Consolidation Test 6gj6j

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Consolidation Test as PDF for free.

More details w3441

- Words: 2,233

- Pages: 16

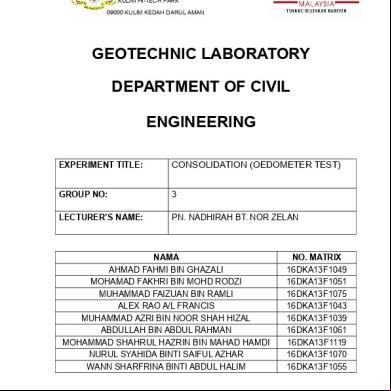

GEOTECHNICAL LABS 2014 CONSOLIDATION TEST DETERMINATION OF ONE DIMENSIONAL CONSOLIDATION PROPERTIES

ODOMETER TEST INTRODUCTION This method covers the determination of the magnitude and rate of consolidation of a saturated or near saturated soil sample in the form of a disc confined laterally, subjected to vertical axial pressure and allowed to drain freely from top and bottom surfaces. THEORY When a saturated clay-water system is subjected to an external pressure, the pressure applied is initially taken by the water in the pores resulting thereby in an excess pore water pressure. If drainage is permitted, the resulting hydraulic gradients initiate a flow of water out of the clay mass and the mass begins to compress. A portion of the applied stress is transferred to the soil skeleton which in turn causes a reduction in the in the excess pore pressure. This process involving a gradual compression occurring simultaneously with flow of water out of the mass and with a gradual transfer of the applied pressure from the pore water to the soil skeleton is called consolidation . The total compression of a saturated soil under excess effective pressure may be considered as the sum of 1. Immediate consolidation, 2. Primary consolidation, and 3. Secondary consolidation. St=si+sp+ss The portion of the settlement of a structure which occurs more or less simultaneously with the applied loads is referred to as the initial or immediate settlement. This settlement is due to the immediate compression of the soil layer under undrained condition and is calculated by assuming the soil mass to behave as an elastic soil. If the rate of compression of the soil layer is controlled solely by the resistance of the flow of water under the induced hydraulic gradients, the process is referred to as primary consolidation. The portion of the settlement that is due to the primary consolidation is called primary consolidation settlement or compression. At the present time the only theory of practical value for estimating time-dependent settlement due to volume changes, that is under primary consolidation is the one-dimensional theory. The third part of the settlement is due to secondary consolidation or compression of the clay layer. This compression is supposed to start after the primary consolidation ceases, that is after the excess pore water pressure approaches zero. It is often assumed that secondary compression proceeds linearly with the logarithm of time. However, a

F16/1334/2010

Page 1

GEOTECHNICAL LABS 2014 satisfactory treatment of this phenomenon has not been formulated for computing settlement under this category. The process opposite to consolidation is called swelling which involves an increase in the water content due an increase in the voids.

In this method the procedure depends on the soil specification classification Fine silts and clays are classified as type A soils, and coarse soils with numerous inclusions such as small stones which break or deform badly on extrusion from the sample tube are classified as type B soils. APPARATUS 1. Fixed ring type apparatus: with metal consolidation ring, bottom and top porous plates, consolidation cell, micro-meter dial gauge and a rigid device for ing the consolidation cell. 2. Apparatus for preparation and testing specimens: A jack and frame to extrude soil from sampling tube, a jig to hold the consolidation ring, a sharp thin palette/ blade, wire saws, metal straight edges, flat glass plate, vernier callipers, tins for moisture content, filter papers, stop watch, tap water, thermometer, a watch glass and specific gravity apparatus. PROCEDURE 1. SPECIMEN PREPARATION A short length of the soil sample was extruded from sample tube by means of the jack and frame and examined for soil type. A consolidation ring of suitable dimensions and the watch glass were cleaned, dried and weighed. The ring was lubricated with grease. 2. SAMPLE A representative sample for testing was extruded from the sample tube and cut off carefully to ensure the two plane surfaces of the disc of soil were parallel to each other. The thickness of the soil disc was a little greater than the height of the consolidation ring. Using the consolidation ring as the template, the disc was trimmed until it could just slid into the ring with the last fraction of soil being pared away by the cutting edge of the ring as it was pushed into the ring carefully. Any voids created were filled with the parings. The

