Ratb 2 5e6iz

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Ratb 2 as PDF for free.

More details w3441

- Words: 6,472

- Pages: 135

REAKTOR ALIR TANGKI BERPENGADUK

DAFTAR PUSTAKA • Fogler, H.S., 1994, “Elements of Chemical Reaction Engineering”, 2 nd. Edition, Pretice-Hall of India, New Delhi • Levenspiel, O., 1999, ”Chemical Reaction Engineering”, 3 th. Edition, John Wiley and Sons, New York. • Smith, J.M., 1985, “ Chemical Engineering Kinetics “, 3 th. Edition, McGrawHill Book Company, New Delhi. • Sri Warnijati Agra, 1985, “ Ringkasan Reaktor Kimia bag. I “, Fakultas Teknik UGM, Yogyakarta

Continuous Stirred-Tank Reactor CSTR adalah reaktor model berupa tangki berpengaduk dan diasumsikan pengaduk yang bekerja dalam tanki sangat sempurna sehingga konsentrasi tiap komponen dalam reaktor seragam sebesar konsentrasi aliran yang keluar dari reaktor

Prinsip Kerja • satu atau lebih reagen fluida dimasukkan pada tangki sebuah reaktor yang dilengkapi dengan kipas atau impeller • impeller mengaduk cairan untuk memastikan cairan tersebut tercampur rata • ada waktu suatu cairan berada di dalam tabung tersebut sebelum keluar

Reactor CSTR. Check of a condition of the case.

Beberapa aspek penting dalam CSTR • Dalam keadaan tetap ( steady state ), fluida yang masuk harus sama dengan fluida yang keluar, sebaliknya tangki akan menjadi meluap atau kosong ( unsteady state ). Jika reaktor dalam keadaan unstedy state , model persamaan model persamaan diturunkan dari deferensiasi neraca massa dan energi. • Semua kalkulasi yang dilakukan CSTR diasumsikan sebagai pencampuran sempurna • Untuk mendapatkan hasil yang lebih banyak dalam waktu yang sama, dapat dilakukan dengan memparalelkan atau memasang seri CSTR ini • RATB kecil yang jumlahnya tak terhingga beroperasi secara seri ekivalen sebuah PFR

Keuntungan: – Suhu dan komposisi campuran dalam reaktor sama – Volume reactor besar, maka waktu tinggal juga besar, berarti zat pereaksi lebih lama bereaksi di reactor.

Keuntungan CSTR • Operasi dalam keadaan tetap menyebabkan peralatan produk lebih stabil • Penggunaan energi yang kualitasnya meningkat • Produktivitas yang lebih tinggi dalam reduksi pada periode tidak aktif (pengisian, pemanasan, pendinginan, dan pengosongan). • Campuran lebih rata karena penggunaan teknik pengadukan (stiring). Suhu dan komposisi

campuran dalam reaktor sama

Kerugian: • Tidak effisien untuk reaksi fase gas dan reaksi yang bertekanan tinggi. • Kecepatan perpindahan panas lebih rendah dibanding RAP • Untuk menghasilkan konversi yang sama, volume yang dibutuhkan RATB lebih besar dari RAP.

Kerugian CSTR • Rata-rata reaksi volumetrik yang lebih rendah akan menghasilkan produktivitas rendah. • Tidak sesuai untuk keseluruhan emulsi proses polimerisasi pada tahap pertama penggunaan CSTR • Timbul endapan di dasar akibat gaya sentrifugal CSTR • Tidak dapat merubah grade dari RTD profile sesering mungkin karena dapat mengurangi fleksibilitas reaktor • Biaya tinggi, semakin besar CSTR yang digunakan atau semakin banyak CSTR kecil yang digunakan semakin besar biaya yang dikeluarkan • Waktu menunggu (proses) yang lebih lama

Cao, Vao

A+BC

CSTR

Cbo, Vbo V

Cc, Vf

CSTR Reactor for Liquid Phase Reaction Reactant supply in: Liquid flow rate = v m3/s Concentration = C0 mol/m3

Volume of reactor = V m3

Reactor operates at outlet conditions. Reactor is wellmixed, hence concentration of reactant throughout is = C

Remaining reactant out: Liquid flow rate = v m3/s Concentration = C mol/m3

Reactor operates at steady-state - variables do not change with t

Reaktor Teraduk Sempurna (Mixed Flow Reactor) Konsentrasi di dalam reaktor = Konsentrasi keluar reaktor = Waktu lewat = Waktu yang dibutuhkan reaktan melalui reaktor

CA0 FA0 v0 XA0 CAf FA vf XAf

CAf

Neraca massa reaktan A : Masuk – Keluar – Hilang bereaksi = Akumulasi Laju molar A masuk (mol/waktu) : FA0 ( 1- XA0 ) = FA0 Laju molar A keluar (mol/waktu) : FA = FA0 ( 1- XAf ) Kehilangan selama reaksi (mol/waktu) : (-rA) V FA0 ( 1- XA0 ) - FA0 ( 1- XAf ) - (-rA) V = 0 FA0 (XA0 - XAf ) = (-rA) V τ

V FA0

V v0

τ C A0

Untuk konstan dan XA0 = 0 :

X Af X A0 rA

V FA0

C A0

XA rA

C A0 C A C A0 ( rA )

Design Equations FA,in FA,out rAV 0 XA

FAO FA FAO

ATAU DITULIS KEMBALI

DISUBTITUSIKAN DAN DIPEROLEH :

FAO X A V rA

X A FAO FA,in FA,exit

FAO/-rA

F V AO X A rA

v XA

The CSTR volume is defined by the outlet conversion, owing to dilution of reactant.

summarize: Mole Balance BATCH RAP RATB

Design Equation

1 dN A rA T , C V dt

N AO dX A rA V dt

dFA rA T , C dV

FAO

0 FA,in FA,out rA T , C V

dX A rA dV

V

FAO X A rA

MFR vs. PLUG FLOW Isothermal MFR

vC A0 X A V rA 1/rA

Kurva laju reaksi

XA PLUG FLOW

V vCA0

XA

0

dX A rA

MFR AB

rA kCA

2A B

rA kCA2

C A C A0 kC 2 A

C A C A0 kCA

1 1 4kCA0 CA 2k

Order 2, reversible, densitas konstan A+B

k1 k2

C+D

Feed: CA0, CB0, CC0 = 0, CD0 = 0

C A0 C A CB 0 CB CC CC 0 CD CD 0 a b c d

C A0 C A CB 0 CB CC CD

MFR rA rf rr k1C AC B k 2CC C D Neraca Massa

C A C A0 rA C A C A0 k1C ACB k 2CC CD

Substitusi CB = CA - CA0 + CB0 CC = CD = CA0 - CA

CA CA0 k1CA CA CA0 CB0 k2 CA0 CA Selesaiakan untuk CA

2

• Damköhler number is a dimensionless number that can give a quick estimate of the degree of conversion that can be achieved in CSTR.

First order : Second order :

Da = 0.1 or less, usually give less than 10% conversion. Da = 10.0 or greater, usually give greater than 90% conversion.

The elementary liquid phase reaction 2 A ----- B is carried out isothermally in a CSTR. Pure A enters at a volumetric flow rate of 25 dm3/s and at a concentration of 0.2 mol/dm3. What CSTR volume is necessary to achieve a 90% conversion when k = 10 dm3/(mol*s)?

• Mole Balance • Rate Law • Stoichiometry liquid phase (v = vo)

• Combine • Evaluate at X = 0.9, • • V = 1125 dm3 • Space Time

Soal-1 •

Direncanakan untuk mengganti sebuah RATB yang ada dengan RATB yang bervolum dua kali. Untuk umpan yang sama dan dengan kecepatan umpan yang sama pula, 10 mol A/liter, tentukan konversi baru ? Kinetika reaksi sebagai berikut : A ------ R -rA = CA1,5 dan konversi awal 70 %

Soal-2 • Suatu umpan “aqueous” A dan B ( 400 liter/menit, 100 mmol A/liter, 200 mmol B/liter) diubah menjadi produk dalam sebuah RATB. Dengan kinetika reaksi sbb: A + B -----R -rA = 200 CA CB mol/(liter.min ) • Hitung volum reactor untuk memperoleh konversi A, 99,9 %.

Soal-3 •

Suatu umpan gas murni A ( 1 mol/liter) dimasukkan dalam sebuah RATB yang bervolum 2 liter dan bereaksi sbagai berikut : 2 A ------ R -rA = 0,05 CA2 mol/(liter.det) Hitung kecepatan umpan (liter/min) untuk memperoleh konsentrasi keluar reactor CA= 0,5 mol/liter.

Soal-4 •

•

Reaktan gas A terdekomposisi sebagai berikut : A ----- 3 R -rA = ( 0,6 min-1) CA Hitung konversi A dalam umpan yang terdiri 50% A dan 50% inert ( denga Vo = 180 liter/min, CAo = 300 mmol/liter) jika dimasukkan dalam RATB yang bervolum 1 m3.

