Palm Oil Gearbox (sumitomo) 4c3u1h

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Palm Oil Gearbox (sumitomo) as PDF for free.

More details w3441

- Words: 1,562

- Pages: 64

Sumitomo Highlight

Sumitomo Companies Sumitomo history traced back to 1691 and evolved in to >USD $400Billion group, consisting of 19 companies Company name

2

Business

Company name

Business

Sumitomo Chemical Co., Ltd.

Chemicals

Mitsui Sumitomo Insurance Co., Ltd.

Insurance

Sumitomo Heavy Industries, Ltd.

Machinery and shipbuilding

Nippon Sheet Glass Co., Ltd.

Glass

Sumitomo Mitsui Banking Corporation

Finance

NEC Corporation

Electronics and electric products

Sumitomo Metal Industries, Ltd.

Steel

Sumitomo Realty & Development Co., Ltd.

Real estate

Sumitomo Metal Mining Co., Ltd.

Nonferrous metals

Sumitomo Osaka Cement Co ., Ltd.

Cement

Sumitomo Corporation

Integrated trading company

Sumitomo Light Metal Industries, Ltd.

Nonferrous metals

The Sumitomo Trust & Banking Co., Ltd.

Finance

Sumitomo Mitsui Construction Co., Ltd.

Construction

Sumitomo Life Insurance Co.

Insurance

Sumitomo Bakelite Co., Ltd.

Chemicals

The Sumitomo Warehouse Co., Ltd.

Warehousing

Sumitomo Forestry Co., Ltd.

Lumber and housing

Sumitomo Electric Industries, Ltd.

Electronics and electric products

Sumitomo Heavy Industries (SHI)

3

Global Presence

4

South East Asia

Country Singapore Malaysia Thailand Indonesia India Philipines Vietnam Myanmar

5

Factory 1 (HQ) 1 1 1 1 1 1 0

Sales Offices 1 5 7 3 9 4 2 1

Widest Direct Network in South East Asia

5

Cyclo

Paramax

Paramax

7

Paramax Features

8

25 degree Tooth Pressure Angle

9

Gearing Features Gear design is based on the AGMA standards with tooth modifications developed with computer technology. The resulting gearing has quieter operating characteristics, improved shock capacity, and longer life. Every PARAMAX 9000 series speed reducer is designed with precisely balanced gear combinations. All gearing is produced from vacuum degassed alloy steel.

Helical gears are produced with 25 normal pressure angle hobs at increased helix angles. This produces stronger and quieter gearing.

10

GB Manufacturing (Asia)

Tang Shan

11

Okayama

GB Manufacturing

Gear grinding machine Made in MAXΦ 1100 Module 22 Size 9136 output stage

12

GB Manufacturing Housing processing equipment Made in Japan

13

GB Manufacturing

14

Slow speed shaft peripheral grinding machine Made in Japan Center distance 2000

GB Manufacturing

Heat treatment (carburizing) equipment

15

GB Manufacturing

Large size 3D measuring equipment Carl Zeiss Measurement range 1600x4200x1400 Size 9136 housing

16

GB Manufacturing

Gear measuring equipment Gleason MAXΦ 1100 Module 22 Size 9136 output stage

17

GB Manufacturing

100% parts inspection

18

Cyclo

19

Cyclo - “CYCLO” is derived from the greek word “Kyklos” for circle. The name was use to refer to the Cyclo Disc’s outer profile which resembles a cycloidal curve. - The Cyclo operating principle was invented in 1931 by a German Engineer, Lorenz Braren. - Since 1937 Sumitomo has continued the development of the Cyclo design and to date have sold over 12 million units.

20

Cyclo Features • •

21

High Shock Load Capacity - 500% Unique load distribution over many points provide a shock load capacity that exceeds conventional gears by 5 times.

Cyclo Features ●

22

No Catastrophic Failure Power transmitted by compression utilizes the material strength, no risk of fractures. Shear stresses on conventional gears would result in fractures on high impact loads.

Cyclo Features ●

23

No Catastrophic Failure Where zero failure rate is priceless !

