Tam Cleaning Instructions 65m2j

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Tam Cleaning Instructions as PDF for free.

More details w3441

- Words: 291

- Pages: 1

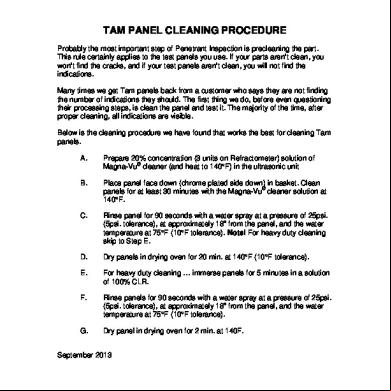

TAM CLEANING PROCEDURE Probably the most important step of Penetrant Inspection is precleaning the part. This rule certainly applies to the test s you use. If your parts aren’t clean, you won’t find the cracks, and if your test s aren’t clean, you will not find the indications. Many times we get Tam s back from a customer who says they are not finding the number of indications they should. The first thing we do, before even questioning their processing steps, is clean the and test it. The majority of the time, after proper cleaning, all indications are visible. Below is the cleaning procedure we have found that works the best for cleaning Tam s. A.

Prepare 20% concentration (3 units on Refractometer) solution of Magna-Vu® cleaner (and heat to 140°F) in the ultrasonic unit

B.

Place face down (chrome plated side down) in basket. Clean s for at least 30 minutes with the Magna-Vu® cleaner solution at 140°F.

C.

Rinse for 90 seconds with a water spray at a pressure of 25psi. (5psi. tolerance), at approximately 18” from the , and the water temperature at 75°F (10°F tolerance). Note! For heavy duty cleaning skip to Step E.

D.

Dry s in drying oven for 20 min. at 140°F (10°F tolerance).

E.

For heavy duty cleaning … immerse s for 5 minutes in a solution of 100% CLR.

F.

Rinse s for 90 seconds with a water spray at a pressure of 25psi. (5psi. tolerance), at approximately 18” from the , and the water temperature at 75°F (10°F tolerance).

G.

Dry in drying oven for 2 min. at 140F.

September 2013

3624 W. LAKE AVENUE GLENVIEW, ILLINOIS 60026 TEL (847) 657-5300 www.magnaflux.com

FAX (847) 657-5388

Prepare 20% concentration (3 units on Refractometer) solution of Magna-Vu® cleaner (and heat to 140°F) in the ultrasonic unit

B.

Place face down (chrome plated side down) in basket. Clean s for at least 30 minutes with the Magna-Vu® cleaner solution at 140°F.

C.

Rinse for 90 seconds with a water spray at a pressure of 25psi. (5psi. tolerance), at approximately 18” from the , and the water temperature at 75°F (10°F tolerance). Note! For heavy duty cleaning skip to Step E.

D.

Dry s in drying oven for 20 min. at 140°F (10°F tolerance).

E.

For heavy duty cleaning … immerse s for 5 minutes in a solution of 100% CLR.

F.

Rinse s for 90 seconds with a water spray at a pressure of 25psi. (5psi. tolerance), at approximately 18” from the , and the water temperature at 75°F (10°F tolerance).

G.

Dry in drying oven for 2 min. at 140F.

September 2013

3624 W. LAKE AVENUE GLENVIEW, ILLINOIS 60026 TEL (847) 657-5300 www.magnaflux.com

FAX (847) 657-5388