Mechanization On Harvesting And Infied Collection Of Oil Palm 2c7157

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Mechanization On Harvesting And Infied Collection Of Oil Palm as PDF for free.

More details w3441

- Words: 4,439

- Pages: 21

MECHANIZATION ON HARVESTING AND INFIELD COLLECTION OF OIL PALM

Shamil Mudhheher Abbood Phd student / Faculty of Engineering /Agricultural process Engineering

CHAPTER 1 INTRODUCTION

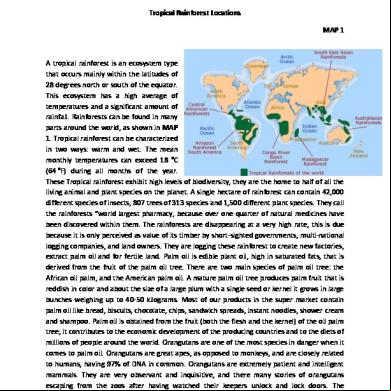

Background 1.1 From time immortal human being on this earth has been living on the natural vegetables and animals . But by the age of time and the evolution of life with the invention of the machines in agricultural production, agriculture evolve day after another down to the present condition. In the present day an increased in demand for agricultural products as a result of the steady increase in the population growth, not only for food that provide Food Security, also the need for greater agricultural products for industrial purposes has entered agricultural products .Nowadays , decrease of petroleum production forced the sciences to thinking about alternative fuel ,one of this now production is bio-chemical that can use as fuel and other consumer. In fact, oil palm has a significant .importance to industry and product the alternative fuel Recent century ,oil palm has become a one of the words major agricultural crop in east and central Africa (Zeven ,1972; smith et; al .,1992).Recently, it has dramatically increasing in southeast Asia (wicke et al , 2011).Actually, Oil palm is one of a highly profitable crop adapted to the humid tropics and the area devoted to this crop is likely to expand significantly in the future. It has many environmentally favorable attributes over its full life cycle. When well managed it has a positive carbon balance and when grown in a landscape mosaic it can play a role in biodiversity conservation. It has driven rapid

economic growth in several tropical developing countries and contributed to the alleviation of rural poverty (.Jeffery .et al, 2012) Nowadays, Malaysia become the largest producer and exporter of oil palm in the world, it is s for about 55%of the world palm and about 62%of world exports. The increased industrialization in this agricultural sector has resulted in the emergence of numerous refineries in the country competition is stiff on the world market, research and development is critical to generate knowledge as well as to increase production and processing efficiency .(W.I.W.Ishak and R.M.Hudzari 2010) Harvesting is the most important an activity in oil palm cultivation. It was estimated that the operation requires about 60%of the total labor for the crop and about 50 %of the total cost.(Abdul razak ,at.al 2007).oil palm harvesting involves four interrelated activities , like cutting the fronds and fruit bunches ,stacking for fronds collecting the lose fruits and carrying the harvested fruit to the collection point .(abdul razak; et; al. 1998).nowadays, there is about 25%of FFB collection is done through mini tractor and 75%is really done on manual labor (Abbai Belai; et; al ,2008). Indeed, a lot of time and energy (and therefore production cost) goes into oil palm harvesting. Such an enormous amount of energy is required for harvesting oil palm that even cutting a single frond alone, using the sickle cutter (the Malaysian knife), could require the exertion of effort force as much as 18,048 N for the most matured frond (Jelani; et; al, 1999). Further, Bevan and Gray (1969) reported that in a study on palms aged between 9 and 25 years in Malaysia, between 43.5 and 45.4 % of the total annual man-days is spent on harvesting. Harvesting from the older trees took more man-days. The situation, most likely, has not changed today because harvesting is still being done .manually

Mechanical harvesting is one of the significant operations to product the oil palm FFB. Throughout the past decades many machines were invented for oil palm harvesting by Malaysian Palm Oil Board (MPOB) but none of them was made commercial due to its inefficiency. This was because the harvester operator faces difficulty in positioning the mechanical cutter to the bunch stalk during cutting process (Helena Anusia and Wan Ishak 2010). The defies of the oil palm is the method of harvesting because the fruits are compactly packed in the bunches are hidden in the leaf axils in the crowns that may be more than 10 m higher .also, each tree need to visited every 10-15 days as fruit bunches ripen (Kwasi, 2002).However, oil palm mechanical harvesting (cutting and collecting) still need more improving to be useable, .low cost and able to reach both high and low palm tree In fact, there are many several machines and tools have manufacturing to achieve these aims such as telescopic and elbow type arm harvester (manufacturing and developing by MPOB).But these machines still have a problems or issues such as a high cost or difficulty of moving around the field between the trees There are several machines have manufactured such us a machine for harvesting tall palms and motorize cutter were developed in MPOB in 2004 and 2010 (Abd rahim shuib et al 2004) (Abd Razak et al. 2010) .But every one of this machine has own problem such as a high cost and limitation of working .For this project we design a low cost liner mechanical cutter with light flexible pole to reach a tall palm tree and scissor basket left install in front of medium tractor to integrate the cutting and collecting oil .palm fruit FFB in one time The previous dump truck FFB collector was modification in 1982 as FFB collector and transporter .the harvester cut the FFB and let it fall in to the modified dumper to reduce damage and avoid loose fruits. The

truck dumber will collect the FFB and transport them to the collection point. In 2004 MPOB has developing tall palms harvesting machine .the machine carry a telescopic boom which the cutting mechanism is mounted onto it .It is able to cut the FFB and convey in to the container . The challenge of this machine it is still costly . Initially, mechanical of oil palm harvesting of oil palm fruit bunches (FFB) remains issue that need to solve, the short tree current methods by using the chisel or sickle, which requires manual labor (Abd Rahim Shuib rt;al.2004). Since 1982 many harvesting machines have been developed for harvesting palm fruit bunches (FFB) .Nowadays, the big define to developing or manufacturing a suitable cutter and collecting machine to reach both of high and low harvesting with light weight, low cost and .lower cutting force and fast The main objectives of this project is design and fabricate the suitable mechanical cutter for cutting leaf and FFB and harvesting platform that has installed on the tractors frame. .The tractor s the hydraulic power to operate the scissor lift and the air compressing power to operate the cutter. So in this new design of mechanical cutter and collection platform will be useful for medium and high trees with plausible cost .also, use the available power sources to operate the cutter and lifting the .platform There are several tools machines have been developing to harvest the FFB. The Malaysian Palm Oil Board (MPOB) has developed a motorized cutter. it has being able to more than double labored productivity for harvesting .The only drawback for this cutter is that can only harvest palms of below 4.5 m . ( Abd Razak; et ;al. 2007). This cutter consists of a petrol engine located of the bottom of the pole .A telescopic aluminum pole , Sickle as cutting head and rotational motion from the engine is transmitted to pear of gears from where the sickle is connected