Cyclo Features AGMA vs Cyclo Service Factors U (Uniform)

Duty

3hrs/Day 10hrs/day 24hrs/day

Load M (Moderate)

H (Heavy)

AGMA

Cyclo

AGMA

Cyclo

AGMA

Cyclo

0.80

0.80

1.00

1.00

1.5

1.35

1.00

1.00

1.25

1.20

1.75

1.50

1.25

1.20

1.50

1.35

2.00

1.60

Lower Service Factor required but with double the Warranty

24

Cyclo Features

Single stage Cyclo 6-119 ratio, efficiency 95%

25

Triple stage helical ratio >25, efficiency 91%

Cyclo Features

26

Applications Study

27

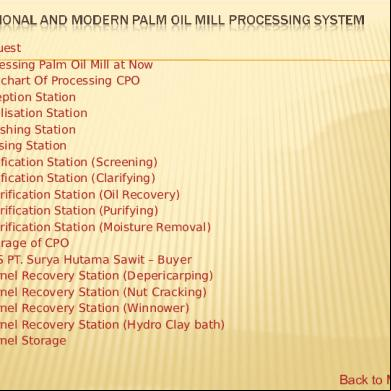

Sample of Gear Drive Application: Palm Oil Mill Machineries

28

FFB Conveyor

29

Capstan

30

Thresher

31

Screw Conveyor

32

Digester

33

Digester

Model Ratio Input speed (rpm) Mech Rating (kW) S.F @ 30kW Rated Torque (Nm)

Digester 3000-3500L (Parallel) Motor 22-30kW input 1450rpm SEW Sumitomo Flender MC3PVSF04 YVA040P3DG H3SV6 57.962 57.962 60.347 1450 1450 1450 46.3 49 38 1.54 1.63 1.27 16600 18000 15500

Tooth Angle

20

25

20

Output Shaft Dia/length (mm) Input Shaft Dia/length (mm) Center distance (mm)

105/210 38/130 444

105/210 38/130 444

110/210 30/?? 440

Screw Press

Screw Press P15

Screw Press P15 Motor 30kW input 1000rpm SEW Sumitomo Flender Model M3PSF50SPD YHD060P3SP H3SH10 Ratio 78.456 78.456 79.046 Input speed (rpm) 1000 1000 1000 Mech Rating (kW) 60 60 57 S.F 2.00 2.00 1.90 Rated Torque (Nm) 45000 45000 43800 Tooth Angle 20 25 20 Output Shaft Dia/length (mm) 150/200 150/200 160/300 Input Shaft Dia/length (mm) 55/95 55/95 45/100 Center height/distance (mm) 310/628 310/628 325/630

Screw Press P20

Model Ratio Input speed (rpm) Mech Rating (kW) S.F Rated Torque (Nm) Tooth Angle Output Shaft Dia/length (mm) Input Shaft Dia/length (mm) Center height/distance (mm)

Screw Press P20 Motor 45kW input 1000rpm SEW Sumitomo M3PSF60SPD YHD070P3SP YHD080P3SP 77.373 77.373 76.353 1000 1000 1000 95 95 100 2.11 2.11 2.22 70000 70000 74000 20 25 25 170/240 170/240 165/248 60/140 60/140 65/140 350/715 350/715 335/722

Flender H3SH11 80.111 1000 83 1.84 63500 20 170/240 42/110 335/705

EFB Press

Kernel Press

Kernel Press

Kernel Press Motor 55kW input 1000rpm SEW Sumitomo Model M3PSF60KPD YHD070P3 YHD080P3 Ratio 55.438 54.891 55.066 Input speed (rpm) 1000 1000 1000 Mech Rating (kW) 139 140 140 S.F 2.53 2.55 2.55 Rated Torque (Nm) 74000 74000 74000 Tooth Angle 20 25 25 Output Shaft Dia/length (mm) 170/240 170/240 165/248 Input Shaft Dia/length (mm) 60/140 60/140 65/140 Center height/distance (mm) 350/715 350/715 335/722

Flender H3SH11 56.924 1000 136 2.47 74000 20 170/240 42/110 335/705

Palm Oil Mill

POM Customers of Sumitomo

And many more!

