Study Project Report-siddharth, Sarvesh 70201e

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

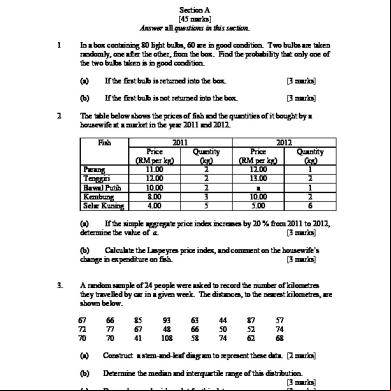

Overview 3e4r5l

& View Study Project Report-siddharth, Sarvesh as PDF for free.

More details w3441

- Words: 3,520

- Pages: 25

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE – PILANI PRACTICE SCHOOL I

KUDANKULAM NUCLEAR POWER PROJECT STUDY PROJECT REPORT ON CORROSION OF STAINLESS STEEL IN THE PRESENCE OF SULPHURIC ACID SIDDHARTH PANDEY [2013A1PS742P – PILANI CAMPUS] SARVESH SHUKLA []

INDEX I. II. III. IV. V. VI.

Index Acknowledgement Introduction Basics of Corrosion Behaviour of stainless steel Sulphuric acid handling system in Kudankulam Nuclear Power Plant VII. Proposed suggestions VIII. Conclusion IX. Bibliography

ACKNOWLEDGEMENT We(Siddharth and Sarvesh) would like to take this opportunity to thank the Senior Staff at Kudankulam Nuclear Power Project, NPCIL because they have granted us the chance to learn directly at the industrial scale by visiting this safe and secure facility. Secondly, we would like to thank the Mrs. Lakshmi and Mr. Shashikanth for continuously guiding us, orienting us with the functionalities, operation and maintenance of the plant. They also arranged an excellent orientation program for the students of BITS-PILANI along with various project opportunities. This study report on the ‘Corrosion of stainless steel in the presence of sulphuric acid’ was allotted to us by our mentor in Kudankulam nuclear power project, Mr. Naveen Balla. It is with his insight and systematic guidance that we have been able to compile this report for the above stated topic. Lastly, we would like to show appreciation towards our institute, Birla Institute of Technology and Science, Pilani and its Practice School Division for directing us towards industrial exposure and helping us tackle real problems in our fields of interest as part of the Practice School I program. Also, all our work has been completed under the guidance and supervision of our

Practice School Professor, Dr. Micheal Alphonse, whose help has been without doubt, irreplaceable in our experience of the Practice School.

INTRODUCTION Sulphuric acid is a chemical that is used in various industrial processes, including ones in Nuclear Power plants and specifically at Kudankulam Nuclear Power Project. It is produced from sulphur dioxide, which may be generated by burning sulphur, it may be a byproduct of a metallurgical smelting process, or it may be produced by thermal decomposition (regeneration) of spent acid. The sulphur dioxide is reacted with oxygen over a catalyst at ~420° to 625°C to form Sulphur trioxide. The latter gas then reacts with water in the absorbing towers to form sulphuric acid. This process is exothermic and the acid can reach temperatures as high as 180° to 200°C. Most of this energy is recovered by a range of means to minimize energy consumption. Usually the acid is then cooled from around 100°C to close to ambient for storage. This process is used in many plants for the production of sulphuric acid, and subsequently its storage.

In a nuclear power plant, handling of this corrosive sulphuric acid requires well designed piping systems inclusive of special valves, storage tanks and mixers. Each of these components requires specific materials to lengthen their lives to reverse the effects of their continuous with sulphuric acid. The most commonly used material for this is stainless steel, a class of steel with slightly varying compositions manufactured to withstand oxidation or reduction reactions with ions in the ing reagents. There are hundreds of grades and sub grades in the stainless steel family, each designed for a special application. Chromium is the magic element that transforms iron into stainless steel. Stainless steel must contain at least 10.5% chromium to provide adequate resistance to rusting, and the more chromium the alloy contains, the better the corrosion resistance becomes. There is, however an upper limit to the amount of chromium the iron can hold. Therefore additional alloying elements are necessary to develop corrosion resistance to specific medias. Thus in this report, a study on the usage of stainless steel is made, along with some other substitute materials, and their specific compositions and usage. This report also studies the phenomenon of corrosion extensively.