through the transmission shaft. (F. Azhar; et; al .2012). Later, improving of oil palm motorize cutter has been done in 2010 by MPOB to be strong to durable enough to overcome high friction due the high speed of cutting (Abd .Razak;et; al. 2010) A linear oscillatory actuator for oil palm mechanical cutter had been designed and fabricated .This cutter can reach palm until 8 m and the weight is 7.5 kg . LOA is proposal to replace the bevel gears to produce direct liner motion .LAO actually is activated by dynamo which converts the mechanical energy provided by the petrol engine to electrical energy .This energy will cause the LOA shaft connected to the sickle to vibrate the sickle .In this system was replace the transmission shaft inside pole with a pair of copper wire to connect the dynamo with the LOA .(F. Azhar et al 2012) In recent years MPOB has been developing of machine for harvesting tall palms .this machine it is carry a telescopic boom which the cutting mechanism is mounted into it. It is able to cutting FFB and covey it into the nearest container without letting it fall on the ground .The challenge of this machine it is heavy and costly(Abd Razak; et; al. 2004) .On the other hand ,collage of food and agriculture in U.A.E has been developed a tractor – mount date palm tree service machine .The developed system is attached to the rear of tractor ,system's power source is the tractor hydraulic system .The machine has the capability to lift a service worker and the required tools to the crown zoon as high as 4.5 m.(Moustafa A.Fadel 2005). A quick attachment mechanism need to be developed to make attachment of the machine to the .tractor easir

In the new design, the pneumatic driven saw is use as cutting tool .The pneumatic driver selected because the

weight is so light (0.9) kg ,also the air power which drove can get from any compressor using a small petrol engine or tractor power through a PTO shaft which provide 5.39 letter/sec .The pneumatic driven saw selected to be suitable for oil palm leaf and FFB. It has 15 cm length with double action cutting, it is manufacturing from high carbon steel .The vibration of the engine is about 5000 SPM with free load. The cutting head connect to the double extension aluminum pole 38ʺ, 42ʺ .Actually, the pole material specifications selected to be compatible with the MBOPs specifications .The two parts of pole t together by double clamp. The air is supply to the cutting head by the 1/4ʺ high pressure tube inside the aluminum pole. T- Double clamp is use to the two parts of pole, this clamp easy to adjust the length of extension pole depend of height of tree; the cutter is light enough to .carry it U-shape basket on a scissor lift will be install in front of the 45 hp tractor. To reach the fruit the worker will be able to utilize until the trees are 25 ft tall. The tractor will be position at the base of the tree in the maturing fruit side ,so the trunk of tree is positioned inside the basket through the U- shape .The basket will lifted to appropriate height . Therefore, the bunch can be easily harvest by the cutter after cutting the nearest leaf .Finally ,the FFB fruit will fall inside the basket directly .after harvesting the fruit the tractor will move to another tree and when the basket be full ,the driver will drive the tractor to nearest .FFB collection point to discharge the harvesting problem Statement– 1.2 Rapid chopping method motorized cutter (cantas) which developed by MPOM was finding an effective solution to solve the oil palm harvesting issues .But this existing cutter is limited to palm trees below 5 meter height .Palm trees higher than 5 meter face a difficulty to

use this cutter because of limitation of height and extra weight. Developing a longer reach cutter with light weight .is necessary demand to solve the cutting problem Collecting oil palm fruit after cutting still critical problem because it need more labor and lose a lot of fruit epically tall tree , .MOPM has been developing a tall palm trees. is machine has ability to convey the FFB to the container .But the significant issues of this machine it is costly and difficult to move among trees. To override these issues of height cost and difficulty of collection ffb ;this research will focus to use a mini tractor to cut and collect ffb .The scissor basket left will install over the min tractor .The basket will reach a 3.5 meter with the height of the tractor ;using a 5 meter cuter ,the total heigh will be 8.5 meter .This new harvesting method will cover the midum and tall trees were in the economical age and integrate cutting . and collecting FFB a ones

Objectives 1.3

To design and fabricate extensions pole and .mechanical cutter .To

1.3.1

design and fabricate a scissor lift basket 1.3.2

To integrate the cutting and collection the oil palm . FFB

1.3.3

CAPTER 2 LITRERTURE REVIEW Introduction 2.1 Oil palm is a tree without branches but with many wide leaves or fronds at the crown of tree. It is become the world's number one fruit crop because of it is unparalleled productivity (Butler 2006).The first large plantation in Sumatra was planted in 1911.Otherwise, in 1917 the first true plantation was established in Malaysia in the Selangor district . Currently, Malaysia has 4.7 million of oil palm plantation and the harvested area is 11.20 million ha. The potential land of oil palm plantation is increasing dramatically. Malaysia can only rely on another 28%of potential oil palm plantation area. Actually, oil palm harvesting in Malaysia is still heavily relied on foreign labor .Initially, there are 369000 foreign workers employed in plantation (Yik Nam Lee 2011).Approximately, harvesting and collections of FFB and a lose fruits are laborious, time consuming and incur the highest cost of operation .Thus it is justified to improve the existing machines and systems in the plantation to solve the labor, .time and cost

