Weld-cost-calculation.xls 5u174w

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Weld-cost-calculation.xls as PDF for free.

More details w3441

- Words: 2,690

- Pages: 25

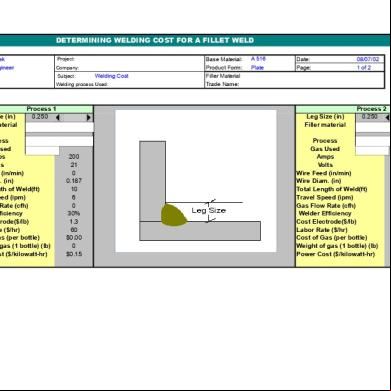

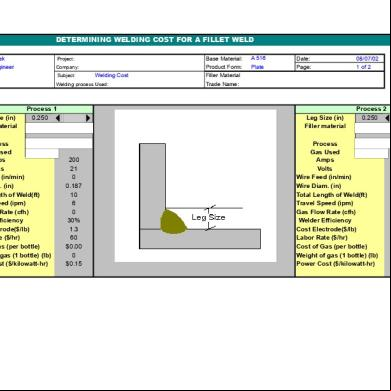

DETERMINING WELDING COST FOR A FILLET WELD Mark Mruczek Welding Engineer

Project: Company: Subject:

Welding Cost

Welding process Used:

Leg Size (in) Filler material

Process 1 0.250 Carbon Steel

SMAW (14" Stick) Process Gas Used N/A Amps 200 Volts 21 Wire Feed (in/min) 0 Wire Diam. (in) 0.187 Total Length of Weld(ft) 10 Travel Speed (ipm) 6 Gas Flow Rate (cfh) 0 Welder Efficiency 30% Cost Electrode($/lb) 1.3 Labor Rate ($/hr) 60 Cost of Gas (per bottle) $0.00 Weight of gas (1 bottle) (lb) 0 Power Cost ($/kilowatt-hr) $0.15

Base Material: Product Form: Filler Material Trade Name:

A 516 Plate

Date: Page:

Leg Size (in) Filler material

08/07/02 1 of 2

Process 2 0.250 Carbon Steel

FCAW (Gas) Process Gas Used Co2 Amps Volts Wire Feed (in/min) Wire Diam. (in) Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas (1 bottle) (lb) Power Cost ($/kilowatt-hr)

200 21 190 0.045 10 8 40 50% 2.5 60 $70.00 50 $0.15

WELDING COST OUTPUT FOR A FILLET WELD OUTPUT FOR PROCESS 1 SMAW (14" Stick) Amount of weld wire needed 2.00 lb Number of es per t ~ 1 Size of fillet weld** 0.290 in Amount of shielding gas 0.00 ft^3 bottles = N/A Actual welding time 1.80 hr Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

$108.15 $2.60 $0.00 $0.35 $111.10 $127.80

Labor Cost Labor Cost 97% Welding Wire Cost 2% Power Cost 0%

Welding Wire Cost Gas Cost Power Cost

Cost per ft of weld $11.11 $/ft Cost per foot filler metal $0.26 $/ft Cost per foot of gas $0.00 $/ft Cost of Labor per foot $10.82 $/ft ** Size of the fillet weld is based on heat input. This information can be used to adjust your amps & volts to achieve the leg size you entered in B10 OUTPUT FOR PROCESS 2 FCAW (Gas) Amount of weld wire needed 2.00 lb Number of es per t ~ 1 Size of fillet weld** 0.251 in Amount of shielding gas 0.00 ft^3 bottles = 1 Actual welding time 0.78 hr Labor Cost Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

Cost per ft of weld

$46.80 $5.00 $2.55 $0.25 $54.60 $62.80

$5.46 $/ft

Labor Cost 86%

Welding Wire Cost Welding Wire Cost 9% Gas Cost 5%

Power Cost 0%

Gas Cost Power Cost

Power Cost 0%

Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$0.50 $/ft $0.26 $/ft $4.68 $/ft

Labor Cost Labor Cost 97% Welding Wire Cost 2% Power Cost 0%

Welding Wire Cost Gas Cost Power Cost

DETERMINING WELDING COST FOR A SINGLE-V GROOVE WELD Mark Mruczek Welding Engineer

Project: Company: Subject:

Welding Cost

Welding process Used:

Base Material: Product Form: Filler Material Trade Name:

