Case Study Of American Box Company 6t6w67

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Case Study Of American Box Company as PDF for free.

More details w3441

- Words: 1,480

- Pages: 11

For Office Use: Grade

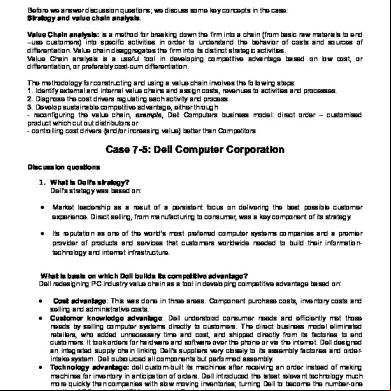

Communication For Managers Case Assignment No. 2 Case Analysis Report on

‘AMERICAN BOX COMPANY’ Submitted by: Name: Chirag Pugaliya Roll No: 171413 Section: D Batch: MBA – FT (2017-19)

Institute of Management, Nirma University Date of Submission: October 10, 2017

EXECUTIVE SUMMARY American Box Company is into business of corrugated cardboards and its boxes. It’s a family business which was currently inherited and headed by Bob Hamilton. The company witnessed fall in sales revenue and profits for last 5 years and to revert this situation they are actively seeking solution. The industry is becoming stagnant and highly competitive. The industrial manufacturers are shifting towards pressboards which ABC doesn’t manufacture. ABC has adopted no advertising policy and two distribution channels: direct and independent sales representatives but still no major advantages because of high commission paid.

Word Count: 92 words

Page 2 of 11

Case Assignment Report

Situational Analysis

American Box Company (ABC) was started by John Hamilton and currently Bob Hamilton, grandson of John, was Chairman and President of the company. It was a family business which was ed on to the third generation of family. It shows that business performed quite well and thus flourished for years. American Box Company manufactured cardboard boxes for Boston area market. 60% of sales could be attributed to Boston area because it was relatively expensive to ship cardboards to other areas. While preparing statement for the 1992 annual board meeting, Bob observed net income had fallen once again. It shows that performance of the company was deteriorating year on year. Same can be observed from Exhibit 1. Moreover Bob was cautious and trying to take preventive measures to avoid such situation in coming years. It shows that company is flexible to accommodate changes. The company was ranked as 23rd largest competitor in U.S. box market. It shows that the industry was highly competitive. The U.S. box industry is dynamic in nature but stagnant as seen in the Exhibit 2. Major players such as Morgan Box and Chase Box were expanding aggressively by purchasing local manufacturers and consolidating their operations. The market share of Morgan Box shot up from 8% in 1983 to 21% in 1991. It was result of the intensive marketing strategies and inorganic expansion strategies adopted by it i.e. mergers and acquisitions. It was a national player as a result it had high demand for its products in the market. Thus the production was also in bulk volume as a result it was enjoying economies of scale. Thus all the expenses such as advertising and shipping were proportioned to the bulk, ensuring competitive pricing. ABC mainly focused on low to medium quality corrugated cardboard and finished corrugated cardboard boxes because the industrial manufacturers were the key customers of their product whose focused on low cost of production by minimizing packaging expenses. As it was a dynamic industry, the preference of the customers (industrial manufacturers) was changing as it can be seen in Exhibit 3 that the demand for pressboard is increasing whereas the demand for corrugated products was decreasing. The ABC did not produce any box material made from pressboard. Reducing demand for corrugated boxes and the stagnant nature of the industry together resulted into the fall in net income of ABC. The cost can be broken down to following components for ABC: manufacturing, assembly, packing, marketing and fixed overheads. Marketing ed for 16.73% of the total expense incurred by the company similarly for other components it can be seen in the Exhibit 4. The revenues had fallen considerably and capacity utilization was 55% only i.e. the company was not using its resources optimally. Low demand can be a possible reason because of which the supply was also kept low resulting in low capacity utilization. ABC followed two channels for distribution i.e. direct sales force and independent representatives. Direct sales force focused on Boston Area which ed for larger sales bills whereas independent representatives were responsible for distant s which was comparatively smaller. The independent representatives contributed to sales majorly by selling boxes more as compared to boards as it can be seen from Exhibit 5. One of the possible reasons can be the higher commissions on sale of boxes. Page 3 of 11

Problem Statement The sales and thus the net income of the American Box Company were falling continuously from last 5 years. Moreover, the preference of the customers was changing from goods made of corrugated boards to higher quality goods made by pressboards. Ultimately it resulted into underutilization of manufacturing capacity which stood at 55%.