oil palm bunch 2.2

Oil palm is monoceous ; both male and female flowers on the same tree. (Mohd Hanif and Mohd Roslan,2002). Bunch harvesting commences about 24 to 30 months after planting; each palm tree can produce between 8-15 fresh fruit bunches of FFB yearly. Each bunch is normally weighting about 5 -25 kg depending on the planting material and age of the palm. Also, each fruit bunch contains between 1000- 1300 fruit lets (Teoh,2002). A fruit bunch takes about 20 to 22 weeks to ripe (Aziz et al,1990). The ripeness is normally indicated Fig 2.1show the fruit bunch after cutting by the fruit color fruit changes from black to reddish orange (Kadia and Zulkily,1992) fig 2.1 shown the fruit bunch . Currently, a new concept of image based measurement for modeling the oil palm FFB maturity predication which enables to determine the correct time for harvesting (W.I.W.Ishak and R.M.Hudzari,2010) Harvesting 2.3 Timeliness harvesting is very crucial to the quantity and quality of yield fruit of oil palm. The under ripe fruit will yield lower quantity of oil while the over ripe will yield oil with high free fatty acid. When a fruit is fully ripe, it loose

itself from the bunch and drops on the ground or it is become easily detachable. So, the idle system of harvesting would be collect loose fruit daily from the ground. (Harcharan 1976). Thus, this method it is clearly impossible with high plantation and production. So, a fruit bunch is normally been as ripe enough for harvesting when a few fruits have loosened themselves from the .bunch and dropped on the ground (D.Adetan et al 2007) Previous methods of harvesting 2.4 There are several methods and activates have been used to harvesting oil palm fruit ,following these activities and a pullers previous methods Cutting 2.4.1 In fact, a lot of time and energy goes into the oil palm fruit harvesting .such as enormous amount of energy is required for harvesting oil palm that even cutting a single front alone ,the Malaysian knife (sickle cutter) could require exertion of force as much as 18 N for the matured frond (Jelani et al;1999). Short trees within arm-reach are harvested using either the cutlass or chisel to cut the bunches and fronds. On another way, tall trees above 9 m in height are harvested using either a single rope and cutlass (SRC) or the double rope and cutlass (DRC) method .the SRC method is Commonly because it is relatively much faster though less save (Ironbar,1981).Fig 2.4.1 .show the manual short tree harvesting

Medium -height oil palm trees beyond arm reach up to height of about 9 m are harvested using the bamboo pole and knife (BPK) method .The heights of pole depend of the average height of the trees .nowadays, another method is the aluminum pole and knife (APK) method . in this method ,a 40 mm diameter pore replace the bamboo pole of the (BPK) harvesting method .It work very well and faster than the BPK method for trees of height below 5.5 m . Above this height ,bending of long harvesting pole that are relatively heavier cutting knives on top constitutes very serious problem as it become difficult to engage the stalks of palm fronts and bunches (D.Adetan et al 2007) .

Fig 2.4.1the manual harvesting fig 2.4.2 the tall balm harvesting Mechanization cutting 2.5 Recently, Malaysian palm oil board (MPOB) has developed an significant oil palm fruit motorized cutter which employs a specially design gears head and sickle which is able perform the cutting with more efficient and faster compared with traditional cutting tools .Field trail shown that the productivity of the workers has been increased to three times as opposed to the manual sickle. The oil palm motorized cutter consists of a petrol engine located at the bottom of pole ,a telescopic aluminum pole and sickle as cutting head as shown in fig 2.5.( Abdul . Razak et al 2007)

Fig 2.5 MPOB motorized cutter To solve the mechanical limitation of existing oil palm motorized cutter such as the extra weight and limitation in height, a linear oscillatory actuator (LOA) is proposed to replace the bevel gears to produce direct liner motion..The LOA is activated by a generator which converts the mechanical energy provided by the two stroke engine (Fairul 2008) Oil palm fruit collection

2.6

In Malaysia various mechanism collection system have been under test since 1980s and have been gradually developed .Wan Ishak in 1982 was modified a dumber as a fresh fruit bunch ( FFB) collector and transporter (Malik and Yaakob .1989). Fawzi;1994 recommended a low powered mechanical buffalo for collecting FFB on terraces and producing higher labor productivity. kamarudzaman et al (1994) studied the introduction of mechanized system of small tractor with mechanical loading , finding that tow worker could be omitted for each unit .deployed and the harvester increased about 65%. Each unit could deal with about 230 to 250 ha of oil palm .field Fruit catching mechanism ( FCM) was fabricated by with Japanese firm . FCM has been developed as MPOB a harvesting machine with the cutting mechanism

attached to a boom .It can reach 10 m height , the maximum height both a cutter blade member and fruit catching mechanism can be extended upwards and retracted using hydraulic cylinders .When the bunch is sighted ,the operator will maneuver the vehicle close to the palm and start harvesting process, then the arm extended to the palm crown by shifting the respective joystick control .A ones time the cutter is brought to suitable position ,the operator will cut the fronds and bunches ,the cut will fall down and placed into bin. (Abd Rahim et al 2004) . Fig 2.6 shown the FCM

.

Fig 2.6 fruit catching mechanism A tractor-mounted date palm tree service machine was developed in U.A.E in 2005. The service platform is a Vshaped basket-like structure to serve date palms, which is attached to the tip of the aerial boom via four ts. The V-shape gives the worker the ability to go around most of the tree trunk to perform comfortably. To complete the circle around the trunk, two extensions on the platform sides and another foldable bridge were added to the platform. The bridge can be folded down to help the operator to go around the tree, and then folded up when

the machine is ready to move(Moustafa A .Fadel,2005).Fig 2.6 shown date palm serves machine

Fig 2.6 date palm serves machine MATERIAL AND METHODOLOGY 3.1 Integrate the harvester and dump track collector system is a urgent necessity for oil palm harvesting .In this research firstly, will design and fabricate the pneumatically cutter with aluminum extensional pole .the cutter has a 6 in high carbon steel saw fig 3.1 shown the cutter design .the 5000 spm saw will vibrate in 0.9 cm stroke .Fig 3.1 shown the sold design for cuter and pole. The cutter will be connected with the pole by using propel structure holder .tow part of pole will t through a double clamp. The cutter will reach the leaf and FFB within 8 m height. Suitable air compressor will install behind the tractor to proved the cutter in air presser trough the three

point attach. On the other hand, scissor lift basket will design and fabricated to install on the 45 hp 4 wheel drive tractor. The hight of scissor is 2 meter .It is installing on the

