Ftq Overview 2u2pz

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Ftq Overview as PDF for free.

More details w3441

- Words: 6,073

- Pages: 65

FTQ

SAP Course #: 62006505

First Time Quality

PPM

TIME

Revised September 11, 2006

FTQ

First Time Quality

What First Time Quality Is Why It Is Important Why We Need to Measure It How to Calculate It FTQ Deployment, Evaluation and Improvement Process Responsibilities The Structured Approach Steps The Basic Quality Tools How to Apply the Quality Tools Monitoring and Reporting Class Exercise

Revised September 11, 2006

2

FTQ

First Time Quality

What is First Time Quality? First Time Quality is a measure of the number of pieces rejected in a manufacturing process versus the total number of pieces attempted.

REJEC TS

Revised September 11, 2006

3

FTQ

First Time Quality

Define ALARM LIMITS

A structured approach

Catch and Count Defects

1

2

React to ALARM LIMITS Reaction Plan

Follow Reaction Plan

ZERO Defects Forward Initiate Structured Problem Solving Voice of the Customer Revised September 11, 2006

4

FTQ

First Time Quality

FTQ can be viewed as a two phase approach: Immediate action and containment Whenever alarm limits are exceeded Helps ensure customer protection

Continual Improvement Management objective to reduce quantity of rejects and operational cost Leadership MUST ensure, and follow-up with implementation of FTQ in their facility to be successful

Revised September 11, 2006

5

FTQ

First Time Quality

Why is FTQ important? Because if we don’t make good parts the first time, we have to “inspect in” quality We know inspection is at best 85% effective Therefore, anytime FTQ is greater than 0, we are dependent on inspection to protect the customer

To reduce manufacturing costs and defects through continual improvement (FTQ Tracker or Step Down Chart are tools to utilize)

To monitor process stability and react quickly to potential issues (Alarm limits and process monitoring sheets) Revised September 11, 2006 6

FTQ

First Time Quality

FTQ should be viewed as a tool to facilitate operational improvement in:

Quality

PPM TIME

Cost

Revised September 11, 2006

7

FTQ

First Time Quality

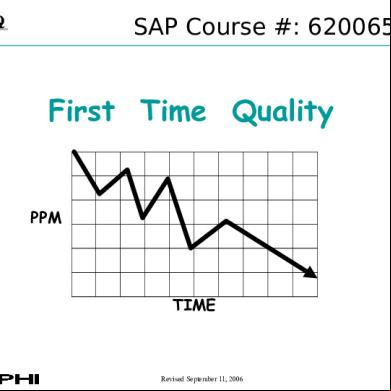

FTQ is Key to our Success to turn this

into this!

PPM

TIME

Revised September 11, 2006

8

FTQ

First Time Quality

Why does FTQ need to be measured? Main

Reasons:

It

is the early signal that a process is out of control It allows us to respond to problems internally before they reach our customers It measures improvement from corrective actions implemented

If we don’t fix our quality problems internally, we will never be able to fix our external customer issues Revised September 11, 2006

9

FTQ

First Time Quality The fatal flaw of inspection Catch Defects

Inspection is like a filter.

D

D

Filter

Inspection misses some defects Defects not caught

D

Problem

Voice of the Customer

Revised September 11, 2006

10

FTQ

Inspection Exercise

Count the Number of ‘F’s contained in the paragraph below (60sec)

THE NECESSITY OF TRAINING FARMHANDS FOR FIRST CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK IS FOREMOST IN THE MINDS OF FARM OWNERS. SINCE THE FOREFATHERS OF THE FARM OWNERS TRAINED THE FARMHANDS FOR THE FIRSTCLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK. THE FARMS OWNERS FEEL THEY SHOULD CARRY ON WITH THE FAMILY TRADITION OF TRAINING FARMHANDS OF FIRST-CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK BECAUSE THEY BELIEVE IT IS THE BASIS OF GOOD FUNDAMENTAL FARM MANAGEMENT.

Revised September 11, 2006

11

FTQ

Inspection Exercise

Total of 36 F’s THE NECESSITY OF TRAINING FARMHANDS FOR FIRST CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK IS FOREMOST IN THE MINDS OF FARM OWNERS. SINCE THE FOREFATHERS OF THE FARM OWNERS TRAINED THE FARMHANDS FOR THE FIRSTCLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK. THE FARMS OWNERS FEEL THEY SHOULD CARRY ON WITH THE FAMILY TRADITION OF TRAINING FARMHANDS OF FIRST-CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK BECAUSE THEY BELIEVE IT IS THE BASIS OF GOOD FUNDAMENTAL FARM MANAGEMENT.

Revised September 11, 2006

12

FTQ

First Time Quality

How is First Time Quality calculated? FTQ is reported in parts per million (PPM) defective It can be measured at any step in the manufacturing process where parts are rejected especially where the defect is originated. It is calculated by counting the number of pieces rejected versus the total number of pieces attempted The total number of pieces attempted includes all good pieces produced plus all pieces rejected Pieces rejected are all parts scrapped or reworked prior to usage by subsequent processes. The actual calculation looks like this:

Number of Pcs. Rejected Total Number of Pcs. Attempted

X 1,000,000 = FTQ PPM

Revised September 11, 2006

13

FTQ

First Time Quality

How is First Time Quality calculated?

Tally Sheet

An example at the cell level: Cell “A” has six operations

1

2

3

4

5

28

6 16

Reject data is collected at operations 3 and 6. Cell “A” produced 1040 good pieces during the first hour. At OP.3, 28 pcs. were rejected. At OP.6, 16 pcs. were rejected. What is the FTQ in PPM for Cell A? 28 + 16 44 1040 + 28 + 16 =1084 X 1,000,000 = 40,590 PPM FTQ Revised September 11, 2006

14

FTQ

First Time Quality

What First Time Quality Is Why It Is Important Why We Need to Measure It How to Calculate It

FTQ Deployment, Evaluation and Improvement Process Responsibilities The Structured Approach The Basic Quality Tools How to Apply the Quality Tools Monitoring and Reporting

Class Exercise

Revised September 11, 2006

15

FTQ

FTQ Improvement Process Stakeholder involvement CELL

Plant A CELL 1

2

3

4

5

6

7

8

N

Plt B

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

Plt C TEAM LEADER

CROSSFUNCTIONAL TEAM

PROCESS ENGINEERING

OPERATIONS

PRODUCT ENGINEERING

Potential : - TEAM LEADER - OPERATIONS/MANUFACTURING - QUALITY ENGINEER - PROCESS ENGINEER - INDUSTRIAL ENGINEER - MAINTENANCE - PRODUCT ENGINEER - SUPPLIER QUALITY

QUALITY

MAINTENANCE

PC&L

PLANT MANAGER

Revised September 11, 2006

16

FTQ

FTQ Improvement Process Typical Responsibilities Flowchart CFT

PROCESS

QUALITY ENGINEER

OPERATIONS

PROCESS ENGINEER

PRODUCT ENGINEER

MAINTENANCE

INDUSTRIAL ENGINEER

DEFINE REACTION PLAN & ALARM LIMITS

IDENTIFY & COUNT DISCREPANT PARTS

IMPLEMENT ALARM REACTION PLAN (IF EXCEEDED) RECORD DATA

ANALYZE DATA

SELECT & PLAN IMPROVEMENT

IMPLEMENT IMPROVEMENT

EVALUATE

INSTITUTIONALIZE LESSONS LEARNED

LEAD

Revised September 11, 2006

17

FTQ

FTQ Implementation

Delphi SQ or SDE Responsibilities Ensure supplier understands, and if necessary, obtains appropriate training on the FTQ Improvement process Monitor implementation progress during FTQ activities Conduct 5 step site evaluation for FTQ implementation Set stage for improvement activities Outline plan of attack Document improvement plan ( i.e. through an A3) Revised September 11, 2006

18

FTQ

FTQ Improvement Process Overall

IMPLEMENT ALARM REACTION PLAN

NO

YES DEFINE REACTION PLAN & ALARM LIMITS

IDENTIFY & COUNT DISCREPANT PARTS

ALARM EXCEEDED ?

NO

RECORD DATA

SELECT & PLAN IMPROVEMENT

IMPLEMENT IMPROVEMENT

EVALUATE

NEW LEVEL OF QUALITY?