Soal-5 • Suatu reaksi A + B <–k1–k2–> M + N, fasa cair dijalankan dalam sebuah RATB yang volumnya 240 L. Umpan A dan B masing2 masuk reaktor dengan laju alir yang sama dengan perbandingan konsentrasi awal = 7 : 4 dan jumlah konsentrasi awal umpan adalah 2,2 mol/L. Tidak ada zat M dan N di umpan. Jika konversi atas dasar reaktan yang sedikit adalah 75% dan harga k1 dan k2 masing-masing 7 dan 3 L/mol.men, Hitung: • a. Laju alir volumetris untuk masing-masing reaktan • b. Space time dan space velocity • c. Gambarkan skema kondisi diatas

Perbandingan MFR vs. PFR (reaksi order n) 100 n=2

n V C A0 v MFR 10 n V C A0 v PFR

A produk

rA kCAn

n=1 n=0.5

1 0.01

0.1 (1-XA)

catatan (1) n#0 VMFR > VPFR (2) n=0 VMFR = VPFR (3) XA,rendah type aliran sedikit berpengaruh

1.0

Perbandingan Reaktor tunggal Untuk reaktor dengan berubah -rA = k CAn n XAf dX 1 XAf 1 A X A A τ P C A0 dX A n 1 n k C A0 0 1 X A XAi rA X Af X Af 1 A X Af n τ M C A0 rA k C A0 n-1 1 X Af n

1 A X Af X Af 1 X Af τM X n>0 1 Af 1 X A Af τP 1 X dX A Af 0 n

τM τP

C A0

X Af rA

atau C A 0 n 1 M VM VP C A 0 n 1 P

A maka

τM τP

dan

VM VP

CSTR Vs. PFR ? – For a given duty the ratio of sizes of CSTR & PFR will depend on: • extent of reaction • stoichiometry • form of the rate equation

For the simple nth-order rate law

For mixed flow reactor, Eq.5.11 gives

For plug flow reactor, Eq.5.17 gives

With constant density, or ε=0, this expression integrates to

Multiple reactors:

• The reactors may or may not be of the same type • They may be connected either in series or parallel

Issues involved:

• How many reactors ?? • What type of reactors ?? • Series / parallel arrangement ?? • Sizes of each reactor ?? • In what order they must be connected ?? • Inter-stage feed injection ?? 42

Types of staged reactors

Reactor battery

Vertically staged

Compartmented

43

Multiple reactors in parallel:

PFRs in parallel

CSTRs in parallel

44

Plug Flow Reactors in Series and/or in parallel

• Consider N plug flow reactors connected in series, and let X1, X2, ……, XN be the fractional conversion of component A leaving reactor 1,2,……,N.

for the N reactors in series

Hence, N plug flow reactors in series with a total volume V gives the same conversion as a single plug flow reactor of volume V.

CSTR VS Plug Flow •A combination of PFRs giving a particular final conversion have the same volume as a single PFR which gives the same total conversion. •A series of CSTRs can be useful to reduce the overall volume: 1/rA V V 1

0

2

XAi

XAf

V2 V1 X Ai

Other rate expressions •rA=kCAn - as n increases, PFR more favourable •zero order reactions are reactor independent •autocatalytic reactions A B rA=kCACB

1/r

XAf XA

Rate low at low conversion due to low CB

VCSTR XIN

VPFR XCSTR

X

XOUT

The reactor setup shown in Fig. E6.1 consists of three plug flow reactors in two parallel branches. Branch D has a reactor of volume 50 liters followed by a reactor of volume 30 liters. Branch E has a reactor of volume 40 liters. What fraction of the feed should go to branch D?

Figure E6.1

Multiple reactors in parallel: • Fluid streams which meet must have the same composition

• Space time () must be same for each parallel line • Any other way of feeding will be less efficient ??

50

For the optimum hook up of plug flow reactors connected in parallel or in any parallel-series combination, we can treat the whole system as a single plug flow reactor of volume equal to the total volume of the individual units if the feed is distributed in such a manner that fluid streams that meet have the same composition. Thus, for reactors in parallel V/F must be the same for each parallel line. Any other way of feeding is less efficient.

Now for reactors in parallel V/F must be identical if the conversion is to be the same in each branch. Therefore

Example: 50 lit

30 lit

F

40 lit

What should be the flow in each parallel line for optimum results. 2F/3

80 lit

F

F/3

40 lit 53

Questions

CSTRs in series Issues involved are: 1. Deg the CSTR battery • How many reactors ?? • Sizes of each ?? • In what order to connect ?? • What is optimum ?? 2. Rating the given CSTR battery • Exit conversion ?? Algebraic method Graphical method 55

TWO CSTRs in SERIES:

F V1 AO X 1 0 rA

FAO/-rA

F V1 AO X 2 X 1 rA

x1 v1

v1

v2 x1 XA

x2

x2 v2

The total volume of the two CSTRs is less than if we just had one huge CSTR.

CSTRs in Series

First-order, no volume change Single CSTR, CA = • Effluent [A] of reactor 1, CA1 = • Effluent [A] of reactor 2, CA2 = • Effluent [A] of reactor n, CAn =

CSTR in Series (Cont.)

Menentukan Sistem Terbaik untuk Konversi Tertentu Konversi tertentu Ukuran minimum ? 2 reaktor teraduk seri

C0 F0

X1

1 r

K

L

N

M

K N

X2 X1

K N X1

1 r

X2

X1

X2

L M

C0 F0

X1

L M

X2

Garis g

1 r

X1

X1

X2

X1

K, L, M, N dimaksimumkan

• Sebuah RATB dipakai untuk mereaksikan A menjadi produk dengan konversi 90%. Reaksi yang terjadi adalah order 2. Direncanakan akan memasang satu reaktor tambahan dengan ukuran sama yang disusun seri dengan reaktor pertama. Jika kondisi operasi sama, berapa konversi setelah keluar reaktor kedua? • Jika konversi keluar reaktor kedua = 90%, berapa perbandingan volume RATB 2 terhadap RATB 1? (Note: cari dulu kCo.t dengan bantuan grafik).

CSTRs in series (Design Problem) The shaded area is the saving with 2 CTSRs when compared to 1 CSTR

The conversion from the exit of the first reactor influences the amount of saving. What is the optimum saving and what is the corresponding 62 conversion

Equal-size mixed flow reactors in series

Though the concentration is uniform in each reactor, there is, nevertheless, a change in concentration as fluid moves from reactor to reactor.

N TANKS IN SERIES: ,…

F V1 AO X 1 0 rA F Vn AO X n X n 1 rA

FAO/-rA

XA

x1 x2

V1

X1

Xn-1 Xn

X2 V2

Vn-1

Xn-1

Vn

Xn

Reaktor Teraduk disusun Seri (Ukuran Sama) X0

X1

Xi-1

Xi

Xn-1

XN

C0

C1

C i-1

Ci

Cn-1

CN

Neraca massa komponen A pada reaktor i : FAi-1 – FAi – (-rA)Vi = 0 FA0 (1-Xi-1) – FA0 (1-Xi) – (-rA)Vi = 0 X i - X i-1 i

( rA ) Vi FA 0

C A 0 Vi C A 0 (X i X i 1 ) FAo rA

V vo

1 = 2 = 3,… = i = N

Reaktor Teraduk disusun Seri (Ukuran Sama) Untuk reaksi orde –1 : -rA = k CA0

X i X i 1 C Ai C Ai 1 k (1 X i ) kC Ai

C Ai 1 1 k i C Ai C A0 C C C 1 A 0 A1 ......... AN 1 (1 k i ) n C AN 1 X Ai C A1 C A 2 C AN C A0 (1 k i ) N C AN 1/ N

CA0 CAN i k

1

N CA0 Ni k CAN

1/ N

Nreaktor

1

Reaktor Teraduk disusun Seri (Ukuran Sama)

Jika N, maka N CA0 k CAN

1 1

1/ N

N lim

N

CA 0 CAN lim N k/N 1 C A0 ln k C AN

1/ N

CA, masuk

Plug flow N=5

= P N P

C A0 1 ln k C AN

N = 1, Mixed flow

Volume reaktor

CA, keluar

Stepwise drop of conversion

The larger the number of units in series, the closer should the behavior of the system approach plug flow.

In the limit, for N this equation reduces to the plug flow equation

Second-order reactions A series of N equal-size mixed flow reactors for elementary second-order reactions

CA0

CA1

CA2

CSTRs in series, 1st order rxn, isothermal

• mole balance

FA1 X FA1 FA 2 v0 C A1 C A2 V rA 2 rA2 rA2

• rate laws

rA2 k2C A2

• Stoichiometry C A2 C A1 (1 X ) • combination ...

1 X 1 n 1 k

C A2

C A0 C A0 C A1 1 2 k 2 1 2 k 2 1 1k1 1 k 2

C A0 C A0 C An n n 1 k 1 Da C An C A0 (1 X )

CSTRs in series • constant flow rate • conversion as a function of the number of tanks in series Two equal-sized CSTRs in series will give a higher conversion than two CSTRs in parallel of the same size when the reaction order is greater than zero.

EXAMPLE 6.2 MIXED FLOW REACTORS IN SERIES

At present 90% of reactant A is converted into product by a first-order reaction in a single mixed flow reactor. We plan to place a second reactor similar to the one being used in series with it. (a) For the same treatment rate as that used at present, how will this addition affect the conversion of reactant?

(b) For the same 90% conversion, by how much can the treatment rate be increased

SOLUTION For the first-order reaction in one mixed flow reactor For ε=0

0.9 k 9 1 0.9 Two mixed flow reactor in series

C0 C0 C1 1 (1 k ) 2 C2 1 X 2 C1 C2

1 1 X 2 1 1 0.99 2 2 (1 k ) (1 9)

Find the treatment rate for the same conversion

C0 C0 C1 1 2 (1 k ) C2 1 X 2 C1 C2 X2=0.9

1 1 k ' 1 1 2.162 1 X 2 1 0.9 V k ' k v0 '

v0 ' k 9 4.16 v0 k ' 2.162

Questions

Mixed flow reactors of different sizes in series Two questions: • How to find the outlet conversion from a given reactor system? • How to find the best setup to achieve a given conversion

Finding the conversion in a given system Consider three mixed flow reactors in series with volumes, feed rates, concentrations, space-times (equal to residence times), and volumetric flow rates as shown in Fig.6.7

Reaktor Teraduk disusun Seri (ukuran Berbeda)

C0

C1

C2

C3

F0

F1

F2

F3

F1 C1 F0 C 0

a. b.

