Akhil Midas 1j2263

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Akhil Midas as PDF for free.

More details w3441

- Words: 6,117

- Pages: 63

INTRODUCTION Kerala, “The God’s Own Country” is a beautiful and evergreen land at the south most tip of the Indian peninsula. It is mostly agrarian and has a flourishing tourist business. Kerala is blessed with beautiful back waters, lakes, beaches, etc and no other state can boast of such diverse attractions.

Indian rubber in now nine decades old and has become third largest of the nation after steel and textile industry. Rubber is Kerala’s primary and prestigious crop. About 90% of the total rubber production in India is ed by state of Kerala. It is cultivated in about 8, 76,000 hectares in the state and nearly 67% of the total used is covered by rubbers plantation crops.

Natural rubber or natural CSI poly isoprene is produced from rubber tree Hevea Brasilienis. The tree is also known as courthouse, a name given by Native Americans, which means weeping tree.

Natural rubber is collected as a milk tapping rubber tree. The most common method of tapping is cutting of thin portion of the bark in the shape of a half spiral using a special tapping knife. The milky sap commonly called latex is a colloidal dispersion in aqueous medium.

The rubber separated from latex by coagulation. The common coagulant is acid, preferable formic or acetic acid. The coagulant is separated and the absorbed water removed by the ing through the pressure rollers. Subsequently the sheet is ed through corrugated rolls to increase the surface area by rubbing. These facilities are

1

fast drying. These sheets are then dried in smoke house at a temperature not exceeding 60 degree Celsius using hot smoke of burning wood. The creosote compounds in the smoke provide a mild protection to the rubber.

Midas Mileage the high mileage compounds are designed to lower running cost by maximizing mileage per retread tyre. Midas is one of the India’s largest suppliers of tyre retreading materials. The company has focused constantly improving compounds to provide customers with best mileage through the Midas brand products.

2

OBJECTIVE OF THE STUDY To understand the activities of various functional departments in the organisation. To understand culture in the organisation and its effectiveness of employees in getting practical experience regarding the organisational function.

SCOPE OF THE STUDY

The study of the Midas Pvt.Ltd analyzes functions of the different departments and their relation. This tries to reveal the several answers related to finance, purchase, production, sales, marketing, R&D, HRM etc.

SIGNIFICANCE OF THE STUDY The major requirement of the study is to get practical exposure towards the office environment and to know how any organisations differ in interacting with each other and to develop our own views regarding the organisation and present the same in the project with suggestions. This study helps us in improving and developing the decision making skills and other managerial skill.

3

METHODOLOGY An organisation is a balanced and structured composition of various professionals under one roof and who are determined to strive for the common objective of the organisation. This program is concerned to give practical exposure towards the business environment. The programme mainly concentrated on understanding the organisational activities.

DATA COLLECTION

PRIMARY DATA

Interview

: - with company professionals after prior appointment.

Discussion : - with expert in the field of activity. Observation:-by observing the functions of various departments.

SECONDARY DATA

Secondary data collected from, various books. Annual report of the company. Records of the company. Company web site and general web site.

4

INDUSTRIAL PROFILE

5

INDUSTRIAL PROFILE

Rubber natural, synthetic and reclaims constitute the major and the most important raw materials of the vital rubber industry and hold a strategic position in the country’s economy. Rubber products are exclusively made out of natural rubber or synthetic or any two or all three rubbers depending on the properties required to the products. Tyres and tyre products are made out of rubber and they are manufactured by the moulding methods. The government of India has made considerable outlay in constructing and maintaining roads, highways and so transport plays a crucial role or the economic development of the country. The no of vehicles playing in the road are increasing day by day and it leads to flourishing automobiles industry. Tyre industry is indispensable to the automobile sector and the tyre consumers, they also think in of quality, cost, optimum utility etc.

6

TYRE INDUSTRY Ever since the invention of vehicles has taken place, man’s quest to reach higher heights started from circular stones to pneumatic tyres. All the phases reflect mans inventing capacity. In the 19th century the tyres was invented from solid rubber tyre. Cotton Pneumatic tyre to Nylon Pneumatic tyre to Radicalized tyre, we have grown in the last hundred years which gives man’s ever upgrading his invention capacity. The Second World War widened this scope of rubber and gave birth to the art of raw rubber and sunk the tyre in the desert and when due to heat got vulcanized and in site for retreading has opened up in a new tyre. The area which comes in to with the road is called tread position. This means out due to the friction between roads and tyres. This constitutes to 10 to 15 percent of the total tyre and hence with the tread wears out there is need for the total tyre is not discarded. Giving new life for the worn out tyre by applying the treading process now widely accepted all over the world. Till 80’s tyres was retreaded in conventional process in which after removing the parent rubber. Rubber was applied and was heated in rigid matrices at room temperatures to vulcanise the rubber. In this process the main advantage is that the tyre was buffed manually. The tyre was build manually and the tyre was cured in the matrices, which is rigid and fixed shape and tyre has to fix in to the matrices where by distortions were taken place during the early 80’s procured tyre retreading was introduced and is now well accepted because of its various advantages. In this process the tread was initially cured to ensure better mileage because the curing was taken place at fixed temperature or a fixed pressure and homogeneity was obtained.