YES

INSTITUTIONALIZE LESSONS LEARNED TOOLS: - PFMEA - PROCESS CONTROL PLAN - LOOK-ACROSS-CHART - 5 WHY'S

TOOL: TOOL: TOOLS: EXAMPLES: TOOLS: - CROSS-FUNCTIONAL - ACTION PLAN - RUN CHART - CONTROL - PARETO - CAUSE & EFFECT TEAMS CHART (FISHBONE) - CHANGE BOARDS - CONCENTRATION - RPN REDUCTION DIAGRAM - STATISTICAL ENGINEERING - FLOW CHART PROJECTS - GATE CHART - HISTOGRAM - SCATTER ACTION PLAN: DIAGRAM - WHAT, WHEN, WHO - CHECK SHEET - 5 WHY'S

TOOLS FOR IDENTIFICATION: - PROCESS CONTROL PLAN - BOUNDARY SAMPLES TOOLS FOR COUNTING: - PARTS COUNTERS - TALLY SHEETS - SIZED CONTAINERS

IDENTIFY

SELECT

ANALYZE DATA

CONTAIN

ANALYZE

PLAN

IMPLEMENT

CORRECT

EVALUATE

PREVENT

Delphi Problem Solving Process Revised September 11, 2006

19

FTQ

First Time Quality

Define ALARM LIMITS

A structured approach

Catch and Count Defects

1

2

React to ALARM LIMITS Reaction Plan

Follow Reaction Plan

ZERO Defects Forward Initiate Structured Problem Solving Voice of the Customer Revised September 11, 2006

20

FTQ

FTQ Improvement Process

Define alarm limits and reaction plan Alarm limits must be based on current process reject data or available data from Machine qualification runs, Run at Rate, historical data, etc. Need to collect data long enough to ensure you understand the types and quantities of defects that fall out from your current process. Limits for common cause (chronic) rejects may be statistically calculated Understand process and expected defects (what types and quantities of defects) Determine the process normal range of variation by charting the reject data over time

Revised September 11, 2006

21

FTQ

FTQ Improvement Process

Define alarm limits and reaction plan Limits for special cause (non chronic) rejects must be set at one piece Limits must be communicated to operators so they can react If alarm limits are exceeded, there must be a documented reaction plan which includes containment of product and process corrections. Employees may find clever ways to identify abnormal process state as the process matures The immediate action taken is the most important step in containing the problem until it has been eliminated and verified Revised September 11, 2006

22

Alarm Limit Calculation using np Chart

FTQ 20 25 18

NP Charting for FTQ

Defects Pareto

100

16 20 14

UCL=16.1

90 80

Nonconforming

UCL=

12 15 10

70

avg= 9.8

60

108 6

avg=

54 2

LCL=

50 40 30

LCL=3.4

20 10

00

0

8 14 9 1017 11 1322 14 11 2 32 4 35 64 7 5 8 9 6 10 11712 13 15 16 18 1912 20 21 23 2415 25 16 17 18 19 20 21 22 23 24 25 Subgroups ( Days) Hours or Days Non-conforming 18 Sample Size (Avg) Defects wing mark wing / body fold wrong paint dot paint location wrong or no clip Total nonconforming: Production PPM Defective np

1 8

2 10

3 9

4 11

5 9

2 3 2

1 2 2 3 2 10 18

5 1 1

4 2 5

2 5 1

11 18

1 9 20

1 8 18

2 9 19

np1+np2+…..npk

6 8

1 2 4 1 8 18

7 6

8 8

9 7

10 11

11 12

12 11

13 13

14 18

15 17

16 12

17 9

18 10

1 2

3 2

4 2

2 5 3

1 3 4

3 4 3 3

2 1 6 2 6 17 17

1 4

2 5

3 8 18

1 5 3 7 2 18 18

1 2 8

2 1 6 17

2 2 5 2 1 12 18

2 2 9 18

2 1 10 19

1 7 18

1 11 19

3 11 19

13 19

1 12 18

19 7

20 8

21 5

6 1

7 1

1 3

7 18

8 20

1 5 18

22 9

23 11

24 8

25 7

1 1 1 2 4 9 18

1 2 4 4

2 3

1 3 3

3 8 18

7 19

11 20

where np= number nonconformin, k= subgroups

k n = avg sample size (18) np

"=SUM(C3:AA3)/25" np = number nonconforming

UCLnp k = subgroups UCLnp = 0

(25)

__ np = np1+np2+…..npk LCLnp LCLnp = k 0

UCL=np + 3* = 0 =

0

LCL=np - 3* Revised September 11, 2006

(np(1-np/n)) (np(1-np/n))

23

FTQ

Alarm Limit Calculation using np calculation and Stop Light control method A

1.-

Broken case

B

CELL:

Quality

(U C L )

T u rn o s

DEFECTS

In d ic a d o r

DEPT:

AREA: HVAC

Monday

259W

Tuesday

WEEK: Wednesday

to Feb 5

Jan 30 Thursday

8 8

C A

2.-

Wrong assembled case

B C A

3.-

Damaged cases

B C A

4.-

Missing screws

B C A

5.-

Warped cases

B C A

6.-

Vibration

B C A

7.-

Wrong assembled thermistor

B C A

8.-

Damaged evaporator pipes

B C A

9.-

Damaged mounting plate

B C A

10.- Air leak

B C

11.11.11.12.12.12.-

5 5 5 4 4 4 4 4 4 4 4 4 3 3 3 3 3 3 3 3 3 2 2 2 2 2 2

A B

NC

C A B

NC

C

Instructions 1.-

Mark to be used by each shift:

GP-12 X (Red X)

Final insp./Rework/Process/Scrap

X (Black X)

2.- Team: a) Shift leader will give follow up to each defect recorded. b) When a defect reaches the yellow color limits, apply supervisor's reaction protocol; if the red co reaction protocol. c) The Quality auditor is responsible for checking the squares with the appropriate color in case that a defect is detected. d) This format is for one we responsible for archiving this format on a weekly basis. f) The Quality engineer is responsible for monthly updating the reaction and control limits. 3.-

Control limits calculation for non chronic defects (np):

a)

b)

Calcular avarage del numero por defecto np = np1 + np2 + np3 + ….. + npk np = Son los numeros de defectos de cada subgrupo de k k Calcular limites de control superior e inferior (UCL, LCL)

UCL

=

np + 3

np ( 1 - np / n )

=

np

+

3

np ( 1 - p )

Revised September 11, 2006

24

FTQ

Example: Rejected Parts Counter

Quality Alarm Limit: The counter is flipped for each defect. The color will change from green to yellow to red. Yellow indicates action required and red will stop the process. Small white tags are placed with each defective part to identify the specific defect. Revised September 11, 2006

25

FTQ

FTQ Improvement Process

Identify and count rejected parts Operators must have sufficient tools and skills in order to identify product discrepancies It is recommended that rejected parts be removed from the cell station at a defined frequency so they may be counted and categorized by defect or rework code Tools to enhance the operator’s ability to identify product discrepancies include:

Boundary Samples Illustrations Photographs Gages

Tools for counting rejected parts include: Parts Counters Tally Sheets Sized Containers

Revised September 11, 2006

26

FTQ

FTQ Improvement Process Special Cause (Non-chronic) Rejects

FAILURE REACT

MODE HAS A KNOWN ASSIGNABLE CAUSE.

AT FIRST OCCURRENCE

IMMEDIATE BASED

FIX / CORRECTION.

ON OPERATOR CERTIFICATION PROGRAM.

STOP & Contain FIX

S F S

START

Revised September 11, 2006

27

FTQ

FTQ Improvement Process Common Cause (Chronic) Rejects

FAILURE MODE ROOT CAUSE NOT IDENTIFIED.* NO IMMEDIATE FIX / CORRECTION. USE PROBLEM SOLVING METHODOLOGIES (RED X / 6 SIGMA) REACTION BASED ON CONTROL LIMITS (STATISTICALLY CALCULATED) np chart

np

15

LCLnp

10

np-bar

5

UCLnp

0 0

10

20

30

40

Lot number

DEFECTS SEGREGATION PROCESS VERIFICATION • Or many sources or causes ( i.e. technology STOP and Contain inherent defects or defects caused by many sources of a root cause such as contamination/foreign material.) No known immediate fix is available to eliminate root cause of defect. Revised September 11, 2006

S F S

FIX START

28

FTQ

FTQ Improvement Process

Implement Alarm Reaction Plan if Limit Exceeded Reaction Plan: Yes

Alarm Limit Exceeded? Contain Investigate

Containment Plan

Implement Containment Plan Until Problem Fixed Revised September 11, 2006

29

FTQ

FTQ Improvement Process

Record Data Data must be recorded and plotted over time: At the cell level, the number of pieces rejected shall be recorded by defect category at a defined frequency. This data must be used to react to abnormal process conditions (process monitoring) Since the area of opportunity varies from sample to sample, the reject count must be converted into a rate (FTQ PPM) prior to charting Each area should have a performance tracking board that would reflect the manufacturing FTQ information by shift Revised September 11, 2006

30

FTQ

FTQ Improvement Process

Analyze Data

The basic quality tools are: Flow Charting Check Sheets Pareto Cause and Effect Run Chart Histogram Scatter Diagram Control Chart

Revised September 11, 2006

31

FTQ

First Time Quality Process

Initiate Structured Problem Solving Understand Defects and Decide the Order of Priority:

Problems 4

1

2

3

3

2

2

2

1

1

1

1

A B C D

Assign problems to Cross-Functional Group: 1

Select and Plan the Improvement: 1

2

Right Information 2

2

1

Responsible Team Works Problems

Right Cause 3 Right Timing

DEFECT 1. ---------------------2. ---------------------3. ----------------------

Fix the Biggest Problems First: Revised September 11, 2006

32

FTQ

FTQ Improvement Process

Analyze Data

Problem Identification

Flowchart Brainstorming

Problem Analysis

Pareto Chart Cause & Effect Control Chart Check Sheet Run Chart Stratification

Histogram Scatter Diagram Process Capability

Charts can be used for different purposes in various stages of the problem-solving process The tools included in the intersecting portion of this diagram can be used in both the problem identification and problem analysis phase of problem solving Revised September 11, 2006

33

FTQ

Histogram FTQ Tools

A histogram is a specialized type of bar chart. Individual data points are grouped together in classes, so that you can get an idea of how frequently data in each class occur in the data set. High bars indicate more points in a class, and low bars indicate fewer points Revised September 11, 2006

34

FTQ

Pareto FTQ Chart Tools

Pareto charts are used to display the Pareto principle in action, arranging data so that the few vital factors that are causing most of the problems reveal themselves. Concentrating improvement efforts on these few will have a greater impact and be more cost-effective than undirected efforts.