BASICS OF CORROSION

What is corrosion? Technically, corrosion is the tendency of any metal to return to its most stable thermodynamic state. Namely, that is the state with the most negative free energy of formation. More simply stated, it is a chemical reaction of the metal with the environment to form an oxide, carbonate, sulfate, or other stable compound. In most cases, using a different alloy, material, proper coating, or impressed current can prevent corrosion problems. When a metal part fails in service, it is essential to determine the cause of the failure so that the replacement part can be manufactured from the proper alloy to prevent future failure. Many times a failed part is replaced with the same alloy. Corrosion can be broadly classified in two forms: (1) chemical dissolution of the metal and (2) galvanic, or electrically driven. Abrasion, fretting and erosion sometimes are classified as corrosion mechanisms, but technically they are a mechanical metal removal process as compared to a chemical removal process. Chemical reaction may accompany the mechanical removal process to speed up the dissolution, but the chemical reaction will fit into the two basic forms. Some authorities list other types of corrosion, but the other types generally are modifications of one of the existing corrosion forms. A correct alloy choice for one type of corrosion mechanism may be entirely the wrong choice for another. Therefore, a proper diagnosis of the failure is

essential to make the correct material choice. Within these two basic classifications there are five types of corrosion: 1.General or uniform corrosion Uniform corrosion occurs over large areas of the metal surface. This is the most common form of corrosion with steel and copper. It is the easiest form of corrosion to measure, and service lifetime is easy to calculate. This is the only form of corrosion that may be accurately calculated for lifetime before failure and the only corrosion mechanism in which increased section thickness gives longer life. This type of corrosion is measured by corrosion rate, usually reported as mpy (mils per year), mm/y (millimeters per year), ipm (inches per month), or mg/sdm/yr (milligrams per square decimeter per year). This type of corrosion may be minimized in the active metals by painting the surface, and unexpected failures can be avoided by periodic inspections. Acid cleaning of metals is an exaggerated example of general corrosion. Every time a copper or carbon steel surface is acid cleaned, the metal walls are thinned due to uniform corrosion. Stainless steel is subject to general corrosion in many acids and some salt solutions. They are not subject to general corrosion in water; therefore, no data is available. Uniform corrosion can be reduced or even prevented by proper selection of materials that are resistant to the corrosive environment. Certain elements make the alloy more resistant to different media. For example, high chromium content imparts oxidation resistance.

Therefore, look for high chromium for use with nitric acid, the higher the better. High chromium is useful for high temperature oxidation resistance; so, any stainless steel is better than carbon steel in elevated temperature applications. High copper content in stainless steel imparts resistance to sulphuric acid. High nickel content gives resistance to reducing acids and produces a tightly adhering oxide film in high temperature oxidation.

2. Inter granular corrosion All metals are composed of small grains that are normally oriented in a random fashion. These grains are each composed of orderly arrays of atoms with the same spacing between the atoms in every grain. Because of the random orientation of the grains, there is a mismatch between the atomic layers where the grains meet. This mismatch is called a "grain boundary." In a typical stainless steel product, there are about 1,000 grain boundaries that intersect a oneinch (25 mm) line drawn on the surface. Grain boundaries are regions of high-energy concentration. Therefore, chemical or metallurgical reactions usually occur at grain boundaries before they occur within the grains. The most common reaction is formation of chromium carbide in the heat-affected zone (HAZ) during welding. These carbides, formed along the grain boundaries, are called "sensitization." Because the carbides require more chromium than is locally available, the carbon pulls chromium from the

area around the carbon. This leaves a low chromium grain boundary zone and creates a new low chromium alloy in that region. Now there is a mismatch in galvanic potential between the base metal and the grain boundary; so, galvanic corrosion begins. The grain boundaries corrode, allowing the central grain and the chromium carbides to drop out as if particles of rusty sand. 3. Galvanic corrosion including pitting and crevice corrosion Galvanic corrosion occurs whenever two electrically different metals are connected in a circuit and are in an electrically conductive solution. This type of corrosion requires three conditions: two metals that differ in the galvanic or electromotive series, an electrically conductive path between the metals and both metals submerged in a conductive solution. A variation of galvanic corrosion can occur with ive film metals. If the alloy loses the ive film in one spot, then it becomes active in that area. Now the metal has both ive and active sites on the same surface. This is the mechanism for pitting and crevice corrosion. The following table is a list of materials and their relative position in the galvanic series. This table allows selection of metal pairs that are galvanically compatible. In general, when an anode, for example aluminum, is connected to a cathode or noble metal in salt water, the anode will corrode and the cathode will be unaffected. Metal

Volt

Corresponding alloy

s Magnesium 1.55 Aluminum 1.33 Zinc 0.76 Iron 0.44 Nickel 0.23 Hydrogen 0.00 Copper +0. 34 Silver Gold

+0. 80 +1. 36

Magnesium Aluminum Zinc Steel, Iron, stainless steel(active), alloy C(active) Nickel (active), Alloy 600 (active), Alloy B-2 Brass, copper, Monel, Nickel (ive), alloy 600 (ive), stainless steel (ive) Silver Gold

