Tool Room Lathe Machine d1u5y

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Tool Room Lathe Machine as PDF for free.

More details w3441

- Words: 713

- Pages: 4

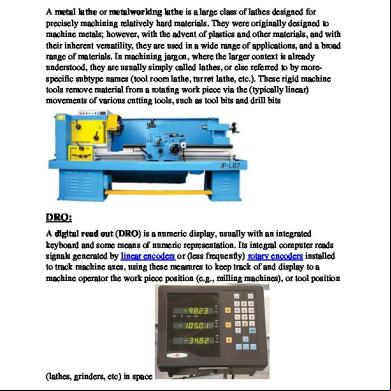

TOOL ROOM LATHE MACHINE A metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by morespecific subtype names (tool room lathe, turret lathe, etc.). These rigid machine tools remove material from a rotating work piece via the (typically linear) movements of various cutting tools, such as tool bits and drill bits

DRO: A digital read out (DRO) is a numeric display, usually with an integrated keyboard and some means of numeric representation. Its integral computer reads signals generated by linear encoders or (less frequently) rotary encoders installed to track machine axes, using these measures to keep track of and display to a machine operator the work piece position (e.g., milling machines), or tool position

(lathes, grinders, etc) in space

Lathes Operations The general operations done with the lathe are grooving, turning, cutting, sanding and etc. if anyone wants to operate the lathe machine then he must first know about the feeds, cutting speed, depth of the cut and usage of tool should be considered. Each lathe operation has got its own factors that need to be considered before doing the work. The factors should be used properly so that one can avoid from mishandling and mishaps while performing any kind of lathe operation. With every cut desired the speed, depth and feed of the lathe machine is changed for precision .

Types of Lathe Operation The working of the lathe machine changes with every operation and cut desired. There are a lot of operations used for using the lathe machine. Some of the common lathe operations are:

Facing This is usually the first step of any lathe operation on the lathe machine. The metal is cut from the end to make it fit in the right angle of the axis and remove the marks.

Tapering

Tapering is to cut the metal to nearly a cone shape with the help of the compound slide. This is something in between the parallel turning and facing off. If one is willing to change the angle then they can adjust the compound slide as they like.

Parallel Turning This operation is adopted in order to cut the metal parallel to the axis. Parallel turning is done to decrease the diameter of the metal.

Parting The part is removed so that it faces the ends. For this the parting tool is involved in slowly to make perform the operation. For to make the cut deeper the parting tool is pulled out and transferred to the side for the cut and to prevent the tool from breaking.

Lathe Cutting Tools There are several lathe cutting tools that help in cutting with the lathe machine. The commonly used tools are mentioned below:

Carbide tip tools Grooving tool Cut-Off blade Parting blades Boring bar Side tool Lathe Applications Lathes have many different applications in an industrial setting. Whether working wooden table legs to constructing baseball trophy top pieces, a lathe exists for almost every type of material. The following table details a few of the applications.

Applications

Description

Woodturning

Used to make wooden objects such as ornate table legs, baseball bats, wooden bowl, and platters; operators use a variety of tools to form

Metalworking

Used to create precision parts; most often associated with a multistep process requiring different tools for each step

Metal Spinning

A process where metal spins on a spindle, while the operator works it with tools; an automated process

Acrylic Spinning

Involves spinning acrylic on a spindle to form items from acrylic; most often used in the making of the top pieces for trophies

Thermal Spraying

Combines the rotating spindle with the painting process; the paint sticks to the stock via processes involving heating the paint materials

Pottery

By using a potter's wheel, artisans can make a variety of pottery pieces; though formed mainly by hand, craftsperson’s also use tools

References: https://en.wikipedia.org/wiki/Lathe https://en.wikipedia.org/wiki/Metal_lathe http://www.engineeringarticles.org/lathe-lathe-operations-types-and-cuttingtools/

DRO: A digital read out (DRO) is a numeric display, usually with an integrated keyboard and some means of numeric representation. Its integral computer reads signals generated by linear encoders or (less frequently) rotary encoders installed to track machine axes, using these measures to keep track of and display to a machine operator the work piece position (e.g., milling machines), or tool position

(lathes, grinders, etc) in space

Lathes Operations The general operations done with the lathe are grooving, turning, cutting, sanding and etc. if anyone wants to operate the lathe machine then he must first know about the feeds, cutting speed, depth of the cut and usage of tool should be considered. Each lathe operation has got its own factors that need to be considered before doing the work. The factors should be used properly so that one can avoid from mishandling and mishaps while performing any kind of lathe operation. With every cut desired the speed, depth and feed of the lathe machine is changed for precision .

Types of Lathe Operation The working of the lathe machine changes with every operation and cut desired. There are a lot of operations used for using the lathe machine. Some of the common lathe operations are:

Facing This is usually the first step of any lathe operation on the lathe machine. The metal is cut from the end to make it fit in the right angle of the axis and remove the marks.

Tapering

Tapering is to cut the metal to nearly a cone shape with the help of the compound slide. This is something in between the parallel turning and facing off. If one is willing to change the angle then they can adjust the compound slide as they like.

Parallel Turning This operation is adopted in order to cut the metal parallel to the axis. Parallel turning is done to decrease the diameter of the metal.

Parting The part is removed so that it faces the ends. For this the parting tool is involved in slowly to make perform the operation. For to make the cut deeper the parting tool is pulled out and transferred to the side for the cut and to prevent the tool from breaking.

Lathe Cutting Tools There are several lathe cutting tools that help in cutting with the lathe machine. The commonly used tools are mentioned below:

Carbide tip tools Grooving tool Cut-Off blade Parting blades Boring bar Side tool Lathe Applications Lathes have many different applications in an industrial setting. Whether working wooden table legs to constructing baseball trophy top pieces, a lathe exists for almost every type of material. The following table details a few of the applications.

Applications

Description

Woodturning

Used to make wooden objects such as ornate table legs, baseball bats, wooden bowl, and platters; operators use a variety of tools to form

Metalworking

Used to create precision parts; most often associated with a multistep process requiring different tools for each step

Metal Spinning

A process where metal spins on a spindle, while the operator works it with tools; an automated process

Acrylic Spinning

Involves spinning acrylic on a spindle to form items from acrylic; most often used in the making of the top pieces for trophies

Thermal Spraying

Combines the rotating spindle with the painting process; the paint sticks to the stock via processes involving heating the paint materials

Pottery

By using a potter's wheel, artisans can make a variety of pottery pieces; though formed mainly by hand, craftsperson’s also use tools

References: https://en.wikipedia.org/wiki/Lathe https://en.wikipedia.org/wiki/Metal_lathe http://www.engineeringarticles.org/lathe-lathe-operations-types-and-cuttingtools/