Revised September 11, 2006

35

FTQ

FTQDiagram Tools Scatter

Scatter Plots (also called scatter diagrams) are used to investigate the possible relationship between two variables that both relate to the same "event." A straight line of best fit (using the least squares method) is often included.

Revised September 11, 2006

36

FTQ

Control Charts FTQ Tools

The point of making control charts is to look at variation, seeking special causes and tracking common causes.

Revised September 11, 2006

37

FTQ

Flow Charting FTQ Tools

Flowcharts are maps or graphical representations of a process. They are particularly useful for displaying how a process currently functions or could ideally function. Flowcharts can help you see whether the steps of a process are logical, uncover problems or miscommunications, define the boundaries of a process, and develop a common base of knowledge about a process. Flowcharting a process often brings to light redundancies, delays, dead ends, and indirect paths that would otherwise remain unnoticed or ignored.

Revised September 11, 2006

38

FTQ

Check FTQSheets Tools

Check sheets are employed to compliance and ensure specific events are completed in the timing and sequence required.

Revised September 11, 2006

39

FTQ

Cause Effect FTQ&Tools

The cause and effect diagram is used to explore all the potential or real causes (or inputs) that result in a single effect (or output). Causes are arranged according to their level of importance or detail, resulting in a depiction of relationships and hierarchy of events. This can help you search for root causes, identify areas where there may be problems, and compare the relative importance of different causes.

Example Cause & Effect Diagram (Fishbone)

Revised September 11, 2006

40

FTQ

Run Charts FTQ Tools

Run charts (often known as line graphs outside the quality management field) display process performance over time. Upward and downward trends, cycles, and large aberrations may be spotted and investigated further. In a run chart, events, shown on the y axis, are graphed against a time period on the x axis.

Revised September 11, 2006

41

First Time Quality Manager Audit Checklist Example

FTQ

FIRST TIME QUALITY AUDIT CHECKLIST

Supplier:

Date:

Location:

Duns:

Part No./Description:

Auditor/Title:

Yes

A.) Define Reaction Plan & Alarm Limits.

No

Comments:

1. Are the alarm limits established based on current process rejects data? 2. Are the alarm limits communicated to operators? 3. Is the reaction plan established by defect? 4. Has the P the FTQ information for Chronic Rejects, KPCs and QCIs? B.) Identify and Count Rejected Parts. . Does the operator have sufficient tools and skills in order to 1.

Yes

Comments:

No

Comments:

Yes

No

Comments:

Yes

No

Comments:

Yes

No

Comments:

identify product discrpancys? 2. Are rejected parts removed from cell station on the established frequency basis?

m a Yes

C.) Record Data 1. Is the FTQ trend chart in PPM ‘s by cell and shift?

x E

e l p No

2. Is the FTQ “Tri Chart” or “Gate Chart” used as standards to record the data?

D.) Implement Alarm Reaction Plan if Limit Exceeded. (Max- Min) 1. Is there an evidence of reaction plan implementation? E.) Select Plan Improvement and Implementation?

1. Is there an evidence of an improvement plan developed? 2. Are corrective actions been implemented? F.) Evaluate 1. Was the record data up-dated to reflect the corrective actions effect? 2. If corrective actions were effective new alarm limits were established?

Revised September 11, 2006

42

FTQ

Additional tools to Facilitate FTQ Improvement

Quality Tools Statistical Engineering to develop solutions 6 Sigma Shainin

Lean Tools Value Stream Mapping Workplace Organization Error Proofing

Revised September 11, 2006

43

FTQ

FTQ Improvement Process

Select and Plan Improvement After FTQ problems have been identified through data analysis, improvement plans must be developed A recommended template has been provided to track implementation status of corrective actions (FTQ Tracker or Step Down Chart) To be make problem solving truly effective, standard work must be utilized. Standard work is like a recipe: varying method and content will not yield same results!

Revised September 11, 2006

44

FTQ

FTQ Improvement Process

Implement and Evaluate Once the Corrective Action has been implemented, the data must be evaluated for trends or shifts Did the problem stay “killed?” Can you turn the problem on and off? If so, change alarm limits and update the documentation This is one of the reasons it is so important to collect data over time Without data there is no way to evaluate the impact of the corrective action on the process If no significant reduction in FTQ PPM is observed, then it is possible the cause was misidentified Revised September 11, 2006

45

FTQ

5 Step Site Evaluation Plan

1 Understand the Value Stream

1. Walk the Value Stream and OBSERVE (5S, standardization, training, metrics, etc.)

2 Pareto Customer Issues

2. Does standardization exist in facility?

1. Pareto customer issues by systemic root causes from past (6-12 mo) of Problem Cases - Input for improvement priorities

3. Review using PFD or Current State Value Stream Maps as needed. Identify Kaizen opportunities.

2. What systems are in place to identify and improve the top issues daily, weekly, and/or monthly?

3 Review Internal Issues

1. Review pareto of internal issues from past 6-12 mo (FTQ, scrap, rejects, audits) 2. What systems are in place to identify and improve the top issues daily, weekly, and/or monthly?

4 Review Other Improvement Activities

1. What other continual Improvement Activities are in progress? 2. How were the activities selected? 3. How is the effectiveness of the activities measured?

Revised September 11, 2006

5 FTQ Process

1. Implement FTQ Improvement Process 2. Prioritize, assign resp., and set target dates for action items 3. Use A3 format to document the plan

46

FTQ

5 Step Site Evaluation Plan

Example: Customer Issues Problem Case Problem Descriptions (Jan03 - Mar03) 7 6 5 4 3 2

(1 ) 1 0 O th e rs

P a rts n o t d is p e n s in g

C o re w id th in c o rre c t

W ro n g b a rc o d e p rin te d

W ro n g c o p y

S m e a re d g ra p h ic s

B a rc o d e n o t re a d in g

C o v is in t la te re s p o n s e

W ound w ro n g

L a te S h ip m e n t

0

W ro n g in fo o n c a rto n la b e l

1

Proble m Case Root Cause s - Syste mic Issue s (Jan03-Mar03)

16

12

8

4

0 Lack of standardized instructions (press setup; f inishing)

No formal system Lack of standard Inadequate fin to manage process f or goods inv levels; customer issues containment No re-order points

Poor Mtrl ID

No PPAP submittal tracking system

Lack of understanding customer ship requirements (Overship)

Revised September 11, 2006

Transmission system f ailure; No system to assure functionality

APQP failure; No system to ctrl Print revisions requirements not f ully review ed

47

FTQ

5 Step Site Evaluation Plan

Example: First Time Quality (internal) First Time Quality - July 2003 62, 849 PPM 25000

PPM

20000 15000 10000

Die Cut

W rink les

Hous ek eeping / 5S

Regis tration

S tic k y

P roc es s / S etup

0

Ink / P rint Q uallity

5000

Next steps: 1. Determine root cause / systemic issue 2. Pareto 3. Attack top 70~80%

FTQ Per Press # (July 2003) 20000 18000 16000

PPM

14000 12000 10000 8000 6000 4000 2000 0 6

1

8

3

NR

7

2

4

5

Press #

Revised September 11, 2006

48

FTQ

FTQ Improvement Process

Institutionalize Lessons Learned and Look Across Lessons Learned must be incorporated into all existing documentation. Then Look Across to ensure implementation in all applicable processes, products. DFMEA’s Process Flow Diagram PFMEA’s Process Control Plans Process Routings Operating Instructions Employee Instructions Product Drawings Tool Drawings Total Productive Maintenance (T.P.M.) Boundary Samples

Revised September 11, 2006

49

FTQ

Alarm Limit Calculation using np Chart- Class Exercise

Class Exercise (notes contain details)

Revised September 11, 2006

50

FTQ

First Time Quality

How is First Time Quality calculated?