7

RETREADING As the tyre moves on the road, the tread portion wears off gradually. The process of removing the old worn out tread and replacing it with a tread surface is called retreading. Tread rubber is the material used to replace the wearing surface on the tyre. The old useless tyre can be made run for at most equal mileage as a new tyre by retreading within the cost on exceeding 1/3rd of that of a new tyre. Virtually all types of tyre can be retreaded including enger cars, truck, motor cycle, tractor etc. Usually tyre can be retreaded many as to 4-5 times, depending on the cased strength. In retreading industry, commonly two methods are adopted, cold processing and hot processing tyre of retread. The cold processing type of retreading and hot process is known as conventional retreading. ADVANTAGES OF RETREADING: Retreading saves money- when a retread gets worn out the tyre won’t be discarded. Like resoling a pair of shoes, for just 1/5th of the cost of new can retread our tyre. Retreading absolutely safe and reliable those even aircraft tyre are now retread without subjecting the tyre to high stress was earlier. OTHER BENEFITS More Mileage. More no of retreads. Less possibility of punctures. Less down time.

8

COMPANY PROFILE

9

COMPANY PROFILE ABOUT MIDAS GROUP– STANDARD TREADS. Sir George Varghese, a creative thinker and industrialist, who organised the importance of retreading well before the retreading become popular in common. He founded the present MIDAS PRE-CURED PRIVATE LIMITED, the ladder in the field of procured treads and conventional treads in the present scenario. Mr George Varghese presently held the MIDAS GROUP was stared as a small tread rubber unit in Ettumanoor industrial estate in Kottayam district, which is known as “The Rubber Land of Kerala” (Kottayam district is the highest producer of natural rubber in India). Mr George Varghese started his small unit in1969, with an investment of Rs 65000, with his dynamic leaderships and innovative ideas, he horned his small unit into a leader in the field in 1985 july31st. MIDAS PRE-CURED PRIVATE LIMITED was established as a small scale unit at Ettumanoor. It has mainly engaged in the manufacturing of precured tread rubber. Now the company is medium scale unit. The introduction of pre-cured trade in India made MIDAS in forefront with the availability of best raw materials that is the natural rubber. MIDAS produce world class rubber products such as procured rubber, camel’s back tread, vulcanizing cement, cushion gum, curing bags and curing envelops, rope rubber and bonding gum etc. The high quality control maintained effectively at every stage, makes MIDAS products much above the lines of normal standards. Now the company has got 36 tread rubber manufacturing units; 26 in Kerala, 8 in Pondicherry and 2 in Tamil Nadu, having group turnover 100crores. When considering quality and revenue, it is the No.1 Company in this field. India’s largest rubber computing unit belongs to MIDAS GROUP. The company’s mixing capacity is 180 tonnes per day. It supplies rubber compounds to many of the India’s major tyre companies like MIDAS TREADS (I) PVT. LTD and STANDARD TREADS PVT. LTD to meet their needs. The Midas Company produces 1800-2000 tonnes in the tread rubber division per month.

10

Midas marketing and management services coordinate its marketing and management functions, having an excellent marketing net work all over India and in the international market. The major revenue for the group is from the sale of precured tread rubber and its market is entirely outside Kerala. MIDAS POLYMER COMPOUND PVT.LTD In 1977, the ministry of industry of government of India made a declaration that an industrial undertaking in which investment in plant and machinery does not exceed rupees 3 cores will be ed as SSI unit. Therefore the management decided to set up a TREADS. Treads is the wearing surface of the tyre which comes in s which the road surface. It is applied in the raw state as an extruded slab of rubber compound. In cross sections it is substantially rectangular across the centre tapering down in the very fine edges. Chervally, Chirakkadavu Panchayath, Manimala and Kottayam district for manufacturing rubber compounds and tyre retreading material viz. tread rubber and allied products. The company had acquired land on lease for 99 years at Chervally, Manimala and decided to construct a factory building with all infrastructure arrangements.

11

PHILOSOPHY OF THE COMPANY The company believes that the only way to give customer ever improving quality and economy is the courage to experiment with every aspect of production from inputs to process. With the best raw materials from all over the world and quality natural rubber close at hand MIDAS products world class rubber products.

OBJECTIVE OF THE COMPANY Quality Time delivery Cost minimization Profit maximization Consistency in sales and service More employment

SERVICES OF THE COMPANY The main feature of MIDAS is the quality of its product. There is no compromising regarding the quality of the product. For improving the quality of their product they adopt latest technology and quality control systems for every production stage.

VISION & MISSION OF THE COMPANY Increase its market share in future. Concentrate more on its quality aspect. To maximize the return on investment. To remain a leading producer of retreading materials in India. To continuously grow in business and become a significant player in world market. To achieve international level of excellence in technology and quality.

VALUE OF THE COMPANY High quality products Customer orientation Team work among the employees Profit for invention and innovation

12

PRODUCT PROFILE

13

PRODUCT PROFILE Midas materials are made to the strictest quality standards. Formulations for all products are developed to suite the exact requirements of the consumer’s. A heavy investment in R&D has also given an access to the best testing equipment available for testing control and development.