F2 C 2 F0 C 0

F3 C 3 F0 C 0

Menentukan konversi pada sistem tertentu Menentukan Sistem Terbaik untuk Konversi Tertentu

86

Reactors of different types in series CSTR - PFR

PFR - CSTR

Concentration Profiles

87

What arrangement is better ?? What is the criteria that need to be adopted ??

88

For ε=0, in the first reactor

Similarly, for the ith reactor we may write

a. Menentukan konversi pada sistem tertentu V1 C 0 C1 1 v (r )

1 (r ) 1 C1 C 0 Untuk reaktor ke –i :

1 (r ) i C i C i 1

-r

slope

( r )1 1 C1 C 0 1

Point M and C1

Point P and C2

Can be repeated as many times as needed

Eldridge and Piret Method

Graphical method to find the number of tanks required to obtain a given conversion

F0 ri ( xi xi 1 ) Vi

Vi xi 1 xi (ri ) F0

For a second order reaction: -ri = k C02(1-xi)2

xi 1 xi kC0 i (1 xi ) 2 Given the kinetics (order and k) and i values, the number of tanks required can be calculated. Plot a graph taking xi-1 as abcissa and xi as coordinate based on the above equation

Plot a 45 degree line.

92

CSTRs in Parallel

FA0 V Vi , FA0i n n V FA0 X i n n rAi

• This result shows that conversion achieved in any one of the reactors in parallel is identical to what would be achieved if the reactant were fed in one stream to one large reactor of volume V!!

FA01

FA0 FA02 .

CSTRs in parallel, isothermal .

• mole balance

Xi Vi FA0i rAi

same T, V, v X 1 X 2 ... X n X rA1 rA2 ... rAn rA

total volume total molar flow rate

V FA0 X n n rA

FA0 X V rA

CSTRs in parallel • constant conversion and rate of reaction in each tank • The sum of the volume of the tanks equals the total volume of a single large CSTR. • The conversion achieved in any one of the reactors in parallel is identical to what would be achieved if the reactant were fed in one stream to one large reactor of volume V. • Considering the degree of mixing and the room required, a large tank might not be appropriate.

• Because the compositions of mixtures leaving a CSTR are those within the reactor, the reaction driving forces, usually the reactant concentrations, are necessarily low. Therefore, except for reaction orders zero- and negative, a CSTR requires the largest volume of the reactor types to obtain desired conversions. However, the low driving force makes possible better control of rapid exothermic and endothermic reactions. When high conversions of reactants are needed, several CSTRs in series can be used. Equally good results can be obtained by dividing a single vessel into compartments while minimizing backmixing and short-circuiting. The larger the number of CSTR stages, the closer the performance approaches that of a tubular plug-flow reactor.

• Continuous-flow stirred-tank reactors in series are simpler and easier to design for isothermal operation than are tubular reactors. Reactions with narrow operating temperature ranges or those requiring close control of reactant concentrations for optimum selectivity benefit from series arrangements. If severe heat-transfer requirements are imposed, heating or cooling zones can be incorporated within or external to the CSTR. For example, impellers or centrally mounted draft tubes circulate liquid upward, then downward through vertical heat-exchanger tubes. In a similar fashion, reactor contents can be recycled through external heat exchangers. • The CSTR configuration is widely used in industrial applications and in wastewater treatment units (i.e. activated sludge reactors).

• What specifically causes a CSTR in series to have a higher conversion than a CSTR in parallel? The CSTR is always operating a the lowest concentration, the exit concentration. When say two CSTRs are in series, the first operates at a higher concentration, therefore the rate is greater, therefore the conversion is greater. The second reactor in series builds on the conversion in the first reactor. The conversion in the parallel scheme is the same as the conversion to the first reactor to the series scheme.

• When are reactors in parallel used since it seems as though reactors in series would always achieve higher conversion? The PBRs in parallel are ued when there would otherwise be a large pressure drop in one long reactor or identically several PBRs connected in series. • Since two equal CSTR in series give a higher conversion than two in parallel, are reactors in parallel ever used to increase conversion? Not for a CSTR, only a PFR/PBR when there is a significant pressure drop.

Reactors in series • To achieve the same overall conversion, the total volume for two CSTRs in series is less than that required for one CSTR.

-1/rA

• The overall conversion of two PFRs in series is the same as one PFR with the same total volumn.

X -1/rA

• CSTRs in series :A PFR can be modelled using a number of CSTR in series – useful in modelling catalyst decay in a packed-bed reactor – modelling transit heat effects in PFRs.

X

Questions

Example 2-4 From example 2-2 & 2-3, to achieve a conversion of 80% with the entering molar flow rate FA0 = 0.4 mol/s and the same feed conditions, The CSTR volume was 6.4 m3 and the PFR volume was 2.165 m3

For isothermal reactions greater than zero order, the CSTR volume will usually be greater than the PFR volume for the same conversion and reaction conditions (temperature, flow rate, etc.)

Example 2-5 For the two CSTRs in series, 40% conversion is achieved in the first reactor. What is the volume of each of the two reactors necessary to achieve 80% overall conversion of the entering species (a) CSTRA? design equation

Example 2-6 calculate the reactor volumes V1 and V2 for the plugflow sequence when the intermediate conversion is 40% and the final conversion is 80%. The entering molar flow rate is the same as in the previous example, 0.4 mol/s.

PFR design equation dX FA0 rA dV

Example 2-7 The isomerization of butane:nC4H10iC4H10 was carried out adiabatically in the liquid phase. The reactor scheme shown in Figure E2-7.1 is used. Calculate the volume of each of the reactors for an entering molar flow rate of n-butane of 50 kmol/hr.

Contoh soal 1 • Asam asetat dihidrolisis dalam tiga reaktor alir tangki berpengaduk yang dipasang seri. Aliran umpan masuk rektor pertama ( V = 1 liter ) pada kecepatan 400 cm3/min. Reaktor ke dua dan ke tiga mempunyai volum berturut-turut 2 dan 1,5 liter. Reaksi order satu tidak bolak-balik dan konstanta kecepatan reaksi k = 0,158 min-1. Hitung konversi hidrolisis yang keluiar dari reaktor ke tiga ?

• Persamaan perancangan untuk seri, reaktor dalam keadaan steady state, Vi =FAo (XA,i - XA,i-1) / (-rA)i • Dengan : Vi = volum reaktor i FAo = kecepatan aliran molar A masuk reaktor pertama XA,i = fraksional konversi A dalam reaktor i XA,i-1 = fraksional konversi A dalam reaktor i-1 • Untuk reaksi order satu , -rA,i = kCA,i = kCAo(1 - XA,i) • v = kecepatan alir volumetrik A = 400 cm3/min = 0.4 lit/min • Untuk reaktor pertama :: (V = 1 lit) (-rA)1 = (kCA)1 = k CA,1 = k CAo ( 1- XA,1) CAo= FAo / v

•

i.e., FAo = v CAo XA,i-1 = XA,0 = 0 • Untuk itu, Vi =FAo (XA,i - XA,i-1) / (-rA)i 1 = 0.4 (XA,1 - 0) / (0.158 x ( 1 - XA,1 ) ) XA,1 = 0.283 • Untuk reaktor ke dua : (V = 2 lit) (-rA)2 = (kCA)2 = k CA,2 = k CAo ( 1- XA,2) • Karena itu, (-rA)2 = k CAo ( 1- XA,2) XA,1 = 0.283 FAo = v CAo Vi =FAo (XA,i - XA,i-1) / (-rA)i 2 = 0.4 (XA,2 - 0.283) / ( k ( 1- XA,2) ) 5 k = (XA,2 - 0.283) / ( 1- XA,2) 0.79 - 0.79 XA,2 = XA,2 - 0.283 1.073 = 1.79 XA,2 XA,2 = 0.60

• Untuk reaktor ke tiga: (V = 1.5 lit) (-rA)3= (kCA)3 = k CA,3 = k CAo ( 1- XA,3) XA,2 = 0.6 FAo = v CAo Vi =FAo (XA,i - XA,i-1) / (-rA)i 1.5 = 0.4 (XA,3 - 0.60) / ( k ( 1- XA,3) ) 0.5925 = (XA,3 - 0.60) / ( 1- XA,3) 0.5925 - 0.5925 XA,3 = XA,3 - 0.60 1.1925 = 1.5925 XA,3 XA,3 = 0.749 • Fraksi hidrolisis ( konversi ) yang keluar dari reaktor ke tiga = 0.749

Contoh soal 2 •

Dua reaktor tangki berpengaduk tersedia dalam pabrik kimia, satu mempunyai volum 100 m3 dan yang lain bervolum 30 m3. Diharapkan reaktor-reaktor ini dapat digunakan sebagai dua tahap RATB untuk menjalankan reaksi fasa cairan tidak bolak-balik, A + B ---- produk,. Dua reaktan sebagai umpan berada dalam jumlah ekuimolar, CAo = CBo = 1.5 gmol/lit. Kecepatan volumetrik adalah 20 lit/min. Reaksi adalah order satu terhadap A dan B atau total order dua. Konstanta kecepatan reaksi 0.011 lit/(gmol.min). • Untuk memperoleh konversi yang tinggi, tangki mana yang diletakkan pada pertama ? • Dengan susunan ini, hitung konversi yang diperoleh pada kondisi stedy state ?