However, there is another factor called "area relationship"; if the anode is very large, such as a vessel wall, and the cathode is small like a bolt head, the galvanic action is slight. But, if the anode is small and the cathode is large, the anode will corrode very rapidly. Pitting corrosion is a form of galvanic corrosion in which the chromium in the ive layer is dissolved leaving only the corrosion prone iron. The voltage difference between the ive and active layer on an austenitic stainless steel is +0.78 volts. Acid chlorides are the most common cause of pitting in stainless

steel. Chlorides react with chromium to form the very soluble chromium chloride (CrCl3). Thus, chromium is removed from the ive layer leaving only the active iron. As the chromium is dissolved, the electrically driven chlorides bore into the stainless steel creating a spherical, smooth wall pit. The residual solution in the pit is ferric chloride (FeCl3), which is very corrosive to stainless steel. This is the reason ferric chloride is used in so many of the corrosion tests for stainless steel. When molybdenum and/or nitrogen is used as an alloying element in stainless steel, the pitting corrosion resistance improves. In an attempt to quantify the effect of alloying elements, a relationship of the various elements responsible for corrosion resistance was developed. The resulting equation is called the pitting resistance equivalent number, or PREN. PREN = %Cr + 3.3(%Mo) + 16(%N) Three factors influence pitting corrosion: chloride content, pH, and temperature. In general, the higher the temperature, higher the chloride content and lower the pH, greater is the probability of pitting. For a given chloride content, a higher temperature and lower pH encourage pitting. Conversely, a lower temperature and a higher pH reduce pitting. The worst conditions occur with acid chlorides, and less dangerous conditions occur with alkaline or high pH chlorides. Pitting can occur rapidly once it starts. Crevice corrosion is another form of galvanic corrosion, which occurs when the corroding metal is in close with anything that makes a tight crevice.

Crevice corrosion is usually the first to occur and is predictable as to when and where it will take place. Like pitting, a conductive solution must be present; and, the presence of chlorides makes the reaction proceed at a fast rate. Crevice corrosion depends on the environmental temperature, alloy content and metallurgical category of the alloy. Also, there is a relationship between the tightness of the crevice and the onset time and severity of corrosion. There is a "critical crevice corrosion temperature" (CCCT) below

which corrosion will not occur.

SOURCE : www.stainless-steel-world.net – reports archive The greater the difference between the CCCT and the operating temperature, the greater the probability that crevice corrosion will occur. This chart is very useful in determining the effect of temperature on corrosion by indicating the approximate temperature at which pitting corrosion begins. The

effect of temperature on pitting corrosion is not as clear as that for crevice corrosion, but by adding approximately 100° F (60° C) to the CCCT, the approximate temperature at which pitting starts can be determined. 4. Stress corrosion cracking Stress corrosion cracking (SCC) is one of the most common and dangerous forms of corrosion. Usually it is associated with other types of corrosion that create a stress concentrator that leads to cracking failure. Nickel containing stainless steel is especially susceptible to chloride induced SCC. Stress corrosion cracking (SCC) has three components: alloy composition, environment and the presence of tensile stress. All metals are susceptible to stress corrosion cracking.

The stress component is more subtle. First the stress must be tensile, and it must exceed the yield strength of the component. This sounds simple enough, but any time a component is bent or straightened, or when any physical exertion is made to place the material into a fixed shape, the yield strength is exceeded. Next, matters can be complicated by stress multiplication factors. If a pit or other sharp notch is present, the residual stress is multiplied several times resulting in a stress far in excess of the tensile yield strength. Thus, SCC usually starts with pitting or crevice corrosion as a precursor to forming a stress concentrator. 5. Microbiologically induced corrosion (MIC). In some cases, the metabolic byproducts react with the environmental solution to create a very

corrosive media. An example is the reaction of chlorine in water with the manganese dioxide byproduct from gallionella bacteria on the surface of the stainless steel. This reaction generates hydrochloric acid, which causes rapid pitting of many common grades of stainless steel. One of the most common forms of MIC is the metabolic byproduct of the sulfur-fixing bacteria that produces sulfurous or sulfuric acid. These bacteria cause rapid corrosion of the lower alloy stainless steels, like Types 304L or 316L, resulting in through wall crevice corrosion under the bacteria colonies.

Many times, a metal starts to corrode by one mechanism, for example pitting corrosion, and then fails by a second mechanism, stress corrosion cracking.