Fig 3.1 the sold drawing design for the cutter and extension pole tractor frame with height 1.5 ,above the scissor the harvesting U-shape basket will install . The basket shape allow the basket go into the palm tree trunk .The basket divide in tow part first part for harvester standing . The harvester stand in basket and controlling the position the basket .After that the worker will use the cutter to cut the bunches, the bunch will fall in the basket. The hydraulic dumper collection system (scissor basket) to ease in catching the fallen FFB, transport them and dumped at the collection point. This new tractor system will reduce time and labor harvest, collect FFB, collect lose fruits and .transport the fruit to the collection point scissor lift 3.2 A scissor lifting device is a system that allows small force (effort) to overcome a large force or load (Alexander et al, 1978, Smith, 1981, Nelkon, 1985). There are practically hundreds of uses for lift scissors in manufacturing, warehousing and distribution facilities. The addition of this device (lift scissor ) makes job faster, safer and easier. Some typical applications include; machine

feeding and offloading, product assembly, inspection quality control repair, feeding and offloading conveyor .levels One of the most important factors of lift platform is its stability. Knowing that stability is a source of concern for a lift platform, its positioning should be on a flat surface and the load should be place or when compared to other lifting device; firstly, its dependency on power supply is eliminated. Secondly, it allows smooth movement without jerking due to steady increase in fluid pressure, majority of .lift platform in market make use of hydraulic

References Alexander j., Kaman P., Jack P., and David S. (1978), -1 Physic for EngineeringTechnology. John Willey and Sons Inc ,.USA. Allens H. R Abd Rahim Shub ,et al, 2004 Development of machine -2 for harvesting tall palms .MPOB information series , ISSN .1511-7871 Abdul Razak ;et al 2010.An improved oil palm motorized .cutter .MPOB information series.ISSN 1511-7871

-3

Abdul Razak ;et al. 2007.High Reach Oil Palm motorized .cutter .MPOB information series.ISSN 1511-7871

-4

Aziz AA.1990 A simple flotation Technique to Gauge -5 Ripeness of Oil Palm Fruit and Their Maximum Oil Content .Proceeding of International Palm Oil Development .Conference ,PORIM,Kuala Lumpur.Malaysia,pp.87-91 Bevan, J. W. L. and Gray, B. S. (1969). The organization -6 and control of field practice for large scale oil palm planting in Malaysia. Kuala Lumpur: Incorporated Society

of Planters. Maturity prediction. Journal of food, Agriculture and Environment .vol.8(2) Butler, R. A. 2006. Why is oil palm replacing tropical -7 rainforests? Why are bio fuels fuelling deforestation? http://news.mongabay.com/2006/0425-oil_palm.html. 14th .October, 2006 D. Adetan, L. Adekoya and K. Oladejo. “An Improved Pole- -8 and-Knife Method of Harvesting the Oil Palm”. Agricultural Engineering International : the CIGR Ejournal. Manuscript .PM 06 027. Vol. IX. June, 2007 Jeffrey Sayer,Jaboury Ghazoul,paul Nelson,Agni Klintni -9 Boedhihartono .(2012)Oil palm expansion transforms tropical landscapes and livelihoods. Global Food - 10 .Security1:2,114-119 online publication date :1-Dec-2012 Jelani, A. R., Ahmad, D., Hitam, A., Yahya, A. and Jamak, -11 J. 1999. Reaction force and energy requirement for cutting .oil palm fronds by spring powered sickle cutter .Journal of Oil Palm Research. Vol.11 (2). pp 114 – 122 Jelani, A. R., Ahmad, D., Hitam, A., Yahya, A. and Jamak, -12 J. 1999. Reaction force and energy requirement for cutting .oil palm fronds by spring powered sickle cutter .Journal of Oil Palm Research. Vol.11 (2). pp 114 – 122 F. Azhar;et al .2012 Initial Progress and Possible -13 Improvement of E-Cutter Linear Actuator Development.IEE International conference on power and energy .2-5 .Dec.2012.Kuta Kanabala,Sabah,Malaysia Fairul Azhar ;2008.Desgin of Liner Ocsillatory Actuator -14 For Oil Palm Mechanical Cutter. Theses University Putra .Malaysia Helena Anusia and Wan Ishak (2010) .Kinematics -15 analysis for five DOF Fresh Fruit Bunch harvester. Int J Agric & Biol Eng. Vol. 3

Kaida K, Zulkifly A.1192.A Micro strip sensor for -16 determination of harvesting time for oil palm fruit ,journal of microwave power and electromagnetic energy ,vol.27, .(1),pp.1-9 Ironbar, J. E. 1981. Report on my one year in office as -17 the officer in charge of Harvesting Unit, NIFOR. An .unpublished report, NIFOR, Benin-City, Nigeria. pp 1 – 8 Kwasi,p.2002.Oil palm processing in Africa .FAO -18 Agricultural Services Bulletin 184. food and agriculture .organization of the United State Nelkon M. (1985): Principles of Physics. Collins International Textbook Dept. 8thEdition

-19

Smith, N.J.H., Williams, J.T., Plucknett, D., Talbot, J.P., -20 1992. Tropical Forests andtheir Crops. Cornell University Press, Ithaca. Emir. J. Agric. Sci. 2005. 17 (2): 30-40 Wicke,B,Sikkema ,R,Durnburg.V,Faji,A,2011 Exploring land use changes and the of palm oil production in .Indonesia and Malaysia .Land use policy 28,193-206

-21

Aziz AA.1990 A simple flotation Technique to Gauge -5 Ripeness of Oil Palm Fruit and Their Maximum Oil Content .Proceeding of International Palm Oil Development .Conference ,PORIM,Kuala Lumpur.Malaysia,pp.87-91 Zeven, A.C., 1972. Partial and complete domestication of oil palm (Elaeis guineensis). Economic Botany 26, .274–279

-23

Mohd Roslan Md Noor and Mohd Haniff Harun (2006). -24 Botani Sawit – Sistem Pengangkutan Dalam Kelapa Sawit (draf). In: Esnan AG, Zin Zawawi Z, Basri MW .eds. Perusahaan Sawit Di Malaysia –satu panduan. Edisi II