F16/1334/2010

Page 2

GEOTECHNICAL LABS 2014 projecting bottom and top edges were then trimmed using the sharp edge to achieve level flash surfaces. Loss of moisture and soil grains was avoided at all stages. A sample of the same soil sample was set aside for specific gravity test. The thickness of the consolidation specimen was measured and the cell placed in a metal tray and weighed. 3. ASSEMBLY OF APPARATUS AND TEST PROCEDURE The dry bottom porous plate was centred in the consolidation cell and the ring complete with the specimen placed centrally on top of it with a filter paper against each face of the specimen. The top porous plate and the loading cap were then placed centrally on top. The consolidation cell complete with specimen was then placed in the bed of the loading apparatus. The counterbalanced loading beam was adjusted carefully into a loading position with the appropriate load transmitting member in with the loading cap. The gauge was clamped into position to record the relative movement between the base of the consolidation cell and the loading cap.

The OEDOMETER Loads were applied in sequence of 50, 100, 200, 400 kN/m2 The initial pressure for each loading was applied and the compression observed to ensure it was large enough to prevent swelling. The compression readings in the intervals were observed at sequence 0,0.25, 0.5, 1,2.25,4.00,6.25,9.00,12.25,16.00,20.25,25,36,49,64,81,100minutes and then up to 24 hrs, time sufficient for full consolidation.

F16/1334/2010

Page 3

GEOTECHNICAL LABS 2014 The gauge reading, time and √

were recorded to facilitate the plotting of the readings.

After each application of loading, the consolidation cell was filled with water to allow for swelling and saturation of specimen before increasing the pressure to the next higher value in the sequence. After the sample had fully consolidated under the full load increment, the pressure was released and the sample moisture content recorded. RESULTS TYPE OF SOIL : Red coffee soil SPECIFIC GRAVITY OF SOIL: 2.66 Sample thickness :19mm Moisture content at end of test: Wet soil= 136g Dry soil =100g Moisture content= 36% The results of the test Time in √time log time 50kN/m2 100kN/m2 200kN/m2 400kN/m2 min min 0 0 #NUM! 2800 2302 2155 1983 0.25 0.5 -0.60206 2725 2210 2055 1866 1 1 0 2700 2198 2045 1854 2.25 1.5 0.352183 2570 2192 2037 1846 4 2 0.60206 2360 2188 2031 1844 6.25 2.5 0.79588 2335 2185 2028 1838 9 3 0.954243 2330 2183 2026 1835 12.25 3.5 1.088136 2323 2180 2024 1833 16 4 1.20412 2320 2178 2020 1830 20.25 4.5 1.306425 2317 2176 2018 1829 25 5 1.39794 2314 2174 2016 1827 36 6 1.556303 2311 2171 2015 1825 49 7 1.690196 2308 2168 2012 1820 64 8 1.80618 2306 2165 2010 1818 81 9 1.908485 2304 2163 2008 1816 100 10 2 2303 2161 2006 1815

F16/1334/2010

Page 4

GEOTECHNICAL LABS 2014 1440

37.94733

3.158362

2302

2155

1983

1810

ANALYSIS GRAPHs OF VOID RATIO AGAINST PRESSURE The pressure void ratio curve can be obtained if the void ratio at the end of each increment of load is determined. A typical void ration pressure curve resembles the one shown below

PHASE DIAGRAM

Compressibility characteristics

Water content at end of test, w =36% Void ratio at end of test =e1=wGs(assuming saturation =100% Thickness of specimen at start of test= h0=19mm Change of thickness during test, dH= 1.98mm Void ratio at start of test=e0=e1+de, de is change in void ratio Where de = dH (

