Effect Of Filler And Aggregate On Bituminous Paving Mixes 41p37

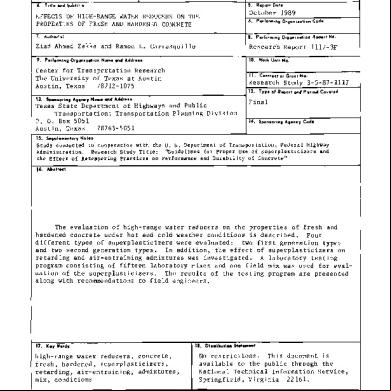

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Effect Of Filler And Aggregate On Bituminous Paving Mixes as PDF for free.

More details w3441

- Words: 1,814

- Pages: 4

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

Effect Of Filler And Aggregate On Bituminous Paving Mixes Prof. S. B. Patil1 , Avinash A. Khot2, Dhanshri P. Yadav3, Rucha B. Bachal4, Prashant M. Patil5 Dept. of civil Engineering, Sanjay Ghodawat Group Of Institutions , Maharashtra, India ---------------------------------------------------------------------***-------------------------------------------------------------------2.1. Coarse Aggregate Abstract: Smooth transport and Road networks plays vital role in the development of country. The total pavement structure "bends" or "deflects" due to traffic loads. Tire pressure and axle load increases mean that the bituminous layer near the pavement surface is exposed to higher stresses. . Suitable material combinations and modified bituminous binders have been found to result longer life for wearing courses depending upon the percentage of filler and type of fillers used. . The Marshall stabilities of mix types containing filler cement and fly ash, were found 3.62KN, 3.34KN, 3.42KN for the percentage of 10, 20, and 30 respectively which satisfy the limiting value. The Marshall stabilities of mix types containing filler cement and steel slag were found as 3.5KN, 3.7KN, 3.6KN for the percentage of 10, 20, and 30 respectively. which satisfy the limiting value Marshall Design criteria. The study indicates the possibility of using fly ash and steel slag as filler in bituminous mix.

Coarse aggregate for bituminous mix has been defined as that portion of the mixture which is retained on 2.36 mm (No. 08) sieve according to the Asphalt Institute. Basalt rock was used as coarse aggregate. It was crushed manually and brought to the sizes 25.0 mm or less. The aggregates were then sieved using U.S. standard sieves and separated out in different fractions.

Key Words: Bituminous Paving Mixes, cement, steel slag, fly ash, fine sand, aggregate. Filler, Marshall Mix Design

1.INTRODUCTION Bituminous roads are defined as the roads in the construction of which bitumen is used as binder. It consists of an intimate mixture of aggregates, filler and bitumen. The quality and life span of bituminous road is influenced by the type and amount of filler material is used. [1]The filler tends to stiffen the pavement mix by getting finely dispersed in it. Various materials such as cement, steel slag, fly ash and fine sand are normally used as filler in bituminous paving mixes. Cement, steel slag and fly ash are expensive and used for other purposes more effectively. Fine sand, fly ash, and steel slag finer than 0.090 mm sieve size appear to be suitable as filler material.

2. MATERIALS

Bituminous mixture is normally composed of aggregate and bitumen. The aggregates are generally divided into coarse, fine and filler fractions according to the size of the particles. The following sections include the description of the coarse aggregate, fine aggregate, mineral fillers and bitumen used in this study.

© 2016, IRJET

Fig.1 appearance of aggregate

2.2 fine aggregate

Aggregate ing through 2.36 mm sieve and retained on 0.090+ mm sieve was selected as fine aggregate. River sand was the source of fine aggregates.

2.3 cement Ordinary Portland cement of 53 grade is used. The specific gravity of cement 3.15.

ISO 9001:2008 Certified Journal

Page 2372

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

2.6 Fly ash The fly ash became available in coal based thermal power station. Coal is a major source of fuel for production of electricity in many countries in the world. In the process of electricity generation large quantity of fly ash gets produced and becomes available as a byproduct of coal-based power stations. It is a fine powder resulting from the combustion of powdered coal transported by the flue gases of the boiler and collected.

Fig-2. appearance of cement 2.4 Bitumen

Bitumen materials have been known and used in building and road construction since ancient times.In this study 80 – 100 grade bitumen was used.same bitumen was used for all the mixes so the type and grade of binder would be constant.