Tally Sheet

An example at the cell level: Cell “A” has six operations

1

2

3

4

5

28

6 16

Reject data is collected at operations 3 and 6. Cell “A” produced 1040 good pieces during the first hour. At OP.3, 28 pcs. were rejected. At OP.6, 16 pcs. were rejected. What is the FTQ in PPM for Cell A? 28 + 16 44 1040 + 28 + 16 =1084 X 1,000,000 = 40,590 PPM FTQ Revised September 11, 2006

51

Alarm Limit Calculation using np Chart- Class Exercise

FTQ

NP Charting for FTQ

25

Defects Pareto

100 90

20

80

Nonconforming

UCL=

70

15

60

avg=

10

50 40 30

LCL=

5

20 10

0

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Subgroups ( Days) Hours or Days Non-conforming 18 Sample Size (Avg) Defects wing mark wing / body fold wrong paint dot paint location wrong or no clip Total nonconforming: Production PPM Defective np

1 8

2 10

3 9

4 11

5 9

2 3 2

1 2 2 3 2 10 18

5 1 1

4 2 5

2 5 1

11 18

1 9 20

1 8 18

2 9 19

np1+np2+…..npk

n = avg sampleksize (18)

6 8

1 2 4 1 8 18

7 6

8 8

9 7

10 11

11 12

12 11

13 13

14 18

15 17

16 12

17 9

18 10

1 2

3 2

4 2

2 5 3

1 3 4

3 4 3 3

2 1 6 2 6 17 17

1 4

2 5

3 8 18

1 5 3 7 2 18 18

1 2 8

2 1 6 17

2 2 5 2 1 12 18

2 2 9 18

2 1 10 19

1 7 18

1 11 19

3 11 19

13 19

1 12 18

19 7

20 8

21 5

6 1

7 1

1 3

7 18

8 20

1 5 18

22 9

23 11

24 8

25 7

1 1 1 2 4 9 18

1 2 4 4

2 3

1 3 3

3 8 18

7 19

11 20

where np= number nonconformin, k= subgroups

Reference Attribute Data, AIAG SPC Manual, page 111

np

"=SUM(C3:AA3)/25" np = number nonconforming

k = subgroups (25)

UCLnp __ UCLnp =

0

LCLnp =

0

np = np1+np2+…..npk k LCLnp

UCL=np + 3* = 0 =

0

LCL=np - 3* Revised September 11, 2006

(np(1-np/n)) (np(1-np/n))

52

FTQ Tools

FTQ

FTQ - Performance Tracking 2004 CY FTQ Performance

FTQ

10000 9000 8000 7000 6000 5000 4000 3000 2000 1000 0

Projection

2003 Dec Final Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

FTQ Value (PPM)

Goal

Monthly Values

Daily Values

2004 CY FTQ Performance Data

FTQ Projection Goal

2003 Dec Final Jan Feb Mar Apr 9000 8000 7000 6000 8000 6500 6000 4500 4500 4500

May 5000 5500 4500

Revised September 11, 2006

Jun 4000 5000 4500

Jul 3000 4500 4500

Aug 3000 4500 4500

3000 4000 4500

54

FTQ

FTQ - Performance Tracking

FTQ In this row put in actual monthly values for FTQ PPM. Chart below will automatically generate and will automatically show up in FTQ display format tab. You can print out the FTQ Display tab to post on you cell " Glass Wall"

FTQ Projection Goal

Year-End Final %: Put in 2003 month of December FTQ value in PPM here

2003 Dec Final Jan Feb Mar Apr May Jun Jul Aug 9000 8000 7000 6000 5000 4000 3000 3000 3000 8000 6500 6000 5500 5000 4500 4500 4000 4500 4500 4500 4500 4500 4500 4500 4500

Goal: Forecast Put in your Forecast by month here. Forecast line will automatically be plotted above.

Put in your year end goal. Corporate goal is a minimum of 50% from December month actual in previous year

Revised September 11, 2006

55

FTQ

FTQ - Top 5 Issues

800 325

120

Branch out of tolerance

Unseated Ternimals

400

Missing Components

575

Damaged Terminals

1000 800 600 400 200 0

Crossed Wires

PPM

FTQ Top 5 Pareto

Cell/Process

Top 5 Quality Defects Revised September 11, 2006

56

FTQ FTQ Tools – Step Down Chart FTQ IMPROVEMENT PROCESS - STEP DOWN CHART Supplier DUNs #

Supplier Name Oct-04

FTQ of Relevant Processes contributing to Delphi APR/WAR/ LP/ FTQ

Supplier

Nov-04

Dec-04

Metric

Start Past 6 Month Ave.

Actual

Target

PPM

5.80

4.7

5.0

10

15.0

(per month)

(monthly average)

Number of Defects

17

(per month)

(monthly average)

FTQ - Process 1

10300

(per month)

(monthly average)

FTQ - Process 4

9700

(per month)

(monthly average)

FTQ - Process 5

1400

(per month)

(monthly average)

FTQ - Process 6

14400

(per month)

(monthly average)

FTQ - Process 9

400

(per month)

(monthly average)

(per month)

(monthly average)

9500

Jan-05

Actual

Target

4.86

4.5

10

13.0

Actual

Target

3

4.0

7

10.0

Feb-05 Actual

Target

(per month)

Metric PPM CYTD

CS

36200

7.0

8500

6300 6600

7500

1100

1100

1300

6500 1200

1200

5500

12000

1000 8500

11000

900 7900

10000

700

320

400

9000 600

33400

33200

(monthly average)

Start Month Status

360

8000

Level 2

27100

25500

27220

24080

20940

Red / Green will indicate whether targets are met

Action Item List Color Code:

Level 1

Level 2

(number new i nitiated) (number of open)

Action item target dates met Action item target dates not met No actions items assigned for this month

Delphi Single Point SQE Name Phone Number

Delphi Purchasing Name Phone Number

Delphi SQ Champion Name Phone Number

240

30360

Current Month Status

6.0 Level 1

3.0

8300

280

FTQ - 5 Processes Total

Actual

7300 7300

900

Target

Apr-05

8.0

9500

2000

Actual

9300 9200

11400

Mar-05

3.5

10000 9500

9600

Kickoff Date

Supplier Name Phone Number

Revised September 11, 2006

57

FTQ

FTQ Tools

FTQ IMPROVEMENT PROCESS - ACTION PLAN

Target Dates

Action Items List Item

Resp

Plan

Impl.

Issue Identified

Action Plan Implemented

Action Plan Proposed

Issue Resolved

Actual Completion Dates Plan

Impl.

Comments

Process 1 Top Defect Action Items

Process 4 Top Defect Action items

Process 6 Top Defect Action items

Process 9 Top Defect Action items

Revised September 11, 2006

58

FTQ FTQ PPM by Issue Pending Actions to address Top 5 Issues Issue Problem Discription Crossed Wires 800 Damaged Terminals 575 Unseated Ternimals 400 Missing Components 325 Branch out of Tolerance 120 99 Issue 6 80 Issue 7 70 Issue 8

Action Plans to Address Top 5 Issues Corrective Action Planned Start Date

mments on each column noted above in red. Mouse over to see.

Target Date

Status

FTQ Impact

Owner(s)

= On track to meet target date = Off track to meet target date by < 1 month = No Plan or off track to meet target date >1 month These have to pasted into the cells in column H above manually. Revised September 11, 2006

59

FTQ

Wrap Up Quiz

Class participants complete FTQ Quiz(10 minutes)

Review Responses

Revised September 11, 2006

60

FTQ

FTQ Quiz Responses

First Time Quality (FTQ) is an improvement measurement of PPM reduction over time . We measure FTQ by counting the number of pieces rejected versus the total number of pieces attempted. If we don’t make good parts the first time, we have to inspect in quality. Inspection is only 85% effective at best. FTQ is a tool to facilitate our operational improvement in quality and cost. Inspection is like a filter, and will miss some defects. If we don’t fix our quality problems internally, we will never be able to fix our external customer issues. Number of pieces rejected /Total number of pieces attempted X 1,000,000 = FTQ PPM Revised September 11, 2006

61

FTQ

FTQ Quiz Responses

The most important step in containing the problem is the immediate action taken, which leads to the elimination of the problem. Non-chronic rejects require immediate reaction at the first occurrence. Chronic rejects are those whose failure mode root cause has not been identified or fixed. When alarm limit is exceeded, the reaction plan must be implemented, and we implement a containment plan until the problem is fixed. One example of a basic quality tool used to analyze data is a Pareto chart. The tool used to track implementation status of corrective action and improvement is the FTQ Tracker (or Step Down Chart). All existing documentation must be updated in order to institutionalize lessons learned. Revised September 11, 2006

62

FTQ

Closing Comments - FTQ Improvement Process

Implement Improvement Work the Action Plan Update plan as required Document improvements

Revised September 11, 2006

63

FTQ

Closing Comments - FTQ Improvement Process

Delphi’s Suppliers are responsible for their sub-tier suppliers: Roll the FTQ process out to sub-tier suppliers to help them gain the improvement benefits and to lower the probability of your company receiving nonconforming parts

Revised September 11, 2006

64

FTQ

FTQ Expectations & Key Points

FTQ is a Requirement: A FTQ Process, that Monitors & Controls at the point of build. Set FTQ Alarm Limits to “1” reject for all safety critical features. Set FTQ Alarm Limits to “1” reject for all non-chronic(special cause) failures Reaction Plans include extra containment to Protect the Customer. Customer notification evaluated by engineering on special cause events. FTQ Reduction through a Rolling Top 5 or equivalent process. Delphi Tier 1 suppliers ensure FTQ is correctly implemented Delphi Customer Specific Requirement 7.3.6.3: Product Approval Process, “The supplier is expected to develop and implement a FTQ process with appropriate alarms and reaction plans defined.” Goal is Zero Incidents, Zero Spills, Zero Defects to our Plants. Revised September 11, 2006

65

SAP Course #: 62006505

First Time Quality

PPM

TIME

Revised September 11, 2006

FTQ

First Time Quality

What First Time Quality Is Why It Is Important Why We Need to Measure It How to Calculate It FTQ Deployment, Evaluation and Improvement Process Responsibilities The Structured Approach Steps The Basic Quality Tools How to Apply the Quality Tools Monitoring and Reporting Class Exercise

Revised September 11, 2006

2

FTQ

First Time Quality

What is First Time Quality? First Time Quality is a measure of the number of pieces rejected in a manufacturing process versus the total number of pieces attempted.