F16/1334/2010

)

Page 5

GEOTECHNICAL LABS 2014 In the test e1= 0.36x2.66 =0.9576 de = 1.98x(

)

de= 0.2277 e0=0.9576+0.2277 =1.185 de= 0.103dH ANALYSIS: COMPRESSIBILITY CHARACTERISTICS

Pressure (kN/m2)

dial gauge reading 24hr

0 50 100 200

log pressure

2800 2302

0 1.69897

2155 1983

2 2.30103

change dH in height

400 1810 2.60206 1.VOID RATIO AGAINST PRESSURE CURVE

F16/1334/2010

Total thickness de e = e0chang of sample de e in mm dH 0 0 19 0 1.185 0.996 0.996 18.004 0.10258 1.08241 8 2 0.294 1.29 17.71 0.13287 1.05213 0.344 1.634 17.366 0.16830 1.01669 2 8 0.346 1.98 17.02 0.20394 0.98106

Page 6

GEOTECHNICAL LABS 2014 1.4 1.2

void ratio,e

1 0.8 void ratiopressure curve

0.6 0.4 0.2 0 0

100

200 300 Pressure in kN/m^2

400

500

2.VOID RATIO AGAIST LOG PRESSURE

1.4

1.2

VOID RATIO, e

1

0.8 void ratio against log p

0.6

0.4

0.2

0 0

F16/1334/2010

0.5

1

LOG PRESSURE 1.5

2

2.5

3

Page 7

GEOTECHNICAL LABS 2014 DISCUSSION OF COMPRESSIBILITY CHARACTERISTICS A typical curves for void ratio against pressure and log pressure resemble the one below:

Void ratio pressure curve

void ratio log pressure curve

From the curves it can be deduced that the voids in any soil sample reduce with increased pressure loading on the soil sample. The voids at any given pressure in the regime of loading can therefore be deduced.

COEFFICIENT OF CONSOLIDATION 1. Square root of time fitting method. Curves for individual load increments were as plotted. 50 kN /m2 CURVE

F16/1334/2010

Page 8

GEOTECHNICAL LABS 2014 3000

gauge reading

2500 2000 50 kN/m^2 pressure

1500

Linear (50 kN/m^2 pressure)

1000 500 0 0

2

4

6

8

10

12

root time

2. 100kN/m2 CURVE 2320 2300 2280

gauge reading

2260 2240 2220

100kN/m^2 Linear (100kN/m^2)

2200 2180 2160 2140 2120 0

2

4

6

8

10

12

root time

F16/1334/2010

Page 9

GEOTECHNICAL LABS 2014 3 200kN/m2 curve 2180 2160 2140

gauge reading

2120 2100 2080 100kN/m^2

2060

Linear (100kN/m^2)