Fig-4. Appearance of thermal fly ash

3. 1 TEST ON BITUMEN 3.1.1 Penetration Test

Penetration is the consistency test used to designate grades of bitumen. It is the distance in tenths of millimeter that a standard needle will penetrate the sample under specified conditions of time, temperature and load on the needle.

3.1.2 softening Point

Fig-3. appearance of bitumen

2.5 steel slag

Steel slag is a by-product of the steel producing process, containing fused mixtures of oxides and silicates. Its highly compressed structure resulted in a very dense and hard material. It is the coarse portion of the residues produced during the separation of the molten steel from impurities in steel making furnaces

© 2016, IRJET

Test may be classed as a consistency test in that it measure the temperature at which the bituminous materials reach a given consistency as determined by the test conditions while it is applicable to semi-solid materials and is useful in characterizing bitumen minute. The temperature at which the sample sagged under the weight of the steel ball and touches the bottom of the container surface 2.5 cm below the sample was the softening point temperature.

3.1.3 Specific Gravity

Specific gravity of bitumen is defined as the ratio of mass of a given volume of substance to the mass of an equal volume of water.

ISO 9001:2008 Certified Journal

Page 2373

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

3.1.4 Viscosity Test The test is conducted mainly for determination of mixing and compaction temperature for bitumen with fly ash and steel slag as fillers.

All physical propertis were ckecked.

4. MARSHAL MIX DESIGN

3.1.5 Ductility Test

The Ductility test is again an empirical test which measures the cohesive strength of bitumen. Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking.

3.2 TEST ON COARSE AGGRAGATE

3.2.1 Impact Value Test

This test is done to determine the aggregate impact value of coarse aggregates as per IS: 2386 (Part IV) – 1963. IS Sieves of sizes – 12.5mm, 10mm and 2.36mm, A cylindrical metal measure of 75mm dia. and 50mm depth, A tamping rod of 10mm circular cross section and 230mm length, rounded at one end and Oven.

3.2.2 Pycnometer

The test was conducted to determine specific gravity of an aggregate. 3.2.3 Water Absorption Test This test helps to determine the water absorption of coarse aggregates as per IS: 2386 (Part III) – 1963.

3.2.4 Abrasion Test

3.6 TEST ON STEEL SLAG

This test helps to determine the abrasion value of coarse aggregates as per IS: 2386 (Part IV) – 1963. The apparatus used in this test are Los Angles abrasion testing machine, IS Sieve of size – 1.7mm, Abrasive charge– 12 nos. cast iron or steel spheres approximately 48mm dia. and each weighing between 390 and 445g ensuring that the total weight of charge is 5000 +25g and Oven.

Three samples casted for bitumen content as 6%, 6.5% and 7% to know the optimum binder content for the mix. The results of the Marshall test of samples and average Marshall properties of Samples prepared with conventional mix for varying bitumen contents.. 4.1 Sample preparation: 1.1200gm aggregates are weighted and heated up to 154160 degree C. 2.Bitumen is heated 175 -190 degree C. 3.Aggregates & Bitumen are mixed thoroughly until a uniform grey color is obtained. 4.Marshall mould diameter 100mm & 64mm ht compacted with 75 blows on each face. 5.Mould is taken out kept under normal laboratory temp for 12 hours. 6.It is immersed in water bath kept at a const temp 60 degrees for 30 minutes 7.Load is applied vertically at the rate of 50mm per minute. 8.The maximum load at sample fails is recorded as the Marshall Stability value. 9.Corresponding vertical strain is termed as the flow value. 10.Stability is calculated by multiplying (100/36) to the observed division to convert it into kilogram force. 11.Flow is determined by multiplying the flow value with 0.01 to convert it into millimeters.