PRODUCTS OF MIDAS PVT. LTD Camel Black (Tread Rubber)

It is also known as hot process. It is kind retreading process in which the company makes the rubber sheet in plain form and is sold to the retreaders. It is the retreaders who convert sheet into different shape and design with customer specifications with the help of modules. Heavy vehicles generally process of retreading. This process gives more mileage compared to pre-cured treads. Under this process the retreaders themselves do buffing.

Cushion Gum Midas manufacturers high quality cushion gum for retreading process to suit temperature of 99c and 150c. This is associated product essential for the retreading process . Rubber Components Midas manufacturer’s custom made rubber compound master batches for a wide variety of uses mixed to the specification in K-4MK3 intermix.

14

ORGANISATIONAL STRUCTURE

15

ORGANISATIONAL STRUCTURE

MIDAS procured tread PVT Ltd is a company in the heart land of rubber country where research and development and customer orientation have come together to manufacture and supply the highest quality retreading materials. MIDAS has chosen to develop as a group of small scale industries unit as far as production is concerned. The small scale unit are at Kottayam, Ettumanoor and Kariakal. The head office at Kottayam controls the group. Here the functions of purchase, marketing, finance, etc are centralized. For a state, which is notorious for it, labour union discipline, MIDAS is an example of extremely good labour management and the company has had no serious problem till date. More over company pays the best wages in the area.

Managing Directors

Manager R & D

Purchase Manager

Sales Manager

Lab Assistant

Assistant

Despatch Manager

Stock Assistant

s Assistant

Computer Assistant

General Workers Assistant

16

ORGANISATIONAL STRUCTURE

Managing Partner

GM istration

GM Marketing

Despatch Manager

Depoh Manager

Service Engineer

HO Sales Executive

Head Office Sales Officer

s Manager

ant

Finance Manager

Data Entry Operator

Cashier

Depoh Sales Executive

17

FUNCTIONAL DEPARTEMENTS

18

PRODUCTION DEPARTMENT

19

PRODUCTION DEPARTMENT

Introduction

Production denotes the conversion of the raw materials to semi finished or finished product, with the help of certain production process. The main aim of any production system is to produce economically the goods and services required by the customer.

Production is the process of transferring input into output. It is the core of every business activities, Midas polymer compound production of tread rubber and rubber compounds is NO.1 in India. It is the largest mixing plant in India with a production capacity of 2000 tonnes per month. The company processing compounds is the number one mixing unit by Ceat Ltd. Midas polymer is the number one mixing unit by ceat since it started its operation for Ceat Ltd.

20

LINE OF STRUCTURE

Director

Factory Manager

s Manager

Manager

Production Manager

Shift Engineer

Loading Supervisor

Shift Supervisor

Workers

21

RAW MATERIALS LIST The main raw materials are

Natural Rubber. Synthetic Rubber. Carbon Black. Process Oil. Zinc Oxide. Anti-oxidants. Sulphur. Accelerations.

SHIFT The company adopts 3 shift systems. These are 8.30 AM TO 4.30 PM 4.30 AM TO 12.30 PM 12.30 PM TO 8.30 AM In these shift 200 workers are divided and work is assigned to them.

AVERAGE DAILY PRODUCTION

Rubber Compound - 60 tonnes Tread Rubber

- 09 tonnes

Cushion Gum

- 500 – 600 kg

22

MACHINES USED K-4 Intermix Accessories

- 2No

Air Compressor

- 1No

Mixing Mill with Accessories

- 5No

Extender with Accessories

- 1No

Calendaring Machine with Accessories

- 1No

725 Kav Generator Dust Collector & Chimney

- 1No

Overhead Crane

- 1No

Electric Good Lift

- 1No

Hand/Mechanical Pallet Trunk

- 4No

Oil Batching & Accessories

- 1No

Weight Bridge 30mt Capacity

- 1No

Electric Weighting Machines

- 1No

Industrial Vacuum Cleaner

- 1No

PRODUCTION LAYOUT It is the process of arranging the machines in to one line depending upon the sequence of operation. Materials are fed in to the first machine and finished product comes out of the last machine. This layout is called product layout or known as straight line layout.

RAW MATERIAL FLOW Purchase of chemicals and raw materials are done by the customer. Incoming, inspection of the chemicals and raw materials are also conducted by the customer.

INPUT OUTPUT PROCESS 1. Raw Materials

Stage I

2. Production Control

Stage II

3. Output

Stage III

4. Storage

Stage IV

5. Despatch

Stage V

23

PROCESS OF MANUFACTURING

The important steps involved in the manufacture of procured tread are described below: 1. Mastication and Mixing. 2. Maturation. 3. Pre-warming. 4. Extrusion. 5. Cooling. 6. Weighting. 7. Moulding and Vulcanisation. 8. Post Curing. 9. Buffing. 10. Inspection and packing.

Mastication and Mixing The compounding ingredients and rubber are waited as par received. The raw material is firstly masticated on a two roll mixing mill for reducing the viscosity and increasing the plasticity after attaining a certain level of plasticity. The mill temperature is kept at 72 degree Celsius by ing cold water through the core of the rolls. To the masticated rubber other compounding ingredients are added which gets dispersed easily.