2040 2020 2000 1980 1960 0

2

4

6 root time

8

10

12

4.400kN/m2 curve 2000

gauge reading

1950

1900 400kN/m^2 Linear (400kN/m^2) 1850

1800

1750 0

F16/1334/2010

2

4

root6time

8

10

12

Page 10

GEOTECHNICAL LABS 2014 METHOD TWO: LOG T FITTING METHOD 1.50 kN/m2 PRESSURE

2750 2700 2650

gauge reading

2600 2550 50 kn pressure

2500 2450 2400 2350 2300 2250 0

0.5

1

1.5 log t

2

2.5

3

3.5

2.100kN/m2 pressure

2205 2200 2195

gauge reading

2190 2185 2180 2175 100kN pressure

2170 2165 2160 2155 2150

F16/1334/2010 0 0.5

1

1.5 log t

2

2.5

3

3.5

Page 11

GEOTECHNICAL LABS 2014 3. 200 kN/m2 pressure loading

2050 2040

gauge reading

2030 2020 2010 200kn pressure

2000 1990 1980 1970 0

1

2

3

4

log time

4.400kN/m2 pressure load 1860 1855 1850

gauge reading

1845 1840 1835 1830

400 pressure

1825 1820 1815 1810 1805 0

1

2

3

4

log t

F16/1334/2010

Page 12

GEOTECHNICAL LABS 2014 ANALYSIS OF THE GRAPHS USING ROOT TIME FITTING METHOD AND LOG TIME FITTING METHOD Values read from the above tables PRESSURE RANGE INITIAL COMPRESSION GAUGE READING FINAL COMPRESSION GAUGE READING THICKNESS OF SPECIMEN BEFORE INCREMENT IS APPLIED CHANGE OF THICKNESS OF SPECIMEN FINAL THICKNESS OF SPECIMEN (H1-dH) AVERAGE THICKNESS OF SPECIMEN 0.5(H1+Hf) TIME FITTING METHOD CORRECTED INITIAL COMPRESSION GAUGE READING COMPRESSION GAUGE READING AT 90% CONSOLIDATION EQUIVALENT TIME FOR d90 FROM CURVE COEFFICIENT OF CONSOLIDATION (0.111H^2/t90)M^2PER YEAR (d0-ds) in mm 10(ds-d90)/9 in mm INITIAL COMPRESSION RATIO(A/dH) PRIMARY COMPRESSION RATIO(B/dH) SECONDARY COMPRESSION RATIO(1-(ᵞo+ᵞP))

LOG t FITTING METHOD COMPRESSION GAUGE READING AT ARBTRARY TIME t COMPRESSION GAUGE READING AT 4 t CORRECTED COMPRESSION GAUGE READING(2d1d2) COMPRESSION GAUGE READING AT 100%CONSOLIDATION MEAN COMPRESSION GAUGE READING 0.5(ds+d100) EQUIVALENT TIME FOR d50 FROM CURVE COEFFICIENT OF CONSOLIDATION= 0.026H^2/t50 m^2/year d0-ds F16/1334/2010

KN/m2 d0 df H1 in mm dH Hf H in mm

50 2800 2302 19

100 2302 2155 18.004

200 2155 1983 17.71

400 1983 1810 17.366

0.996 18.004 18.502

0.294 17.71 17.857

0.344 17.366 17.538

0.346 17.02 17.193

ds

2590

2217

2065

1877

d90

2300

2216

2060

1876

t90 Cv

49 0.000775

44.89 0.000788

43.56 0.000784

46.24 0.00071

A B ᵞo ᵞp ᵞs

0.42 0.644444 0.421687 0.647033 -0.06872

0.17 0.002222 0.578231 0.007559 0.41421

0.18 0.011111 0.523256 0.0323 0.444444

0.212 0.002222 0.612717 0.006423 0.380861

d1

2450

2190

2033

1845

d2 Ds

2300 2600

2161 2219

2006 2060

1815 1875

d100

2300

2161

2012

1816

d50

2450

2190

2036

1845.5

t50 Cv A

0.5 0.5 0.4 0.4 0.0077801 0.0076581 0.0079993 0.0079214 0.4

0.166

0.19 Page 13

0.216

GEOTECHNICAL LABS 2014 ds-d100 INITIAL COMPRESSION RATIO A/dH PRIMARY COMPRESSION RATIO B/dH SECONDARY COMPRESSION RATIO 1-(ᵞo-ᵞp)

B Ro Rp Rs

0.6 0.401606 0.60241 1.200803

0.116 0.564626 0.394558 0.829932

0.096 0.552326 0.27907 0.726744

ANALYSES discussion The coefficient of consolidation, cv generally decreases as the liquid limit of soil increases. The two methods above are commonly used for determining this coefficient for each load increment from one dimension consolidation tests. The forms of theoretical and experimental curves are as shown below

1.Root time fitting method

F16/1334/2010

Page 14

0.118 0.624277 0.34104 0.716763

GEOTECHNICAL LABS 2014 2. Log Time fitting method

Hence from these curves, initial, primary and secondary consolidation can be derived as well as the consolidation coefficients for a given soil at given loadings. Compression ratios can also be deduced as on the table.