A 516 Plate E7018

Date: Page:

08/07/02 1 of 2

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 1 0.625 0.063 0.094 0.063

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 2 0.625 0.063 0.094 0.063

Filler material

Carbon Steel

Filler material

Carbon Steel

SMAW (14" Stick) Process Gas Used N/A Amps 200 Volts 22 Wire Feed (in/min) 0 Wire Diam. (in) 0.1875 t Angle 60 Total Length of Weld(ft) 1000 Travel Speed (ipm) 6 Gas Flow Rate (cfh) 0 Welder Efficiency 30% Cost Electrode($/lb) 1.26 Labor Rate ($/hr) 60 Cost of Gas (per bottle) $0.00 Weight of gas in one bottle ( 0 Power Cost ($/kilowatt-hr) $0.10

FCAW (Gas) Process Gas Used C25 Amps Volts Wire Feed (in/min) Wire Diam. (in) t Angle Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas in one bottle (l Power Cost ($/kilowatt-hr)

WELDING COST OUTPUT FOR A SINGLE-V GROOVE WELD OUTPUT FOR SMAW (14" Stick) Amount of weld wire needed 1492.13 lb Number of es per t ~ 6 Amount of shielding gas 0.00 ft^3 bottles = N/A Actual welding time 1344.26 hr

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

$50,006.52 $1,880.08 $0.00 $177.44 $52,064.05 $59,873.65

Labor Cost 96% Welding Wire Cost 4% Power Cost 0%

Cost per ft of weld Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$52.06 $1.88 $0.00 $50.01

OUTPUT FOR FCAW (Gas) Amount of weld wire needed Number of es per t ~ Amount of shielding gas Actual welding time

1075.72 lb 9 6196.31 ft^3 bottles = 14 354.07 hr

Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

Cost per ft of weld Cost per foot filler metal Cost per foot of gas

$/ft $/ft $/ft $/ft

$18,270.25 $2,420.37 $1,068.86 $84.98 $21,844.47 $ 25,121.13

$21.84 $/ft $2.42 $/ft $1.07 $/ft

Labor Cost Gas Cost 5% Welding Wire Cost Power Cost 11% Labor Cost 0% 84%

Welding Wire Cost Gas Cost Power Cost

Cost of Labor per foot

$18.27 $/ft

Process 2

Carbon Steel FCAW (Gas) C25

200 20 225 0.05 60 1000 8 35 50% 2.25 60 $75.00 50 $0.12

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost 96% Welding Wire Cost 4% Power Cost 0%

Labor Cost Gas Cost 5% Welding Wire Cost Power Cost 11% Labor Cost 0% 84%

Welding Wire Cost Gas Cost Power Cost

DETERMINING WELDING COST FOR A SINGLE-BEVEL GROOVE WELD Mark Mruczek Welding Engineer

Project: Company: Subject:

Welding Cost

Welding process Used:

SMAW + GMAW

Base Material: Product Form: Filler Material Trade Name:

A 516 Plate E7018 Lincoln

Date: Page:

05/22/02 1 of 2

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 1 2.25 0.09375 0.125 0.09375

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 2 2.25 0.09375 0.125 0.09375

Filler material

Carbon Steel

Filler material

Carbon Steel

Process FCAW (Gas) Gas Used C25 Amps Volts Wire Feed (in/min) Wire Diam. (in) t Angle Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas in one bottle Power Cost ($/kilowatt-hr)

200 21 225 0.052 45 3.535 9 35 50% 2.45 50 $50.00 50 $0.15

SMAW (14" Stick) Process Gas Used N/A Amps Volts Wire Feed (in/min) Wire Diam. (in) t Angle Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas in one bottle (l Power Cost ($/kilowatt-hr)

WELDING COST OUTPUT FOR A SINGLE-BEVEL GROOVE WELD OUTPUT FOR FCAW (Gas) Amount of weld wire needed Number of es per t ~ Amount of shielding gas Actual welding time Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

Cost per ft of weld Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$

38.37 lb 100 165.52 ft^3 bottles = 1 9.46 hr Labor Cost 78% Power Cost Welding Wire Cost Gas Cost 1% 4% 18%

