Maxwell Needle 3v45a

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Maxwell Needle as PDF for free.

More details w3441

- Words: 1,422

- Pages: 10

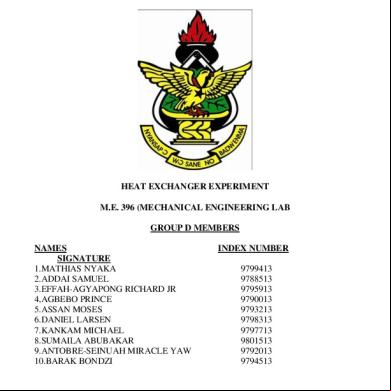

KWAME NKRUMAH UNIVERSITY OF SCIENCE AND TECHNOLOGY COLLEDGE OF ENGINEERING DEPARTMENT OF MECHANICAL ENGINEERING

HEAT EXCHANGER EXPERIMENT M.E. 396 (MECHANICAL ENGINEERING LAB GROUP D NAMES SIGNATURE 1.MATHIAS NYAKA 2.ADDAI SAMUEL 3.EFFAH-AGYAPONG RICHARD JR 4,AGBEBO PRINCE 5.ASSAN MOSES 6.DANIEL LARSEN 7.KANKAM MICHAEL 8.SUMAILA ABUBAKAR 9.ANTOBRE-SEINUAH MIRACLE YAW 10.BARAK BONDZI

INDEX NUMBER 9799413 9788513 9795913 9790013 9793213 9798313 9797713 9801513 9792013 9794513

OBJECTIVES:To determine the elastic constants of the spring material, by measuring the translational and torsional vibration/oscillations of a loaded spring.

INTRODUCTION A spring is a flexible mechanical components found in many mechanical systems. Developments in material, design procedures and manufacturing processes permit springs to be made with longer fatigue life, reduced complexity, and higher production rate. Since they are used extensively in engineering application, there is the need for engineers to be able to determine the elastic constants or stiffness of springs. The elastic constant of a linear spring is simply defined as the ratio of the force used in stretching the spring to the displacement. Some springs include: helical coil spring, leaf spring, flat spiral spring and so on. This experiment looks at a helical coil spring.

Diagram

Helical spring Retort Stand

Maxwell needle

THEORY D = mean diameter of coil d= wire diameter n = number of coils

Under axial load, W

Since the helix angle is small the action on any cross-section is approximately a pure torque = W. D/2, and the bending and shear effects may be neglected. The wire is therefore being twisted like a shaft, and if is the total angle of twist along the wire, and x the deflection of W along the axis of the coils, x= (D/2) L = Dn D W 2 2 G 2 x / D 4 Dn d / 32 d

8WD /d d 4 Gx / D 2 n..................1

Or

The....spring ...stiffness Gd 4 s 3 ..................a 8D n Under axial torque, T, we will have a pure bending moment of magnitude T at all cross-sections. The total strain energy is therefore

T 2l T 2Dn U 2 EI 2 Exd 4 / 64 32T 2 Dn U 2 Ed 4

But if T causes a rotation of one end of the spring through an angle about the axis, relate to the other end. U= (1/2) T …………………………………….(3) From equations (2) and (3):

Tl EI 64TDn 64 Dn T Ed 4 Ed 4 Ed 4 or T / 64 Dn Now T / c, the torsional stiffness

Ed 4 c 4 64 Dn

s x0 m s 2 m x

s m m s

hence , the period , T 2

m T 2 4 2 ............b s For the torsional oscillatio ns Re storing torque c c I

2

c 0 I c I

The period , T 2

I c

I T 2 4 2 ...........(c ) c

Where I is the moment of inertia of the attached, I = mx2/3 where m is the attached mass and x is the perpendicular distance of the attached mass from the center of mass of the rod.

But torsional stiffness c : 4

c

Ed ...........( d ) 64 Dn

APPARATUS 2 music wires(springs) Maxwell’s needle: Stop watch:

used to measure time

Micrometer screw gauge: used to measure diameter of the music wire

Vernier caliper : used to measure big diameter of coils Beam balance : used to measure mass of metals weights Metre rule :

used to measure length of needle

Metal weights

PROCEDURE By using the rod and the sliding masses and some masses available, purely vertical vibrations were obtained. Each time, the bar was slightly displaced downwards and released. The time for twenty (20) oscillations was obtained using a stopwatch. The experiment was repeated for other masses and each time, the time was determined and recorded. During the experiment, the bench was freed of all vibration from the group . This was to ensure good results. Now, by varying the positions of the sliding masses along the rod, torsional oscillations were produce. For each distance, the time for twenty (20) oscillations was determined and recorded. The angular displacement of the rod was very acute. The diameter (d) of the springs was determined using a micrometer screw gauge. The mean diameter of the coil (D) was also determined using a vernier caliper. The mass of the needle and that of the attached masses was also determined with a beam balance and recorded

RESULTS Mass of block and needle mb = 1.2 Kg

Properties

Spring 1

Spring 2

Wire diameter, d

1.95mm

1.