F16/1334/2010

Page 15

GEOTECHNICAL LABS 2014

From above the ranges of consolidation coefficients for different soil types is given. From the experimental results, the soil was red earth. CONCLUSION The soil can be classified as red earth. F16/1334/2010

Page 16

ODOMETER TEST INTRODUCTION This method covers the determination of the magnitude and rate of consolidation of a saturated or near saturated soil sample in the form of a disc confined laterally, subjected to vertical axial pressure and allowed to drain freely from top and bottom surfaces. THEORY When a saturated clay-water system is subjected to an external pressure, the pressure applied is initially taken by the water in the pores resulting thereby in an excess pore water pressure. If drainage is permitted, the resulting hydraulic gradients initiate a flow of water out of the clay mass and the mass begins to compress. A portion of the applied stress is transferred to the soil skeleton which in turn causes a reduction in the in the excess pore pressure. This process involving a gradual compression occurring simultaneously with flow of water out of the mass and with a gradual transfer of the applied pressure from the pore water to the soil skeleton is called consolidation . The total compression of a saturated soil under excess effective pressure may be considered as the sum of 1. Immediate consolidation, 2. Primary consolidation, and 3. Secondary consolidation. St=si+sp+ss The portion of the settlement of a structure which occurs more or less simultaneously with the applied loads is referred to as the initial or immediate settlement. This settlement is due to the immediate compression of the soil layer under undrained condition and is calculated by assuming the soil mass to behave as an elastic soil. If the rate of compression of the soil layer is controlled solely by the resistance of the flow of water under the induced hydraulic gradients, the process is referred to as primary consolidation. The portion of the settlement that is due to the primary consolidation is called primary consolidation settlement or compression. At the present time the only theory of practical value for estimating time-dependent settlement due to volume changes, that is under primary consolidation is the one-dimensional theory. The third part of the settlement is due to secondary consolidation or compression of the clay layer. This compression is supposed to start after the primary consolidation ceases, that is after the excess pore water pressure approaches zero. It is often assumed that secondary compression proceeds linearly with the logarithm of time. However, a

F16/1334/2010

Page 1

GEOTECHNICAL LABS 2014 satisfactory treatment of this phenomenon has not been formulated for computing settlement under this category. The process opposite to consolidation is called swelling which involves an increase in the water content due an increase in the voids.

In this method the procedure depends on the soil specification classification Fine silts and clays are classified as type A soils, and coarse soils with numerous inclusions such as small stones which break or deform badly on extrusion from the sample tube are classified as type B soils. APPARATUS 1. Fixed ring type apparatus: with metal consolidation ring, bottom and top porous plates, consolidation cell, micro-meter dial gauge and a rigid device for ing the consolidation cell. 2. Apparatus for preparation and testing specimens: A jack and frame to extrude soil from sampling tube, a jig to hold the consolidation ring, a sharp thin palette/ blade, wire saws, metal straight edges, flat glass plate, vernier callipers, tins for moisture content, filter papers, stop watch, tap water, thermometer, a watch glass and specific gravity apparatus. PROCEDURE 1. SPECIMEN PREPARATION A short length of the soil sample was extruded from sample tube by means of the jack and frame and examined for soil type. A consolidation ring of suitable dimensions and the watch glass were cleaned, dried and weighed. The ring was lubricated with grease. 2. SAMPLE A representative sample for testing was extruded from the sample tube and cut off carefully to ensure the two plane surfaces of the disc of soil were parallel to each other. The thickness of the soil disc was a little greater than the height of the consolidation ring. Using the consolidation ring as the template, the disc was trimmed until it could just slid into the ring with the last fraction of soil being pared away by the cutting edge of the ring as it was pushed into the ring carefully. Any voids created were filled with the parings. The