$406.70 $94.01 $19.03 $2.98 $522.72 601.13

$147.87 $26.59 $5.38 $115.05

Labor Cost Welding Wire Cost Gas Cost Power Cost

$/ft $/ft $/ft $/ft

OUTPUT FOR SMAW (14" Stick) Amount of weld wire needed 54.00 lb Number of es per t ~ 73 Amount of shielding gas 0.00 ft^3 bottles = N/A Actual welding time 60.00 hr Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

$3,000.00 $70.20 $0.00 $0.28 $3,081.00 $ 3,543.15

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

Power Cost

Cost per ft of weld Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$871.57 $19.86 $0.00 $848.66

$/ft $/ft $/ft $/ft

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

Process 2

Carbon Steel SMAW (14" Stick) N/A

175 20 0 0.188 45 3.535 5.5 0 30% 1.3 50 $0.00 0 $0.15

Labor Cost 78% Power Cost Welding Wire Cost Gas Cost 1% 4% 18%

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

Power Cost

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

0.5625 0.6495 0.6495 0.7433 0.283 0.0311 0.1058 0.0586 0.199 0.1827 0.620 0.9251 1492.13 3.70 $177.44

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 1 Single-V Groove Process Efficiency 62% Process Welder Efficiency 30% Bottles of gas needed Arc Time 403.28 hr Radius of cap "r" Total welding time 1344.26 hr Deposited Weld Metal Wt. Density of gas 0 lb/ft^3 Volume of gas in one 0.00 ft^3 bottle Total gas needed 0.00 ft^3 Labor Cost $ 50,006.52 Gas Cost $0.00 Cost Electrode $1,880.08 Total Cost $ 52,064.05 Final Cost $ 7,809.61 $ 59,873.65 Heat Input 44 Number of es 6

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

0.5625 0.6495 0.6495 0.7433 0.283 0.0311 0.1058 0.0586 0.199 0.1827 0.620 0.9251 1075.72 6.08 $84.98

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 2 Single-V Groove Process Efficiency 86% Process Welder Efficiency 50% Bottles of gas needed Arc Time 177.04 hr Radius of cap "r" Total welding time 354.07 hr Deposited Weld Metal Wt. Density of gas 0.115 lb/ft^3 Volume of gas in one 434.78 ft^3 bottle Total gas needed 6196.31 ft^3 Labor Cost $ 18,270.25 Gas Cost $1,068.86 Cost Electrode $2,420.37 Total Cost $ 21,844.47 Final Cost $ 3,276.67 $ 25,121.13 Heat Input 30 Number of es 9

SMAW (14" Stick) N/A 1.136146 925

FCAW (Gas) 14 1.136146 925.1206

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

2.15625 3.0494 2.1563 2.2813 0.283 0.1428 0.4848 0.2813 0.955 2.3247 7.895 9.335 38.37 8.11 $2.98

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 1 Single-Bevel Groove Process Efficiency 86% Process Welder Efficiency 50% Bottles of gas needed Arc Time 4.73 hr Radius of cap "r" Total welding time 9.46 hr Beta Density of gas 0.115 lb/ft^3 Deposited Weld Metal Wt. Volume of gas in one 434.78 ft^3 bottle Total gas needed 165.52 ft^3 Labor Cost $ 406.70 Gas Cost $19.03 Cost Electrode $94.01 Total Cost $ 522.72 Final Cost $ 78.41 $ 601.13 Heat Input 28 Number of es 100

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

2.15625 3.0494 2.1563 2.2813 0.283 0.1428 0.4848 0.2813 0.955 2.3247 7.895 9.335 54.00 3.000 $10.80

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 2 Single-Bevel Groove Process Efficiency 62% Process Welder Efficiency 30% Bottles of gas needed Arc Time 18.00 hr Radius of cap "r" Total welding time 60.00 hr Beta Density of gas 0 lb/ft^3 Deposited Weld Metal Wt. Volume of gas in one 0.00 ft^3 bottle Total gas needed 0.00 ft^3 Labor Cost $ 3,000.00 Gas Cost $0.00 Cost Electrode $70.20 Total Cost $ 3,081.00 Final Cost $ 3,543.15 Heat Input 38.18181818 Number of es 73