Objectives

To ensure there is no downfall in the net income in subsequent years. To increase the net income and thus, profit maximization. To improve current 55% capacity utilization rate. To outperform competitors in order to improve the market position of the company.

Options: 1. Expand to new markets. 2. Product diversification: Add pressboard goods to product portfolio. 3. Contract manufacturing for major players.

Evaluation of Options: 1. Expand to new markets: Pros: a) b) c) d)

Increased capacity utilisation. Higher sales revenues. Higher profitability. Economies of scale.

Cons: a) Higher shipping charges. b) Higher marketing expenses. c) Stiff competition from national players.

2. Product Diversification: Economies of scope

Pros: a) Sales revenue will increase. b) Market share will increase. c) Higher profitability Cons: a) Changes in machinery. b) Capital expenditure in the form of new machineries or training employees. Page 4 of 11

3. Contract Manufacturing for major players:

Pros: a) No marketing expenses. b) No additional investment. c) Technical assistance from ing parties. d) No direct competition. Cons: a) Loss of autonomy b) Loss of family heritage, since its family owned business.

Decision American Box Company should go with diversification to pressboard based goods. It may lead to capital expenditure i.e. one time big investment for altering existing machines. The expenses are fixed in nature and would be recovered gradually because of higher demand of pressboard based goods in industry. Thus it will reap benefits in longer run.

Action Plan Initially the company should alter the machines as per requirement then increase its efforts in marketing with an objective of creating awareness about its new pressboard based goods in order to get demand. Then start with production as per the demand or orders received.

Contingency Plan If product diversification plan fails then the company should go with market expansion plan i.e. try to tap the market outside the Boston area. The shipping charges would be high relatively initially but would be recovered in long run profitably because of economies of scale.

Page 5 of 11

EXHIBITS

EXHIBIT 1

ABC Sales and Profit Results ($000) Year 1988 1989 1990 1991

Sales Revenues 7210 6845 6011 5642

Profit After Taxes 633 336 279 230

9000

8000 7000 6000 5000

Profit After Taxes

4000

Sales Revenues

3000 2000 1000 0 1988

1989

1990

1991

Graphical presentation shows that profits and sales revenue declined every year 1988 onwards.

Page 6 of 11

EXHIBIT 2

Cardboard Industry Sales (tons)

Year 1988 1989 1990 1991 1992

Industry Sales 5,247,321 5,158,469 5,327,628 5,209,421 5,168,210

Industry Sales 53,50,000 53,00,000 52,50,000 52,00,000

Industry Sales

51,50,000

51,00,000 50,50,000 1988

1989

1990

1991

1992

The overall industry sales have been stagnant in the range of $5150000 to $5325000.

Page 7 of 11

Exhibit 3: Market share of different types of cardboards.

Year 1988 1989 1990 1991 1992

Corrugated (in %) 72 66 60 51 48

Pressboard (in %)

28 34 40 49 52

The market share of corrugated card board based goods decreased year on year whereas the market share for pressboard based goods increased every year.

Page 8 of 11

Exhibit: 4 Cost Elements

Expense Element Manufacturing Assembly(box only) Packing(board only) Marketing: Direct Total Sales force Rep sales commissions(boards) Rep sales commission(box) Fixed Charges Total Expenses

1992 Expenses($) 1,416,940 1,560,320 158,250 281,200 266,320 327,000 1,218,000 5,228,030

Manufacturing = 1416940*100/5228030 = 27.10% Assembly = 29.845% Packing = 3% Marketing = 16.73% Fixed Charges = 23.29%

Page 9 of 11

Exhibit 5

ABC Sales Revenues ($000)

Year 1988 1989 1990 1991 1992

Board Reps 185 210 260 321 391

Direct 2800 2526 1631 1426 955

Box Reps 3139 2862 2492 2033 1947

Total Direct 1086 1247 1628 1844 2085

7210 6845 6011 5624 5378

The sale of board by reps increased whereas sale of box decreased year on year. But overall volume of boxes sold by reps is very high.