BEHAVIOUR OF STAINLESS STEEL Common stainless steel compositions Name 304 316 310 Alloy 20 Zeron 100 2507 S-23 S-25 S-SX ZeCor

Fe Bal Bal Bal Bal Bal

Cr 18 17 25 20 25

Ni 8 10 20 28 7

Mo 2 2.5 3.5

N 0.25

Cu 3.5 0.7

W 0.7

Si 0.6

Bal Bal Bal Bal Bal

25 18 18 18 14

7 18 18 18 15

3.5 1 1 1

0.25 -

2 2 1

-

0.6 5 5 5 6

-

Traditionally materials such as acid-brick lined steel were used for vessels, and ductile irons, such as Mondi® or low alloy austenitic stainless steels such as 316 for piping, within a limited temperature and acid concentration range. However, the development of modern, high alloy stainless steels, with improved resistance to hot concentrated acid has changed the materials selection options. Table 1 shows the composition of some stainless steels that are used with sulphuric acid. 304 and 316 are the common austenitic grades that are widely used by the chemical and process industry. Alloy 310 is a high chromium, nickel austenitic alloy that has superior acid corrosion resistance compared with 304 and 316. ZERON100

and 2507 are superduplex stainless steels with an approximate 50/50 austenite/ferrite phase balance. This structure gives a much higher strength (~2½ times) than that of the austenitic alloys and offers the possibility of wall thickness savings for applications involving high pressures and/or temperatures. Saramet, Sandvik SX and ZeCor are all proprietary austenitic stainless steels containing ~ 5% silicon, which improves the corrosion resistance in hot strong acid. Saramet comes in two variants, with slightly different compositions. ZeCor is leaner in chromium and nickel than the other two proprietary alloys but it contains more silicon, an element known to promote corrosion resistance in hot, strong acid. The naming and compositions (within 0.05%) differ from country to country and from company to company but it is the core composition that matters here, neither the name nor its origin.

Figure 1 shows the iso-corrosion curves for some common alloys in sulphuric acid. It can be seen that the superduplex alloys are superior to 316L. ZERON 100 is also superior to 2507, which is believed to be due to the deliberate additions of tungsten and copper to ZERON 100. Alloy 20 is commonly used in sulphuric acid and from about 50% to 90% acid it is superior to ZERON 100. However, in strong acid (>90%) ZERON 100 shows a marked increase in corrosion resistance compared with 2507 and alloy 20.

Figure 2 compares the iso-corrosion curves for the three proprietary alloys containing silicon and ZERON 100. There are clearly differences between the alloys, with the silicon-containing alloys showing improved corrosion resistance in more dilute acid. Figure 3 shows the iso-corrosion curves for 304, 310 and Saramet 23 in very strong acid 1,2. It can be seen that there is an increase in the corrosion resistance of both 310 and Saramet in the temperature range 180º to 200ºC. It is assumed that SX and ZeCor show

similar behaviour. This means that these alloys can be used in the higher temperature parts of acid plants.

Figure 4 shows the corrosion rate of some stainless steels in strong sulphuric acid at 110°C taken from the manufacturers’ published data. It can be seen that the corrosion resistance of Saramet 23 decreases with increasing acid concentration unlike the other alloys. At acid concentrations greater than 100% there is excess sulphur trioxide and the mixture is then known as oleum. This is known to be more corrosive to alloys like Saramet than to ZERON 100 and alloy 310.

Although there is no publicly available data on 310 stainless in very strong acid, there is a single data point. At an acid concentration of 99% and a temperature of 110ºC, the corrosion rate of 310 was 0.1mm/y1. This shows the improved resistance of ZERON 100 over 310 stainless at this temperature (Figure 4). ZERON 100 also has similar corrosion resistance to ZeCor and Sandvik SX in stronger acid, >97 wt%. In commercial acid plants there is usually a small quantity of iron present (typically 5ppm) and this can affect the corrosion rate of some alloys.

Figure 5 shows the effect of 5ppm of iron on the corrosion rate of ZERON 100 at 110°C. It can be seen that, within experimental error, there was no significant effect of iron on corrosion.

Effect of velocity of flow Because stainless steels are often active (as opposed to ive) in hot, concentrated sulphuric acid, the corrosion rate is a function of velocity. It is commonly recommended that alloys such as 316 and 310 be restricted to a maximum flow velocity of

1.5m/sec 2. Velocity tests have been conducted in aerated 95 wt% sulphuric acid at 70°C using rotating cylindrical samples. The corrosion rate of ZERON 100 was high for the first two or three days. Thereafter the corrosion rate was less than 0.1mm/year. The high initial rate of corrosion was associated with the formation of a thin black film on the metal surface. The film appears to confer corrosion resistance as shown by the subsequent low metal loss rate. These results show that ZERON 100 can be used at higher temperatures and velocities than 316L in strong sulphuric acid. Tests in stronger acid showed even lower corrosion rates. Silicon additions tend to remove the velocity sensitivity of stainless steels to corrosion in hot, strong sulphuric acid. Sandvik reported extremely low corrosion rates (<0.01mm/y) for SX in 96% acid at 70°C and 25m/sec in the alloy data sheet. They obtained a similar corrosion rate in 98.5% acid at 115°C and 10m/sec flow velocity. Saramet 35 showed similar very low corrosion rates in 98.5% acid at 120°C at 9 and 25 m/s velocity4. Although there is no data published for ZeCor at high velocities, it is presumed that it is also superior to the 304 and 316 grades(most commonly used grades of stainless steels). After conducting multiple tests on most samples, it was found that since sulphuric acid density increases sharply with concentration along with its viscosity, it is advisable for plant designers to maintain a low velocity in acid piping systems to prevent the corrosion of the ive layer that protects the inner lying steel. A low

temperature field further aids the longevity of the piping systems.