Area of Fillet Weld

CALCULATIONS PROCESS 1 Fillet Weld 0.0313 in2 Process Efficiency

62%

FCAW (Gas) 1 6.986 45 33.00

SMAW (14" Stick) N/A 6.986 45 33.00

Volume of Weld Metal 3.750 in3 Filler Density lb/in3 0.283 lb/in3 Total Weld Metal Weight 0.106 lb/ft Amount of Welding Wire 2.000 lb Deposition Rate 3.700 lb/hr Density of gas 0 lb/ft3 Volume of gas in one 0 ft3 bottle Total gas needed 0 ft3 Bottles of gas needed N/A Process SMAW (14" Stick)

Welder Efficiency Arc Time Total welding time Heat Input Fillet Weld Size Number of es Labor Cost Gas Cost Cost Electrode Total Power Cost Total Cost Final Cost

30% 0.541 1.802 42 0.290 1 $108.15 $0.00 $2.60 $0.35 $111.10 $127.80

CALCULATIONS PROCESS 2 Fillet Weld Area of Fillet Weld 0.0313 in2 Process Efficiency 3 Volume of Weld Metal 3.750 in Welder Efficiency 3 3 Filler Density lb/in 0.283 lb/in Arc Time Total Weld Metal Weight 0.106 lb/ft Total welding time Amount of Welding Wire 2.000 lb Heat Input Deposition Rate 5.1310494 lb/hr Fillet Weld Size 3 Density of gas 0.116 lb/ft Number of es 3 Volume of gas in one 431.034483 ft Labor Cost bottle Gas Cost 3 Total gas needed 15.5913525 ft Cost Electrode Bottles of gas needed 1 Total Power Cost Process FCAW (Gas) Total Cost Final Cost

86% 50% 0.390 0.780 31.5 0.251 1 $46.80 $2.55 $5.00 $0.25 $54.60 $62.80

hr hr kJ/in in

hr hr kJ/in in

SMAW (14" Stick) in lb

FCAW (Gas) in lb

FCAW (Gas) in lb

SMAW (14" Stick) in lb

Alloy Density Carbon Steel 0.283 Stainless Steel 0.29 Nickel Alloy 0.31 1 1 1

1 1 1

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.000 6.076 0.000 0.000 0.000 6.076

Weld Size 0.125 0.1875 0.250 0.313 0.375 0.438 0.500 0.5625 0.625 0.688 0.750

5 0 0 0 0 200 0 0 0

Process&Welder Eff (%) SAW 99% 98% GMAW (98Ar-2O2) 96% GMAW (75Ar-25CO2) GMAW CO2 93% FCAW (Gas) 86% 78% FCAW (Self Shield) 59% SMAW (12" Stick) 0.62 SMAW (14" Stick) 66% SMAW (18" Stick) 8 5 Sing-V 5 8 Sing-Bev 8 5 Fillet Single_V Deposition Rates SMAW 8 110 1.8 0 125 2 0 150 2.6 0 175 3 0 200 3.7 200 225 4.2 0 275 7 0 325 9 0 400 10

GAS Densities N/A Ar Co2 C25 1 4 1

70% 50% 50% 50% 50% 50% 30% 30% 30%

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 3.000 0.000 0.000 0.000 0.000 3.000

0 0.111 0.116 0.115 4 Single V 1 Single Bev 3 Fillet

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.000 3.700 0.000 0.000 0.000 3.700

8 0 0 0 175 0 0 0 0

Single Bevel Deposition Rates SMAW 110 1.8 125 2 150 2.6 175 3 200 3.7 225 4.2 275 7 325 9 400 10

5 0 0 0 0 200 0 0 0

Cap Hieght 0 0.03125 0.063 0.094 0.125 0.25 0.375 2 3 3 3 4 3

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.000 8.114 0.000 0.000 0.000 8.114

Single V Single Bevel Fillet Weld

0.8125 0.875 0.938 1.000 1.125 1.25 1.375 1.5 1.5625 1.625 1.75 1.8125 1.875 2 2.125 2.25 2.375 2.5 2.5625 2.625 2.75 2.8125 2.875 3 3.125 3.25 3.375 3.5 3.5625 3.625 3.75 3.8125 9 27 3

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.00 3.700 0.000 0.000 0.000 3.700

9 27 3

8 0 0 0 0 200 0 0 0

Fillet Weld Deposition Rates SMAW 110 1.8 125 2 150 2.6 175 3 200 3.7 225 4.2 275 7 325 9 400 10

5 0 0 0 0 200 0 0 0

Interpolation of Deposit Rate Process 1 0 0 0 0 5.131 0 0 0 5.131

3 2 2 3 4 3

Project: Company: Subject:

Welding Cost

Welding process Used:

Leg Size (in) Filler material

Process 1 0.250 Carbon Steel

SMAW (14" Stick) Process Gas Used N/A Amps 200 Volts 21 Wire Feed (in/min) 0 Wire Diam. (in) 0.187 Total Length of Weld(ft) 10 Travel Speed (ipm) 6 Gas Flow Rate (cfh) 0 Welder Efficiency 30% Cost Electrode($/lb) 1.3 Labor Rate ($/hr) 60 Cost of Gas (per bottle) $0.00 Weight of gas (1 bottle) (lb) 0 Power Cost ($/kilowatt-hr) $0.15

Base Material: Product Form: Filler Material Trade Name:

A 516 Plate

Date: Page:

Leg Size (in) Filler material

08/07/02 1 of 2

Process 2 0.250 Carbon Steel

FCAW (Gas) Process Gas Used Co2 Amps Volts Wire Feed (in/min) Wire Diam. (in) Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas (1 bottle) (lb) Power Cost ($/kilowatt-hr)

200 21 190 0.045 10 8 40 50% 2.5 60 $70.00 50 $0.15

WELDING COST OUTPUT FOR A FILLET WELD OUTPUT FOR PROCESS 1 SMAW (14" Stick) Amount of weld wire needed 2.00 lb Number of es per t ~ 1 Size of fillet weld** 0.290 in Amount of shielding gas 0.00 ft^3 bottles = N/A Actual welding time 1.80 hr Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

$108.15 $2.60 $0.00 $0.35 $111.10 $127.80

Labor Cost Labor Cost 97% Welding Wire Cost 2% Power Cost 0%

Welding Wire Cost Gas Cost Power Cost

Cost per ft of weld $11.11 $/ft Cost per foot filler metal $0.26 $/ft Cost per foot of gas $0.00 $/ft Cost of Labor per foot $10.82 $/ft ** Size of the fillet weld is based on heat input. This information can be used to adjust your amps & volts to achieve the leg size you entered in B10 OUTPUT FOR PROCESS 2 FCAW (Gas) Amount of weld wire needed 2.00 lb Number of es per t ~ 1 Size of fillet weld** 0.251 in Amount of shielding gas 0.00 ft^3 bottles = 1 Actual welding time 0.78 hr Labor Cost Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

Cost per ft of weld

$46.80 $5.00 $2.55 $0.25 $54.60 $62.80

$5.46 $/ft

Labor Cost 86%

Welding Wire Cost Welding Wire Cost 9% Gas Cost 5%

Power Cost 0%

Gas Cost Power Cost

Power Cost 0%

Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$0.50 $/ft $0.26 $/ft $4.68 $/ft

Labor Cost Labor Cost 97% Welding Wire Cost 2% Power Cost 0%

Welding Wire Cost Gas Cost Power Cost

DETERMINING WELDING COST FOR A SINGLE-V GROOVE WELD Mark Mruczek Welding Engineer

Project: Company: Subject:

Welding Cost

Welding process Used:

Base Material: Product Form: Filler Material Trade Name:

A 516 Plate E7018

Date: Page:

08/07/02 1 of 2

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 1 0.625 0.063 0.094 0.063

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 2 0.625 0.063 0.094 0.063

Filler material

Carbon Steel

Filler material

Carbon Steel

SMAW (14" Stick) Process Gas Used N/A Amps 200 Volts 22 Wire Feed (in/min) 0 Wire Diam. (in) 0.1875 t Angle 60 Total Length of Weld(ft) 1000 Travel Speed (ipm) 6 Gas Flow Rate (cfh) 0 Welder Efficiency 30% Cost Electrode($/lb) 1.26 Labor Rate ($/hr) 60 Cost of Gas (per bottle) $0.00 Weight of gas in one bottle ( 0 Power Cost ($/kilowatt-hr) $0.10

FCAW (Gas) Process Gas Used C25 Amps Volts Wire Feed (in/min) Wire Diam. (in) t Angle Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas in one bottle (l Power Cost ($/kilowatt-hr)

WELDING COST OUTPUT FOR A SINGLE-V GROOVE WELD OUTPUT FOR SMAW (14" Stick) Amount of weld wire needed 1492.13 lb Number of es per t ~ 6 Amount of shielding gas 0.00 ft^3 bottles = N/A Actual welding time 1344.26 hr