Maturation The sheeted compound is kept for 24 hours for maturation. The process is done to get technological properties to the compound. During the maturation the ingredients are well immersed in the rubber to get good technological properties.

24

Pre-Warming Pre-warming is done on a16” X 42” mill. The matured compound is stiff, during this operation, the temperature and plasticity of the compound is increased. This facilitates easy extrusion through the dye. At the end of preparing, the nip is adjusted to 15mm and small strips are directly fed to the extruder.

Extrusion Extrusion is the processing operation intended to shape the compound in the required shape. The production of procured tread, small strips of the mixed compound is fed to the extruder and it is forced through the dye and the material comes out in the dimension 7” width and 22mm thickness. On the starting of the extrusion process the dye is heated and when the process is progressing the temperature of the barrel may increase resulting in the vulcanisation of the compound. In order to prevent this, ing cold water through the extruder controls temperature.

Cooling The continuously extruded slab is ed into a tank containing cold water which helps to decrease dyes level. After a certain time, the slab is taken and cut into a length of 128” and is wrapped in a polythene film. This avoids sticking problem when the slab is weighted and the subsequent handling operation.

Weighting The polythene wrapped slab is weighted to the required weight. A 5% excess weight is taken for flash. Then it is taken for moulding.

25

Moulding & Vulcanization The weighted slab is then transferred to the moulding section. A polythene sheet is removed and the green compound is loaded in the pre heated lubrication mould, which is having the trade pattern in it. A silicon emulsion is used as the mould – releasing agents. This helps easy striping of the cured slab. The mould is then closed and it is then transferred to the platens of the hydraulic press and then the pleasure is applied. The maximum pressure applied for the production of procured tread is2250 amt. At temperature of 160 degree Celsius the suggested compound will have a cured cycle of 12-14 minutes. After curing, the press is opened and from the mould he strips of cured tread are taken after finishing operation.

Post -Curing Post-curing is carried out to improve the technological properties and also help to complete the curing process. This can be done on two ways, either by exposing the tread to 60 degree Celsius far 3-4 hours or keeping the product in room temperature for 24 hours. The proposed product is post cured in room temperature for 24 hours.

Buffing The cured tread is buffered on the base side to present a clean surface which is properly prepared for adhesion to the casing by means of bonding layer of cushion gum. It is compactable to both tread and wide variety of tyre compound to which the tread is a adhering and this can be done on a buffing machine.

Inspection & packing The buffer trade is inspected for ensuring the quality. The hardness is checked and visual inspection is done where there is any air bubble in the tread. Check all the dimensions of the tread. After the packing is done, the tread is covered within polythene film and it is rolled and put in the cardboard box and sealed. A label is pasted on the box which indicates the trade name and size of the trade. It is then transferred to the customer.

26

QUALITY CONTROL The word quality refers to the degree of excellence of a product. Modern age is the area of quality. The compensation today is cutthroat and every producer tries of to improve the quality of the product to lure the customer. To him for improving quality control is a must. Quality control is a systematic control of those variables which affect the excellence of the ultimate product. The company uses all types of production oriented quality control, Q1, Q2, Q3, Q4, Q5, & Q6. The factory manager and the production manager are assigned for quality control. The absolute quality controls are properly checked in the research and development group located at Ettumanoor.

PRODUCTION FLOW OF RUBBERCOMPOUND

A

• Weighing approved chemicals (Q1)

B

• Mixing of Raw Materials and Chemicals (Q2) • Milling - First and Second (Q3)

C

D

• Sheeting (Batch of Master compounds) Q4

E

• Weighing & Storage (Q5)

F

• Despatch (Q6)

27

FINANCE DEPARTEMENT

28

FINANCE DEPARTEMENT

Introduction Finance is the life blood of the business. For every activities related to business finance is required. Finance may be defined as the money at the time when it is wanted. His efficiency of production and marketing operations is directly influenced by the marketing which the finance function of the enterprise is performed by the finance division.

Maintenance of s s in Midas are maintained as per the requirements of the companies Act 1956. The company maintain detailed of its asset and liabilities, income and expenditure. At the end of the year s are finalized and annual s are prepared. They are properly audited.

Main Functions Cash Management. Taxation. Credit istration. Management & Control. Obtaining Finance. Financial ing. Banking Relationship.

29

Main Functions (Contd...) Internal Auditing. Funds Management. Evaluation Of Group Finance. Preparation Of Financial Report. Expense Analysis.

Line of Structure

Managing Partner

GM istration

Finance Manager

Data Entry Operator

Cashier

30

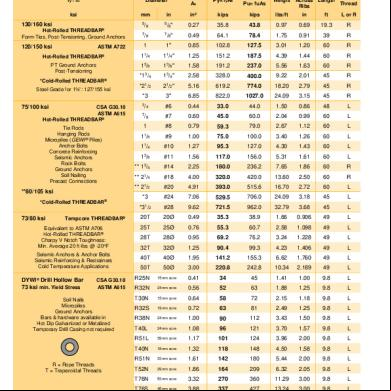

Cost of the Project Table Sl. No.