KUDANKULAM NUCLEAR POWER PROJECT STUDY PROJECT REPORT ON CORROSION OF STAINLESS STEEL IN THE PRESENCE OF SULPHURIC ACID SIDDHARTH PANDEY [2013A1PS742P – PILANI CAMPUS] SARVESH SHUKLA []

INDEX I. II. III. IV. V. VI.

Index Acknowledgement Introduction Basics of Corrosion Behaviour of stainless steel Sulphuric acid handling system in Kudankulam Nuclear Power Plant VII. Proposed suggestions VIII. Conclusion IX. Bibliography

ACKNOWLEDGEMENT We(Siddharth and Sarvesh) would like to take this opportunity to thank the Senior Staff at Kudankulam Nuclear Power Project, NPCIL because they have granted us the chance to learn directly at the industrial scale by visiting this safe and secure facility. Secondly, we would like to thank the Mrs. Lakshmi and Mr. Shashikanth for continuously guiding us, orienting us with the functionalities, operation and maintenance of the plant. They also arranged an excellent orientation program for the students of BITS-PILANI along with various project opportunities. This study report on the ‘Corrosion of stainless steel in the presence of sulphuric acid’ was allotted to us by our mentor in Kudankulam nuclear power project, Mr. Naveen Balla. It is with his insight and systematic guidance that we have been able to compile this report for the above stated topic. Lastly, we would like to show appreciation towards our institute, Birla Institute of Technology and Science, Pilani and its Practice School Division for directing us towards industrial exposure and helping us tackle real problems in our fields of interest as part of the Practice School I program. Also, all our work has been completed under the guidance and supervision of our

Practice School Professor, Dr. Micheal Alphonse, whose help has been without doubt, irreplaceable in our experience of the Practice School.

INTRODUCTION Sulphuric acid is a chemical that is used in various industrial processes, including ones in Nuclear Power plants and specifically at Kudankulam Nuclear Power Project. It is produced from sulphur dioxide, which may be generated by burning sulphur, it may be a byproduct of a metallurgical smelting process, or it may be produced by thermal decomposition (regeneration) of spent acid. The sulphur dioxide is reacted with oxygen over a catalyst at ~420° to 625°C to form Sulphur trioxide. The latter gas then reacts with water in the absorbing towers to form sulphuric acid. This process is exothermic and the acid can reach temperatures as high as 180° to 200°C. Most of this energy is recovered by a range of means to minimize energy consumption. Usually the acid is then cooled from around 100°C to close to ambient for storage. This process is used in many plants for the production of sulphuric acid, and subsequently its storage.

In a nuclear power plant, handling of this corrosive sulphuric acid requires well designed piping systems inclusive of special valves, storage tanks and mixers. Each of these components requires specific materials to lengthen their lives to reverse the effects of their continuous with sulphuric acid. The most commonly used material for this is stainless steel, a class of steel with slightly varying compositions manufactured to withstand oxidation or reduction reactions with ions in the ing reagents. There are hundreds of grades and sub grades in the stainless steel family, each designed for a special application. Chromium is the magic element that transforms iron into stainless steel. Stainless steel must contain at least 10.5% chromium to provide adequate resistance to rusting, and the more chromium the alloy contains, the better the corrosion resistance becomes. There is, however an upper limit to the amount of chromium the iron can hold. Therefore additional alloying elements are necessary to develop corrosion resistance to specific medias. Thus in this report, a study on the usage of stainless steel is made, along with some other substitute materials, and their specific compositions and usage. This report also studies the phenomenon of corrosion extensively.

BASICS OF CORROSION

What is corrosion? Technically, corrosion is the tendency of any metal to return to its most stable thermodynamic state. Namely, that is the state with the most negative free energy of formation. More simply stated, it is a chemical reaction of the metal with the environment to form an oxide, carbonate, sulfate, or other stable compound. In most cases, using a different alloy, material, proper coating, or impressed current can prevent corrosion problems. When a metal part fails in service, it is essential to determine the cause of the failure so that the replacement part can be manufactured from the proper alloy to prevent future failure. Many times a failed part is replaced with the same alloy. Corrosion can be broadly classified in two forms: (1) chemical dissolution of the metal and (2) galvanic, or electrically driven. Abrasion, fretting and erosion sometimes are classified as corrosion mechanisms, but technically they are a mechanical metal removal process as compared to a chemical removal process. Chemical reaction may accompany the mechanical removal process to speed up the dissolution, but the chemical reaction will fit into the two basic forms. Some authorities list other types of corrosion, but the other types generally are modifications of one of the existing corrosion forms. A correct alloy choice for one type of corrosion mechanism may be entirely the wrong choice for another. Therefore, a proper diagnosis of the failure is