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

$50,006.52 $1,880.08 $0.00 $177.44 $52,064.05 $59,873.65

Labor Cost 96% Welding Wire Cost 4% Power Cost 0%

Cost per ft of weld Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$52.06 $1.88 $0.00 $50.01

OUTPUT FOR FCAW (Gas) Amount of weld wire needed Number of es per t ~ Amount of shielding gas Actual welding time

1075.72 lb 9 6196.31 ft^3 bottles = 14 354.07 hr

Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

Cost per ft of weld Cost per foot filler metal Cost per foot of gas

$/ft $/ft $/ft $/ft

$18,270.25 $2,420.37 $1,068.86 $84.98 $21,844.47 $ 25,121.13

$21.84 $/ft $2.42 $/ft $1.07 $/ft

Labor Cost Gas Cost 5% Welding Wire Cost Power Cost 11% Labor Cost 0% 84%

Welding Wire Cost Gas Cost Power Cost

Cost of Labor per foot

$18.27 $/ft

Process 2

Carbon Steel FCAW (Gas) C25

200 20 225 0.05 60 1000 8 35 50% 2.25 60 $75.00 50 $0.12

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost 96% Welding Wire Cost 4% Power Cost 0%

Labor Cost Gas Cost 5% Welding Wire Cost Power Cost 11% Labor Cost 0% 84%

Welding Wire Cost Gas Cost Power Cost

DETERMINING WELDING COST FOR A SINGLE-BEVEL GROOVE WELD Mark Mruczek Welding Engineer

Project: Company: Subject:

Welding Cost

Welding process Used:

SMAW + GMAW

Base Material: Product Form: Filler Material Trade Name:

A 516 Plate E7018 Lincoln

Date: Page:

05/22/02 1 of 2

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 1 2.25 0.09375 0.125 0.09375

Thickness (in) Height of "h" (in) Root Opening (in) Root Face(in)

Process 2 2.25 0.09375 0.125 0.09375

Filler material

Carbon Steel

Filler material

Carbon Steel

Process FCAW (Gas) Gas Used C25 Amps Volts Wire Feed (in/min) Wire Diam. (in) t Angle Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas in one bottle Power Cost ($/kilowatt-hr)

200 21 225 0.052 45 3.535 9 35 50% 2.45 50 $50.00 50 $0.15

SMAW (14" Stick) Process Gas Used N/A Amps Volts Wire Feed (in/min) Wire Diam. (in) t Angle Total Length of Weld(ft) Travel Speed (ipm) Gas Flow Rate (cfh) Welder Efficiency Cost Electrode($/lb) Labor Rate ($/hr) Cost of Gas (per bottle) Weight of gas in one bottle (l Power Cost ($/kilowatt-hr)

WELDING COST OUTPUT FOR A SINGLE-BEVEL GROOVE WELD OUTPUT FOR FCAW (Gas) Amount of weld wire needed Number of es per t ~ Amount of shielding gas Actual welding time Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

Cost per ft of weld Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$

38.37 lb 100 165.52 ft^3 bottles = 1 9.46 hr Labor Cost 78% Power Cost Welding Wire Cost Gas Cost 1% 4% 18%

$406.70 $94.01 $19.03 $2.98 $522.72 601.13

$147.87 $26.59 $5.38 $115.05

Labor Cost Welding Wire Cost Gas Cost Power Cost

$/ft $/ft $/ft $/ft

OUTPUT FOR SMAW (14" Stick) Amount of weld wire needed 54.00 lb Number of es per t ~ 73 Amount of shielding gas 0.00 ft^3 bottles = N/A Actual welding time 60.00 hr Labor Cost Welding Wire Cost Gas Cost Power Cost Initial Cost Final Cost

$3,000.00 $70.20 $0.00 $0.28 $3,081.00 $ 3,543.15

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

Power Cost

Cost per ft of weld Cost per foot filler metal Cost per foot of gas Cost of Labor per foot

$871.57 $19.86 $0.00 $848.66

$/ft $/ft $/ft $/ft

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

Process 2

Carbon Steel SMAW (14" Stick) N/A

175 20 0 0.188 45 3.535 5.5 0 30% 1.3 50 $0.00 0 $0.15

Labor Cost 78% Power Cost Welding Wire Cost Gas Cost 1% 4% 18%

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost Welding Wire Cost Gas Cost Power Cost