Item

Amt in Lakhs

01

Land Levelling (15000 cum at Rs.300)

45.00

02

Building (500 sqm at Rs.3000)

150.00

03

Plant & Machinery (Installation expenses included)

250.00

04

Industrial Electrification

90.00

05

Water Supply

20.00

06

Weighbridge and Electronic Weighing Machine

7.50

07

Other tools for handling materials

20.00

08

Genset with sound proof covering

35.00

09

Pollution Control Equipment

12.50

10

Other assets including furniture and fixtures

20.00

Total

650.00

31

PURCHASE DEPARTMENT

32

PURCHASE DEPARTMENT The company purchase of raw materials from approved suppliers only. The approved given on the basis of quality text of raw materials price negotiations and delivery. The company does make forecasting on purchase. The major purchase raw materials like carbon, natural rubber are bought based on the principles of purchase. The company adopt mainly just in time purchase.

LINE OF STRUCTURE

Managing Partner

Director

Purchase Manager

Office Supdt

Office Assistant

33

FUNCTIONS OF PURCHASE DEPARTMENT. Raw Material Pure Study. Market Intelligence Report Analysis. Complete Purchase Policy. Turnover Analysis. Pure Negotiation. Turnover Analysis. Purchase Order. Follow Up Rating Under Supplies. Vendor rating. Purchase Monitoring Invoice Checking etc.

CREDIT PATTERN The company’s purchases are of bulk nature and payment is immediately made. There is 0% credit against cash purchase. For certain raw materials like rubber chemicals, the company does take a credit time of 15 to 30 days. Annual contract is made for carbon black. The company also provide advance payment for reputed suppliers. The amount is being advanced to the companies and interested

JUST IN TIME PURCHASE

The Midas adopts just in time purchase policies. Purchase is made at the right time. The raw material like rubber is bought to be production plant, in one day advance of the production.

34

PURCHASE CONCEPT

A

• Right Qualtiy Material

B

• Right Price

C

• Right Delivery

35

SUPPLIERS INFORMATION TABLE

RAW MATERIALS

NAME OF THECOMPANY

Carbon Black

Philips Carbon Hi-tech Carbon

Synthetic Rubber

Indian Petrochemicals Ltd. Bayer AG Hyundai Petrochemicals, Korea

Rubber Chemicals

Bayer India Mai Ltd National Organic Chemicals Ltd ICL Ltd

Process Oil

Indian Oil Corporation

Natural Rubber

Local Suppliers Rubber Dealers Rubber Marketing Federation

36

MARKETING DEPARTMENT

37

MARKETTING DEPARTMENT

Introduction Marketing concept was born out of the awareness that a business to start with the determination of consumer wants and ends the satisfaction of those who wants. Marketing is the economic process by which goods and services are exchanged between the markets and the s, and there value is determined in of money price.

LINE OF STRUCTURE

Managing Partner

GM Marketing

Despatch Manager Sales Officers

HO Sales Executives

Head Office Engineers

Service

Depot Manager

Depot Sales Executive

38

MARKETTING PROCESS CHART

Depot Dealers

Product

Despatch

C & F Agents

Customer

Consumer

Corporation

MARKETING SERVICES Uncompromising Quality. Economy. Distribution Network. Technology.

MIDAS MARKETING It is ed as a partnership company as per the Indian partnership Act of 1932. JOHN ZACHARIACH BUILDING, THIRUNAKKARA, KOTTAYAM, KERALA is the ed partnership office of Midas. The business of the partnership shall be carried at Kottayam with branches, agency offices, distribution centres etc. The object of the partnership shall be to carry on business as dealers distributors, consignment, agents, commission agent, sales representatives, exporters, importers and merchants of all kind of rubbers and rubber products, procured tread rubbers, cushion gum, tread gum, vulcanising solution, other retreading materials from rubbers, bushes, sheets, flaps, channels, industrial lining, transmission belt tubes, tyres and other compounds, articles and appliances made with or form, and involving the use of natural rubber and synthetic rubber and all type of raw materials use in the manufacture of the product.

EXPORT MARKETING Midas exports its products to developing markets of the world including: Middle East 39

Africa & South America and South East Asia.

TARGET OF THE COMPANY

The company is targeting an export of about 1000 tonnes in the next five years. Moreover Midas has planned to form dealers network in the International market. The immediate plans are to double the export every year. Last year they participated in various shows organised into Brazil , Singapore, China and Italy for Globalizing their product.

MENT

Advertising is an avoidable part of marketing. The Midas spent only an average amount of ment. So the ment cost is minimum. The company keeps its position in branding. It includes 12 lakh labels around India.

AFTER SALES The company provides a clear cut after sale services to the customers. The service engineers provide all kind of assistance to retreaters’. The after sales programs cover: Periodical Assistance Market & Sales Service Engineers visit Forecasting Analysis etc

40

SALES DEPARTMENT

41

SALES DEPARTMENT Introduction

The concept of sales is that the company has to promote and push. Their product aggressively sold in the market. It cannot expect the product to get picked up automatically by the customer.