Teoh, C. H. 2002. The Palm Oil Industry in Malaysia: -25 From Seed to Frying Pan Prepared. WWF Switzerland Hon. .Advisor, Plantation Agriculture, WWF Malaysia Yik Nam Lee; 2011, Increase Malaysia Palm Oil Production efficiency. Submitted in Partial Fulfilment of the Requirements for the Degree of Master of Philosophy in .System Dynamics Zeven, A.C., 1972. Partial and complete domestication of oil palm (Elaeis guineensis). Economic Botany 26, 274– .279

-

Shamil Mudhheher Abbood Phd student / Faculty of Engineering /Agricultural process Engineering

CHAPTER 1 INTRODUCTION

Background 1.1 From time immortal human being on this earth has been living on the natural vegetables and animals . But by the age of time and the evolution of life with the invention of the machines in agricultural production, agriculture evolve day after another down to the present condition. In the present day an increased in demand for agricultural products as a result of the steady increase in the population growth, not only for food that provide Food Security, also the need for greater agricultural products for industrial purposes has entered agricultural products .Nowadays , decrease of petroleum production forced the sciences to thinking about alternative fuel ,one of this now production is bio-chemical that can use as fuel and other consumer. In fact, oil palm has a significant .importance to industry and product the alternative fuel Recent century ,oil palm has become a one of the words major agricultural crop in east and central Africa (Zeven ,1972; smith et; al .,1992).Recently, it has dramatically increasing in southeast Asia (wicke et al , 2011).Actually, Oil palm is one of a highly profitable crop adapted to the humid tropics and the area devoted to this crop is likely to expand significantly in the future. It has many environmentally favorable attributes over its full life cycle. When well managed it has a positive carbon balance and when grown in a landscape mosaic it can play a role in biodiversity conservation. It has driven rapid

economic growth in several tropical developing countries and contributed to the alleviation of rural poverty (.Jeffery .et al, 2012) Nowadays, Malaysia become the largest producer and exporter of oil palm in the world, it is s for about 55%of the world palm and about 62%of world exports. The increased industrialization in this agricultural sector has resulted in the emergence of numerous refineries in the country competition is stiff on the world market, research and development is critical to generate knowledge as well as to increase production and processing efficiency .(W.I.W.Ishak and R.M.Hudzari 2010) Harvesting is the most important an activity in oil palm cultivation. It was estimated that the operation requires about 60%of the total labor for the crop and about 50 %of the total cost.(Abdul razak ,at.al 2007).oil palm harvesting involves four interrelated activities , like cutting the fronds and fruit bunches ,stacking for fronds collecting the lose fruits and carrying the harvested fruit to the collection point .(abdul razak; et; al. 1998).nowadays, there is about 25%of FFB collection is done through mini tractor and 75%is really done on manual labor (Abbai Belai; et; al ,2008). Indeed, a lot of time and energy (and therefore production cost) goes into oil palm harvesting. Such an enormous amount of energy is required for harvesting oil palm that even cutting a single frond alone, using the sickle cutter (the Malaysian knife), could require the exertion of effort force as much as 18,048 N for the most matured frond (Jelani; et; al, 1999). Further, Bevan and Gray (1969) reported that in a study on palms aged between 9 and 25 years in Malaysia, between 43.5 and 45.4 % of the total annual man-days is spent on harvesting. Harvesting from the older trees took more man-days. The situation, most likely, has not changed today because harvesting is still being done .manually

Mechanical harvesting is one of the significant operations to product the oil palm FFB. Throughout the past decades many machines were invented for oil palm harvesting by Malaysian Palm Oil Board (MPOB) but none of them was made commercial due to its inefficiency. This was because the harvester operator faces difficulty in positioning the mechanical cutter to the bunch stalk during cutting process (Helena Anusia and Wan Ishak 2010). The defies of the oil palm is the method of harvesting because the fruits are compactly packed in the bunches are hidden in the leaf axils in the crowns that may be more than 10 m higher .also, each tree need to visited every 10-15 days as fruit bunches ripen (Kwasi, 2002).However, oil palm mechanical harvesting (cutting and collecting) still need more improving to be useable, .low cost and able to reach both high and low palm tree In fact, there are many several machines and tools have manufacturing to achieve these aims such as telescopic and elbow type arm harvester (manufacturing and developing by MPOB).But these machines still have a problems or issues such as a high cost or difficulty of moving around the field between the trees There are several machines have manufactured such us a machine for harvesting tall palms and motorize cutter were developed in MPOB in 2004 and 2010 (Abd rahim shuib et al 2004) (Abd Razak et al. 2010) .But every one of this machine has own problem such as a high cost and limitation of working .For this project we design a low cost liner mechanical cutter with light flexible pole to reach a tall palm tree and scissor basket left install in front of medium tractor to integrate the cutting and collecting oil .palm fruit FFB in one time The previous dump truck FFB collector was modification in 1982 as FFB collector and transporter .the harvester cut the FFB and let it fall in to the modified dumper to reduce damage and avoid loose fruits. The

truck dumber will collect the FFB and transport them to the collection point. In 2004 MPOB has developing tall palms harvesting machine .the machine carry a telescopic boom which the cutting mechanism is mounted onto it .It is able to cut the FFB and convey in to the container . The challenge of this machine it is still costly . Initially, mechanical of oil palm harvesting of oil palm fruit bunches (FFB) remains issue that need to solve, the short tree current methods by using the chisel or sickle, which requires manual labor (Abd Rahim Shuib rt;al.2004). Since 1982 many harvesting machines have been developed for harvesting palm fruit bunches (FFB) .Nowadays, the big define to developing or manufacturing a suitable cutter and collecting machine to reach both of high and low harvesting with light weight, low cost and .lower cutting force and fast The main objectives of this project is design and fabricate the suitable mechanical cutter for cutting leaf and FFB and harvesting platform that has installed on the tractors frame. .The tractor s the hydraulic power to operate the scissor lift and the air compressing power to operate the cutter. So in this new design of mechanical cutter and collection platform will be useful for medium and high trees with plausible cost .also, use the available power sources to operate the cutter and lifting the .platform There are several tools machines have been developing to harvest the FFB. The Malaysian Palm Oil Board (MPOB) has developed a motorized cutter. it has being able to more than double labored productivity for harvesting .The only drawback for this cutter is that can only harvest palms of below 4.5 m . ( Abd Razak; et ;al. 2007). This cutter consists of a petrol engine located of the bottom of the pole .A telescopic aluminum pole , Sickle as cutting head and rotational motion from the engine is transmitted to pear of gears from where the sickle is connected

