is a strong austenite former and largely responsible for the balance between ferrite and austenite phases and the materials superior corrosion resistance. Nitrogen can’t be added to filler metal, as it does not transfer across the arc. It can also be lost from molten parent metal during welding. Its loss can lead to high ferrite and reduced corrosion resistance. Nitrogen can be added to the shielding gas and backing gas, Up to about 10%; however this makes welding difficult as it can cause porosity and contamination of the Tungsten electrode unless the correct welding technique is used. Too much Nitrogen will form a layer of Austenite on the weld surface. In my experience most duplex and super duplex are TIG welded using pure argon. Backing / purge gas should contain less than 25ppm Oxygen for optimum corrosion resistance. Fast cooling from molten will promote the formation of ferrite, slow cooling will promote austenite. During welding fast cooling is most likely, therefore welding consumables usually contain up to 2 - 4% extra Nickel to promote austenite formation in the weld. Duplex should never be welded without filler metal, as this will promote excessive ferrite, unless the welded component is solution annealed. Acceptable phase balance is usually 30 – 70% Ferrite Duplex welding consumables are suitable for ing duplex to austenitic stainless steel or carbon steel; they can also be used for corrosion resistant overlays. Nickel based welding consumables can be used but the weld strength will not be as good as the parent metal, particularly on super duplex.

Low levels of austenite: - Poor toughness and general corrosion resistance.

High levels of austenite: - Some Reduction in strength and reduced resistance to stress corrosion cracking.

Good impact test results are a good indication that the material has been successfully welded. The parent metal usually exceeds 200J. The ductile to brittle transition temperature is about –50°C. The transition is not as steep as that of carbon steel and depends on the welding process used. Flux protected processes, such as MMA; tend to have a steeper transition curve and lower toughness. Multi run welds tend to promote austenite and thus exhibit higher toughness Tight controls and the use of arc monitors are recommended during welding and automatic or mechanised welding is preferred. Repair welding can seriously affect corrosion resistance and toughness; therefore any repairs should follow specially developed procedures. See BS4515 Part 2 for details. Production control test plates are recommended for all critical poduction welds. Welding procedures should be supplemented by additional tests, depending on the application and the requirements of any application code:-

A ferrite count using a Ferro scope is probably the most popular. For best accuracy the ferrite count should be performed manually and include a check for deleterious phases.

Good impact test results are also a good indication of a successful welding procedure and are mandatory in BS4515 Part 2.

A corrosion test, such as the G48 test, is highly recommended. The test may not model the exact service corrosion environment, but gives a good qualative assessment of the welds general corrosion resistance; this gives a good indication that the welding method is satisfactory. G48 test temperature for standard duplex is typically 22°C, for super duplex 35°C

Typical Welding Procedure For Zeron 100 (Super Duplex) Pipe 60mm Od x 4mm Thick Maximum Inter 100°C 1.6mm Filler Wire

Temperature at the end of welding < 250°C

85 amps 2 weld runs (Root and Cap)

Arc energy 1 to 1,5 KJ/mm

Recommended Testing

Position 6G

Travel speed 0.75 to 1 mm/sec

1. Ferric Chloride Pitting Test To ASTM G48 : Method A 2. Chemical analysis of root 3. Ferrite count http://www.gowelding.com/met/duplex.html