Page 10 of 11

UNDERTAKING

To Whom It May Concern: I, Chirag Pugaliya, hereby declare that this assignment is my original work and is not copied from anyone/ anywhere. If found similar to other sources, I shall take complete responsibility of the action, taken thereof by, CFM Team.

Signature: Name: Chirag Pugaliya Roll No: 171413 Section: D Batch: MBA – FT (2017-19) Date: October 10, 2017

Page 11 of 11

Communication For Managers Case Assignment No. 2 Case Analysis Report on

‘AMERICAN BOX COMPANY’ Submitted by: Name: Chirag Pugaliya Roll No: 171413 Section: D Batch: MBA – FT (2017-19)

Institute of Management, Nirma University Date of Submission: October 10, 2017

EXECUTIVE SUMMARY American Box Company is into business of corrugated cardboards and its boxes. It’s a family business which was currently inherited and headed by Bob Hamilton. The company witnessed fall in sales revenue and profits for last 5 years and to revert this situation they are actively seeking solution. The industry is becoming stagnant and highly competitive. The industrial manufacturers are shifting towards pressboards which ABC doesn’t manufacture. ABC has adopted no advertising policy and two distribution channels: direct and independent sales representatives but still no major advantages because of high commission paid.

Word Count: 92 words

Page 2 of 11

Case Assignment Report

Situational Analysis

American Box Company (ABC) was started by John Hamilton and currently Bob Hamilton, grandson of John, was Chairman and President of the company. It was a family business which was ed on to the third generation of family. It shows that business performed quite well and thus flourished for years. American Box Company manufactured cardboard boxes for Boston area market. 60% of sales could be attributed to Boston area because it was relatively expensive to ship cardboards to other areas. While preparing statement for the 1992 annual board meeting, Bob observed net income had fallen once again. It shows that performance of the company was deteriorating year on year. Same can be observed from Exhibit 1. Moreover Bob was cautious and trying to take preventive measures to avoid such situation in coming years. It shows that company is flexible to accommodate changes. The company was ranked as 23rd largest competitor in U.S. box market. It shows that the industry was highly competitive. The U.S. box industry is dynamic in nature but stagnant as seen in the Exhibit 2. Major players such as Morgan Box and Chase Box were expanding aggressively by purchasing local manufacturers and consolidating their operations. The market share of Morgan Box shot up from 8% in 1983 to 21% in 1991. It was result of the intensive marketing strategies and inorganic expansion strategies adopted by it i.e. mergers and acquisitions. It was a national player as a result it had high demand for its products in the market. Thus the production was also in bulk volume as a result it was enjoying economies of scale. Thus all the expenses such as advertising and shipping were proportioned to the bulk, ensuring competitive pricing. ABC mainly focused on low to medium quality corrugated cardboard and finished corrugated cardboard boxes because the industrial manufacturers were the key customers of their product whose focused on low cost of production by minimizing packaging expenses. As it was a dynamic industry, the preference of the customers (industrial manufacturers) was changing as it can be seen in Exhibit 3 that the demand for pressboard is increasing whereas the demand for corrugated products was decreasing. The ABC did not produce any box material made from pressboard. Reducing demand for corrugated boxes and the stagnant nature of the industry together resulted into the fall in net income of ABC. The cost can be broken down to following components for ABC: manufacturing, assembly, packing, marketing and fixed overheads. Marketing ed for 16.73% of the total expense incurred by the company similarly for other components it can be seen in the Exhibit 4. The revenues had fallen considerably and capacity utilization was 55% only i.e. the company was not using its resources optimally. Low demand can be a possible reason because of which the supply was also kept low resulting in low capacity utilization. ABC followed two channels for distribution i.e. direct sales force and independent representatives. Direct sales force focused on Boston Area which ed for larger sales bills whereas independent representatives were responsible for distant s which was comparatively smaller. The independent representatives contributed to sales majorly by selling boxes more as compared to boards as it can be seen from Exhibit 5. One of the possible reasons can be the higher commissions on sale of boxes. Page 3 of 11

Problem Statement The sales and thus the net income of the American Box Company were falling continuously from last 5 years. Moreover, the preference of the customers was changing from goods made of corrugated boards to higher quality goods made by pressboards. Ultimately it resulted into underutilization of manufacturing capacity which stood at 55%.

Objectives

To ensure there is no downfall in the net income in subsequent years. To increase the net income and thus, profit maximization. To improve current 55% capacity utilization rate. To outperform competitors in order to improve the market position of the company.