essential to make the correct material choice. Within these two basic classifications there are five types of corrosion: 1.General or uniform corrosion Uniform corrosion occurs over large areas of the metal surface. This is the most common form of corrosion with steel and copper. It is the easiest form of corrosion to measure, and service lifetime is easy to calculate. This is the only form of corrosion that may be accurately calculated for lifetime before failure and the only corrosion mechanism in which increased section thickness gives longer life. This type of corrosion is measured by corrosion rate, usually reported as mpy (mils per year), mm/y (millimeters per year), ipm (inches per month), or mg/sdm/yr (milligrams per square decimeter per year). This type of corrosion may be minimized in the active metals by painting the surface, and unexpected failures can be avoided by periodic inspections. Acid cleaning of metals is an exaggerated example of general corrosion. Every time a copper or carbon steel surface is acid cleaned, the metal walls are thinned due to uniform corrosion. Stainless steel is subject to general corrosion in many acids and some salt solutions. They are not subject to general corrosion in water; therefore, no data is available. Uniform corrosion can be reduced or even prevented by proper selection of materials that are resistant to the corrosive environment. Certain elements make the alloy more resistant to different media. For example, high chromium content imparts oxidation resistance.

Therefore, look for high chromium for use with nitric acid, the higher the better. High chromium is useful for high temperature oxidation resistance; so, any stainless steel is better than carbon steel in elevated temperature applications. High copper content in stainless steel imparts resistance to sulphuric acid. High nickel content gives resistance to reducing acids and produces a tightly adhering oxide film in high temperature oxidation.

2. Inter granular corrosion All metals are composed of small grains that are normally oriented in a random fashion. These grains are each composed of orderly arrays of atoms with the same spacing between the atoms in every grain. Because of the random orientation of the grains, there is a mismatch between the atomic layers where the grains meet. This mismatch is called a "grain boundary." In a typical stainless steel product, there are about 1,000 grain boundaries that intersect a oneinch (25 mm) line drawn on the surface. Grain boundaries are regions of high-energy concentration. Therefore, chemical or metallurgical reactions usually occur at grain boundaries before they occur within the grains. The most common reaction is formation of chromium carbide in the heat-affected zone (HAZ) during welding. These carbides, formed along the grain boundaries, are called "sensitization." Because the carbides require more chromium than is locally available, the carbon pulls chromium from the

area around the carbon. This leaves a low chromium grain boundary zone and creates a new low chromium alloy in that region. Now there is a mismatch in galvanic potential between the base metal and the grain boundary; so, galvanic corrosion begins. The grain boundaries corrode, allowing the central grain and the chromium carbides to drop out as if particles of rusty sand. 3. Galvanic corrosion including pitting and crevice corrosion Galvanic corrosion occurs whenever two electrically different metals are connected in a circuit and are in an electrically conductive solution. This type of corrosion requires three conditions: two metals that differ in the galvanic or electromotive series, an electrically conductive path between the metals and both metals submerged in a conductive solution. A variation of galvanic corrosion can occur with ive film metals. If the alloy loses the ive film in one spot, then it becomes active in that area. Now the metal has both ive and active sites on the same surface. This is the mechanism for pitting and crevice corrosion. The following table is a list of materials and their relative position in the galvanic series. This table allows selection of metal pairs that are galvanically compatible. In general, when an anode, for example aluminum, is connected to a cathode or noble metal in salt water, the anode will corrode and the cathode will be unaffected. Metal

Volt

Corresponding alloy

s Magnesium 1.55 Aluminum 1.33 Zinc 0.76 Iron 0.44 Nickel 0.23 Hydrogen 0.00 Copper +0. 34 Silver Gold

+0. 80 +1. 36

Magnesium Aluminum Zinc Steel, Iron, stainless steel(active), alloy C(active) Nickel (active), Alloy 600 (active), Alloy B-2 Brass, copper, Monel, Nickel (ive), alloy 600 (ive), stainless steel (ive) Silver Gold