• Jawab : • -rA = -dCA/dt = k CACB i.e., • -rA = k (CAo - CAoXA) (CBo - CBoXB) • Jumlah A dan B yang bereaksi pada saat t adalah sama dan diberikan oleh CAoXA = CBoXB • Dan untuk soal ini diketahui CAo = CBo , karena itu, -rA,i = k CAo2(1 - XA,i)2 • Diambil reaktor terkecil sebagai reaktor pertama , volum (V1)= 30 m3 Persamaan perancangan untuk RATB seri adalah, ti/CAo = (XA,i - XA,i-1) / (-rA)i dengan CAo = konsentrasi awal A masuk reaktor pertama = 1.5 gmol/lit Kecepatan alir Volumetrik (v) = 20 lit/min

• • • • • • • • • • • • •

t1 = V1/v = 30 x 1000 /20 = 1500 min 1500/ CAo = (XA,i - XA,i-1)/ k CAo2(1 - XA,i)2 1500 = (XA,1 - 0)/ (0.011 CAo(1 - XA,1)2) 1500 = XA,1/(0.011 x 1.5 x (1 - XA,1)2 24.75 = XA,1/(1 - XA,1)2 24.75(1 - 2XA,1 + XA,12) = XA,1 24.75 - 50.5 XA,1 + 24.75 XA,12 = 0 XA,1 = 0.82 Untuk reaktor ke dua , t2 = V2/v = 100 x 1000 /20 = 5000 min 5000/ CAo = (XA,2 - 0.82)/ k CAo2(1 - XA,2)2 5000 x 0.011 x 1.5 = (XA,2 - 0.82)/ (1 - XA,2)2 82.5 (1 - 2XA,2 + XA,22) = XA,2 - 0.82 83.32 - 166 XA,2 + 82.5 XA,22 = 0 XA,2 = 0.96

Jika reaktor disusun yang terbesar dipasang sebagai reaktor pertama. Untuk reaktor pertama, • t1 = V1/v = 1000 x 1000 /20 = 5000 min • 5000/ CAo = (XA,1 - 0)/ k CAo2(1 - XA,1)2 • 5000 = XA,1/(0.011 x 1.5 x (1 - XA,1)2 • 82.5 = XA,1/(1 - XA,1)2 • 82.5(1 - 2XA,1 + XA,12) = XA,1 • 82.5 - 166 XA,1 + 82.5 XA,12 = 0 • XA,1 = 0.90 Untuk reaktor ke dua , t2 = V2/v = 30 x 1000 /20 = 1500 min • 1500/ CAo = (XA,2 - 0.90)/ k CAo2(1 - XA,2)2

• 1500 x 0.011 x 1.5 = (XA,2 - 0.90)/ (1 XA,2)2 • 24.75 (1 - 2XA,2 + XA,22) = XA,2 - 0.90 • 25.65 - 50.5 XA,2 + 24.75 XA,22 = 0 • XA,2 = 0.92 • Dari perhitungan diatas, reaktor bervolum terkecil dipasang sebagai reaktor pertama. Dan konversi total pada pemasangan ini adalah 96%.

Example 4-2 Close to 12.2 billion metric tons of ethylene glycol (EG) were produced in 2000, which ranked it the twenty-sixth most produced chemical in the nation that year on a total pound basis. About one-half of the ethylene glycol is used for antifreeze while the other half is used in the manufacture of polyesters. In the polyester category, 88% was used for fibers and 12% for the manufacture of bottles and films. The 2004 selling price for ethylene glycol was $0.28 per pound. It is desired to produce 200 million pounds per year of EG. The reactor is to be operated isothermally. A 1 lb mol/ft3 solution of ethylene oxide (EO) in water is fed to the reactor (shown in Figure E4-2.1) together with an equal volumetric solution of water containing 0.9 wt% of the catalyst H2SO4. The specific reaction rate constant is 0.311 min-1, as determined in Example 4-1.

A B C catalyst

The specified ethylene glycol (EG) production rate:

(a) If 80% conversion is to be achieved, determine the necessary CSTR volume. catalyst

CSTR Design equation: Rate law: Stoichiometry: Combinatio n:

A B C

(b) If two 800-gal reactors were arranged in parallel, what is the corresponding conversion?

CSTR Design equation: Rate law: Stoichiometry: Combination:

The conversion exiting each of the CSTRs in parallel is 81%.

(c) If two 800-gal reactor were arranged in series, what is the corresponding conversion?

The two equal-sized CSTRs in series will give a higher conversion than two CSTRs in parallel of the same size when the reaction order is greater than zero.

Questions

Soal 1

Soal 2 • There are two reactors of equal volume available for your use: one a CSTR, the other a PFR. The reaction is second order ( rA = kCA2 = kCA02(1 X)2), irreversible, and is carried out isothermally AB There are three ways you can arrange your system: • Reactors in series: CSTR followed by PFR • Reactors in series: PFR followed by CSTR • Reactors in parallel with half the feed rate going to each reactor after which the exit streams are mixed. • State which system will give the highest overall conversion and which system will give the lowest overall conversion

C A 0 C A 1

C A 2

(a) X1 = 0.382, X2 = 0.618 (b) X1 = 0.5, X2 = 0.634 (c) PFR:

CSTR: X1 = 0.5

X1 = 2/3 X1,ave = 0.5(0.5 + 2/3) = 0.5833

(d) State which system will give the highest overall conversion and which system will give the lowest overall conversion. System 2: highest conversion. System 3: lowest conversion

Soal 3 • • •

The exothermic reaction AB+C was carried out adiabatically and the following data recorded:

• •

X rA mol/Lmin

• •

The entering molar flow rate of A was 300 mol/min. What are the PFR and CSTR volumes necessary to achieve 40% conversion? Over what range of conversions would the CSTR and PFR reactor volumes be identical? What conversion can be achieved in a 10.5 L CSTR? What conversion can be achieved if a 7.2 L PFR is followed in series by a 2.4 L CSTR? What conversion can be achieved if a 2.4 L CSTRR is followed in series by a 7.2 L PFR? Plot the conversion and rate of reaction as a function of PFR reactor volume up to a volume of 10 L.

• • • • •

0 0.2 0.4 10 16.67 50

0.5 50

0.6 50

0.8 12.5

0.9 9.09

Solution CSTR: V = = 2.4 liters

PFR : V = 7.2 liters

(b) •

Over what range of conversions would the CSTR and PFR reactor volumes be identical? For a feed stream that enters the reaction with a previous conversion of 0.40 and leaves at any conversion up to 0.60, the volumes of the PFR and CSTR will be identical because the rate is constant over this conversion range VPFR = FA0 = = VCSTR

(c)

Therefore 70% conversion can be achieved in a 10.5 L CSTR.

(d)

60% conversion can be achieved if a 7.2 L PFR is followed in series by a 2.4 L CSTR.

(e) What conversion can be achieved if a 2.4 L CSTR is followed in series by a 7.2 L PFR? 90% conversion can be achieved if a 2.4 L CSTR is followed in series by a 7.2 L PFR. (f)

Plot the conversion and rate of reaction as a function of PFR reactor volume up to a volume of 10 L.

Soal 4 • • •

•

•

The elementary gas-phase reaction3 (CH3)3COOH(CH3)3 C2H6 + 2CH3COCH3 is carried out isothermally in a flow reactor with no pressure drop. The specific reaction rate at 50oC is 10-4 min-1 and the activation energy is 85 kJ/mol. Pure di-tert-butyl peroxide enters the reactor at 10 atm and 127oC and a molar flow rate of 2.5 mol/min. Calculate the reactor volume to achieve 90% conversion in a CSTR and a PFR. If this reaction is to be carried out at 10 atm and 127oC in a batch mode with 90% conversion, what reactor size would be required to process (2.5 mol/min 60 min/h 24 h/day) 3600 mol of di-tert-butyl peroxide per day? You can assume a downtime of 6 hr between batches for cleaning and feed preparation. Assume that the reaction is reversible with equilibrium constant KC = 0.025 mol2/L6 and calculate the equilibrium conversion and then repeat the calculation for the CSTR and the PFR to achieve 90% of the equilibrium conversion.

• 3 Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall

Soal 5

Soal 6

Its not just about numbers of experiments

Stop Doing This

Don’t Do This

Do This

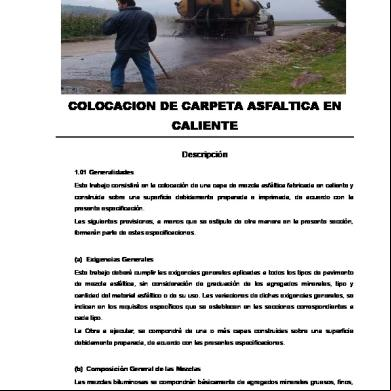

CSTR dengan cooling jacket

Pada CSTR di samping yang terjadi adalah reaksi tunggal dalam keadaan eksoterm yang tidak dapat balik (irreversible). dapat dilihat bahwa aliran fluida dimasukkan secara terusmenerus ke dalam reactor dan aliran fluida lainnya dikeluarkan terusmenerus dari reactor. Sejak reactor tersebut menggabungkan dengan sempurna, aliran keluar memiliki konsentrasi dan temperatur yang sama dengan fluida dalam reaktor. Menyadari bahwa lapisan disekitar reaktor juga masuk dan keluar aliranaliran, pelapis diasumsikan bergabung dengan sempurna dan pada temperatur yang lebih rendah dari reaktor. Energi lalu melewati dinding reaktor menuju pelapis, memindahkan panas yang dihasilkan oleh reaksi.