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

Power Cost

Labor Cost 98% Welding Wire Cost 2% Power Cost 0%

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

0.5625 0.6495 0.6495 0.7433 0.283 0.0311 0.1058 0.0586 0.199 0.1827 0.620 0.9251 1492.13 3.70 $177.44

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 1 Single-V Groove Process Efficiency 62% Process Welder Efficiency 30% Bottles of gas needed Arc Time 403.28 hr Radius of cap "r" Total welding time 1344.26 hr Deposited Weld Metal Wt. Density of gas 0 lb/ft^3 Volume of gas in one 0.00 ft^3 bottle Total gas needed 0.00 ft^3 Labor Cost $ 50,006.52 Gas Cost $0.00 Cost Electrode $1,880.08 Total Cost $ 52,064.05 Final Cost $ 7,809.61 $ 59,873.65 Heat Input 44 Number of es 6

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

0.5625 0.6495 0.6495 0.7433 0.283 0.0311 0.1058 0.0586 0.199 0.1827 0.620 0.9251 1075.72 6.08 $84.98

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 2 Single-V Groove Process Efficiency 86% Process Welder Efficiency 50% Bottles of gas needed Arc Time 177.04 hr Radius of cap "r" Total welding time 354.07 hr Deposited Weld Metal Wt. Density of gas 0.115 lb/ft^3 Volume of gas in one 434.78 ft^3 bottle Total gas needed 6196.31 ft^3 Labor Cost $ 18,270.25 Gas Cost $1,068.86 Cost Electrode $2,420.37 Total Cost $ 21,844.47 Final Cost $ 3,276.67 $ 25,121.13 Heat Input 30 Number of es 9

SMAW (14" Stick) N/A 1.136146 925

FCAW (Gas) 14 1.136146 925.1206

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

2.15625 3.0494 2.1563 2.2813 0.283 0.1428 0.4848 0.2813 0.955 2.3247 7.895 9.335 38.37 8.11 $2.98

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 1 Single-Bevel Groove Process Efficiency 86% Process Welder Efficiency 50% Bottles of gas needed Arc Time 4.73 hr Radius of cap "r" Total welding time 9.46 hr Beta Density of gas 0.115 lb/ft^3 Deposited Weld Metal Wt. Volume of gas in one 434.78 ft^3 bottle Total gas needed 165.52 ft^3 Labor Cost $ 406.70 Gas Cost $19.03 Cost Electrode $94.01 Total Cost $ 522.72 Final Cost $ 78.41 $ 601.13 Heat Input 28 Number of es 100

distance "d" = Distance "R" = Distance c1 = Distance "c" = Filler Density lb/in^3 Area Cap "C" Weld Metal Weight "C" Area Rectangle "A" Weld Metal Weight "A" Area of two Triangles "B" Weld Metal Weight "B" Total Weld Metal Weight Amount of Welding Wire Deposition Rate Total Power Cost

2.15625 3.0494 2.1563 2.2813 0.283 0.1428 0.4848 0.2813 0.955 2.3247 7.895 9.335 54.00 3.000 $10.80

in in in in lb/in^3 in^2 lb/ft in^2 lb/ft in^2 lb/ft lb/ft lb Lb/hr

CALCULATIONS PROCESS 2 Single-Bevel Groove Process Efficiency 62% Process Welder Efficiency 30% Bottles of gas needed Arc Time 18.00 hr Radius of cap "r" Total welding time 60.00 hr Beta Density of gas 0 lb/ft^3 Deposited Weld Metal Wt. Volume of gas in one 0.00 ft^3 bottle Total gas needed 0.00 ft^3 Labor Cost $ 3,000.00 Gas Cost $0.00 Cost Electrode $70.20 Total Cost $ 3,081.00 Final Cost $ 3,543.15 Heat Input 38.18181818 Number of es 73

Area of Fillet Weld

CALCULATIONS PROCESS 1 Fillet Weld 0.0313 in2 Process Efficiency

62%

FCAW (Gas) 1 6.986 45 33.00

SMAW (14" Stick) N/A 6.986 45 33.00

Volume of Weld Metal 3.750 in3 Filler Density lb/in3 0.283 lb/in3 Total Weld Metal Weight 0.106 lb/ft Amount of Welding Wire 2.000 lb Deposition Rate 3.700 lb/hr Density of gas 0 lb/ft3 Volume of gas in one 0 ft3 bottle Total gas needed 0 ft3 Bottles of gas needed N/A Process SMAW (14" Stick)