TECHNIQUES FOR IMPROVING THE SALES Heavy Advertising High power personal selling Large scale Sales Promotion

LINE OF STRUCTURE

Managing Director

Director

Sales Manager

Department Manager

Stock Assistant

s Assistant

Computer Assistant

General Workers Asstt

42

FUNCTION The sale of Midas products is based on the following sales policies and norms: Sales department receives the order from agents, dealers, contractors, etc and es the order to the factory for production. Then the product is moved to the dispatch manager and is sold to the customers as per the order. Order receiving and dispatch are the major function of the sales department

DISTRIBUTION CHANNEL

Direct Dealers C & F Agents People in Retread business Licensed Parties Contractors.

The company sells its products through the above distribution channels. Midas has dealers in all states. The company do supply its product based on agreement.

43

PROCESS CHART

Sales Order - Sales Manager Final Product - Factory Manager Despatch Manager Consumers Customers

DEPOTS AND SALES OFFICES OF THE COMPANY

Sl. No. 01 02 03 04 05

Place Coimbatore Vijayawada Baroda Jodhpur Bhopal

Tamil Nadu Andhra Pradesh Gujarat Rajasthan Madhya Pradesh

TABLE FOR TOTAL SALES OF LAST TWO YEARS

Products Tread Rubber Bonding Gum

Total Sales 2006-07

Total Sales 2007-08

6,34,65,787,.65

8,56,43,543.87

44

SALES FORECASTING

Major forecasting is done at production meeting held at every month. The include production engineers, factory managers, supervisors, sales personal’s etc. The product of the company is seasonal nature. So seasonal forecasting is also conducted along with the meeting. Forecasting are conducted in monthly, quarterly, yearly, basis.

SALES PROMOTION POLICIES Sales promotion policies of the company are as follows; 1. Right quality product, right price, right time deliver 2. The executives makes periodical visit to the dealers and agents on their arrival to the head office. 3. Meetings and seminar are conducted occasionally and proper sales analysis is made for promotion. 4. The company safeguards the customer’s interest and keeps a very strong relationship with them. 5. The sales executives make a visit to the agents and retreading people, to provide all kind of assistance.

PRICE Price = Cost +Profit

This is due to the fact that these are agri-products and are seasonal in nature. The price rate of the company is much less compared to is competitors.

45

HUMAN RESOURCE DEPARTMENT

46

HUMAN RESOURCE DEPARTMENT Introduction

Production is the combined process of factors like the Land, Labour, Capital, Enterprise, and Management. All these factors occupy a significant place in production. Yet labour and man-power are most important. There may be land, capital, enterprise, but they cannot function without the active labour force.

Personal management is the specialized branch of management, that deals with people n any organization, there has to be someone concerned with the welfare and performance of persons who are a part of the operation. When an individual or a team of individuals takes on this task of seeing to programs and setting policies that impact everyone associated with the company, they are engaged in the process of personnel management, sometimes referred to as human resources management.

The function of a personnel manager usually begins with the staffing process. Someone has to be focused on screening and interviewing persons, with an eye to placing individuals with the right skill sets in the right position within the company. Along with placement, the HR manager may also oversee or at least be involved in the creation of entry level training programs, as well as continuing education opportunities for existing employees.

47

Determining company policies and procedures as they relate to personnel is another important aspect of the personnel management process. HR functions often include drafting vacation, sick leave, and bereavement policies that apply to all employees of the company. The personnel management team often is also responsible for managing the health care program provided to the employees as well.

Midas group as well as the company does not have a Human Resource development departments as well as personal department. Other department managers like s and istration are given the charge of personal department. The personal department who is in charge of s and istration look forward the personal activities of the workers.

LINE OF STRUCTURE

Managing Director

Director

Manager Personnel In-Charge

Factory Manager

Manager s & istration

48

FUNCTIONS OF PERSONAL DEPARTMENT

Recruitment Maintenance of personnel files Time keeping Selection Management development Organisation change & organisation development Job analysis Human resources planning Wages and salaries istration Training Introduction & orientation Performance appraisal Career planning & development.

49

WAGES

Daily wages are usually given to the workers. Wages = basic pay + dearness allowance Dearness allowance is given as per the norms of the statistical department, government of Kerala

OTHER BENEFITS

The other benefits provide by the company are as follows;

Medical aids Loans Night Bata Overtime allowances Production incentives Insurance Medical allowance leave with wages Provident fund

TIME AND ATTENDENCE

Strict policy is followed by the company regarding the attendance and timing.

1. Attendance card

- it is manufactured for the workers.

2. Attendance - it is maintained for the office staff.

50

HEALTH AND SAFETY

Following are the safety measures done by the company as per safety precaution act. All type of safety cover for rotations pasts Break system for machinery.. Safety belt for above three meters. Pressure vessels safety certificate given by the factory inspector. Fire fighting equipment. Environment safety. All kind of electrical safety.

JOB ROTAION & JOB SCHEDULE

The rotation and job schedule are favourably done for the both office staff and workers. Factory manager does job rotation and job schedule for workers.

TRADE UNION

The trade union is operating in the company is CITU, INTUC,BMS. Agreement is made between the union and the company. It includes bonus wages and other allowances.