F16/1334/2010

Page 2

GEOTECHNICAL LABS 2014 projecting bottom and top edges were then trimmed using the sharp edge to achieve level flash surfaces. Loss of moisture and soil grains was avoided at all stages. A sample of the same soil sample was set aside for specific gravity test. The thickness of the consolidation specimen was measured and the cell placed in a metal tray and weighed. 3. ASSEMBLY OF APPARATUS AND TEST PROCEDURE The dry bottom porous plate was centred in the consolidation cell and the ring complete with the specimen placed centrally on top of it with a filter paper against each face of the specimen. The top porous plate and the loading cap were then placed centrally on top. The consolidation cell complete with specimen was then placed in the bed of the loading apparatus. The counterbalanced loading beam was adjusted carefully into a loading position with the appropriate load transmitting member in with the loading cap. The gauge was clamped into position to record the relative movement between the base of the consolidation cell and the loading cap.

The OEDOMETER Loads were applied in sequence of 50, 100, 200, 400 kN/m2 The initial pressure for each loading was applied and the compression observed to ensure it was large enough to prevent swelling. The compression readings in the intervals were observed at sequence 0,0.25, 0.5, 1,2.25,4.00,6.25,9.00,12.25,16.00,20.25,25,36,49,64,81,100minutes and then up to 24 hrs, time sufficient for full consolidation.

F16/1334/2010

Page 3

GEOTECHNICAL LABS 2014 The gauge reading, time and √

were recorded to facilitate the plotting of the readings.

After each application of loading, the consolidation cell was filled with water to allow for swelling and saturation of specimen before increasing the pressure to the next higher value in the sequence. After the sample had fully consolidated under the full load increment, the pressure was released and the sample moisture content recorded. RESULTS TYPE OF SOIL : Red coffee soil SPECIFIC GRAVITY OF SOIL: 2.66 Sample thickness :19mm Moisture content at end of test: Wet soil= 136g Dry soil =100g Moisture content= 36% The results of the test Time in √time log time 50kN/m2 100kN/m2 200kN/m2 400kN/m2 min min 0 0 #NUM! 2800 2302 2155 1983 0.25 0.5 -0.60206 2725 2210 2055 1866 1 1 0 2700 2198 2045 1854 2.25 1.5 0.352183 2570 2192 2037 1846 4 2 0.60206 2360 2188 2031 1844 6.25 2.5 0.79588 2335 2185 2028 1838 9 3 0.954243 2330 2183 2026 1835 12.25 3.5 1.088136 2323 2180 2024 1833 16 4 1.20412 2320 2178 2020 1830 20.25 4.5 1.306425 2317 2176 2018 1829 25 5 1.39794 2314 2174 2016 1827 36 6 1.556303 2311 2171 2015 1825 49 7 1.690196 2308 2168 2012 1820 64 8 1.80618 2306 2165 2010 1818 81 9 1.908485 2304 2163 2008 1816 100 10 2 2303 2161 2006 1815

F16/1334/2010

Page 4

GEOTECHNICAL LABS 2014 1440

37.94733

3.158362

2302

2155

1983

1810

ANALYSIS GRAPHs OF VOID RATIO AGAINST PRESSURE The pressure void ratio curve can be obtained if the void ratio at the end of each increment of load is determined. A typical void ration pressure curve resembles the one shown below

PHASE DIAGRAM

Compressibility characteristics

Water content at end of test, w =36% Void ratio at end of test =e1=wGs(assuming saturation =100% Thickness of specimen at start of test= h0=19mm Change of thickness during test, dH= 1.98mm Void ratio at start of test=e0=e1+de, de is change in void ratio Where de = dH (

F16/1334/2010

)