41

Palm Oil Mill

Direct factory with spares parts/units In Malaysia, Thailand & Indonesia

Why Sumitomo? > 40 years of experience in POM

Sumitomo Reducer for Screw Press in Southern Mill Malaysia, operating since 1971. Customer: ‘Only oil changed so far’

Highest product quality Sumitomo POM ‘Y’ series are among the top seller in POM market, designed specifically for POM as to withstand harsh POM operating condition

42

Widest direct network in South East Asia. Fastest and parts availability Fully equipped service teams for and diagnosis.

Palm Oil Mill Why Sumitomo?

Special POM replacement policy - Sumitomo will replace any breakdown unit (less likely) during warranty period from nearest available factory. - Inspection for cause of damage & warranty status to be carry out in later part. - This is to assure short down time and customer get to resume operation as usual.

43

Palm Oil Mill Why Sumitomo?

44

We exist because of you, our customer. We will always standby for your need. Let’s work and success together. Thank You!

45

Other Applications

46

Mining/Material Handling High Speed Conveyor

47

Winch Drives

Leach Tank Mixer

Mining/Material Handling Bucket Elevator

48

Feeder Breaker

Crusher

Mining/Material Handling Feeder Drives

49

Rail Stacker Drive

Retrofit Units

Knowing Mining Requirements

Mining/Material Handling Why Sumitomo? Complete Package

Tapping on our worldwide experience in mining/MH sector, Sumitomo products are always Designed & improved for our customers

Sumitomo is capable in supply, design and install all required items and accessories as a complete drive package. We provide solutions

After Sales Limiting machinery downtime is crucial. Proper maintenance and excellent after sales is always the priority. Sumitomo is renowned for the best & well trained engineers. Whenever you are in South East Asia, Sumitomo engineers will be the closest to you.

50

Mining/Material Handling Customers of Sumitomo

Pha Lai Power

51

And many more!

Rubber Industry Dry Pre-breaker

52

Slab Cutter

Crepe

Rubber Industry

Always prepare to change for customers

Why Sumitomo? No.1 Brand in Rubber Industry

From pulley & belt to direct input adapter all the way to special drain valve and special warning sticker. Sumitomo always strike to meet our customer demands, because we treat customers’ seriously. Thanks to the rugged design, high shock load capacity and established sales and service network, Sumitomo Paramax is the leader in Rubber industry.

Peace of mind Backed up with the best track record & reputation in rubber industry, choosing Sumitomo Paramax allows you to enjoy uninterrupted production & ease of spare parts availability.

53

Rubber Industry What’s More? Compact Yet Powerful!

Higher rating lower C. height Easy replacement

54

Brand

Model

Ratio

Sumitomo Flender

PHD9060P3 S2SH08B

25 25

Brand

Model

Ratio

Sumitomo Flender

PHD9065P3 S3SH09B

25 25

Input 75kW 1000rpm O/p Speed Mech Rating S.F (rpm) (kW) 40 109 1.45 40 100 1.33 Input 90kW 1000rpm

Center Height Housing (mm) 265 Split 280 Mono

O/p Speed Mech Rating (rpm) (kW)

Center Height Housing (mm)

40 40

152 149

S.F 1.69 1.66

300 320

Split Mono

Tooth Angle 25 20

Tooth Angle 25 20

Rubber Industry What’s More? Stronger Gearing

55

Rubber Industry What’s More? Easy Maintenance

Split Housing for >24400Nm (Creper 55kW onwards) Easy Maintenance

56

Monoblock Housing Require special press set, inner jig etc

Rubber Industry What’s More? Easy Maintenance

2600Nm - 19900Nm Size 9015-9055 Monoblock Housing

Sumitomo Paramax > 24400Nm Size 9060-9136 Split Housing Flender 2300Nm - 78000Nm Size 3-12 Monoblock Housing

57

>86000Nm Size >13 Split Housing

Rubber Industry Customers of Sumitomo

And many more!