REJEC TS

Revised September 11, 2006

3

FTQ

First Time Quality

Define ALARM LIMITS

A structured approach

Catch and Count Defects

1

2

React to ALARM LIMITS Reaction Plan

Follow Reaction Plan

ZERO Defects Forward Initiate Structured Problem Solving Voice of the Customer Revised September 11, 2006

4

FTQ

First Time Quality

FTQ can be viewed as a two phase approach: Immediate action and containment Whenever alarm limits are exceeded Helps ensure customer protection

Continual Improvement Management objective to reduce quantity of rejects and operational cost Leadership MUST ensure, and follow-up with implementation of FTQ in their facility to be successful

Revised September 11, 2006

5

FTQ

First Time Quality

Why is FTQ important? Because if we don’t make good parts the first time, we have to “inspect in” quality We know inspection is at best 85% effective Therefore, anytime FTQ is greater than 0, we are dependent on inspection to protect the customer

To reduce manufacturing costs and defects through continual improvement (FTQ Tracker or Step Down Chart are tools to utilize)

To monitor process stability and react quickly to potential issues (Alarm limits and process monitoring sheets) Revised September 11, 2006 6

FTQ

First Time Quality

FTQ should be viewed as a tool to facilitate operational improvement in:

Quality

PPM TIME

Cost

Revised September 11, 2006

7

FTQ

First Time Quality

FTQ is Key to our Success to turn this

into this!

PPM

TIME

Revised September 11, 2006

8

FTQ

First Time Quality

Why does FTQ need to be measured? Main

Reasons:

It

is the early signal that a process is out of control It allows us to respond to problems internally before they reach our customers It measures improvement from corrective actions implemented

If we don’t fix our quality problems internally, we will never be able to fix our external customer issues Revised September 11, 2006

9

FTQ

First Time Quality The fatal flaw of inspection Catch Defects

Inspection is like a filter.

D

D

Filter

Inspection misses some defects Defects not caught

D

Problem

Voice of the Customer

Revised September 11, 2006

10

FTQ

Inspection Exercise

Count the Number of ‘F’s contained in the paragraph below (60sec)

THE NECESSITY OF TRAINING FARMHANDS FOR FIRST CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK IS FOREMOST IN THE MINDS OF FARM OWNERS. SINCE THE FOREFATHERS OF THE FARM OWNERS TRAINED THE FARMHANDS FOR THE FIRSTCLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK. THE FARMS OWNERS FEEL THEY SHOULD CARRY ON WITH THE FAMILY TRADITION OF TRAINING FARMHANDS OF FIRST-CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK BECAUSE THEY BELIEVE IT IS THE BASIS OF GOOD FUNDAMENTAL FARM MANAGEMENT.

Revised September 11, 2006

11

FTQ

Inspection Exercise

Total of 36 F’s THE NECESSITY OF TRAINING FARMHANDS FOR FIRST CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK IS FOREMOST IN THE MINDS OF FARM OWNERS. SINCE THE FOREFATHERS OF THE FARM OWNERS TRAINED THE FARMHANDS FOR THE FIRSTCLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK. THE FARMS OWNERS FEEL THEY SHOULD CARRY ON WITH THE FAMILY TRADITION OF TRAINING FARMHANDS OF FIRST-CLASS FARMS IN THE FATHERLY HANDLING OF FARM LIVESTOCK BECAUSE THEY BELIEVE IT IS THE BASIS OF GOOD FUNDAMENTAL FARM MANAGEMENT.

Revised September 11, 2006

12

FTQ

First Time Quality

How is First Time Quality calculated? FTQ is reported in parts per million (PPM) defective It can be measured at any step in the manufacturing process where parts are rejected especially where the defect is originated. It is calculated by counting the number of pieces rejected versus the total number of pieces attempted The total number of pieces attempted includes all good pieces produced plus all pieces rejected Pieces rejected are all parts scrapped or reworked prior to usage by subsequent processes. The actual calculation looks like this:

Number of Pcs. Rejected Total Number of Pcs. Attempted

X 1,000,000 = FTQ PPM

Revised September 11, 2006

13

FTQ

First Time Quality

How is First Time Quality calculated?

Tally Sheet

An example at the cell level: Cell “A” has six operations

1

2

3

4

5

28

6 16

Reject data is collected at operations 3 and 6. Cell “A” produced 1040 good pieces during the first hour. At OP.3, 28 pcs. were rejected. At OP.6, 16 pcs. were rejected. What is the FTQ in PPM for Cell A? 28 + 16 44 1040 + 28 + 16 =1084 X 1,000,000 = 40,590 PPM FTQ Revised September 11, 2006

14

FTQ

First Time Quality

What First Time Quality Is Why It Is Important Why We Need to Measure It How to Calculate It

FTQ Deployment, Evaluation and Improvement Process Responsibilities The Structured Approach The Basic Quality Tools How to Apply the Quality Tools Monitoring and Reporting

Class Exercise

Revised September 11, 2006

15

FTQ

FTQ Improvement Process Stakeholder involvement CELL

Plant A CELL 1

2

3

4

5

6

7

8

N

Plt B

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

Plt C TEAM LEADER

CROSSFUNCTIONAL TEAM

PROCESS ENGINEERING

OPERATIONS

PRODUCT ENGINEERING

Potential : - TEAM LEADER - OPERATIONS/MANUFACTURING - QUALITY ENGINEER - PROCESS ENGINEER - INDUSTRIAL ENGINEER - MAINTENANCE - PRODUCT ENGINEER - SUPPLIER QUALITY

QUALITY

MAINTENANCE

PC&L

PLANT MANAGER

Revised September 11, 2006

16

FTQ

FTQ Improvement Process Typical Responsibilities Flowchart CFT

PROCESS

QUALITY ENGINEER

OPERATIONS

PROCESS ENGINEER

PRODUCT ENGINEER

MAINTENANCE

INDUSTRIAL ENGINEER

DEFINE REACTION PLAN & ALARM LIMITS

IDENTIFY & COUNT DISCREPANT PARTS

IMPLEMENT ALARM REACTION PLAN (IF EXCEEDED) RECORD DATA

ANALYZE DATA

SELECT & PLAN IMPROVEMENT

IMPLEMENT IMPROVEMENT

EVALUATE

INSTITUTIONALIZE LESSONS LEARNED

LEAD

Revised September 11, 2006

17

FTQ

FTQ Implementation

Delphi SQ or SDE Responsibilities Ensure supplier understands, and if necessary, obtains appropriate training on the FTQ Improvement process Monitor implementation progress during FTQ activities Conduct 5 step site evaluation for FTQ implementation Set stage for improvement activities Outline plan of attack Document improvement plan ( i.e. through an A3) Revised September 11, 2006

18

FTQ

FTQ Improvement Process Overall

IMPLEMENT ALARM REACTION PLAN

NO

YES DEFINE REACTION PLAN & ALARM LIMITS

IDENTIFY & COUNT DISCREPANT PARTS

ALARM EXCEEDED ?

NO

RECORD DATA

SELECT & PLAN IMPROVEMENT

IMPLEMENT IMPROVEMENT

EVALUATE

NEW LEVEL OF QUALITY?