through the transmission shaft. (F. Azhar; et; al .2012). Later, improving of oil palm motorize cutter has been done in 2010 by MPOB to be strong to durable enough to overcome high friction due the high speed of cutting (Abd .Razak;et; al. 2010) A linear oscillatory actuator for oil palm mechanical cutter had been designed and fabricated .This cutter can reach palm until 8 m and the weight is 7.5 kg . LOA is proposal to replace the bevel gears to produce direct liner motion .LAO actually is activated by dynamo which converts the mechanical energy provided by the petrol engine to electrical energy .This energy will cause the LOA shaft connected to the sickle to vibrate the sickle .In this system was replace the transmission shaft inside pole with a pair of copper wire to connect the dynamo with the LOA .(F. Azhar et al 2012) In recent years MPOB has been developing of machine for harvesting tall palms .this machine it is carry a telescopic boom which the cutting mechanism is mounted into it. It is able to cutting FFB and covey it into the nearest container without letting it fall on the ground .The challenge of this machine it is heavy and costly(Abd Razak; et; al. 2004) .On the other hand ,collage of food and agriculture in U.A.E has been developed a tractor – mount date palm tree service machine .The developed system is attached to the rear of tractor ,system's power source is the tractor hydraulic system .The machine has the capability to lift a service worker and the required tools to the crown zoon as high as 4.5 m.(Moustafa A.Fadel 2005). A quick attachment mechanism need to be developed to make attachment of the machine to the .tractor easir

In the new design, the pneumatic driven saw is use as cutting tool .The pneumatic driver selected because the

weight is so light (0.9) kg ,also the air power which drove can get from any compressor using a small petrol engine or tractor power through a PTO shaft which provide 5.39 letter/sec .The pneumatic driven saw selected to be suitable for oil palm leaf and FFB. It has 15 cm length with double action cutting, it is manufacturing from high carbon steel .The vibration of the engine is about 5000 SPM with free load. The cutting head connect to the double extension aluminum pole 38ʺ, 42ʺ .Actually, the pole material specifications selected to be compatible with the MBOPs specifications .The two parts of pole t together by double clamp. The air is supply to the cutting head by the 1/4ʺ high pressure tube inside the aluminum pole. T- Double clamp is use to the two parts of pole, this clamp easy to adjust the length of extension pole depend of height of tree; the cutter is light enough to .carry it U-shape basket on a scissor lift will be install in front of the 45 hp tractor. To reach the fruit the worker will be able to utilize until the trees are 25 ft tall. The tractor will be position at the base of the tree in the maturing fruit side ,so the trunk of tree is positioned inside the basket through the U- shape .The basket will lifted to appropriate height . Therefore, the bunch can be easily harvest by the cutter after cutting the nearest leaf .Finally ,the FFB fruit will fall inside the basket directly .after harvesting the fruit the tractor will move to another tree and when the basket be full ,the driver will drive the tractor to nearest .FFB collection point to discharge the harvesting problem Statement– 1.2 Rapid chopping method motorized cutter (cantas) which developed by MPOM was finding an effective solution to solve the oil palm harvesting issues .But this existing cutter is limited to palm trees below 5 meter height .Palm trees higher than 5 meter face a difficulty to

use this cutter because of limitation of height and extra weight. Developing a longer reach cutter with light weight .is necessary demand to solve the cutting problem Collecting oil palm fruit after cutting still critical problem because it need more labor and lose a lot of fruit epically tall tree , .MOPM has been developing a tall palm trees. is machine has ability to convey the FFB to the container .But the significant issues of this machine it is costly and difficult to move among trees. To override these issues of height cost and difficulty of collection ffb ;this research will focus to use a mini tractor to cut and collect ffb .The scissor basket left will install over the min tractor .The basket will reach a 3.5 meter with the height of the tractor ;using a 5 meter cuter ,the total heigh will be 8.5 meter .This new harvesting method will cover the midum and tall trees were in the economical age and integrate cutting . and collecting FFB a ones

Objectives 1.3

To design and fabricate extensions pole and .mechanical cutter .To

1.3.1

design and fabricate a scissor lift basket 1.3.2

To integrate the cutting and collection the oil palm . FFB

1.3.3

CAPTER 2 LITRERTURE REVIEW Introduction 2.1 Oil palm is a tree without branches but with many wide leaves or fronds at the crown of tree. It is become the world's number one fruit crop because of it is unparalleled productivity (Butler 2006).The first large plantation in Sumatra was planted in 1911.Otherwise, in 1917 the first true plantation was established in Malaysia in the Selangor district . Currently, Malaysia has 4.7 million of oil palm plantation and the harvested area is 11.20 million ha. The potential land of oil palm plantation is increasing dramatically. Malaysia can only rely on another 28%of potential oil palm plantation area. Actually, oil palm harvesting in Malaysia is still heavily relied on foreign labor .Initially, there are 369000 foreign workers employed in plantation (Yik Nam Lee 2011).Approximately, harvesting and collections of FFB and a lose fruits are laborious, time consuming and incur the highest cost of operation .Thus it is justified to improve the existing machines and systems in the plantation to solve the labor, .time and cost

oil palm bunch 2.2

Oil palm is monoceous ; both male and female flowers on the same tree. (Mohd Hanif and Mohd Roslan,2002). Bunch harvesting commences about 24 to 30 months after planting; each palm tree can produce between 8-15 fresh fruit bunches of FFB yearly. Each bunch is normally weighting about 5 -25 kg depending on the planting material and age of the palm. Also, each fruit bunch contains between 1000- 1300 fruit lets (Teoh,2002). A fruit bunch takes about 20 to 22 weeks to ripe (Aziz et al,1990). The ripeness is normally indicated Fig 2.1show the fruit bunch after cutting by the fruit color fruit changes from black to reddish orange (Kadia and Zulkily,1992) fig 2.1 shown the fruit bunch . Currently, a new concept of image based measurement for modeling the oil palm FFB maturity predication which enables to determine the correct time for harvesting (W.I.W.Ishak and R.M.Hudzari,2010) Harvesting 2.3 Timeliness harvesting is very crucial to the quantity and quality of yield fruit of oil palm. The under ripe fruit will yield lower quantity of oil while the over ripe will yield oil with high free fatty acid. When a fruit is fully ripe, it loose