Figure 3. Continuous stirred tank reactors, (a) With agitator and internal heat transfer surface, (b) With pump around mixing and external heat transfer surface, (adopted by ref. 5).

DAFTAR PUSTAKA • Fogler, H.S., 1994, “Elements of Chemical Reaction Engineering”, 2 nd. Edition, Pretice-Hall of India, New Delhi • Levenspiel, O., 1999, ”Chemical Reaction Engineering”, 3 th. Edition, John Wiley and Sons, New York. • Smith, J.M., 1985, “ Chemical Engineering Kinetics “, 3 th. Edition, McGrawHill Book Company, New Delhi. • Sri Warnijati Agra, 1985, “ Ringkasan Reaktor Kimia bag. I “, Fakultas Teknik UGM, Yogyakarta

Continuous Stirred-Tank Reactor CSTR adalah reaktor model berupa tangki berpengaduk dan diasumsikan pengaduk yang bekerja dalam tanki sangat sempurna sehingga konsentrasi tiap komponen dalam reaktor seragam sebesar konsentrasi aliran yang keluar dari reaktor

Prinsip Kerja • satu atau lebih reagen fluida dimasukkan pada tangki sebuah reaktor yang dilengkapi dengan kipas atau impeller • impeller mengaduk cairan untuk memastikan cairan tersebut tercampur rata • ada waktu suatu cairan berada di dalam tabung tersebut sebelum keluar

Reactor CSTR. Check of a condition of the case.

Beberapa aspek penting dalam CSTR • Dalam keadaan tetap ( steady state ), fluida yang masuk harus sama dengan fluida yang keluar, sebaliknya tangki akan menjadi meluap atau kosong ( unsteady state ). Jika reaktor dalam keadaan unstedy state , model persamaan model persamaan diturunkan dari deferensiasi neraca massa dan energi. • Semua kalkulasi yang dilakukan CSTR diasumsikan sebagai pencampuran sempurna • Untuk mendapatkan hasil yang lebih banyak dalam waktu yang sama, dapat dilakukan dengan memparalelkan atau memasang seri CSTR ini • RATB kecil yang jumlahnya tak terhingga beroperasi secara seri ekivalen sebuah PFR

Keuntungan: – Suhu dan komposisi campuran dalam reaktor sama – Volume reactor besar, maka waktu tinggal juga besar, berarti zat pereaksi lebih lama bereaksi di reactor.

Keuntungan CSTR • Operasi dalam keadaan tetap menyebabkan peralatan produk lebih stabil • Penggunaan energi yang kualitasnya meningkat • Produktivitas yang lebih tinggi dalam reduksi pada periode tidak aktif (pengisian, pemanasan, pendinginan, dan pengosongan). • Campuran lebih rata karena penggunaan teknik pengadukan (stiring). Suhu dan komposisi

campuran dalam reaktor sama

Kerugian: • Tidak effisien untuk reaksi fase gas dan reaksi yang bertekanan tinggi. • Kecepatan perpindahan panas lebih rendah dibanding RAP • Untuk menghasilkan konversi yang sama, volume yang dibutuhkan RATB lebih besar dari RAP.

Kerugian CSTR • Rata-rata reaksi volumetrik yang lebih rendah akan menghasilkan produktivitas rendah. • Tidak sesuai untuk keseluruhan emulsi proses polimerisasi pada tahap pertama penggunaan CSTR • Timbul endapan di dasar akibat gaya sentrifugal CSTR • Tidak dapat merubah grade dari RTD profile sesering mungkin karena dapat mengurangi fleksibilitas reaktor • Biaya tinggi, semakin besar CSTR yang digunakan atau semakin banyak CSTR kecil yang digunakan semakin besar biaya yang dikeluarkan • Waktu menunggu (proses) yang lebih lama

Cao, Vao

A+BC

CSTR

Cbo, Vbo V

Cc, Vf

CSTR Reactor for Liquid Phase Reaction Reactant supply in: Liquid flow rate = v m3/s Concentration = C0 mol/m3

Volume of reactor = V m3

Reactor operates at outlet conditions. Reactor is wellmixed, hence concentration of reactant throughout is = C

Remaining reactant out: Liquid flow rate = v m3/s Concentration = C mol/m3

Reactor operates at steady-state - variables do not change with t

Reaktor Teraduk Sempurna (Mixed Flow Reactor) Konsentrasi di dalam reaktor = Konsentrasi keluar reaktor = Waktu lewat = Waktu yang dibutuhkan reaktan melalui reaktor

CA0 FA0 v0 XA0 CAf FA vf XAf

CAf

Neraca massa reaktan A : Masuk – Keluar – Hilang bereaksi = Akumulasi Laju molar A masuk (mol/waktu) : FA0 ( 1- XA0 ) = FA0 Laju molar A keluar (mol/waktu) : FA = FA0 ( 1- XAf ) Kehilangan selama reaksi (mol/waktu) : (-rA) V FA0 ( 1- XA0 ) - FA0 ( 1- XAf ) - (-rA) V = 0 FA0 (XA0 - XAf ) = (-rA) V τ

V FA0

V v0

τ C A0

Untuk konstan dan XA0 = 0 :

X Af X A0 rA

V FA0

C A0

XA rA

C A0 C A C A0 ( rA )

Design Equations FA,in FA,out rAV 0 XA

FAO FA FAO

ATAU DITULIS KEMBALI

DISUBTITUSIKAN DAN DIPEROLEH :

FAO X A V rA

X A FAO FA,in FA,exit

FAO/-rA

F V AO X A rA

v XA

The CSTR volume is defined by the outlet conversion, owing to dilution of reactant.

summarize: Mole Balance BATCH RAP RATB

Design Equation

1 dN A rA T , C V dt

N AO dX A rA V dt

dFA rA T , C dV

FAO

0 FA,in FA,out rA T , C V

dX A rA dV

V

FAO X A rA

MFR vs. PLUG FLOW Isothermal MFR

vC A0 X A V rA 1/rA

Kurva laju reaksi

XA PLUG FLOW

V vCA0

XA

0

dX A rA

MFR AB

rA kCA

2A B

rA kCA2

C A C A0 kC 2 A

C A C A0 kCA

1 1 4kCA0 CA 2k

Order 2, reversible, densitas konstan A+B

k1 k2

C+D

Feed: CA0, CB0, CC0 = 0, CD0 = 0

C A0 C A CB 0 CB CC CC 0 CD CD 0 a b c d

C A0 C A CB 0 CB CC CD

MFR rA rf rr k1C AC B k 2CC C D Neraca Massa

C A C A0 rA C A C A0 k1C ACB k 2CC CD

Substitusi CB = CA - CA0 + CB0 CC = CD = CA0 - CA

CA CA0 k1CA CA CA0 CB0 k2 CA0 CA Selesaiakan untuk CA

2

• Damköhler number is a dimensionless number that can give a quick estimate of the degree of conversion that can be achieved in CSTR.

First order : Second order :

Da = 0.1 or less, usually give less than 10% conversion. Da = 10.0 or greater, usually give greater than 90% conversion.

The elementary liquid phase reaction 2 A ----- B is carried out isothermally in a CSTR. Pure A enters at a volumetric flow rate of 25 dm3/s and at a concentration of 0.2 mol/dm3. What CSTR volume is necessary to achieve a 90% conversion when k = 10 dm3/(mol*s)?

• Mole Balance • Rate Law • Stoichiometry liquid phase (v = vo)

• Combine • Evaluate at X = 0.9, • • V = 1125 dm3 • Space Time

Soal-1 •

Direncanakan untuk mengganti sebuah RATB yang ada dengan RATB yang bervolum dua kali. Untuk umpan yang sama dan dengan kecepatan umpan yang sama pula, 10 mol A/liter, tentukan konversi baru ? Kinetika reaksi sebagai berikut : A ------ R -rA = CA1,5 dan konversi awal 70 %

Soal-2 • Suatu umpan “aqueous” A dan B ( 400 liter/menit, 100 mmol A/liter, 200 mmol B/liter) diubah menjadi produk dalam sebuah RATB. Dengan kinetika reaksi sbb: A + B -----R -rA = 200 CA CB mol/(liter.min ) • Hitung volum reactor untuk memperoleh konversi A, 99,9 %.

Soal-3 •

Suatu umpan gas murni A ( 1 mol/liter) dimasukkan dalam sebuah RATB yang bervolum 2 liter dan bereaksi sbagai berikut : 2 A ------ R -rA = 0,05 CA2 mol/(liter.det) Hitung kecepatan umpan (liter/min) untuk memperoleh konsentrasi keluar reactor CA= 0,5 mol/liter.

Soal-4 •

•

Reaktan gas A terdekomposisi sebagai berikut : A ----- 3 R -rA = ( 0,6 min-1) CA Hitung konversi A dalam umpan yang terdiri 50% A dan 50% inert ( denga Vo = 180 liter/min, CAo = 300 mmol/liter) jika dimasukkan dalam RATB yang bervolum 1 m3.