YES

INSTITUTIONALIZE LESSONS LEARNED TOOLS: - PFMEA - PROCESS CONTROL PLAN - LOOK-ACROSS-CHART - 5 WHY'S

TOOL: TOOL: TOOLS: EXAMPLES: TOOLS: - CROSS-FUNCTIONAL - ACTION PLAN - RUN CHART - CONTROL - PARETO - CAUSE & EFFECT TEAMS CHART (FISHBONE) - CHANGE BOARDS - CONCENTRATION - RPN REDUCTION DIAGRAM - STATISTICAL ENGINEERING - FLOW CHART PROJECTS - GATE CHART - HISTOGRAM - SCATTER ACTION PLAN: DIAGRAM - WHAT, WHEN, WHO - CHECK SHEET - 5 WHY'S

TOOLS FOR IDENTIFICATION: - PROCESS CONTROL PLAN - BOUNDARY SAMPLES TOOLS FOR COUNTING: - PARTS COUNTERS - TALLY SHEETS - SIZED CONTAINERS

IDENTIFY

SELECT

ANALYZE DATA

CONTAIN

ANALYZE

PLAN

IMPLEMENT

CORRECT

EVALUATE

PREVENT

Delphi Problem Solving Process Revised September 11, 2006

19

FTQ

First Time Quality

Define ALARM LIMITS

A structured approach

Catch and Count Defects

1

2

React to ALARM LIMITS Reaction Plan

Follow Reaction Plan

ZERO Defects Forward Initiate Structured Problem Solving Voice of the Customer Revised September 11, 2006

20

FTQ

FTQ Improvement Process

Define alarm limits and reaction plan Alarm limits must be based on current process reject data or available data from Machine qualification runs, Run at Rate, historical data, etc. Need to collect data long enough to ensure you understand the types and quantities of defects that fall out from your current process. Limits for common cause (chronic) rejects may be statistically calculated Understand process and expected defects (what types and quantities of defects) Determine the process normal range of variation by charting the reject data over time

Revised September 11, 2006

21

FTQ

FTQ Improvement Process

Define alarm limits and reaction plan Limits for special cause (non chronic) rejects must be set at one piece Limits must be communicated to operators so they can react If alarm limits are exceeded, there must be a documented reaction plan which includes containment of product and process corrections. Employees may find clever ways to identify abnormal process state as the process matures The immediate action taken is the most important step in containing the problem until it has been eliminated and verified Revised September 11, 2006

22

Alarm Limit Calculation using np Chart

FTQ 20 25 18

NP Charting for FTQ

Defects Pareto

100

16 20 14

UCL=16.1

90 80

Nonconforming

UCL=

12 15 10

70

avg= 9.8

60

108 6

avg=

54 2

LCL=

50 40 30

LCL=3.4

20 10

00

0

8 14 9 1017 11 1322 14 11 2 32 4 35 64 7 5 8 9 6 10 11712 13 15 16 18 1912 20 21 23 2415 25 16 17 18 19 20 21 22 23 24 25 Subgroups ( Days) Hours or Days Non-conforming 18 Sample Size (Avg) Defects wing mark wing / body fold wrong paint dot paint location wrong or no clip Total nonconforming: Production PPM Defective np

1 8

2 10

3 9

4 11

5 9

2 3 2

1 2 2 3 2 10 18

5 1 1

4 2 5

2 5 1

11 18

1 9 20

1 8 18

2 9 19

np1+np2+…..npk

6 8

1 2 4 1 8 18

7 6

8 8

9 7

10 11

11 12

12 11

13 13

14 18

15 17

16 12

17 9

18 10

1 2

3 2

4 2

2 5 3

1 3 4

3 4 3 3

2 1 6 2 6 17 17

1 4

2 5

3 8 18

1 5 3 7 2 18 18

1 2 8

2 1 6 17

2 2 5 2 1 12 18

2 2 9 18

2 1 10 19

1 7 18

1 11 19

3 11 19

13 19

1 12 18

19 7

20 8

21 5

6 1

7 1

1 3

7 18

8 20

1 5 18

22 9

23 11

24 8

25 7

1 1 1 2 4 9 18

1 2 4 4

2 3

1 3 3

3 8 18

7 19

11 20

where np= number nonconformin, k= subgroups

k n = avg sample size (18) np

"=SUM(C3:AA3)/25" np = number nonconforming

UCLnp k = subgroups UCLnp = 0

(25)

__ np = np1+np2+…..npk LCLnp LCLnp = k 0

UCL=np + 3* = 0 =

0

LCL=np - 3* Revised September 11, 2006

(np(1-np/n)) (np(1-np/n))

23

FTQ

Alarm Limit Calculation using np calculation and Stop Light control method A

1.-

Broken case

B

CELL:

Quality

(U C L )

T u rn o s

DEFECTS

In d ic a d o r

DEPT:

AREA: HVAC

Monday

259W

Tuesday

WEEK: Wednesday

to Feb 5

Jan 30 Thursday

8 8

C A

2.-

Wrong assembled case

B C A

3.-

Damaged cases

B C A

4.-

Missing screws

B C A

5.-

Warped cases

B C A

6.-

Vibration

B C A

7.-

Wrong assembled thermistor

B C A

8.-

Damaged evaporator pipes

B C A

9.-

Damaged mounting plate

B C A

10.- Air leak

B C

11.11.11.12.12.12.-

5 5 5 4 4 4 4 4 4 4 4 4 3 3 3 3 3 3 3 3 3 2 2 2 2 2 2

A B

NC

C A B

NC

C

Instructions 1.-

Mark to be used by each shift:

GP-12 X (Red X)

Final insp./Rework/Process/Scrap

X (Black X)

2.- Team: a) Shift leader will give follow up to each defect recorded. b) When a defect reaches the yellow color limits, apply supervisor's reaction protocol; if the red co reaction protocol. c) The Quality auditor is responsible for checking the squares with the appropriate color in case that a defect is detected. d) This format is for one we responsible for archiving this format on a weekly basis. f) The Quality engineer is responsible for monthly updating the reaction and control limits. 3.-

Control limits calculation for non chronic defects (np):

a)

b)

Calcular avarage del numero por defecto np = np1 + np2 + np3 + ….. + npk np = Son los numeros de defectos de cada subgrupo de k k Calcular limites de control superior e inferior (UCL, LCL)

UCL

=

np + 3

np ( 1 - np / n )

=

np

+

3

np ( 1 - p )

Revised September 11, 2006

24

FTQ

Example: Rejected Parts Counter

Quality Alarm Limit: The counter is flipped for each defect. The color will change from green to yellow to red. Yellow indicates action required and red will stop the process. Small white tags are placed with each defective part to identify the specific defect. Revised September 11, 2006

25

FTQ

FTQ Improvement Process

Identify and count rejected parts Operators must have sufficient tools and skills in order to identify product discrepancies It is recommended that rejected parts be removed from the cell station at a defined frequency so they may be counted and categorized by defect or rework code Tools to enhance the operator’s ability to identify product discrepancies include:

Boundary Samples Illustrations Photographs Gages

Tools for counting rejected parts include: Parts Counters Tally Sheets Sized Containers

Revised September 11, 2006

26

FTQ

FTQ Improvement Process Special Cause (Non-chronic) Rejects

FAILURE REACT

MODE HAS A KNOWN ASSIGNABLE CAUSE.

AT FIRST OCCURRENCE

IMMEDIATE BASED

FIX / CORRECTION.

ON OPERATOR CERTIFICATION PROGRAM.

STOP & Contain FIX

S F S

START

Revised September 11, 2006

27

FTQ

FTQ Improvement Process Common Cause (Chronic) Rejects

FAILURE MODE ROOT CAUSE NOT IDENTIFIED.* NO IMMEDIATE FIX / CORRECTION. USE PROBLEM SOLVING METHODOLOGIES (RED X / 6 SIGMA) REACTION BASED ON CONTROL LIMITS (STATISTICALLY CALCULATED) np chart

np

15

LCLnp

10

np-bar

5

UCLnp

0 0

10

20

30

40

Lot number

DEFECTS SEGREGATION PROCESS VERIFICATION • Or many sources or causes ( i.e. technology STOP and Contain inherent defects or defects caused by many sources of a root cause such as contamination/foreign material.) No known immediate fix is available to eliminate root cause of defect. Revised September 11, 2006

S F S

FIX START

28

FTQ

FTQ Improvement Process

Implement Alarm Reaction Plan if Limit Exceeded Reaction Plan: Yes

Alarm Limit Exceeded? Contain Investigate

Containment Plan

Implement Containment Plan Until Problem Fixed Revised September 11, 2006

29

FTQ

FTQ Improvement Process

Record Data Data must be recorded and plotted over time: At the cell level, the number of pieces rejected shall be recorded by defect category at a defined frequency. This data must be used to react to abnormal process conditions (process monitoring) Since the area of opportunity varies from sample to sample, the reject count must be converted into a rate (FTQ PPM) prior to charting Each area should have a performance tracking board that would reflect the manufacturing FTQ information by shift Revised September 11, 2006

30

FTQ

FTQ Improvement Process

Analyze Data

The basic quality tools are: Flow Charting Check Sheets Pareto Cause and Effect Run Chart Histogram Scatter Diagram Control Chart

Revised September 11, 2006

31

FTQ

First Time Quality Process

Initiate Structured Problem Solving Understand Defects and Decide the Order of Priority:

Problems 4

1

2

3

3

2

2

2

1

1

1

1

A B C D

Assign problems to Cross-Functional Group: 1

Select and Plan the Improvement: 1

2

Right Information 2

2

1

Responsible Team Works Problems

Right Cause 3 Right Timing

DEFECT 1. ---------------------2. ---------------------3. ----------------------

Fix the Biggest Problems First: Revised September 11, 2006

32

FTQ

FTQ Improvement Process

Analyze Data

Problem Identification

Flowchart Brainstorming

Problem Analysis

Pareto Chart Cause & Effect Control Chart Check Sheet Run Chart Stratification

Histogram Scatter Diagram Process Capability

Charts can be used for different purposes in various stages of the problem-solving process The tools included in the intersecting portion of this diagram can be used in both the problem identification and problem analysis phase of problem solving Revised September 11, 2006

33

FTQ

Histogram FTQ Tools

A histogram is a specialized type of bar chart. Individual data points are grouped together in classes, so that you can get an idea of how frequently data in each class occur in the data set. High bars indicate more points in a class, and low bars indicate fewer points Revised September 11, 2006

34

FTQ

Pareto FTQ Chart Tools

Pareto charts are used to display the Pareto principle in action, arranging data so that the few vital factors that are causing most of the problems reveal themselves. Concentrating improvement efforts on these few will have a greater impact and be more cost-effective than undirected efforts.