itself from the bunch and drops on the ground or it is become easily detachable. So, the idle system of harvesting would be collect loose fruit daily from the ground. (Harcharan 1976). Thus, this method it is clearly impossible with high plantation and production. So, a fruit bunch is normally been as ripe enough for harvesting when a few fruits have loosened themselves from the .bunch and dropped on the ground (D.Adetan et al 2007) Previous methods of harvesting 2.4 There are several methods and activates have been used to harvesting oil palm fruit ,following these activities and a pullers previous methods Cutting 2.4.1 In fact, a lot of time and energy goes into the oil palm fruit harvesting .such as enormous amount of energy is required for harvesting oil palm that even cutting a single front alone ,the Malaysian knife (sickle cutter) could require exertion of force as much as 18 N for the matured frond (Jelani et al;1999). Short trees within arm-reach are harvested using either the cutlass or chisel to cut the bunches and fronds. On another way, tall trees above 9 m in height are harvested using either a single rope and cutlass (SRC) or the double rope and cutlass (DRC) method .the SRC method is Commonly because it is relatively much faster though less save (Ironbar,1981).Fig 2.4.1 .show the manual short tree harvesting

Medium -height oil palm trees beyond arm reach up to height of about 9 m are harvested using the bamboo pole and knife (BPK) method .The heights of pole depend of the average height of the trees .nowadays, another method is the aluminum pole and knife (APK) method . in this method ,a 40 mm diameter pore replace the bamboo pole of the (BPK) harvesting method .It work very well and faster than the BPK method for trees of height below 5.5 m . Above this height ,bending of long harvesting pole that are relatively heavier cutting knives on top constitutes very serious problem as it become difficult to engage the stalks of palm fronts and bunches (D.Adetan et al 2007) .

Fig 2.4.1the manual harvesting fig 2.4.2 the tall balm harvesting Mechanization cutting 2.5 Recently, Malaysian palm oil board (MPOB) has developed an significant oil palm fruit motorized cutter which employs a specially design gears head and sickle which is able perform the cutting with more efficient and faster compared with traditional cutting tools .Field trail shown that the productivity of the workers has been increased to three times as opposed to the manual sickle. The oil palm motorized cutter consists of a petrol engine located at the bottom of pole ,a telescopic aluminum pole and sickle as cutting head as shown in fig 2.5.( Abdul . Razak et al 2007)

Fig 2.5 MPOB motorized cutter To solve the mechanical limitation of existing oil palm motorized cutter such as the extra weight and limitation in height, a linear oscillatory actuator (LOA) is proposed to replace the bevel gears to produce direct liner motion..The LOA is activated by a generator which converts the mechanical energy provided by the two stroke engine (Fairul 2008) Oil palm fruit collection

2.6

In Malaysia various mechanism collection system have been under test since 1980s and have been gradually developed .Wan Ishak in 1982 was modified a dumber as a fresh fruit bunch ( FFB) collector and transporter (Malik and Yaakob .1989). Fawzi;1994 recommended a low powered mechanical buffalo for collecting FFB on terraces and producing higher labor productivity. kamarudzaman et al (1994) studied the introduction of mechanized system of small tractor with mechanical loading , finding that tow worker could be omitted for each unit .deployed and the harvester increased about 65%. Each unit could deal with about 230 to 250 ha of oil palm .field Fruit catching mechanism ( FCM) was fabricated by with Japanese firm . FCM has been developed as MPOB a harvesting machine with the cutting mechanism

attached to a boom .It can reach 10 m height , the maximum height both a cutter blade member and fruit catching mechanism can be extended upwards and retracted using hydraulic cylinders .When the bunch is sighted ,the operator will maneuver the vehicle close to the palm and start harvesting process, then the arm extended to the palm crown by shifting the respective joystick control .A ones time the cutter is brought to suitable position ,the operator will cut the fronds and bunches ,the cut will fall down and placed into bin. (Abd Rahim et al 2004) . Fig 2.6 shown the FCM

.

Fig 2.6 fruit catching mechanism A tractor-mounted date palm tree service machine was developed in U.A.E in 2005. The service platform is a Vshaped basket-like structure to serve date palms, which is attached to the tip of the aerial boom via four ts. The V-shape gives the worker the ability to go around most of the tree trunk to perform comfortably. To complete the circle around the trunk, two extensions on the platform sides and another foldable bridge were added to the platform. The bridge can be folded down to help the operator to go around the tree, and then folded up when

the machine is ready to move(Moustafa A .Fadel,2005).Fig 2.6 shown date palm serves machine

Fig 2.6 date palm serves machine MATERIAL AND METHODOLOGY 3.1 Integrate the harvester and dump track collector system is a urgent necessity for oil palm harvesting .In this research firstly, will design and fabricate the pneumatically cutter with aluminum extensional pole .the cutter has a 6 in high carbon steel saw fig 3.1 shown the cutter design .the 5000 spm saw will vibrate in 0.9 cm stroke .Fig 3.1 shown the sold design for cuter and pole. The cutter will be connected with the pole by using propel structure holder .tow part of pole will t through a double clamp. The cutter will reach the leaf and FFB within 8 m height. Suitable air compressor will install behind the tractor to proved the cutter in air presser trough the three

point attach. On the other hand, scissor lift basket will design and fabricated to install on the 45 hp 4 wheel drive tractor. The hight of scissor is 2 meter .It is installing on the