58

Other Applications Main Hoist & Gantry, Overhead Crane

59

Pulp & Paper

Other Applications Cooling Tower

60

Bucket Elevator (Cement)

Other Applications Plastic Extrusion

Screens

Sugar Cane Carrier

61

Other Applications Port Machinery

Gantry

62

Main Hoist

Other Applications Port Machinery

Gantry

63

Main Hoist & Trolley

Other Applications Chemical Mixing Tank

64

Steel Industry

Sumitomo Companies Sumitomo history traced back to 1691 and evolved in to >USD $400Billion group, consisting of 19 companies Company name

2

Business

Company name

Business

Sumitomo Chemical Co., Ltd.

Chemicals

Mitsui Sumitomo Insurance Co., Ltd.

Insurance

Sumitomo Heavy Industries, Ltd.

Machinery and shipbuilding

Nippon Sheet Glass Co., Ltd.

Glass

Sumitomo Mitsui Banking Corporation

Finance

NEC Corporation

Electronics and electric products

Sumitomo Metal Industries, Ltd.

Steel

Sumitomo Realty & Development Co., Ltd.

Real estate

Sumitomo Metal Mining Co., Ltd.

Nonferrous metals

Sumitomo Osaka Cement Co ., Ltd.

Cement

Sumitomo Corporation

Integrated trading company

Sumitomo Light Metal Industries, Ltd.

Nonferrous metals

The Sumitomo Trust & Banking Co., Ltd.

Finance

Sumitomo Mitsui Construction Co., Ltd.

Construction

Sumitomo Life Insurance Co.

Insurance

Sumitomo Bakelite Co., Ltd.

Chemicals

The Sumitomo Warehouse Co., Ltd.

Warehousing

Sumitomo Forestry Co., Ltd.

Lumber and housing

Sumitomo Electric Industries, Ltd.

Electronics and electric products

Sumitomo Heavy Industries (SHI)

3

Global Presence

4

South East Asia

Country Singapore Malaysia Thailand Indonesia India Philipines Vietnam Myanmar

5

Factory 1 (HQ) 1 1 1 1 1 1 0

Sales Offices 1 5 7 3 9 4 2 1

Widest Direct Network in South East Asia

5

Cyclo

Paramax

Paramax

7

Paramax Features

8

25 degree Tooth Pressure Angle

9

Gearing Features Gear design is based on the AGMA standards with tooth modifications developed with computer technology. The resulting gearing has quieter operating characteristics, improved shock capacity, and longer life. Every PARAMAX 9000 series speed reducer is designed with precisely balanced gear combinations. All gearing is produced from vacuum degassed alloy steel.

Helical gears are produced with 25 normal pressure angle hobs at increased helix angles. This produces stronger and quieter gearing.

10

GB Manufacturing (Asia)

Tang Shan

11

Okayama

GB Manufacturing

Gear grinding machine Made in MAXΦ 1100 Module 22 Size 9136 output stage

12

GB Manufacturing Housing processing equipment Made in Japan

13

GB Manufacturing

14

Slow speed shaft peripheral grinding machine Made in Japan Center distance 2000

GB Manufacturing

Heat treatment (carburizing) equipment

15

GB Manufacturing

Large size 3D measuring equipment Carl Zeiss Measurement range 1600x4200x1400 Size 9136 housing

16

GB Manufacturing

Gear measuring equipment Gleason MAXΦ 1100 Module 22 Size 9136 output stage

17

GB Manufacturing

100% parts inspection

18

Cyclo

19

Cyclo - “CYCLO” is derived from the greek word “Kyklos” for circle. The name was use to refer to the Cyclo Disc’s outer profile which resembles a cycloidal curve. - The Cyclo operating principle was invented in 1931 by a German Engineer, Lorenz Braren. - Since 1937 Sumitomo has continued the development of the Cyclo design and to date have sold over 12 million units.

20

Cyclo Features • •

21

High Shock Load Capacity - 500% Unique load distribution over many points provide a shock load capacity that exceeds conventional gears by 5 times.

Cyclo Features ●

22

No Catastrophic Failure Power transmitted by compression utilizes the material strength, no risk of fractures. Shear stresses on conventional gears would result in fractures on high impact loads.