However, there is another factor called "area relationship"; if the anode is very large, such as a vessel wall, and the cathode is small like a bolt head, the galvanic action is slight. But, if the anode is small and the cathode is large, the anode will corrode very rapidly. Pitting corrosion is a form of galvanic corrosion in which the chromium in the ive layer is dissolved leaving only the corrosion prone iron. The voltage difference between the ive and active layer on an austenitic stainless steel is +0.78 volts. Acid chlorides are the most common cause of pitting in stainless

steel. Chlorides react with chromium to form the very soluble chromium chloride (CrCl3). Thus, chromium is removed from the ive layer leaving only the active iron. As the chromium is dissolved, the electrically driven chlorides bore into the stainless steel creating a spherical, smooth wall pit. The residual solution in the pit is ferric chloride (FeCl3), which is very corrosive to stainless steel. This is the reason ferric chloride is used in so many of the corrosion tests for stainless steel. When molybdenum and/or nitrogen is used as an alloying element in stainless steel, the pitting corrosion resistance improves. In an attempt to quantify the effect of alloying elements, a relationship of the various elements responsible for corrosion resistance was developed. The resulting equation is called the pitting resistance equivalent number, or PREN. PREN = %Cr + 3.3(%Mo) + 16(%N) Three factors influence pitting corrosion: chloride content, pH, and temperature. In general, the higher the temperature, higher the chloride content and lower the pH, greater is the probability of pitting. For a given chloride content, a higher temperature and lower pH encourage pitting. Conversely, a lower temperature and a higher pH reduce pitting. The worst conditions occur with acid chlorides, and less dangerous conditions occur with alkaline or high pH chlorides. Pitting can occur rapidly once it starts. Crevice corrosion is another form of galvanic corrosion, which occurs when the corroding metal is in close with anything that makes a tight crevice.

Crevice corrosion is usually the first to occur and is predictable as to when and where it will take place. Like pitting, a conductive solution must be present; and, the presence of chlorides makes the reaction proceed at a fast rate. Crevice corrosion depends on the environmental temperature, alloy content and metallurgical category of the alloy. Also, there is a relationship between the tightness of the crevice and the onset time and severity of corrosion. There is a "critical crevice corrosion temperature" (CCCT) below

which corrosion will not occur.

SOURCE : www.stainless-steel-world.net – reports archive The greater the difference between the CCCT and the operating temperature, the greater the probability that crevice corrosion will occur. This chart is very useful in determining the effect of temperature on corrosion by indicating the approximate temperature at which pitting corrosion begins. The

effect of temperature on pitting corrosion is not as clear as that for crevice corrosion, but by adding approximately 100° F (60° C) to the CCCT, the approximate temperature at which pitting starts can be determined. 4. Stress corrosion cracking Stress corrosion cracking (SCC) is one of the most common and dangerous forms of corrosion. Usually it is associated with other types of corrosion that create a stress concentrator that leads to cracking failure. Nickel containing stainless steel is especially susceptible to chloride induced SCC. Stress corrosion cracking (SCC) has three components: alloy composition, environment and the presence of tensile stress. All metals are susceptible to stress corrosion cracking.

The stress component is more subtle. First the stress must be tensile, and it must exceed the yield strength of the component. This sounds simple enough, but any time a component is bent or straightened, or when any physical exertion is made to place the material into a fixed shape, the yield strength is exceeded. Next, matters can be complicated by stress multiplication factors. If a pit or other sharp notch is present, the residual stress is multiplied several times resulting in a stress far in excess of the tensile yield strength. Thus, SCC usually starts with pitting or crevice corrosion as a precursor to forming a stress concentrator. 5. Microbiologically induced corrosion (MIC). In some cases, the metabolic byproducts react with the environmental solution to create a very

corrosive media. An example is the reaction of chlorine in water with the manganese dioxide byproduct from gallionella bacteria on the surface of the stainless steel. This reaction generates hydrochloric acid, which causes rapid pitting of many common grades of stainless steel. One of the most common forms of MIC is the metabolic byproduct of the sulfur-fixing bacteria that produces sulfurous or sulfuric acid. These bacteria cause rapid corrosion of the lower alloy stainless steels, like Types 304L or 316L, resulting in through wall crevice corrosion under the bacteria colonies.

Many times, a metal starts to corrode by one mechanism, for example pitting corrosion, and then fails by a second mechanism, stress corrosion cracking.

BEHAVIOUR OF STAINLESS STEEL Common stainless steel compositions Name 304 316 310 Alloy 20 Zeron 100 2507 S-23 S-25 S-SX ZeCor

Fe Bal Bal Bal Bal Bal

Cr 18 17 25 20 25

Ni 8 10 20 28 7

Mo 2 2.5 3.5

N 0.25

Cu 3.5 0.7

W 0.7

Si 0.6

Bal Bal Bal Bal Bal

25 18 18 18 14

7 18 18 18 15

3.5 1 1 1

0.25 -

2 2 1

-

0.6 5 5 5 6

-

Traditionally materials such as acid-brick lined steel were used for vessels, and ductile irons, such as Mondi® or low alloy austenitic stainless steels such as 316 for piping, within a limited temperature and acid concentration range. However, the development of modern, high alloy stainless steels, with improved resistance to hot concentrated acid has changed the materials selection options. Table 1 shows the composition of some stainless steels that are used with sulphuric acid. 304 and 316 are the common austenitic grades that are widely used by the chemical and process industry. Alloy 310 is a high chromium, nickel austenitic alloy that has superior acid corrosion resistance compared with 304 and 316. ZERON100