Soal-5 • Suatu reaksi A + B <–k1–k2–> M + N, fasa cair dijalankan dalam sebuah RATB yang volumnya 240 L. Umpan A dan B masing2 masuk reaktor dengan laju alir yang sama dengan perbandingan konsentrasi awal = 7 : 4 dan jumlah konsentrasi awal umpan adalah 2,2 mol/L. Tidak ada zat M dan N di umpan. Jika konversi atas dasar reaktan yang sedikit adalah 75% dan harga k1 dan k2 masing-masing 7 dan 3 L/mol.men, Hitung: • a. Laju alir volumetris untuk masing-masing reaktan • b. Space time dan space velocity • c. Gambarkan skema kondisi diatas

Perbandingan MFR vs. PFR (reaksi order n) 100 n=2

n V C A0 v MFR 10 n V C A0 v PFR

A produk

rA kCAn

n=1 n=0.5

1 0.01

0.1 (1-XA)

catatan (1) n#0 VMFR > VPFR (2) n=0 VMFR = VPFR (3) XA,rendah type aliran sedikit berpengaruh

1.0

Perbandingan Reaktor tunggal Untuk reaktor dengan berubah -rA = k CAn n XAf dX 1 XAf 1 A X A A τ P C A0 dX A n 1 n k C A0 0 1 X A XAi rA X Af X Af 1 A X Af n τ M C A0 rA k C A0 n-1 1 X Af n

1 A X Af X Af 1 X Af τM X n>0 1 Af 1 X A Af τP 1 X dX A Af 0 n

τM τP

C A0

X Af rA

atau C A 0 n 1 M VM VP C A 0 n 1 P

A maka

τM τP

dan

VM VP

CSTR Vs. PFR ? – For a given duty the ratio of sizes of CSTR & PFR will depend on: • extent of reaction • stoichiometry • form of the rate equation

For the simple nth-order rate law

For mixed flow reactor, Eq.5.11 gives

For plug flow reactor, Eq.5.17 gives

With constant density, or ε=0, this expression integrates to

Multiple reactors:

• The reactors may or may not be of the same type • They may be connected either in series or parallel

Issues involved:

• How many reactors ?? • What type of reactors ?? • Series / parallel arrangement ?? • Sizes of each reactor ?? • In what order they must be connected ?? • Inter-stage feed injection ?? 42

Types of staged reactors

Reactor battery

Vertically staged

Compartmented

43

Multiple reactors in parallel:

PFRs in parallel

CSTRs in parallel

44

Plug Flow Reactors in Series and/or in parallel

• Consider N plug flow reactors connected in series, and let X1, X2, ……, XN be the fractional conversion of component A leaving reactor 1,2,……,N.

for the N reactors in series

Hence, N plug flow reactors in series with a total volume V gives the same conversion as a single plug flow reactor of volume V.

CSTR VS Plug Flow •A combination of PFRs giving a particular final conversion have the same volume as a single PFR which gives the same total conversion. •A series of CSTRs can be useful to reduce the overall volume: 1/rA V V 1

0

2

XAi

XAf

V2 V1 X Ai

Other rate expressions •rA=kCAn - as n increases, PFR more favourable •zero order reactions are reactor independent •autocatalytic reactions A B rA=kCACB

1/r

XAf XA

Rate low at low conversion due to low CB

VCSTR XIN

VPFR XCSTR

X

XOUT

The reactor setup shown in Fig. E6.1 consists of three plug flow reactors in two parallel branches. Branch D has a reactor of volume 50 liters followed by a reactor of volume 30 liters. Branch E has a reactor of volume 40 liters. What fraction of the feed should go to branch D?

Figure E6.1

Multiple reactors in parallel: • Fluid streams which meet must have the same composition

• Space time () must be same for each parallel line • Any other way of feeding will be less efficient ??

50

For the optimum hook up of plug flow reactors connected in parallel or in any parallel-series combination, we can treat the whole system as a single plug flow reactor of volume equal to the total volume of the individual units if the feed is distributed in such a manner that fluid streams that meet have the same composition. Thus, for reactors in parallel V/F must be the same for each parallel line. Any other way of feeding is less efficient.

Now for reactors in parallel V/F must be identical if the conversion is to be the same in each branch. Therefore

Example: 50 lit

30 lit

F

40 lit

What should be the flow in each parallel line for optimum results. 2F/3

80 lit

F

F/3

40 lit 53

Questions

CSTRs in series Issues involved are: 1. Deg the CSTR battery • How many reactors ?? • Sizes of each ?? • In what order to connect ?? • What is optimum ?? 2. Rating the given CSTR battery • Exit conversion ?? Algebraic method Graphical method 55

TWO CSTRs in SERIES:

F V1 AO X 1 0 rA

FAO/-rA

F V1 AO X 2 X 1 rA

x1 v1

v1

v2 x1 XA

x2

x2 v2

The total volume of the two CSTRs is less than if we just had one huge CSTR.

CSTRs in Series

First-order, no volume change Single CSTR, CA = • Effluent [A] of reactor 1, CA1 = • Effluent [A] of reactor 2, CA2 = • Effluent [A] of reactor n, CAn =

CSTR in Series (Cont.)

Menentukan Sistem Terbaik untuk Konversi Tertentu Konversi tertentu Ukuran minimum ? 2 reaktor teraduk seri

C0 F0

X1

1 r

K

L

N

M

K N

X2 X1

K N X1

1 r

X2

X1

X2

L M

C0 F0

X1

L M

X2

Garis g

1 r

X1

X1

X2

X1

K, L, M, N dimaksimumkan

• Sebuah RATB dipakai untuk mereaksikan A menjadi produk dengan konversi 90%. Reaksi yang terjadi adalah order 2. Direncanakan akan memasang satu reaktor tambahan dengan ukuran sama yang disusun seri dengan reaktor pertama. Jika kondisi operasi sama, berapa konversi setelah keluar reaktor kedua? • Jika konversi keluar reaktor kedua = 90%, berapa perbandingan volume RATB 2 terhadap RATB 1? (Note: cari dulu kCo.t dengan bantuan grafik).

CSTRs in series (Design Problem) The shaded area is the saving with 2 CTSRs when compared to 1 CSTR

The conversion from the exit of the first reactor influences the amount of saving. What is the optimum saving and what is the corresponding 62 conversion

Equal-size mixed flow reactors in series

Though the concentration is uniform in each reactor, there is, nevertheless, a change in concentration as fluid moves from reactor to reactor.

N TANKS IN SERIES: ,…

F V1 AO X 1 0 rA F Vn AO X n X n 1 rA

FAO/-rA

XA

x1 x2

V1

X1

Xn-1 Xn

X2 V2

Vn-1

Xn-1

Vn

Xn

Reaktor Teraduk disusun Seri (Ukuran Sama) X0

X1

Xi-1

Xi

Xn-1

XN

C0

C1

C i-1

Ci

Cn-1

CN

Neraca massa komponen A pada reaktor i : FAi-1 – FAi – (-rA)Vi = 0 FA0 (1-Xi-1) – FA0 (1-Xi) – (-rA)Vi = 0 X i - X i-1 i

( rA ) Vi FA 0

C A 0 Vi C A 0 (X i X i 1 ) FAo rA

V vo

1 = 2 = 3,… = i = N

Reaktor Teraduk disusun Seri (Ukuran Sama) Untuk reaksi orde –1 : -rA = k CA0

X i X i 1 C Ai C Ai 1 k (1 X i ) kC Ai

C Ai 1 1 k i C Ai C A0 C C C 1 A 0 A1 ......... AN 1 (1 k i ) n C AN 1 X Ai C A1 C A 2 C AN C A0 (1 k i ) N C AN 1/ N

CA0 CAN i k

1

N CA0 Ni k CAN

1/ N

Nreaktor

1

Reaktor Teraduk disusun Seri (Ukuran Sama)

Jika N, maka N CA0 k CAN

1 1

1/ N

N lim

N

CA 0 CAN lim N k/N 1 C A0 ln k C AN

1/ N

CA, masuk

Plug flow N=5

= P N P

C A0 1 ln k C AN

N = 1, Mixed flow

Volume reaktor

CA, keluar

Stepwise drop of conversion

The larger the number of units in series, the closer should the behavior of the system approach plug flow.

In the limit, for N this equation reduces to the plug flow equation

Second-order reactions A series of N equal-size mixed flow reactors for elementary second-order reactions

CA0

CA1

CA2

CSTRs in series, 1st order rxn, isothermal

• mole balance

FA1 X FA1 FA 2 v0 C A1 C A2 V rA 2 rA2 rA2

• rate laws

rA2 k2C A2

• Stoichiometry C A2 C A1 (1 X ) • combination ...

1 X 1 n 1 k

C A2

C A0 C A0 C A1 1 2 k 2 1 2 k 2 1 1k1 1 k 2

C A0 C A0 C An n n 1 k 1 Da C An C A0 (1 X )

CSTRs in series • constant flow rate • conversion as a function of the number of tanks in series Two equal-sized CSTRs in series will give a higher conversion than two CSTRs in parallel of the same size when the reaction order is greater than zero.

EXAMPLE 6.2 MIXED FLOW REACTORS IN SERIES

At present 90% of reactant A is converted into product by a first-order reaction in a single mixed flow reactor. We plan to place a second reactor similar to the one being used in series with it. (a) For the same treatment rate as that used at present, how will this addition affect the conversion of reactant?

(b) For the same 90% conversion, by how much can the treatment rate be increased

SOLUTION For the first-order reaction in one mixed flow reactor For ε=0

0.9 k 9 1 0.9 Two mixed flow reactor in series

C0 C0 C1 1 (1 k ) 2 C2 1 X 2 C1 C2

1 1 X 2 1 1 0.99 2 2 (1 k ) (1 9)

Find the treatment rate for the same conversion

C0 C0 C1 1 2 (1 k ) C2 1 X 2 C1 C2 X2=0.9

1 1 k ' 1 1 2.162 1 X 2 1 0.9 V k ' k v0 '

v0 ' k 9 4.16 v0 k ' 2.162

Questions

Mixed flow reactors of different sizes in series Two questions: • How to find the outlet conversion from a given reactor system? • How to find the best setup to achieve a given conversion

Finding the conversion in a given system Consider three mixed flow reactors in series with volumes, feed rates, concentrations, space-times (equal to residence times), and volumetric flow rates as shown in Fig.6.7

Reaktor Teraduk disusun Seri (ukuran Berbeda)

C0

C1

C2

C3

F0

F1

F2

F3

F1 C1 F0 C 0

a. b.