Page 5

GEOTECHNICAL LABS 2014 In the test e1= 0.36x2.66 =0.9576 de = 1.98x(

)

de= 0.2277 e0=0.9576+0.2277 =1.185 de= 0.103dH ANALYSIS: COMPRESSIBILITY CHARACTERISTICS

Pressure (kN/m2)

dial gauge reading 24hr

0 50 100 200

log pressure

2800 2302

0 1.69897

2155 1983

2 2.30103

change dH in height

400 1810 2.60206 1.VOID RATIO AGAINST PRESSURE CURVE

F16/1334/2010

Total thickness de e = e0chang of sample de e in mm dH 0 0 19 0 1.185 0.996 0.996 18.004 0.10258 1.08241 8 2 0.294 1.29 17.71 0.13287 1.05213 0.344 1.634 17.366 0.16830 1.01669 2 8 0.346 1.98 17.02 0.20394 0.98106

Page 6

GEOTECHNICAL LABS 2014 1.4 1.2

void ratio,e

1 0.8 void ratiopressure curve

0.6 0.4 0.2 0 0

100

200 300 Pressure in kN/m^2

400

500

2.VOID RATIO AGAIST LOG PRESSURE

1.4

1.2

VOID RATIO, e

1

0.8 void ratio against log p

0.6

0.4

0.2

0 0

F16/1334/2010

0.5

1

LOG PRESSURE 1.5

2

2.5

3

Page 7

GEOTECHNICAL LABS 2014 DISCUSSION OF COMPRESSIBILITY CHARACTERISTICS A typical curves for void ratio against pressure and log pressure resemble the one below:

Void ratio pressure curve

void ratio log pressure curve

From the curves it can be deduced that the voids in any soil sample reduce with increased pressure loading on the soil sample. The voids at any given pressure in the regime of loading can therefore be deduced.

COEFFICIENT OF CONSOLIDATION 1. Square root of time fitting method. Curves for individual load increments were as plotted. 50 kN /m2 CURVE

F16/1334/2010

Page 8

GEOTECHNICAL LABS 2014 3000

gauge reading

2500 2000 50 kN/m^2 pressure

1500

Linear (50 kN/m^2 pressure)

1000 500 0 0

2

4

6

8

10

12

root time

2. 100kN/m2 CURVE 2320 2300 2280

gauge reading

2260 2240 2220

100kN/m^2 Linear (100kN/m^2)

2200 2180 2160 2140 2120 0

2

4

6

8

10

12

root time

F16/1334/2010

Page 9

GEOTECHNICAL LABS 2014 3 200kN/m2 curve 2180 2160 2140

gauge reading

2120 2100 2080 100kN/m^2

2060

Linear (100kN/m^2)