and 2507 are superduplex stainless steels with an approximate 50/50 austenite/ferrite phase balance. This structure gives a much higher strength (~2½ times) than that of the austenitic alloys and offers the possibility of wall thickness savings for applications involving high pressures and/or temperatures. Saramet, Sandvik SX and ZeCor are all proprietary austenitic stainless steels containing ~ 5% silicon, which improves the corrosion resistance in hot strong acid. Saramet comes in two variants, with slightly different compositions. ZeCor is leaner in chromium and nickel than the other two proprietary alloys but it contains more silicon, an element known to promote corrosion resistance in hot, strong acid. The naming and compositions (within 0.05%) differ from country to country and from company to company but it is the core composition that matters here, neither the name nor its origin.

Figure 1 shows the iso-corrosion curves for some common alloys in sulphuric acid. It can be seen that the superduplex alloys are superior to 316L. ZERON 100 is also superior to 2507, which is believed to be due to the deliberate additions of tungsten and copper to ZERON 100. Alloy 20 is commonly used in sulphuric acid and from about 50% to 90% acid it is superior to ZERON 100. However, in strong acid (>90%) ZERON 100 shows a marked increase in corrosion resistance compared with 2507 and alloy 20.

Figure 2 compares the iso-corrosion curves for the three proprietary alloys containing silicon and ZERON 100. There are clearly differences between the alloys, with the silicon-containing alloys showing improved corrosion resistance in more dilute acid. Figure 3 shows the iso-corrosion curves for 304, 310 and Saramet 23 in very strong acid 1,2. It can be seen that there is an increase in the corrosion resistance of both 310 and Saramet in the temperature range 180º to 200ºC. It is assumed that SX and ZeCor show

similar behaviour. This means that these alloys can be used in the higher temperature parts of acid plants.

Figure 4 shows the corrosion rate of some stainless steels in strong sulphuric acid at 110°C taken from the manufacturers’ published data. It can be seen that the corrosion resistance of Saramet 23 decreases with increasing acid concentration unlike the other alloys. At acid concentrations greater than 100% there is excess sulphur trioxide and the mixture is then known as oleum. This is known to be more corrosive to alloys like Saramet than to ZERON 100 and alloy 310.

Although there is no publicly available data on 310 stainless in very strong acid, there is a single data point. At an acid concentration of 99% and a temperature of 110ºC, the corrosion rate of 310 was 0.1mm/y1. This shows the improved resistance of ZERON 100 over 310 stainless at this temperature (Figure 4). ZERON 100 also has similar corrosion resistance to ZeCor and Sandvik SX in stronger acid, >97 wt%. In commercial acid plants there is usually a small quantity of iron present (typically 5ppm) and this can affect the corrosion rate of some alloys.

Figure 5 shows the effect of 5ppm of iron on the corrosion rate of ZERON 100 at 110°C. It can be seen that, within experimental error, there was no significant effect of iron on corrosion.

Effect of velocity of flow Because stainless steels are often active (as opposed to ive) in hot, concentrated sulphuric acid, the corrosion rate is a function of velocity. It is commonly recommended that alloys such as 316 and 310 be restricted to a maximum flow velocity of

1.5m/sec 2. Velocity tests have been conducted in aerated 95 wt% sulphuric acid at 70°C using rotating cylindrical samples. The corrosion rate of ZERON 100 was high for the first two or three days. Thereafter the corrosion rate was less than 0.1mm/year. The high initial rate of corrosion was associated with the formation of a thin black film on the metal surface. The film appears to confer corrosion resistance as shown by the subsequent low metal loss rate. These results show that ZERON 100 can be used at higher temperatures and velocities than 316L in strong sulphuric acid. Tests in stronger acid showed even lower corrosion rates. Silicon additions tend to remove the velocity sensitivity of stainless steels to corrosion in hot, strong sulphuric acid. Sandvik reported extremely low corrosion rates (<0.01mm/y) for SX in 96% acid at 70°C and 25m/sec in the alloy data sheet. They obtained a similar corrosion rate in 98.5% acid at 115°C and 10m/sec flow velocity. Saramet 35 showed similar very low corrosion rates in 98.5% acid at 120°C at 9 and 25 m/s velocity4. Although there is no data published for ZeCor at high velocities, it is presumed that it is also superior to the 304 and 316 grades(most commonly used grades of stainless steels). After conducting multiple tests on most samples, it was found that since sulphuric acid density increases sharply with concentration along with its viscosity, it is advisable for plant designers to maintain a low velocity in acid piping systems to prevent the corrosion of the ive layer that protects the inner lying steel. A low

temperature field further aids the longevity of the piping systems.