Welder Efficiency Arc Time Total welding time Heat Input Fillet Weld Size Number of es Labor Cost Gas Cost Cost Electrode Total Power Cost Total Cost Final Cost

30% 0.541 1.802 42 0.290 1 $108.15 $0.00 $2.60 $0.35 $111.10 $127.80

CALCULATIONS PROCESS 2 Fillet Weld Area of Fillet Weld 0.0313 in2 Process Efficiency 3 Volume of Weld Metal 3.750 in Welder Efficiency 3 3 Filler Density lb/in 0.283 lb/in Arc Time Total Weld Metal Weight 0.106 lb/ft Total welding time Amount of Welding Wire 2.000 lb Heat Input Deposition Rate 5.1310494 lb/hr Fillet Weld Size 3 Density of gas 0.116 lb/ft Number of es 3 Volume of gas in one 431.034483 ft Labor Cost bottle Gas Cost 3 Total gas needed 15.5913525 ft Cost Electrode Bottles of gas needed 1 Total Power Cost Process FCAW (Gas) Total Cost Final Cost

86% 50% 0.390 0.780 31.5 0.251 1 $46.80 $2.55 $5.00 $0.25 $54.60 $62.80

hr hr kJ/in in

hr hr kJ/in in

SMAW (14" Stick) in lb

FCAW (Gas) in lb

FCAW (Gas) in lb

SMAW (14" Stick) in lb

Alloy Density Carbon Steel 0.283 Stainless Steel 0.29 Nickel Alloy 0.31 1 1 1

1 1 1

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.000 6.076 0.000 0.000 0.000 6.076

Weld Size 0.125 0.1875 0.250 0.313 0.375 0.438 0.500 0.5625 0.625 0.688 0.750

5 0 0 0 0 200 0 0 0

Process&Welder Eff (%) SAW 99% 98% GMAW (98Ar-2O2) 96% GMAW (75Ar-25CO2) GMAW CO2 93% FCAW (Gas) 86% 78% FCAW (Self Shield) 59% SMAW (12" Stick) 0.62 SMAW (14" Stick) 66% SMAW (18" Stick) 8 5 Sing-V 5 8 Sing-Bev 8 5 Fillet Single_V Deposition Rates SMAW 8 110 1.8 0 125 2 0 150 2.6 0 175 3 0 200 3.7 200 225 4.2 0 275 7 0 325 9 0 400 10

GAS Densities N/A Ar Co2 C25 1 4 1

70% 50% 50% 50% 50% 50% 30% 30% 30%

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 3.000 0.000 0.000 0.000 0.000 3.000

0 0.111 0.116 0.115 4 Single V 1 Single Bev 3 Fillet

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.000 3.700 0.000 0.000 0.000 3.700

8 0 0 0 175 0 0 0 0

Single Bevel Deposition Rates SMAW 110 1.8 125 2 150 2.6 175 3 200 3.7 225 4.2 275 7 325 9 400 10

5 0 0 0 0 200 0 0 0

Cap Hieght 0 0.03125 0.063 0.094 0.125 0.25 0.375 2 3 3 3 4 3

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.000 8.114 0.000 0.000 0.000 8.114

Single V Single Bevel Fillet Weld

0.8125 0.875 0.938 1.000 1.125 1.25 1.375 1.5 1.5625 1.625 1.75 1.8125 1.875 2 2.125 2.25 2.375 2.5 2.5625 2.625 2.75 2.8125 2.875 3 3.125 3.25 3.375 3.5 3.5625 3.625 3.75 3.8125 9 27 3

Interpolation of Deposit Rate Process 1 0.000 0.000 0.000 0.00 3.700 0.000 0.000 0.000 3.700

9 27 3

8 0 0 0 0 200 0 0 0

Fillet Weld Deposition Rates SMAW 110 1.8 125 2 150 2.6 175 3 200 3.7 225 4.2 275 7 325 9 400 10

5 0 0 0 0 200 0 0 0

Interpolation of Deposit Rate Process 1 0 0 0 0 5.131 0 0 0 5.131

3 2 2 3 4 3