Number of coils, n

20

18

Mean coil diameter

36.55mm

50.275mm

Table for vertical oscillations with spring 1 Mass, (Kg) 0.6 0.98 1.45

m Time for 20 oscillations (s) t1 13.1 15 18.41

t2 13.5 15.5 19.1

mean (t/s) 13.3 15.25 18.76

Period, T T2(s2) =t/20 (s) 0.67 0.76 0.94

0.45 0.58 0.88

Table for vertical oscillations with spring 2 Mass, (Kg) 0.6 0.98 1.45

m Time for 20 oscillations (s) t1

t2

17.65 21.9 25.2

18.2 22.1 26.3

mean (t/s) 17.93 22 25.75

Period, T2(s2) T =t/20 (s) 0.90 1.1 1.29

0.81 1.21 1.66

Table for torsion oscillation using spring 1 x(m)

X2 (m2)

I(kgm2)

Time of 10 oscillations, t(s ) t1

t2

mean t(s)

T (s) =t/20

T2 (s2)

0.015

0.0002

0.00022

48

49

48.50

2.43

0.035

0.0012

0.00132

49.8

50.65

50.26

2.51

6.30

0.092

0.0085

0.00935

59.5

58.5

59

2.95

8.70

0.132

0.0174

0.01914

71

69.5

70.25

3.51

12.32

0.19

0.0361

0.03971

88.5

89..25

88.88

4.44

19.71

T (s) =t/10

T2 (s2)

x(m)

X2 (m2)

I (Kgm2)

Time of 10 oscillations, t(s ) t1

t2

mean t(s)

5.90

0.015

0.0002

0.00022

50.50

51.12

51.14

2.557

6.54

0.035

0.0012

0.00132

53.80

54.25

54.275

2.714

7.364

0.092

0.0085

0.00935

66.00

59.42

59.22

2.961

8.77

0.132

0.0174

0.01914

79.40

64.42

64.455

3.22

10.386

0.19

0.0361

0.03971

81.6

68.48

68.495

3.423

11.729

0.12

0.0144

0.01584

74.49

74.33

74.41

3.72

13.84

0.14

0.0196

0.02156

80.04

80.36

80.2

4.01

16.08

Tabl e for torsi on oscill ation using sprin g2

AN AL YSI S Res pect ive gra phs and calc ulat ions

Figure 1 a graph of period squared, T2 against mass, m when using spring 1 Gradient of the slope, g1= 0.5059

Figure 2 a graph of period squared, T2 against mass, m when using spring 2 Gradient, g2= 0.98

Figure 3 a graph of moment of inertia, I against period squared, T2 when using spring 1

Figure 3 a graph of moment of inertia, I, against period squared T2 when using spring 1

Substituting S…….(a) into ……(b)

T m with

2

32

2

D 3n Gd 4

T2 gradient of slopes , g1 and g 2 m

For music wire (spring) 1 with g1 = 0.667, D=0.037m, d=0.0017m and n=20 coils

The modulus of rigidity for music wire (spring )1, G1 is 57.3 GPa. For music wire (spring) 2 with g2 = 0.93, D=0.037m, d=0.001875m and n=18 coils The modulus of rigidity for music wire(spring )2, G2 is 61.8 GPa. Substituting C ….(d) into ……(c)

T I

2

256 2 Dn ...........(c) Ed 4

with

T2 gradient of slopes , g 3 and g 4 c

For music wire (spring) 1 with g3 = 0.00177-1, D=0.037m, d=0.0017m, n= 20. The modulus of elasticity for music wire (spring)1 is 352.8GPa For music wire(spring)1 with g3 = 0.00172-1, D=0.050m, d=0.001875m, n= 18. The modulus of elasticity for music wire (spring)1 is 351.6GPa

PRECAUTIONS 1. The setup was not disturbed 2. Parallax error was avoided CONCLUSION According to the results, the modulus of elasticity, E of the music wire(springs) 1 and 2 are 57.3 GPa and 61.8 GPa According to the results, the modulus of rigidity, G of the music wire(springs) 1 and 2 are 352.8 GPa and 351.6 GPa COMMENTS Comparing the obtained elastic constants with the standard values, E=200GPa and G=81.7GPa, there was a vast difference due to the tempered state of the music wire (spring).