4.2 Marshall Stability:

3.3 TESTS ON FINE AGGREGATES Following test were conducted. 1. specific gravity. 2. sieve analysis.

3.4 TEST ON CEMENT Following test were conducted on cement 1. Fineness Test 2.Consistancy test.

3.5 TEST ON FLY ASH Following test were conducted. 1 2

Soundness test Consistancy Test

© 2016, IRJET

Fig. 4.1 Variation of Marshall Stability with different binder content ISO 9001:2008 Certified Journal

Page 2374

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

4.3 Marshall Flow Value (mm): [6] [7]

[8]

[9]

and Construction. NAPA Research and Education Foundation. Lanham. Watson, D. E. and Jared, D. (1995). Stone Mastic Asphalt. Georgia Experience. Georgia Department of Transportation. USA. Mangan, D. and Butcher, M. (2004). Technical Note 16 Stone Mastic Asphalt. Australian Roads Research Boards. Australia. National Asphalt Pavement Association (NAPA). 1999. Deg and Constructing SMA Mixture: State of the Practice, QIP 122. Roberts, F. L., Mohammad, L. N., & Wang, L. B. (2002). History of hot mix asphalt mixture design in the United States. Journal of Materials in Civil Engineering, 14(4), 279-293. Wagaman, T and W.J.Stanley (2005),"Slag: The Ultimate Renewable Resource." Pit and Quarry, May 24 2007.

Fig.-6. Variation of Flow Value with different binder content

5. CONCLUSIONS Bituminous mixes containing fly ash as filler displayed maximum stability at 6.5% content of bitumen having an increasing trend up to 6.5% and then gradually decreasing, the unit weight/ bulk density also displayed a similar trend with flow value being satisfactory at 6.5% content of bitumen. Bituminous mixes containing steel slag as filler showed maximum stability at 6.5% content of bitumen displaying an ascending trend up till 6.5% and then decreasing, the flow value showed an increasing trend and similar was the trend shown by unit weight/bulk density, the percentage of air voids obtained were seen to be decreasing with increase in bitumen content thus from here we can see that at 6.5% bitumen content we are obtaining satisfactory results. From the above discussion it is evident that with further tests fly ash and steel slag generated as waste materials can be utilized effectively in the making of bitumen concrete mixes for pavement purposes.

REFERENCES

[1] Martin J Rogers(1991) , Wallace A Hugh Design and construction of Bitumen Pavements John Wiley son publications Vth edition 1991 [2] YoderE,J, .Witczak M.W(1975), Principles of Pavement Design, a. John Wiley son publications 2nd edition 1975. [3] S.S Awanthi, M.S.Amarnath & Prof A.Veeraragavan(2003) Effect of Aggregate Gradation Limits o Fatigue Life of Neat & SBS Modified Bituminous Concrete mixes. [4] D.Larson Thomas(1963), Portland Cement and Bitumen Concretes, Mc Graw Hill Publication 1963. [5] Roberts, F. L., Kandhal, P. S. and Brown, E. R. (1996). Hot Mix Asphalt Materials, Mixture Design

© 2016, IRJET

ISO 9001:2008 Certified Journal

Page 2375

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

Effect Of Filler And Aggregate On Bituminous Paving Mixes Prof. S. B. Patil1 , Avinash A. Khot2, Dhanshri P. Yadav3, Rucha B. Bachal4, Prashant M. Patil5 Dept. of civil Engineering, Sanjay Ghodawat Group Of Institutions , Maharashtra, India ---------------------------------------------------------------------***-------------------------------------------------------------------2.1. Coarse Aggregate Abstract: Smooth transport and Road networks plays vital role in the development of country. The total pavement structure "bends" or "deflects" due to traffic loads. Tire pressure and axle load increases mean that the bituminous layer near the pavement surface is exposed to higher stresses. . Suitable material combinations and modified bituminous binders have been found to result longer life for wearing courses depending upon the percentage of filler and type of fillers used. . The Marshall stabilities of mix types containing filler cement and fly ash, were found 3.62KN, 3.34KN, 3.42KN for the percentage of 10, 20, and 30 respectively which satisfy the limiting value. The Marshall stabilities of mix types containing filler cement and steel slag were found as 3.5KN, 3.7KN, 3.6KN for the percentage of 10, 20, and 30 respectively. which satisfy the limiting value Marshall Design criteria. The study indicates the possibility of using fly ash and steel slag as filler in bituminous mix.

Coarse aggregate for bituminous mix has been defined as that portion of the mixture which is retained on 2.36 mm (No. 08) sieve according to the Asphalt Institute. Basalt rock was used as coarse aggregate. It was crushed manually and brought to the sizes 25.0 mm or less. The aggregates were then sieved using U.S. standard sieves and separated out in different fractions.