Options: 1. Expand to new markets. 2. Product diversification: Add pressboard goods to product portfolio. 3. Contract manufacturing for major players.

Evaluation of Options: 1. Expand to new markets: Pros: a) b) c) d)

Increased capacity utilisation. Higher sales revenues. Higher profitability. Economies of scale.

Cons: a) Higher shipping charges. b) Higher marketing expenses. c) Stiff competition from national players.

2. Product Diversification: Economies of scope

Pros: a) Sales revenue will increase. b) Market share will increase. c) Higher profitability Cons: a) Changes in machinery. b) Capital expenditure in the form of new machineries or training employees. Page 4 of 11

3. Contract Manufacturing for major players:

Pros: a) No marketing expenses. b) No additional investment. c) Technical assistance from ing parties. d) No direct competition. Cons: a) Loss of autonomy b) Loss of family heritage, since its family owned business.

Decision American Box Company should go with diversification to pressboard based goods. It may lead to capital expenditure i.e. one time big investment for altering existing machines. The expenses are fixed in nature and would be recovered gradually because of higher demand of pressboard based goods in industry. Thus it will reap benefits in longer run.

Action Plan Initially the company should alter the machines as per requirement then increase its efforts in marketing with an objective of creating awareness about its new pressboard based goods in order to get demand. Then start with production as per the demand or orders received.

Contingency Plan If product diversification plan fails then the company should go with market expansion plan i.e. try to tap the market outside the Boston area. The shipping charges would be high relatively initially but would be recovered in long run profitably because of economies of scale.

Page 5 of 11

EXHIBITS

EXHIBIT 1

ABC Sales and Profit Results ($000) Year 1988 1989 1990 1991

Sales Revenues 7210 6845 6011 5642

Profit After Taxes 633 336 279 230

9000

8000 7000 6000 5000

Profit After Taxes

4000

Sales Revenues

3000 2000 1000 0 1988

1989

1990

1991

Graphical presentation shows that profits and sales revenue declined every year 1988 onwards.

Page 6 of 11

EXHIBIT 2

Cardboard Industry Sales (tons)

Year 1988 1989 1990 1991 1992

Industry Sales 5,247,321 5,158,469 5,327,628 5,209,421 5,168,210

Industry Sales 53,50,000 53,00,000 52,50,000 52,00,000

Industry Sales

51,50,000

51,00,000 50,50,000 1988

1989

1990

1991

1992

The overall industry sales have been stagnant in the range of $5150000 to $5325000.

Page 7 of 11

Exhibit 3: Market share of different types of cardboards.

Year 1988 1989 1990 1991 1992

Corrugated (in %) 72 66 60 51 48

Pressboard (in %)

28 34 40 49 52

The market share of corrugated card board based goods decreased year on year whereas the market share for pressboard based goods increased every year.

Page 8 of 11

Exhibit: 4 Cost Elements

Expense Element Manufacturing Assembly(box only) Packing(board only) Marketing: Direct Total Sales force Rep sales commissions(boards) Rep sales commission(box) Fixed Charges Total Expenses

1992 Expenses($) 1,416,940 1,560,320 158,250 281,200 266,320 327,000 1,218,000 5,228,030

Manufacturing = 1416940*100/5228030 = 27.10% Assembly = 29.845% Packing = 3% Marketing = 16.73% Fixed Charges = 23.29%

Page 9 of 11

Exhibit 5

ABC Sales Revenues ($000)

Year 1988 1989 1990 1991 1992

Board Reps 185 210 260 321 391

Direct 2800 2526 1631 1426 955

Box Reps 3139 2862 2492 2033 1947

Total Direct 1086 1247 1628 1844 2085

7210 6845 6011 5624 5378

The sale of board by reps increased whereas sale of box decreased year on year. But overall volume of boxes sold by reps is very high.

Page 10 of 11

UNDERTAKING

To Whom It May Concern: I, Chirag Pugaliya, hereby declare that this assignment is my original work and is not copied from anyone/ anywhere. If found similar to other sources, I shall take complete responsibility of the action, taken thereof by, CFM Team.

Signature: Name: Chirag Pugaliya Roll No: 171413 Section: D Batch: MBA – FT (2017-19) Date: October 10, 2017

Page 11 of 11