Revised September 11, 2006

35

FTQ

FTQDiagram Tools Scatter

Scatter Plots (also called scatter diagrams) are used to investigate the possible relationship between two variables that both relate to the same "event." A straight line of best fit (using the least squares method) is often included.

Revised September 11, 2006

36

FTQ

Control Charts FTQ Tools

The point of making control charts is to look at variation, seeking special causes and tracking common causes.

Revised September 11, 2006

37

FTQ

Flow Charting FTQ Tools

Flowcharts are maps or graphical representations of a process. They are particularly useful for displaying how a process currently functions or could ideally function. Flowcharts can help you see whether the steps of a process are logical, uncover problems or miscommunications, define the boundaries of a process, and develop a common base of knowledge about a process. Flowcharting a process often brings to light redundancies, delays, dead ends, and indirect paths that would otherwise remain unnoticed or ignored.

Revised September 11, 2006

38

FTQ

Check FTQSheets Tools

Check sheets are employed to compliance and ensure specific events are completed in the timing and sequence required.

Revised September 11, 2006

39

FTQ

Cause Effect FTQ&Tools

The cause and effect diagram is used to explore all the potential or real causes (or inputs) that result in a single effect (or output). Causes are arranged according to their level of importance or detail, resulting in a depiction of relationships and hierarchy of events. This can help you search for root causes, identify areas where there may be problems, and compare the relative importance of different causes.

Example Cause & Effect Diagram (Fishbone)

Revised September 11, 2006

40

FTQ

Run Charts FTQ Tools

Run charts (often known as line graphs outside the quality management field) display process performance over time. Upward and downward trends, cycles, and large aberrations may be spotted and investigated further. In a run chart, events, shown on the y axis, are graphed against a time period on the x axis.

Revised September 11, 2006

41

First Time Quality Manager Audit Checklist Example

FTQ

FIRST TIME QUALITY AUDIT CHECKLIST

Supplier:

Date:

Location:

Duns:

Part No./Description:

Auditor/Title:

Yes

A.) Define Reaction Plan & Alarm Limits.

No

Comments:

1. Are the alarm limits established based on current process rejects data? 2. Are the alarm limits communicated to operators? 3. Is the reaction plan established by defect? 4. Has the P the FTQ information for Chronic Rejects, KPCs and QCIs? B.) Identify and Count Rejected Parts. . Does the operator have sufficient tools and skills in order to 1.

Yes

Comments:

No

Comments:

Yes

No

Comments:

Yes

No

Comments:

Yes

No

Comments:

identify product discrpancys? 2. Are rejected parts removed from cell station on the established frequency basis?

m a Yes

C.) Record Data 1. Is the FTQ trend chart in PPM ‘s by cell and shift?

x E

e l p No

2. Is the FTQ “Tri Chart” or “Gate Chart” used as standards to record the data?

D.) Implement Alarm Reaction Plan if Limit Exceeded. (Max- Min) 1. Is there an evidence of reaction plan implementation? E.) Select Plan Improvement and Implementation?

1. Is there an evidence of an improvement plan developed? 2. Are corrective actions been implemented? F.) Evaluate 1. Was the record data up-dated to reflect the corrective actions effect? 2. If corrective actions were effective new alarm limits were established?

Revised September 11, 2006

42

FTQ

Additional tools to Facilitate FTQ Improvement

Quality Tools Statistical Engineering to develop solutions 6 Sigma Shainin

Lean Tools Value Stream Mapping Workplace Organization Error Proofing

Revised September 11, 2006

43

FTQ

FTQ Improvement Process

Select and Plan Improvement After FTQ problems have been identified through data analysis, improvement plans must be developed A recommended template has been provided to track implementation status of corrective actions (FTQ Tracker or Step Down Chart) To be make problem solving truly effective, standard work must be utilized. Standard work is like a recipe: varying method and content will not yield same results!

Revised September 11, 2006

44

FTQ

FTQ Improvement Process

Implement and Evaluate Once the Corrective Action has been implemented, the data must be evaluated for trends or shifts Did the problem stay “killed?” Can you turn the problem on and off? If so, change alarm limits and update the documentation This is one of the reasons it is so important to collect data over time Without data there is no way to evaluate the impact of the corrective action on the process If no significant reduction in FTQ PPM is observed, then it is possible the cause was misidentified Revised September 11, 2006

45

FTQ

5 Step Site Evaluation Plan

1 Understand the Value Stream

1. Walk the Value Stream and OBSERVE (5S, standardization, training, metrics, etc.)

2 Pareto Customer Issues

2. Does standardization exist in facility?

1. Pareto customer issues by systemic root causes from past (6-12 mo) of Problem Cases - Input for improvement priorities

3. Review using PFD or Current State Value Stream Maps as needed. Identify Kaizen opportunities.

2. What systems are in place to identify and improve the top issues daily, weekly, and/or monthly?

3 Review Internal Issues

1. Review pareto of internal issues from past 6-12 mo (FTQ, scrap, rejects, audits) 2. What systems are in place to identify and improve the top issues daily, weekly, and/or monthly?

4 Review Other Improvement Activities

1. What other continual Improvement Activities are in progress? 2. How were the activities selected? 3. How is the effectiveness of the activities measured?

Revised September 11, 2006

5 FTQ Process

1. Implement FTQ Improvement Process 2. Prioritize, assign resp., and set target dates for action items 3. Use A3 format to document the plan

46

FTQ

5 Step Site Evaluation Plan

Example: Customer Issues Problem Case Problem Descriptions (Jan03 - Mar03) 7 6 5 4 3 2

(1 ) 1 0 O th e rs

P a rts n o t d is p e n s in g

C o re w id th in c o rre c t

W ro n g b a rc o d e p rin te d

W ro n g c o p y

S m e a re d g ra p h ic s

B a rc o d e n o t re a d in g

C o v is in t la te re s p o n s e

W ound w ro n g

L a te S h ip m e n t

0

W ro n g in fo o n c a rto n la b e l

1

Proble m Case Root Cause s - Syste mic Issue s (Jan03-Mar03)

16

12

8

4

0 Lack of standardized instructions (press setup; f inishing)

No formal system Lack of standard Inadequate fin to manage process f or goods inv levels; customer issues containment No re-order points

Poor Mtrl ID

No PPAP submittal tracking system

Lack of understanding customer ship requirements (Overship)

Revised September 11, 2006

Transmission system f ailure; No system to assure functionality

APQP failure; No system to ctrl Print revisions requirements not f ully review ed

47

FTQ

5 Step Site Evaluation Plan

Example: First Time Quality (internal) First Time Quality - July 2003 62, 849 PPM 25000

PPM

20000 15000 10000

Die Cut

W rink les

Hous ek eeping / 5S

Regis tration

S tic k y

P roc es s / S etup

0

Ink / P rint Q uallity

5000

Next steps: 1. Determine root cause / systemic issue 2. Pareto 3. Attack top 70~80%

FTQ Per Press # (July 2003) 20000 18000 16000

PPM

14000 12000 10000 8000 6000 4000 2000 0 6

1

8

3

NR

7

2

4

5

Press #

Revised September 11, 2006

48

FTQ

FTQ Improvement Process

Institutionalize Lessons Learned and Look Across Lessons Learned must be incorporated into all existing documentation. Then Look Across to ensure implementation in all applicable processes, products. DFMEA’s Process Flow Diagram PFMEA’s Process Control Plans Process Routings Operating Instructions Employee Instructions Product Drawings Tool Drawings Total Productive Maintenance (T.P.M.) Boundary Samples

Revised September 11, 2006

49

FTQ

Alarm Limit Calculation using np Chart- Class Exercise

Class Exercise (notes contain details)

Revised September 11, 2006

50

FTQ

First Time Quality

How is First Time Quality calculated?