Key Words: Bituminous Paving Mixes, cement, steel slag, fly ash, fine sand, aggregate. Filler, Marshall Mix Design

1.INTRODUCTION Bituminous roads are defined as the roads in the construction of which bitumen is used as binder. It consists of an intimate mixture of aggregates, filler and bitumen. The quality and life span of bituminous road is influenced by the type and amount of filler material is used. [1]The filler tends to stiffen the pavement mix by getting finely dispersed in it. Various materials such as cement, steel slag, fly ash and fine sand are normally used as filler in bituminous paving mixes. Cement, steel slag and fly ash are expensive and used for other purposes more effectively. Fine sand, fly ash, and steel slag finer than 0.090 mm sieve size appear to be suitable as filler material.

2. MATERIALS

Bituminous mixture is normally composed of aggregate and bitumen. The aggregates are generally divided into coarse, fine and filler fractions according to the size of the particles. The following sections include the description of the coarse aggregate, fine aggregate, mineral fillers and bitumen used in this study.

© 2016, IRJET

Fig.1 appearance of aggregate

2.2 fine aggregate

Aggregate ing through 2.36 mm sieve and retained on 0.090+ mm sieve was selected as fine aggregate. River sand was the source of fine aggregates.

2.3 cement Ordinary Portland cement of 53 grade is used. The specific gravity of cement 3.15.

ISO 9001:2008 Certified Journal

Page 2372

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

2.6 Fly ash The fly ash became available in coal based thermal power station. Coal is a major source of fuel for production of electricity in many countries in the world. In the process of electricity generation large quantity of fly ash gets produced and becomes available as a byproduct of coal-based power stations. It is a fine powder resulting from the combustion of powdered coal transported by the flue gases of the boiler and collected.

Fig-2. appearance of cement 2.4 Bitumen

Bitumen materials have been known and used in building and road construction since ancient times.In this study 80 – 100 grade bitumen was used.same bitumen was used for all the mixes so the type and grade of binder would be constant.

Fig-4. Appearance of thermal fly ash

3. 1 TEST ON BITUMEN 3.1.1 Penetration Test

Penetration is the consistency test used to designate grades of bitumen. It is the distance in tenths of millimeter that a standard needle will penetrate the sample under specified conditions of time, temperature and load on the needle.

3.1.2 softening Point

Fig-3. appearance of bitumen

2.5 steel slag

Steel slag is a by-product of the steel producing process, containing fused mixtures of oxides and silicates. Its highly compressed structure resulted in a very dense and hard material. It is the coarse portion of the residues produced during the separation of the molten steel from impurities in steel making furnaces

© 2016, IRJET

Test may be classed as a consistency test in that it measure the temperature at which the bituminous materials reach a given consistency as determined by the test conditions while it is applicable to semi-solid materials and is useful in characterizing bitumen minute. The temperature at which the sample sagged under the weight of the steel ball and touches the bottom of the container surface 2.5 cm below the sample was the softening point temperature.

3.1.3 Specific Gravity

Specific gravity of bitumen is defined as the ratio of mass of a given volume of substance to the mass of an equal volume of water.

ISO 9001:2008 Certified Journal

Page 2373

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

3.1.4 Viscosity Test The test is conducted mainly for determination of mixing and compaction temperature for bitumen with fly ash and steel slag as fillers.

All physical propertis were ckecked.

4. MARSHAL MIX DESIGN

3.1.5 Ductility Test

The Ductility test is again an empirical test which measures the cohesive strength of bitumen. Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking.

3.2 TEST ON COARSE AGGRAGATE

3.2.1 Impact Value Test

This test is done to determine the aggregate impact value of coarse aggregates as per IS: 2386 (Part IV) – 1963. IS Sieves of sizes – 12.5mm, 10mm and 2.36mm, A cylindrical metal measure of 75mm dia. and 50mm depth, A tamping rod of 10mm circular cross section and 230mm length, rounded at one end and Oven.

3.2.2 Pycnometer

The test was conducted to determine specific gravity of an aggregate. 3.2.3 Water Absorption Test This test helps to determine the water absorption of coarse aggregates as per IS: 2386 (Part III) – 1963.

3.2.4 Abrasion Test

3.6 TEST ON STEEL SLAG

This test helps to determine the abrasion value of coarse aggregates as per IS: 2386 (Part IV) – 1963. The apparatus used in this test are Los Angles abrasion testing machine, IS Sieve of size – 1.7mm, Abrasive charge– 12 nos. cast iron or steel spheres approximately 48mm dia. and each weighing between 390 and 445g ensuring that the total weight of charge is 5000 +25g and Oven.