Cyclo Features ●

23

No Catastrophic Failure Where zero failure rate is priceless !

Cyclo Features AGMA vs Cyclo Service Factors U (Uniform)

Duty

3hrs/Day 10hrs/day 24hrs/day

Load M (Moderate)

H (Heavy)

AGMA

Cyclo

AGMA

Cyclo

AGMA

Cyclo

0.80

0.80

1.00

1.00

1.5

1.35

1.00

1.00

1.25

1.20

1.75

1.50

1.25

1.20

1.50

1.35

2.00

1.60

Lower Service Factor required but with double the Warranty

24

Cyclo Features

Single stage Cyclo 6-119 ratio, efficiency 95%

25

Triple stage helical ratio >25, efficiency 91%

Cyclo Features

26

Applications Study

27

Sample of Gear Drive Application: Palm Oil Mill Machineries

28

FFB Conveyor

29

Capstan

30

Thresher

31

Screw Conveyor

32

Digester

33

Digester

Model Ratio Input speed (rpm) Mech Rating (kW) S.F @ 30kW Rated Torque (Nm)

Digester 3000-3500L (Parallel) Motor 22-30kW input 1450rpm SEW Sumitomo Flender MC3PVSF04 YVA040P3DG H3SV6 57.962 57.962 60.347 1450 1450 1450 46.3 49 38 1.54 1.63 1.27 16600 18000 15500

Tooth Angle

20

25

20

Output Shaft Dia/length (mm) Input Shaft Dia/length (mm) Center distance (mm)

105/210 38/130 444

105/210 38/130 444

110/210 30/?? 440

Screw Press

Screw Press P15

Screw Press P15 Motor 30kW input 1000rpm SEW Sumitomo Flender Model M3PSF50SPD YHD060P3SP H3SH10 Ratio 78.456 78.456 79.046 Input speed (rpm) 1000 1000 1000 Mech Rating (kW) 60 60 57 S.F 2.00 2.00 1.90 Rated Torque (Nm) 45000 45000 43800 Tooth Angle 20 25 20 Output Shaft Dia/length (mm) 150/200 150/200 160/300 Input Shaft Dia/length (mm) 55/95 55/95 45/100 Center height/distance (mm) 310/628 310/628 325/630

Screw Press P20

Model Ratio Input speed (rpm) Mech Rating (kW) S.F Rated Torque (Nm) Tooth Angle Output Shaft Dia/length (mm) Input Shaft Dia/length (mm) Center height/distance (mm)

Screw Press P20 Motor 45kW input 1000rpm SEW Sumitomo M3PSF60SPD YHD070P3SP YHD080P3SP 77.373 77.373 76.353 1000 1000 1000 95 95 100 2.11 2.11 2.22 70000 70000 74000 20 25 25 170/240 170/240 165/248 60/140 60/140 65/140 350/715 350/715 335/722

Flender H3SH11 80.111 1000 83 1.84 63500 20 170/240 42/110 335/705

EFB Press

Kernel Press

Kernel Press

Kernel Press Motor 55kW input 1000rpm SEW Sumitomo Model M3PSF60KPD YHD070P3 YHD080P3 Ratio 55.438 54.891 55.066 Input speed (rpm) 1000 1000 1000 Mech Rating (kW) 139 140 140 S.F 2.53 2.55 2.55 Rated Torque (Nm) 74000 74000 74000 Tooth Angle 20 25 25 Output Shaft Dia/length (mm) 170/240 170/240 165/248 Input Shaft Dia/length (mm) 60/140 60/140 65/140 Center height/distance (mm) 350/715 350/715 335/722

Flender H3SH11 56.924 1000 136 2.47 74000 20 170/240 42/110 335/705

Palm Oil Mill

POM Customers of Sumitomo

And many more!

41

Palm Oil Mill

Direct factory with spares parts/units In Malaysia, Thailand & Indonesia

Why Sumitomo? > 40 years of experience in POM

Sumitomo Reducer for Screw Press in Southern Mill Malaysia, operating since 1971. Customer: ‘Only oil changed so far’

Highest product quality Sumitomo POM ‘Y’ series are among the top seller in POM market, designed specifically for POM as to withstand harsh POM operating condition

42

Widest direct network in South East Asia. Fastest and parts availability Fully equipped service teams for and diagnosis.