2040 2020 2000 1980 1960 0

2

4

6 root time

8

10

12

4.400kN/m2 curve 2000

gauge reading

1950

1900 400kN/m^2 Linear (400kN/m^2) 1850

1800

1750 0

F16/1334/2010

2

4

root6time

8

10

12

Page 10

GEOTECHNICAL LABS 2014 METHOD TWO: LOG T FITTING METHOD 1.50 kN/m2 PRESSURE

2750 2700 2650

gauge reading

2600 2550 50 kn pressure

2500 2450 2400 2350 2300 2250 0

0.5

1

1.5 log t

2

2.5

3

3.5

2.100kN/m2 pressure

2205 2200 2195

gauge reading

2190 2185 2180 2175 100kN pressure

2170 2165 2160 2155 2150

F16/1334/2010 0 0.5

1

1.5 log t

2

2.5

3

3.5

Page 11

GEOTECHNICAL LABS 2014 3. 200 kN/m2 pressure loading

2050 2040

gauge reading

2030 2020 2010 200kn pressure

2000 1990 1980 1970 0

1

2

3

4

log time

4.400kN/m2 pressure load 1860 1855 1850

gauge reading

1845 1840 1835 1830

400 pressure

1825 1820 1815 1810 1805 0

1

2

3

4

log t

F16/1334/2010

Page 12

GEOTECHNICAL LABS 2014 ANALYSIS OF THE GRAPHS USING ROOT TIME FITTING METHOD AND LOG TIME FITTING METHOD Values read from the above tables PRESSURE RANGE INITIAL COMPRESSION GAUGE READING FINAL COMPRESSION GAUGE READING THICKNESS OF SPECIMEN BEFORE INCREMENT IS APPLIED CHANGE OF THICKNESS OF SPECIMEN FINAL THICKNESS OF SPECIMEN (H1-dH) AVERAGE THICKNESS OF SPECIMEN 0.5(H1+Hf) TIME FITTING METHOD CORRECTED INITIAL COMPRESSION GAUGE READING COMPRESSION GAUGE READING AT 90% CONSOLIDATION EQUIVALENT TIME FOR d90 FROM CURVE COEFFICIENT OF CONSOLIDATION (0.111H^2/t90)M^2PER YEAR (d0-ds) in mm 10(ds-d90)/9 in mm INITIAL COMPRESSION RATIO(A/dH) PRIMARY COMPRESSION RATIO(B/dH) SECONDARY COMPRESSION RATIO(1-(ᵞo+ᵞP))

LOG t FITTING METHOD COMPRESSION GAUGE READING AT ARBTRARY TIME t COMPRESSION GAUGE READING AT 4 t CORRECTED COMPRESSION GAUGE READING(2d1d2) COMPRESSION GAUGE READING AT 100%CONSOLIDATION MEAN COMPRESSION GAUGE READING 0.5(ds+d100) EQUIVALENT TIME FOR d50 FROM CURVE COEFFICIENT OF CONSOLIDATION= 0.026H^2/t50 m^2/year d0-ds F16/1334/2010

KN/m2 d0 df H1 in mm dH Hf H in mm

50 2800 2302 19

100 2302 2155 18.004

200 2155 1983 17.71

400 1983 1810 17.366

0.996 18.004 18.502

0.294 17.71 17.857

0.344 17.366 17.538

0.346 17.02 17.193

ds

2590

2217

2065

1877

d90

2300

2216

2060

1876

t90 Cv

49 0.000775

44.89 0.000788

43.56 0.000784

46.24 0.00071

A B ᵞo ᵞp ᵞs

0.42 0.644444 0.421687 0.647033 -0.06872

0.17 0.002222 0.578231 0.007559 0.41421

0.18 0.011111 0.523256 0.0323 0.444444

0.212 0.002222 0.612717 0.006423 0.380861

d1

2450

2190

2033

1845

d2 Ds

2300 2600

2161 2219

2006 2060

1815 1875

d100

2300

2161

2012

1816

d50

2450

2190

2036

1845.5

t50 Cv A

0.5 0.5 0.4 0.4 0.0077801 0.0076581 0.0079993 0.0079214 0.4

0.166

0.19 Page 13

0.216

GEOTECHNICAL LABS 2014 ds-d100 INITIAL COMPRESSION RATIO A/dH PRIMARY COMPRESSION RATIO B/dH SECONDARY COMPRESSION RATIO 1-(ᵞo-ᵞp)

B Ro Rp Rs

0.6 0.401606 0.60241 1.200803

0.116 0.564626 0.394558 0.829932

0.096 0.552326 0.27907 0.726744

ANALYSES discussion The coefficient of consolidation, cv generally decreases as the liquid limit of soil increases. The two methods above are commonly used for determining this coefficient for each load increment from one dimension consolidation tests. The forms of theoretical and experimental curves are as shown below

1.Root time fitting method

F16/1334/2010

Page 14

0.118 0.624277 0.34104 0.716763

GEOTECHNICAL LABS 2014 2. Log Time fitting method

Hence from these curves, initial, primary and secondary consolidation can be derived as well as the consolidation coefficients for a given soil at given loadings. Compression ratios can also be deduced as on the table.

F16/1334/2010

Page 15

GEOTECHNICAL LABS 2014

From above the ranges of consolidation coefficients for different soil types is given. From the experimental results, the soil was red earth. CONCLUSION The soil can be classified as red earth. F16/1334/2010

Page 16