51

RESEARCH AND DEVELOPMENT

52

RESEARCH AND DEVELOPMENT Introduction The base of all present quality products belongs to the research & development of Midas R & D. R & D comprises of major three functions that include product development quality checking and control & research. Apart from this after sale services are also done as part of research and development. It can be called as Testing Centre. Midas has a well equipped laboratory which we used to develop new product and carry out quality an daily production. It constantly develops new compounds for various uses, and for improved mileage and properties. Midas value the customers on how their products performs on the road to help improve it in the future. MIDAS conducts road test programs to ensure that the laboratory results convert to real world benefits for its customers.

LINE OF STRUCTURE Managing Director

Director

Manaager R & D

Lab Technicians .

53

FINDINGS & SUGGESTIONS

54

FINDINGS & SUGGESTIONS

1. The company should maintain an adequate quantum of current asset in relation to current liabilities as to keep a good amount of liquidity in the system.

2. The inventory of slow moving items in store should be reduced to the maxim possible level to increase profitability.

3. The company should improve debt collection efforts to bring down the amount tied up in debtors.

4. The company can start a unit to treat worn tyres, which an increase their profit level. Due importance be given to ments as it is the soul of marketing.

55

CONCLUSION

56

CONCLUSION

Midas established in 1969 and has an experience on more than 35 years in tread industry. It started as a small tread rubber unit in Ettumanoor near Kottayam district. But Midas is the market leader in the field. Maintain the consistency in quality and services is the main aim of the company. Midas is now India’s popular brand of tyre retreading materials more than 1000 tonnes of sales per month. The dynamic leadership and innovative ideas made Midas as one of the leading manufacturers of tread rubber and aligned product in India.

The main objective of the study is to understand and find out the functioning of various departments in the organisation. The study gave a detailed knowledge about the establishment and functioning of istrative and related functional department in MIDAS pvt ltd

57

BIBLOGRAPHY

REFERENCE BOOKS

1. Research Methodology & Technique, 2nd edition. Kotharic C.R 2. Production & Operation Management, 5th edition. Evertte E Adam & Ronald J Ebert. 3. Marketing Management, 10th edition. Philip Kotler 4. Finance Management, 2nd edition. Subir Kumar Banarjee.

JOURNALS & MAGAZINE

1. Company Magazines. 2. Annual Report.

WEBSITE

1. www.midastreads.com

58

59

60

61

62

63

Indian rubber in now nine decades old and has become third largest of the nation after steel and textile industry. Rubber is Kerala’s primary and prestigious crop. About 90% of the total rubber production in India is ed by state of Kerala. It is cultivated in about 8, 76,000 hectares in the state and nearly 67% of the total used is covered by rubbers plantation crops.

Natural rubber or natural CSI poly isoprene is produced from rubber tree Hevea Brasilienis. The tree is also known as courthouse, a name given by Native Americans, which means weeping tree.

Natural rubber is collected as a milk tapping rubber tree. The most common method of tapping is cutting of thin portion of the bark in the shape of a half spiral using a special tapping knife. The milky sap commonly called latex is a colloidal dispersion in aqueous medium.

The rubber separated from latex by coagulation. The common coagulant is acid, preferable formic or acetic acid. The coagulant is separated and the absorbed water removed by the ing through the pressure rollers. Subsequently the sheet is ed through corrugated rolls to increase the surface area by rubbing. These facilities are

1

fast drying. These sheets are then dried in smoke house at a temperature not exceeding 60 degree Celsius using hot smoke of burning wood. The creosote compounds in the smoke provide a mild protection to the rubber.

Midas Mileage the high mileage compounds are designed to lower running cost by maximizing mileage per retread tyre. Midas is one of the India’s largest suppliers of tyre retreading materials. The company has focused constantly improving compounds to provide customers with best mileage through the Midas brand products.

2

OBJECTIVE OF THE STUDY To understand the activities of various functional departments in the organisation. To understand culture in the organisation and its effectiveness of employees in getting practical experience regarding the organisational function.

SCOPE OF THE STUDY

The study of the Midas Pvt.Ltd analyzes functions of the different departments and their relation. This tries to reveal the several answers related to finance, purchase, production, sales, marketing, R&D, HRM etc.

SIGNIFICANCE OF THE STUDY The major requirement of the study is to get practical exposure towards the office environment and to know how any organisations differ in interacting with each other and to develop our own views regarding the organisation and present the same in the project with suggestions. This study helps us in improving and developing the decision making skills and other managerial skill.

3

METHODOLOGY An organisation is a balanced and structured composition of various professionals under one roof and who are determined to strive for the common objective of the organisation. This program is concerned to give practical exposure towards the business environment. The programme mainly concentrated on understanding the organisational activities.

DATA COLLECTION

PRIMARY DATA

Interview

: - with company professionals after prior appointment.

Discussion : - with expert in the field of activity. Observation:-by observing the functions of various departments.

SECONDARY DATA

Secondary data collected from, various books. Annual report of the company. Records of the company. Company web site and general web site.