Fig 3.1 the sold drawing design for the cutter and extension pole tractor frame with height 1.5 ,above the scissor the harvesting U-shape basket will install . The basket shape allow the basket go into the palm tree trunk .The basket divide in tow part first part for harvester standing . The harvester stand in basket and controlling the position the basket .After that the worker will use the cutter to cut the bunches, the bunch will fall in the basket. The hydraulic dumper collection system (scissor basket) to ease in catching the fallen FFB, transport them and dumped at the collection point. This new tractor system will reduce time and labor harvest, collect FFB, collect lose fruits and .transport the fruit to the collection point scissor lift 3.2 A scissor lifting device is a system that allows small force (effort) to overcome a large force or load (Alexander et al, 1978, Smith, 1981, Nelkon, 1985). There are practically hundreds of uses for lift scissors in manufacturing, warehousing and distribution facilities. The addition of this device (lift scissor ) makes job faster, safer and easier. Some typical applications include; machine

feeding and offloading, product assembly, inspection quality control repair, feeding and offloading conveyor .levels One of the most important factors of lift platform is its stability. Knowing that stability is a source of concern for a lift platform, its positioning should be on a flat surface and the load should be place or when compared to other lifting device; firstly, its dependency on power supply is eliminated. Secondly, it allows smooth movement without jerking due to steady increase in fluid pressure, majority of .lift platform in market make use of hydraulic

References Alexander j., Kaman P., Jack P., and David S. (1978), -1 Physic for EngineeringTechnology. John Willey and Sons Inc ,.USA. Allens H. R Abd Rahim Shub ,et al, 2004 Development of machine -2 for harvesting tall palms .MPOB information series , ISSN .1511-7871 Abdul Razak ;et al 2010.An improved oil palm motorized .cutter .MPOB information series.ISSN 1511-7871

-3

Abdul Razak ;et al. 2007.High Reach Oil Palm motorized .cutter .MPOB information series.ISSN 1511-7871

-4

Aziz AA.1990 A simple flotation Technique to Gauge -5 Ripeness of Oil Palm Fruit and Their Maximum Oil Content .Proceeding of International Palm Oil Development .Conference ,PORIM,Kuala Lumpur.Malaysia,pp.87-91 Bevan, J. W. L. and Gray, B. S. (1969). The organization -6 and control of field practice for large scale oil palm planting in Malaysia. Kuala Lumpur: Incorporated Society

of Planters. Maturity prediction. Journal of food, Agriculture and Environment .vol.8(2) Butler, R. A. 2006. Why is oil palm replacing tropical -7 rainforests? Why are bio fuels fuelling deforestation? http://news.mongabay.com/2006/0425-oil_palm.html. 14th .October, 2006 D. Adetan, L. Adekoya and K. Oladejo. “An Improved Pole- -8 and-Knife Method of Harvesting the Oil Palm”. Agricultural Engineering International : the CIGR Ejournal. Manuscript .PM 06 027. Vol. IX. June, 2007 Jeffrey Sayer,Jaboury Ghazoul,paul Nelson,Agni Klintni -9 Boedhihartono .(2012)Oil palm expansion transforms tropical landscapes and livelihoods. Global Food - 10 .Security1:2,114-119 online publication date :1-Dec-2012 Jelani, A. R., Ahmad, D., Hitam, A., Yahya, A. and Jamak, -11 J. 1999. Reaction force and energy requirement for cutting .oil palm fronds by spring powered sickle cutter .Journal of Oil Palm Research. Vol.11 (2). pp 114 – 122 Jelani, A. R., Ahmad, D., Hitam, A., Yahya, A. and Jamak, -12 J. 1999. Reaction force and energy requirement for cutting .oil palm fronds by spring powered sickle cutter .Journal of Oil Palm Research. Vol.11 (2). pp 114 – 122 F. Azhar;et al .2012 Initial Progress and Possible -13 Improvement of E-Cutter Linear Actuator Development.IEE International conference on power and energy .2-5 .Dec.2012.Kuta Kanabala,Sabah,Malaysia Fairul Azhar ;2008.Desgin of Liner Ocsillatory Actuator -14 For Oil Palm Mechanical Cutter. Theses University Putra .Malaysia Helena Anusia and Wan Ishak (2010) .Kinematics -15 analysis for five DOF Fresh Fruit Bunch harvester. Int J Agric & Biol Eng. Vol. 3

Kaida K, Zulkifly A.1192.A Micro strip sensor for -16 determination of harvesting time for oil palm fruit ,journal of microwave power and electromagnetic energy ,vol.27, .(1),pp.1-9 Ironbar, J. E. 1981. Report on my one year in office as -17 the officer in charge of Harvesting Unit, NIFOR. An .unpublished report, NIFOR, Benin-City, Nigeria. pp 1 – 8 Kwasi,p.2002.Oil palm processing in Africa .FAO -18 Agricultural Services Bulletin 184. food and agriculture .organization of the United State Nelkon M. (1985): Principles of Physics. Collins International Textbook Dept. 8thEdition

-19

Smith, N.J.H., Williams, J.T., Plucknett, D., Talbot, J.P., -20 1992. Tropical Forests andtheir Crops. Cornell University Press, Ithaca. Emir. J. Agric. Sci. 2005. 17 (2): 30-40 Wicke,B,Sikkema ,R,Durnburg.V,Faji,A,2011 Exploring land use changes and the of palm oil production in .Indonesia and Malaysia .Land use policy 28,193-206

-21

Aziz AA.1990 A simple flotation Technique to Gauge -5 Ripeness of Oil Palm Fruit and Their Maximum Oil Content .Proceeding of International Palm Oil Development .Conference ,PORIM,Kuala Lumpur.Malaysia,pp.87-91 Zeven, A.C., 1972. Partial and complete domestication of oil palm (Elaeis guineensis). Economic Botany 26, .274–279

-23

Mohd Roslan Md Noor and Mohd Haniff Harun (2006). -24 Botani Sawit – Sistem Pengangkutan Dalam Kelapa Sawit (draf). In: Esnan AG, Zin Zawawi Z, Basri MW .eds. Perusahaan Sawit Di Malaysia –satu panduan. Edisi II

Teoh, C. H. 2002. The Palm Oil Industry in Malaysia: -25 From Seed to Frying Pan Prepared. WWF Switzerland Hon. .Advisor, Plantation Agriculture, WWF Malaysia Yik Nam Lee; 2011, Increase Malaysia Palm Oil Production efficiency. Submitted in Partial Fulfilment of the Requirements for the Degree of Master of Philosophy in .System Dynamics Zeven, A.C., 1972. Partial and complete domestication of oil palm (Elaeis guineensis). Economic Botany 26, 274– .279

-