F2 C 2 F0 C 0

F3 C 3 F0 C 0

Menentukan konversi pada sistem tertentu Menentukan Sistem Terbaik untuk Konversi Tertentu

86

Reactors of different types in series CSTR - PFR

PFR - CSTR

Concentration Profiles

87

What arrangement is better ?? What is the criteria that need to be adopted ??

88

For ε=0, in the first reactor

Similarly, for the ith reactor we may write

a. Menentukan konversi pada sistem tertentu V1 C 0 C1 1 v (r )

1 (r ) 1 C1 C 0 Untuk reaktor ke –i :

1 (r ) i C i C i 1

-r

slope

( r )1 1 C1 C 0 1

Point M and C1

Point P and C2

Can be repeated as many times as needed

Eldridge and Piret Method

Graphical method to find the number of tanks required to obtain a given conversion

F0 ri ( xi xi 1 ) Vi

Vi xi 1 xi (ri ) F0

For a second order reaction: -ri = k C02(1-xi)2

xi 1 xi kC0 i (1 xi ) 2 Given the kinetics (order and k) and i values, the number of tanks required can be calculated. Plot a graph taking xi-1 as abcissa and xi as coordinate based on the above equation

Plot a 45 degree line.

92

CSTRs in Parallel

FA0 V Vi , FA0i n n V FA0 X i n n rAi

• This result shows that conversion achieved in any one of the reactors in parallel is identical to what would be achieved if the reactant were fed in one stream to one large reactor of volume V!!

FA01

FA0 FA02 .

CSTRs in parallel, isothermal .

• mole balance

Xi Vi FA0i rAi

same T, V, v X 1 X 2 ... X n X rA1 rA2 ... rAn rA

total volume total molar flow rate

V FA0 X n n rA

FA0 X V rA

CSTRs in parallel • constant conversion and rate of reaction in each tank • The sum of the volume of the tanks equals the total volume of a single large CSTR. • The conversion achieved in any one of the reactors in parallel is identical to what would be achieved if the reactant were fed in one stream to one large reactor of volume V. • Considering the degree of mixing and the room required, a large tank might not be appropriate.

• Because the compositions of mixtures leaving a CSTR are those within the reactor, the reaction driving forces, usually the reactant concentrations, are necessarily low. Therefore, except for reaction orders zero- and negative, a CSTR requires the largest volume of the reactor types to obtain desired conversions. However, the low driving force makes possible better control of rapid exothermic and endothermic reactions. When high conversions of reactants are needed, several CSTRs in series can be used. Equally good results can be obtained by dividing a single vessel into compartments while minimizing backmixing and short-circuiting. The larger the number of CSTR stages, the closer the performance approaches that of a tubular plug-flow reactor.

• Continuous-flow stirred-tank reactors in series are simpler and easier to design for isothermal operation than are tubular reactors. Reactions with narrow operating temperature ranges or those requiring close control of reactant concentrations for optimum selectivity benefit from series arrangements. If severe heat-transfer requirements are imposed, heating or cooling zones can be incorporated within or external to the CSTR. For example, impellers or centrally mounted draft tubes circulate liquid upward, then downward through vertical heat-exchanger tubes. In a similar fashion, reactor contents can be recycled through external heat exchangers. • The CSTR configuration is widely used in industrial applications and in wastewater treatment units (i.e. activated sludge reactors).

• What specifically causes a CSTR in series to have a higher conversion than a CSTR in parallel? The CSTR is always operating a the lowest concentration, the exit concentration. When say two CSTRs are in series, the first operates at a higher concentration, therefore the rate is greater, therefore the conversion is greater. The second reactor in series builds on the conversion in the first reactor. The conversion in the parallel scheme is the same as the conversion to the first reactor to the series scheme.

• When are reactors in parallel used since it seems as though reactors in series would always achieve higher conversion? The PBRs in parallel are ued when there would otherwise be a large pressure drop in one long reactor or identically several PBRs connected in series. • Since two equal CSTR in series give a higher conversion than two in parallel, are reactors in parallel ever used to increase conversion? Not for a CSTR, only a PFR/PBR when there is a significant pressure drop.

Reactors in series • To achieve the same overall conversion, the total volume for two CSTRs in series is less than that required for one CSTR.

-1/rA

• The overall conversion of two PFRs in series is the same as one PFR with the same total volumn.

X -1/rA

• CSTRs in series :A PFR can be modelled using a number of CSTR in series – useful in modelling catalyst decay in a packed-bed reactor – modelling transit heat effects in PFRs.

X

Questions

Example 2-4 From example 2-2 & 2-3, to achieve a conversion of 80% with the entering molar flow rate FA0 = 0.4 mol/s and the same feed conditions, The CSTR volume was 6.4 m3 and the PFR volume was 2.165 m3

For isothermal reactions greater than zero order, the CSTR volume will usually be greater than the PFR volume for the same conversion and reaction conditions (temperature, flow rate, etc.)

Example 2-5 For the two CSTRs in series, 40% conversion is achieved in the first reactor. What is the volume of each of the two reactors necessary to achieve 80% overall conversion of the entering species (a) CSTRA? design equation

Example 2-6 calculate the reactor volumes V1 and V2 for the plugflow sequence when the intermediate conversion is 40% and the final conversion is 80%. The entering molar flow rate is the same as in the previous example, 0.4 mol/s.

PFR design equation dX FA0 rA dV

Example 2-7 The isomerization of butane:nC4H10iC4H10 was carried out adiabatically in the liquid phase. The reactor scheme shown in Figure E2-7.1 is used. Calculate the volume of each of the reactors for an entering molar flow rate of n-butane of 50 kmol/hr.

Contoh soal 1 • Asam asetat dihidrolisis dalam tiga reaktor alir tangki berpengaduk yang dipasang seri. Aliran umpan masuk rektor pertama ( V = 1 liter ) pada kecepatan 400 cm3/min. Reaktor ke dua dan ke tiga mempunyai volum berturut-turut 2 dan 1,5 liter. Reaksi order satu tidak bolak-balik dan konstanta kecepatan reaksi k = 0,158 min-1. Hitung konversi hidrolisis yang keluiar dari reaktor ke tiga ?

• Persamaan perancangan untuk seri, reaktor dalam keadaan steady state, Vi =FAo (XA,i - XA,i-1) / (-rA)i • Dengan : Vi = volum reaktor i FAo = kecepatan aliran molar A masuk reaktor pertama XA,i = fraksional konversi A dalam reaktor i XA,i-1 = fraksional konversi A dalam reaktor i-1 • Untuk reaksi order satu , -rA,i = kCA,i = kCAo(1 - XA,i) • v = kecepatan alir volumetrik A = 400 cm3/min = 0.4 lit/min • Untuk reaktor pertama :: (V = 1 lit) (-rA)1 = (kCA)1 = k CA,1 = k CAo ( 1- XA,1) CAo= FAo / v

•

i.e., FAo = v CAo XA,i-1 = XA,0 = 0 • Untuk itu, Vi =FAo (XA,i - XA,i-1) / (-rA)i 1 = 0.4 (XA,1 - 0) / (0.158 x ( 1 - XA,1 ) ) XA,1 = 0.283 • Untuk reaktor ke dua : (V = 2 lit) (-rA)2 = (kCA)2 = k CA,2 = k CAo ( 1- XA,2) • Karena itu, (-rA)2 = k CAo ( 1- XA,2) XA,1 = 0.283 FAo = v CAo Vi =FAo (XA,i - XA,i-1) / (-rA)i 2 = 0.4 (XA,2 - 0.283) / ( k ( 1- XA,2) ) 5 k = (XA,2 - 0.283) / ( 1- XA,2) 0.79 - 0.79 XA,2 = XA,2 - 0.283 1.073 = 1.79 XA,2 XA,2 = 0.60

• Untuk reaktor ke tiga: (V = 1.5 lit) (-rA)3= (kCA)3 = k CA,3 = k CAo ( 1- XA,3) XA,2 = 0.6 FAo = v CAo Vi =FAo (XA,i - XA,i-1) / (-rA)i 1.5 = 0.4 (XA,3 - 0.60) / ( k ( 1- XA,3) ) 0.5925 = (XA,3 - 0.60) / ( 1- XA,3) 0.5925 - 0.5925 XA,3 = XA,3 - 0.60 1.1925 = 1.5925 XA,3 XA,3 = 0.749 • Fraksi hidrolisis ( konversi ) yang keluar dari reaktor ke tiga = 0.749

Contoh soal 2 •

Dua reaktor tangki berpengaduk tersedia dalam pabrik kimia, satu mempunyai volum 100 m3 dan yang lain bervolum 30 m3. Diharapkan reaktor-reaktor ini dapat digunakan sebagai dua tahap RATB untuk menjalankan reaksi fasa cairan tidak bolak-balik, A + B ---- produk,. Dua reaktan sebagai umpan berada dalam jumlah ekuimolar, CAo = CBo = 1.5 gmol/lit. Kecepatan volumetrik adalah 20 lit/min. Reaksi adalah order satu terhadap A dan B atau total order dua. Konstanta kecepatan reaksi 0.011 lit/(gmol.min). • Untuk memperoleh konversi yang tinggi, tangki mana yang diletakkan pada pertama ? • Dengan susunan ini, hitung konversi yang diperoleh pada kondisi stedy state ?