RECOMMENDATIONS

1.The music wire (spring) must be changed because of the high in built fatigue. 2.The balance for measuring the masses should be replaced with a new one

HEAT EXCHANGER EXPERIMENT M.E. 396 (MECHANICAL ENGINEERING LAB GROUP D NAMES SIGNATURE 1.MATHIAS NYAKA 2.ADDAI SAMUEL 3.EFFAH-AGYAPONG RICHARD JR 4,AGBEBO PRINCE 5.ASSAN MOSES 6.DANIEL LARSEN 7.KANKAM MICHAEL 8.SUMAILA ABUBAKAR 9.ANTOBRE-SEINUAH MIRACLE YAW 10.BARAK BONDZI

INDEX NUMBER 9799413 9788513 9795913 9790013 9793213 9798313 9797713 9801513 9792013 9794513

OBJECTIVES:To determine the elastic constants of the spring material, by measuring the translational and torsional vibration/oscillations of a loaded spring.

INTRODUCTION A spring is a flexible mechanical components found in many mechanical systems. Developments in material, design procedures and manufacturing processes permit springs to be made with longer fatigue life, reduced complexity, and higher production rate. Since they are used extensively in engineering application, there is the need for engineers to be able to determine the elastic constants or stiffness of springs. The elastic constant of a linear spring is simply defined as the ratio of the force used in stretching the spring to the displacement. Some springs include: helical coil spring, leaf spring, flat spiral spring and so on. This experiment looks at a helical coil spring.

Diagram

Helical spring Retort Stand

Maxwell needle

THEORY D = mean diameter of coil d= wire diameter n = number of coils

Under axial load, W

Since the helix angle is small the action on any cross-section is approximately a pure torque = W. D/2, and the bending and shear effects may be neglected. The wire is therefore being twisted like a shaft, and if is the total angle of twist along the wire, and x the deflection of W along the axis of the coils, x= (D/2) L = Dn D W 2 2 G 2 x / D 4 Dn d / 32 d

8WD /d d 4 Gx / D 2 n..................1

Or

The....spring ...stiffness Gd 4 s 3 ..................a 8D n Under axial torque, T, we will have a pure bending moment of magnitude T at all cross-sections. The total strain energy is therefore

T 2l T 2Dn U 2 EI 2 Exd 4 / 64 32T 2 Dn U 2 Ed 4

But if T causes a rotation of one end of the spring through an angle about the axis, relate to the other end. U= (1/2) T …………………………………….(3) From equations (2) and (3):

Tl EI 64TDn 64 Dn T Ed 4 Ed 4 Ed 4 or T / 64 Dn Now T / c, the torsional stiffness

Ed 4 c 4 64 Dn

s x0 m s 2 m x

s m m s

hence , the period , T 2

m T 2 4 2 ............b s For the torsional oscillatio ns Re storing torque c c I

2

c 0 I c I

The period , T 2

I c

I T 2 4 2 ...........(c ) c

Where I is the moment of inertia of the attached, I = mx2/3 where m is the attached mass and x is the perpendicular distance of the attached mass from the center of mass of the rod.

But torsional stiffness c : 4

c

Ed ...........( d ) 64 Dn

APPARATUS 2 music wires(springs) Maxwell’s needle: Stop watch:

used to measure time

Micrometer screw gauge: used to measure diameter of the music wire

Vernier caliper : used to measure big diameter of coils Beam balance : used to measure mass of metals weights Metre rule :

used to measure length of needle

Metal weights

PROCEDURE By using the rod and the sliding masses and some masses available, purely vertical vibrations were obtained. Each time, the bar was slightly displaced downwards and released. The time for twenty (20) oscillations was obtained using a stopwatch. The experiment was repeated for other masses and each time, the time was determined and recorded. During the experiment, the bench was freed of all vibration from the group . This was to ensure good results. Now, by varying the positions of the sliding masses along the rod, torsional oscillations were produce. For each distance, the time for twenty (20) oscillations was determined and recorded. The angular displacement of the rod was very acute. The diameter (d) of the springs was determined using a micrometer screw gauge. The mean diameter of the coil (D) was also determined using a vernier caliper. The mass of the needle and that of the attached masses was also determined with a beam balance and recorded

RESULTS Mass of block and needle mb = 1.2 Kg

Properties

Spring 1

Spring 2

Wire diameter, d

1.95mm

1.