Tally Sheet

An example at the cell level: Cell “A” has six operations

1

2

3

4

5

28

6 16

Reject data is collected at operations 3 and 6. Cell “A” produced 1040 good pieces during the first hour. At OP.3, 28 pcs. were rejected. At OP.6, 16 pcs. were rejected. What is the FTQ in PPM for Cell A? 28 + 16 44 1040 + 28 + 16 =1084 X 1,000,000 = 40,590 PPM FTQ Revised September 11, 2006

51

Alarm Limit Calculation using np Chart- Class Exercise

FTQ

NP Charting for FTQ

25

Defects Pareto

100 90

20

80

Nonconforming

UCL=

70

15

60

avg=

10

50 40 30

LCL=

5

20 10

0

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Subgroups ( Days) Hours or Days Non-conforming 18 Sample Size (Avg) Defects wing mark wing / body fold wrong paint dot paint location wrong or no clip Total nonconforming: Production PPM Defective np

1 8

2 10

3 9

4 11

5 9

2 3 2

1 2 2 3 2 10 18

5 1 1

4 2 5

2 5 1

11 18

1 9 20

1 8 18

2 9 19

np1+np2+…..npk

n = avg sampleksize (18)

6 8

1 2 4 1 8 18

7 6

8 8

9 7

10 11

11 12

12 11

13 13

14 18

15 17

16 12

17 9

18 10

1 2

3 2

4 2

2 5 3

1 3 4

3 4 3 3

2 1 6 2 6 17 17

1 4

2 5

3 8 18

1 5 3 7 2 18 18

1 2 8

2 1 6 17

2 2 5 2 1 12 18

2 2 9 18

2 1 10 19

1 7 18

1 11 19

3 11 19

13 19

1 12 18

19 7

20 8

21 5

6 1

7 1

1 3

7 18

8 20

1 5 18

22 9

23 11

24 8

25 7

1 1 1 2 4 9 18

1 2 4 4

2 3

1 3 3

3 8 18

7 19

11 20

where np= number nonconformin, k= subgroups

Reference Attribute Data, AIAG SPC Manual, page 111

np

"=SUM(C3:AA3)/25" np = number nonconforming

k = subgroups (25)

UCLnp __ UCLnp =

0

LCLnp =

0

np = np1+np2+…..npk k LCLnp

UCL=np + 3* = 0 =

0

LCL=np - 3* Revised September 11, 2006

(np(1-np/n)) (np(1-np/n))

52

FTQ Tools

FTQ

FTQ - Performance Tracking 2004 CY FTQ Performance

FTQ

10000 9000 8000 7000 6000 5000 4000 3000 2000 1000 0

Projection

2003 Dec Final Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

FTQ Value (PPM)

Goal

Monthly Values

Daily Values

2004 CY FTQ Performance Data

FTQ Projection Goal

2003 Dec Final Jan Feb Mar Apr 9000 8000 7000 6000 8000 6500 6000 4500 4500 4500

May 5000 5500 4500

Revised September 11, 2006

Jun 4000 5000 4500

Jul 3000 4500 4500

Aug 3000 4500 4500

3000 4000 4500

54

FTQ

FTQ - Performance Tracking

FTQ In this row put in actual monthly values for FTQ PPM. Chart below will automatically generate and will automatically show up in FTQ display format tab. You can print out the FTQ Display tab to post on you cell " Glass Wall"

FTQ Projection Goal

Year-End Final %: Put in 2003 month of December FTQ value in PPM here

2003 Dec Final Jan Feb Mar Apr May Jun Jul Aug 9000 8000 7000 6000 5000 4000 3000 3000 3000 8000 6500 6000 5500 5000 4500 4500 4000 4500 4500 4500 4500 4500 4500 4500 4500

Goal: Forecast Put in your Forecast by month here. Forecast line will automatically be plotted above.

Put in your year end goal. Corporate goal is a minimum of 50% from December month actual in previous year

Revised September 11, 2006

55

FTQ

FTQ - Top 5 Issues

800 325

120

Branch out of tolerance

Unseated Ternimals

400

Missing Components

575

Damaged Terminals

1000 800 600 400 200 0

Crossed Wires

PPM

FTQ Top 5 Pareto

Cell/Process

Top 5 Quality Defects Revised September 11, 2006

56

FTQ FTQ Tools – Step Down Chart FTQ IMPROVEMENT PROCESS - STEP DOWN CHART Supplier DUNs #

Supplier Name Oct-04

FTQ of Relevant Processes contributing to Delphi APR/WAR/ LP/ FTQ

Supplier

Nov-04

Dec-04

Metric

Start Past 6 Month Ave.

Actual

Target

PPM

5.80

4.7

5.0

10

15.0

(per month)

(monthly average)

Number of Defects

17

(per month)

(monthly average)

FTQ - Process 1

10300

(per month)

(monthly average)

FTQ - Process 4

9700

(per month)

(monthly average)

FTQ - Process 5

1400

(per month)

(monthly average)

FTQ - Process 6

14400

(per month)

(monthly average)

FTQ - Process 9

400

(per month)

(monthly average)

(per month)

(monthly average)

9500

Jan-05

Actual

Target

4.86

4.5

10

13.0

Actual

Target

3

4.0

7

10.0

Feb-05 Actual

Target

(per month)

Metric PPM CYTD

CS

36200

7.0

8500

6300 6600

7500

1100

1100

1300

6500 1200

1200

5500

12000

1000 8500

11000

900 7900

10000

700

320

400

9000 600

33400

33200

(monthly average)

Start Month Status

360

8000

Level 2

27100

25500

27220

24080

20940

Red / Green will indicate whether targets are met

Action Item List Color Code:

Level 1

Level 2

(number new i nitiated) (number of open)

Action item target dates met Action item target dates not met No actions items assigned for this month

Delphi Single Point SQE Name Phone Number

Delphi Purchasing Name Phone Number

Delphi SQ Champion Name Phone Number

240

30360

Current Month Status

6.0 Level 1

3.0

8300

280

FTQ - 5 Processes Total

Actual

7300 7300

900

Target

Apr-05

8.0

9500

2000

Actual

9300 9200

11400

Mar-05

3.5

10000 9500

9600

Kickoff Date

Supplier Name Phone Number

Revised September 11, 2006

57

FTQ

FTQ Tools

FTQ IMPROVEMENT PROCESS - ACTION PLAN

Target Dates

Action Items List Item

Resp

Plan

Impl.

Issue Identified

Action Plan Implemented

Action Plan Proposed

Issue Resolved

Actual Completion Dates Plan

Impl.

Comments

Process 1 Top Defect Action Items

Process 4 Top Defect Action items

Process 6 Top Defect Action items

Process 9 Top Defect Action items

Revised September 11, 2006

58

FTQ FTQ PPM by Issue Pending Actions to address Top 5 Issues Issue Problem Discription Crossed Wires 800 Damaged Terminals 575 Unseated Ternimals 400 Missing Components 325 Branch out of Tolerance 120 99 Issue 6 80 Issue 7 70 Issue 8

Action Plans to Address Top 5 Issues Corrective Action Planned Start Date

mments on each column noted above in red. Mouse over to see.

Target Date

Status

FTQ Impact

Owner(s)

= On track to meet target date = Off track to meet target date by < 1 month = No Plan or off track to meet target date >1 month These have to pasted into the cells in column H above manually. Revised September 11, 2006

59

FTQ

Wrap Up Quiz

Class participants complete FTQ Quiz(10 minutes)

Review Responses

Revised September 11, 2006

60

FTQ

FTQ Quiz Responses

First Time Quality (FTQ) is an improvement measurement of PPM reduction over time . We measure FTQ by counting the number of pieces rejected versus the total number of pieces attempted. If we don’t make good parts the first time, we have to inspect in quality. Inspection is only 85% effective at best. FTQ is a tool to facilitate our operational improvement in quality and cost. Inspection is like a filter, and will miss some defects. If we don’t fix our quality problems internally, we will never be able to fix our external customer issues. Number of pieces rejected /Total number of pieces attempted X 1,000,000 = FTQ PPM Revised September 11, 2006

61

FTQ

FTQ Quiz Responses

The most important step in containing the problem is the immediate action taken, which leads to the elimination of the problem. Non-chronic rejects require immediate reaction at the first occurrence. Chronic rejects are those whose failure mode root cause has not been identified or fixed. When alarm limit is exceeded, the reaction plan must be implemented, and we implement a containment plan until the problem is fixed. One example of a basic quality tool used to analyze data is a Pareto chart. The tool used to track implementation status of corrective action and improvement is the FTQ Tracker (or Step Down Chart). All existing documentation must be updated in order to institutionalize lessons learned. Revised September 11, 2006

62

FTQ

Closing Comments - FTQ Improvement Process

Implement Improvement Work the Action Plan Update plan as required Document improvements

Revised September 11, 2006

63

FTQ

Closing Comments - FTQ Improvement Process

Delphi’s Suppliers are responsible for their sub-tier suppliers: Roll the FTQ process out to sub-tier suppliers to help them gain the improvement benefits and to lower the probability of your company receiving nonconforming parts

Revised September 11, 2006

64

FTQ

FTQ Expectations & Key Points

FTQ is a Requirement: A FTQ Process, that Monitors & Controls at the point of build. Set FTQ Alarm Limits to “1” reject for all safety critical features. Set FTQ Alarm Limits to “1” reject for all non-chronic(special cause) failures Reaction Plans include extra containment to Protect the Customer. Customer notification evaluated by engineering on special cause events. FTQ Reduction through a Rolling Top 5 or equivalent process. Delphi Tier 1 suppliers ensure FTQ is correctly implemented Delphi Customer Specific Requirement 7.3.6.3: Product Approval Process, “The supplier is expected to develop and implement a FTQ process with appropriate alarms and reaction plans defined.” Goal is Zero Incidents, Zero Spills, Zero Defects to our Plants. Revised September 11, 2006

65