Palm Oil Mill Why Sumitomo?

Special POM replacement policy - Sumitomo will replace any breakdown unit (less likely) during warranty period from nearest available factory. - Inspection for cause of damage & warranty status to be carry out in later part. - This is to assure short down time and customer get to resume operation as usual.

43

Palm Oil Mill Why Sumitomo?

44

We exist because of you, our customer. We will always standby for your need. Let’s work and success together. Thank You!

45

Other Applications

46

Mining/Material Handling High Speed Conveyor

47

Winch Drives

Leach Tank Mixer

Mining/Material Handling Bucket Elevator

48

Feeder Breaker

Crusher

Mining/Material Handling Feeder Drives

49

Rail Stacker Drive

Retrofit Units

Knowing Mining Requirements

Mining/Material Handling Why Sumitomo? Complete Package

Tapping on our worldwide experience in mining/MH sector, Sumitomo products are always Designed & improved for our customers

Sumitomo is capable in supply, design and install all required items and accessories as a complete drive package. We provide solutions

After Sales Limiting machinery downtime is crucial. Proper maintenance and excellent after sales is always the priority. Sumitomo is renowned for the best & well trained engineers. Whenever you are in South East Asia, Sumitomo engineers will be the closest to you.

50

Mining/Material Handling Customers of Sumitomo

Pha Lai Power

51

And many more!

Rubber Industry Dry Pre-breaker

52

Slab Cutter

Crepe

Rubber Industry

Always prepare to change for customers

Why Sumitomo? No.1 Brand in Rubber Industry

From pulley & belt to direct input adapter all the way to special drain valve and special warning sticker. Sumitomo always strike to meet our customer demands, because we treat customers’ seriously. Thanks to the rugged design, high shock load capacity and established sales and service network, Sumitomo Paramax is the leader in Rubber industry.

Peace of mind Backed up with the best track record & reputation in rubber industry, choosing Sumitomo Paramax allows you to enjoy uninterrupted production & ease of spare parts availability.

53

Rubber Industry What’s More? Compact Yet Powerful!

Higher rating lower C. height Easy replacement

54

Brand

Model

Ratio

Sumitomo Flender

PHD9060P3 S2SH08B

25 25

Brand

Model

Ratio

Sumitomo Flender

PHD9065P3 S3SH09B

25 25

Input 75kW 1000rpm O/p Speed Mech Rating S.F (rpm) (kW) 40 109 1.45 40 100 1.33 Input 90kW 1000rpm

Center Height Housing (mm) 265 Split 280 Mono

O/p Speed Mech Rating (rpm) (kW)

Center Height Housing (mm)

40 40

152 149

S.F 1.69 1.66

300 320

Split Mono

Tooth Angle 25 20

Tooth Angle 25 20

Rubber Industry What’s More? Stronger Gearing

55

Rubber Industry What’s More? Easy Maintenance

Split Housing for >24400Nm (Creper 55kW onwards) Easy Maintenance

56

Monoblock Housing Require special press set, inner jig etc

Rubber Industry What’s More? Easy Maintenance

2600Nm - 19900Nm Size 9015-9055 Monoblock Housing

Sumitomo Paramax > 24400Nm Size 9060-9136 Split Housing Flender 2300Nm - 78000Nm Size 3-12 Monoblock Housing

57

>86000Nm Size >13 Split Housing

Rubber Industry Customers of Sumitomo

And many more!

58

Other Applications Main Hoist & Gantry, Overhead Crane

59

Pulp & Paper

Other Applications Cooling Tower

60

Bucket Elevator (Cement)

Other Applications Plastic Extrusion

Screens

Sugar Cane Carrier

61

Other Applications Port Machinery

Gantry

62

Main Hoist

Other Applications Port Machinery

Gantry

63

Main Hoist & Trolley

Other Applications Chemical Mixing Tank

64

Steel Industry