• Jawab : • -rA = -dCA/dt = k CACB i.e., • -rA = k (CAo - CAoXA) (CBo - CBoXB) • Jumlah A dan B yang bereaksi pada saat t adalah sama dan diberikan oleh CAoXA = CBoXB • Dan untuk soal ini diketahui CAo = CBo , karena itu, -rA,i = k CAo2(1 - XA,i)2 • Diambil reaktor terkecil sebagai reaktor pertama , volum (V1)= 30 m3 Persamaan perancangan untuk RATB seri adalah, ti/CAo = (XA,i - XA,i-1) / (-rA)i dengan CAo = konsentrasi awal A masuk reaktor pertama = 1.5 gmol/lit Kecepatan alir Volumetrik (v) = 20 lit/min

• • • • • • • • • • • • •

t1 = V1/v = 30 x 1000 /20 = 1500 min 1500/ CAo = (XA,i - XA,i-1)/ k CAo2(1 - XA,i)2 1500 = (XA,1 - 0)/ (0.011 CAo(1 - XA,1)2) 1500 = XA,1/(0.011 x 1.5 x (1 - XA,1)2 24.75 = XA,1/(1 - XA,1)2 24.75(1 - 2XA,1 + XA,12) = XA,1 24.75 - 50.5 XA,1 + 24.75 XA,12 = 0 XA,1 = 0.82 Untuk reaktor ke dua , t2 = V2/v = 100 x 1000 /20 = 5000 min 5000/ CAo = (XA,2 - 0.82)/ k CAo2(1 - XA,2)2 5000 x 0.011 x 1.5 = (XA,2 - 0.82)/ (1 - XA,2)2 82.5 (1 - 2XA,2 + XA,22) = XA,2 - 0.82 83.32 - 166 XA,2 + 82.5 XA,22 = 0 XA,2 = 0.96

Jika reaktor disusun yang terbesar dipasang sebagai reaktor pertama. Untuk reaktor pertama, • t1 = V1/v = 1000 x 1000 /20 = 5000 min • 5000/ CAo = (XA,1 - 0)/ k CAo2(1 - XA,1)2 • 5000 = XA,1/(0.011 x 1.5 x (1 - XA,1)2 • 82.5 = XA,1/(1 - XA,1)2 • 82.5(1 - 2XA,1 + XA,12) = XA,1 • 82.5 - 166 XA,1 + 82.5 XA,12 = 0 • XA,1 = 0.90 Untuk reaktor ke dua , t2 = V2/v = 30 x 1000 /20 = 1500 min • 1500/ CAo = (XA,2 - 0.90)/ k CAo2(1 - XA,2)2

• 1500 x 0.011 x 1.5 = (XA,2 - 0.90)/ (1 XA,2)2 • 24.75 (1 - 2XA,2 + XA,22) = XA,2 - 0.90 • 25.65 - 50.5 XA,2 + 24.75 XA,22 = 0 • XA,2 = 0.92 • Dari perhitungan diatas, reaktor bervolum terkecil dipasang sebagai reaktor pertama. Dan konversi total pada pemasangan ini adalah 96%.

Example 4-2 Close to 12.2 billion metric tons of ethylene glycol (EG) were produced in 2000, which ranked it the twenty-sixth most produced chemical in the nation that year on a total pound basis. About one-half of the ethylene glycol is used for antifreeze while the other half is used in the manufacture of polyesters. In the polyester category, 88% was used for fibers and 12% for the manufacture of bottles and films. The 2004 selling price for ethylene glycol was $0.28 per pound. It is desired to produce 200 million pounds per year of EG. The reactor is to be operated isothermally. A 1 lb mol/ft3 solution of ethylene oxide (EO) in water is fed to the reactor (shown in Figure E4-2.1) together with an equal volumetric solution of water containing 0.9 wt% of the catalyst H2SO4. The specific reaction rate constant is 0.311 min-1, as determined in Example 4-1.

A B C catalyst

The specified ethylene glycol (EG) production rate:

(a) If 80% conversion is to be achieved, determine the necessary CSTR volume. catalyst

CSTR Design equation: Rate law: Stoichiometry: Combinatio n:

A B C

(b) If two 800-gal reactors were arranged in parallel, what is the corresponding conversion?

CSTR Design equation: Rate law: Stoichiometry: Combination:

The conversion exiting each of the CSTRs in parallel is 81%.

(c) If two 800-gal reactor were arranged in series, what is the corresponding conversion?

The two equal-sized CSTRs in series will give a higher conversion than two CSTRs in parallel of the same size when the reaction order is greater than zero.

Questions

Soal 1

Soal 2 • There are two reactors of equal volume available for your use: one a CSTR, the other a PFR. The reaction is second order ( rA = kCA2 = kCA02(1 X)2), irreversible, and is carried out isothermally AB There are three ways you can arrange your system: • Reactors in series: CSTR followed by PFR • Reactors in series: PFR followed by CSTR • Reactors in parallel with half the feed rate going to each reactor after which the exit streams are mixed. • State which system will give the highest overall conversion and which system will give the lowest overall conversion

C A 0 C A 1

C A 2

(a) X1 = 0.382, X2 = 0.618 (b) X1 = 0.5, X2 = 0.634 (c) PFR:

CSTR: X1 = 0.5

X1 = 2/3 X1,ave = 0.5(0.5 + 2/3) = 0.5833

(d) State which system will give the highest overall conversion and which system will give the lowest overall conversion. System 2: highest conversion. System 3: lowest conversion

Soal 3 • • •

The exothermic reaction AB+C was carried out adiabatically and the following data recorded:

• •

X rA mol/Lmin

• •

The entering molar flow rate of A was 300 mol/min. What are the PFR and CSTR volumes necessary to achieve 40% conversion? Over what range of conversions would the CSTR and PFR reactor volumes be identical? What conversion can be achieved in a 10.5 L CSTR? What conversion can be achieved if a 7.2 L PFR is followed in series by a 2.4 L CSTR? What conversion can be achieved if a 2.4 L CSTRR is followed in series by a 7.2 L PFR? Plot the conversion and rate of reaction as a function of PFR reactor volume up to a volume of 10 L.

• • • • •

0 0.2 0.4 10 16.67 50

0.5 50

0.6 50

0.8 12.5

0.9 9.09

Solution CSTR: V = = 2.4 liters

PFR : V = 7.2 liters

(b) •

Over what range of conversions would the CSTR and PFR reactor volumes be identical? For a feed stream that enters the reaction with a previous conversion of 0.40 and leaves at any conversion up to 0.60, the volumes of the PFR and CSTR will be identical because the rate is constant over this conversion range VPFR = FA0 = = VCSTR

(c)

Therefore 70% conversion can be achieved in a 10.5 L CSTR.

(d)

60% conversion can be achieved if a 7.2 L PFR is followed in series by a 2.4 L CSTR.

(e) What conversion can be achieved if a 2.4 L CSTR is followed in series by a 7.2 L PFR? 90% conversion can be achieved if a 2.4 L CSTR is followed in series by a 7.2 L PFR. (f)

Plot the conversion and rate of reaction as a function of PFR reactor volume up to a volume of 10 L.

Soal 4 • • •

•

•

The elementary gas-phase reaction3 (CH3)3COOH(CH3)3 C2H6 + 2CH3COCH3 is carried out isothermally in a flow reactor with no pressure drop. The specific reaction rate at 50oC is 10-4 min-1 and the activation energy is 85 kJ/mol. Pure di-tert-butyl peroxide enters the reactor at 10 atm and 127oC and a molar flow rate of 2.5 mol/min. Calculate the reactor volume to achieve 90% conversion in a CSTR and a PFR. If this reaction is to be carried out at 10 atm and 127oC in a batch mode with 90% conversion, what reactor size would be required to process (2.5 mol/min 60 min/h 24 h/day) 3600 mol of di-tert-butyl peroxide per day? You can assume a downtime of 6 hr between batches for cleaning and feed preparation. Assume that the reaction is reversible with equilibrium constant KC = 0.025 mol2/L6 and calculate the equilibrium conversion and then repeat the calculation for the CSTR and the PFR to achieve 90% of the equilibrium conversion.

• 3 Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall

Soal 5

Soal 6

Its not just about numbers of experiments

Stop Doing This

Don’t Do This

Do This

CSTR dengan cooling jacket

Pada CSTR di samping yang terjadi adalah reaksi tunggal dalam keadaan eksoterm yang tidak dapat balik (irreversible). dapat dilihat bahwa aliran fluida dimasukkan secara terusmenerus ke dalam reactor dan aliran fluida lainnya dikeluarkan terusmenerus dari reactor. Sejak reactor tersebut menggabungkan dengan sempurna, aliran keluar memiliki konsentrasi dan temperatur yang sama dengan fluida dalam reaktor. Menyadari bahwa lapisan disekitar reaktor juga masuk dan keluar aliranaliran, pelapis diasumsikan bergabung dengan sempurna dan pada temperatur yang lebih rendah dari reaktor. Energi lalu melewati dinding reaktor menuju pelapis, memindahkan panas yang dihasilkan oleh reaksi.

Figure 3. Continuous stirred tank reactors, (a) With agitator and internal heat transfer surface, (b) With pump around mixing and external heat transfer surface, (adopted by ref. 5).