Three samples casted for bitumen content as 6%, 6.5% and 7% to know the optimum binder content for the mix. The results of the Marshall test of samples and average Marshall properties of Samples prepared with conventional mix for varying bitumen contents.. 4.1 Sample preparation: 1.1200gm aggregates are weighted and heated up to 154160 degree C. 2.Bitumen is heated 175 -190 degree C. 3.Aggregates & Bitumen are mixed thoroughly until a uniform grey color is obtained. 4.Marshall mould diameter 100mm & 64mm ht compacted with 75 blows on each face. 5.Mould is taken out kept under normal laboratory temp for 12 hours. 6.It is immersed in water bath kept at a const temp 60 degrees for 30 minutes 7.Load is applied vertically at the rate of 50mm per minute. 8.The maximum load at sample fails is recorded as the Marshall Stability value. 9.Corresponding vertical strain is termed as the flow value. 10.Stability is calculated by multiplying (100/36) to the observed division to convert it into kilogram force. 11.Flow is determined by multiplying the flow value with 0.01 to convert it into millimeters.

4.2 Marshall Stability:

3.3 TESTS ON FINE AGGREGATES Following test were conducted. 1. specific gravity. 2. sieve analysis.

3.4 TEST ON CEMENT Following test were conducted on cement 1. Fineness Test 2.Consistancy test.

3.5 TEST ON FLY ASH Following test were conducted. 1 2

Soundness test Consistancy Test

© 2016, IRJET

Fig. 4.1 Variation of Marshall Stability with different binder content ISO 9001:2008 Certified Journal

Page 2374

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 05 | May-2016

p-ISSN: 2395-0072

www.irjet.net

4.3 Marshall Flow Value (mm): [6] [7]

[8]

[9]

and Construction. NAPA Research and Education Foundation. Lanham. Watson, D. E. and Jared, D. (1995). Stone Mastic Asphalt. Georgia Experience. Georgia Department of Transportation. USA. Mangan, D. and Butcher, M. (2004). Technical Note 16 Stone Mastic Asphalt. Australian Roads Research Boards. Australia. National Asphalt Pavement Association (NAPA). 1999. Deg and Constructing SMA Mixture: State of the Practice, QIP 122. Roberts, F. L., Mohammad, L. N., & Wang, L. B. (2002). History of hot mix asphalt mixture design in the United States. Journal of Materials in Civil Engineering, 14(4), 279-293. Wagaman, T and W.J.Stanley (2005),"Slag: The Ultimate Renewable Resource." Pit and Quarry, May 24 2007.

Fig.-6. Variation of Flow Value with different binder content

5. CONCLUSIONS Bituminous mixes containing fly ash as filler displayed maximum stability at 6.5% content of bitumen having an increasing trend up to 6.5% and then gradually decreasing, the unit weight/ bulk density also displayed a similar trend with flow value being satisfactory at 6.5% content of bitumen. Bituminous mixes containing steel slag as filler showed maximum stability at 6.5% content of bitumen displaying an ascending trend up till 6.5% and then decreasing, the flow value showed an increasing trend and similar was the trend shown by unit weight/bulk density, the percentage of air voids obtained were seen to be decreasing with increase in bitumen content thus from here we can see that at 6.5% bitumen content we are obtaining satisfactory results. From the above discussion it is evident that with further tests fly ash and steel slag generated as waste materials can be utilized effectively in the making of bitumen concrete mixes for pavement purposes.

REFERENCES

[1] Martin J Rogers(1991) , Wallace A Hugh Design and construction of Bitumen Pavements John Wiley son publications Vth edition 1991 [2] YoderE,J, .Witczak M.W(1975), Principles of Pavement Design, a. John Wiley son publications 2nd edition 1975. [3] S.S Awanthi, M.S.Amarnath & Prof A.Veeraragavan(2003) Effect of Aggregate Gradation Limits o Fatigue Life of Neat & SBS Modified Bituminous Concrete mixes. [4] D.Larson Thomas(1963), Portland Cement and Bitumen Concretes, Mc Graw Hill Publication 1963. [5] Roberts, F. L., Kandhal, P. S. and Brown, E. R. (1996). Hot Mix Asphalt Materials, Mixture Design

© 2016, IRJET

ISO 9001:2008 Certified Journal

Page 2375