Number of coils, n

20

18

Mean coil diameter

36.55mm

50.275mm

Table for vertical oscillations with spring 1 Mass, (Kg) 0.6 0.98 1.45

m Time for 20 oscillations (s) t1 13.1 15 18.41

t2 13.5 15.5 19.1

mean (t/s) 13.3 15.25 18.76

Period, T T2(s2) =t/20 (s) 0.67 0.76 0.94

0.45 0.58 0.88

Table for vertical oscillations with spring 2 Mass, (Kg) 0.6 0.98 1.45

m Time for 20 oscillations (s) t1

t2

17.65 21.9 25.2

18.2 22.1 26.3

mean (t/s) 17.93 22 25.75

Period, T2(s2) T =t/20 (s) 0.90 1.1 1.29

0.81 1.21 1.66

Table for torsion oscillation using spring 1 x(m)

X2 (m2)

I(kgm2)

Time of 10 oscillations, t(s ) t1

t2

mean t(s)

T (s) =t/20

T2 (s2)

0.015

0.0002

0.00022

48

49

48.50

2.43

0.035

0.0012

0.00132

49.8

50.65

50.26

2.51

6.30

0.092

0.0085

0.00935

59.5

58.5

59

2.95

8.70

0.132

0.0174

0.01914

71

69.5

70.25

3.51

12.32

0.19

0.0361

0.03971

88.5

89..25

88.88

4.44

19.71

T (s) =t/10

T2 (s2)

x(m)

X2 (m2)

I (Kgm2)

Time of 10 oscillations, t(s ) t1

t2

mean t(s)

5.90

0.015

0.0002

0.00022

50.50

51.12

51.14

2.557

6.54

0.035

0.0012

0.00132

53.80

54.25

54.275

2.714

7.364

0.092

0.0085

0.00935

66.00

59.42

59.22

2.961

8.77

0.132

0.0174

0.01914

79.40

64.42

64.455

3.22

10.386

0.19

0.0361

0.03971

81.6

68.48

68.495

3.423

11.729

0.12

0.0144

0.01584

74.49

74.33

74.41

3.72

13.84

0.14

0.0196

0.02156

80.04

80.36

80.2

4.01

16.08

Tabl e for torsi on oscill ation using sprin g2

AN AL YSI S Res pect ive gra phs and calc ulat ions

Figure 1 a graph of period squared, T2 against mass, m when using spring 1 Gradient of the slope, g1= 0.5059

Figure 2 a graph of period squared, T2 against mass, m when using spring 2 Gradient, g2= 0.98

Figure 3 a graph of moment of inertia, I against period squared, T2 when using spring 1

Figure 3 a graph of moment of inertia, I, against period squared T2 when using spring 1

Substituting S…….(a) into ……(b)

T m with

2

32

2

D 3n Gd 4

T2 gradient of slopes , g1 and g 2 m

For music wire (spring) 1 with g1 = 0.667, D=0.037m, d=0.0017m and n=20 coils

The modulus of rigidity for music wire (spring )1, G1 is 57.3 GPa. For music wire (spring) 2 with g2 = 0.93, D=0.037m, d=0.001875m and n=18 coils The modulus of rigidity for music wire(spring )2, G2 is 61.8 GPa. Substituting C ….(d) into ……(c)

T I

2

256 2 Dn ...........(c) Ed 4

with

T2 gradient of slopes , g 3 and g 4 c

For music wire (spring) 1 with g3 = 0.00177-1, D=0.037m, d=0.0017m, n= 20. The modulus of elasticity for music wire (spring)1 is 352.8GPa For music wire(spring)1 with g3 = 0.00172-1, D=0.050m, d=0.001875m, n= 18. The modulus of elasticity for music wire (spring)1 is 351.6GPa

PRECAUTIONS 1. The setup was not disturbed 2. Parallax error was avoided CONCLUSION According to the results, the modulus of elasticity, E of the music wire(springs) 1 and 2 are 57.3 GPa and 61.8 GPa According to the results, the modulus of rigidity, G of the music wire(springs) 1 and 2 are 352.8 GPa and 351.6 GPa COMMENTS Comparing the obtained elastic constants with the standard values, E=200GPa and G=81.7GPa, there was a vast difference due to the tempered state of the music wire (spring).

RECOMMENDATIONS

1.The music wire (spring) must be changed because of the high in built fatigue. 2.The balance for measuring the masses should be replaced with a new one