4

INDUSTRIAL PROFILE

5

INDUSTRIAL PROFILE

Rubber natural, synthetic and reclaims constitute the major and the most important raw materials of the vital rubber industry and hold a strategic position in the country’s economy. Rubber products are exclusively made out of natural rubber or synthetic or any two or all three rubbers depending on the properties required to the products. Tyres and tyre products are made out of rubber and they are manufactured by the moulding methods. The government of India has made considerable outlay in constructing and maintaining roads, highways and so transport plays a crucial role or the economic development of the country. The no of vehicles playing in the road are increasing day by day and it leads to flourishing automobiles industry. Tyre industry is indispensable to the automobile sector and the tyre consumers, they also think in of quality, cost, optimum utility etc.

6

TYRE INDUSTRY Ever since the invention of vehicles has taken place, man’s quest to reach higher heights started from circular stones to pneumatic tyres. All the phases reflect mans inventing capacity. In the 19th century the tyres was invented from solid rubber tyre. Cotton Pneumatic tyre to Nylon Pneumatic tyre to Radicalized tyre, we have grown in the last hundred years which gives man’s ever upgrading his invention capacity. The Second World War widened this scope of rubber and gave birth to the art of raw rubber and sunk the tyre in the desert and when due to heat got vulcanized and in site for retreading has opened up in a new tyre. The area which comes in to with the road is called tread position. This means out due to the friction between roads and tyres. This constitutes to 10 to 15 percent of the total tyre and hence with the tread wears out there is need for the total tyre is not discarded. Giving new life for the worn out tyre by applying the treading process now widely accepted all over the world. Till 80’s tyres was retreaded in conventional process in which after removing the parent rubber. Rubber was applied and was heated in rigid matrices at room temperatures to vulcanise the rubber. In this process the main advantage is that the tyre was buffed manually. The tyre was build manually and the tyre was cured in the matrices, which is rigid and fixed shape and tyre has to fix in to the matrices where by distortions were taken place during the early 80’s procured tyre retreading was introduced and is now well accepted because of its various advantages. In this process the tread was initially cured to ensure better mileage because the curing was taken place at fixed temperature or a fixed pressure and homogeneity was obtained.

7

RETREADING As the tyre moves on the road, the tread portion wears off gradually. The process of removing the old worn out tread and replacing it with a tread surface is called retreading. Tread rubber is the material used to replace the wearing surface on the tyre. The old useless tyre can be made run for at most equal mileage as a new tyre by retreading within the cost on exceeding 1/3rd of that of a new tyre. Virtually all types of tyre can be retreaded including enger cars, truck, motor cycle, tractor etc. Usually tyre can be retreaded many as to 4-5 times, depending on the cased strength. In retreading industry, commonly two methods are adopted, cold processing and hot processing tyre of retread. The cold processing type of retreading and hot process is known as conventional retreading. ADVANTAGES OF RETREADING: Retreading saves money- when a retread gets worn out the tyre won’t be discarded. Like resoling a pair of shoes, for just 1/5th of the cost of new can retread our tyre. Retreading absolutely safe and reliable those even aircraft tyre are now retread without subjecting the tyre to high stress was earlier. OTHER BENEFITS More Mileage. More no of retreads. Less possibility of punctures. Less down time.

8

COMPANY PROFILE

9

COMPANY PROFILE ABOUT MIDAS GROUP– STANDARD TREADS. Sir George Varghese, a creative thinker and industrialist, who organised the importance of retreading well before the retreading become popular in common. He founded the present MIDAS PRE-CURED PRIVATE LIMITED, the ladder in the field of procured treads and conventional treads in the present scenario. Mr George Varghese presently held the MIDAS GROUP was stared as a small tread rubber unit in Ettumanoor industrial estate in Kottayam district, which is known as “The Rubber Land of Kerala” (Kottayam district is the highest producer of natural rubber in India). Mr George Varghese started his small unit in1969, with an investment of Rs 65000, with his dynamic leaderships and innovative ideas, he horned his small unit into a leader in the field in 1985 july31st. MIDAS PRE-CURED PRIVATE LIMITED was established as a small scale unit at Ettumanoor. It has mainly engaged in the manufacturing of precured tread rubber. Now the company is medium scale unit. The introduction of pre-cured trade in India made MIDAS in forefront with the availability of best raw materials that is the natural rubber. MIDAS produce world class rubber products such as procured rubber, camel’s back tread, vulcanizing cement, cushion gum, curing bags and curing envelops, rope rubber and bonding gum etc. The high quality control maintained effectively at every stage, makes MIDAS products much above the lines of normal standards. Now the company has got 36 tread rubber manufacturing units; 26 in Kerala, 8 in Pondicherry and 2 in Tamil Nadu, having group turnover 100crores. When considering quality and revenue, it is the No.1 Company in this field. India’s largest rubber computing unit belongs to MIDAS GROUP. The company’s mixing capacity is 180 tonnes per day. It supplies rubber compounds to many of the India’s major tyre companies like MIDAS TREADS (I) PVT. LTD and STANDARD TREADS PVT. LTD to meet their needs. The Midas Company produces 1800-2000 tonnes in the tread rubber division per month.

10

Midas marketing and management services coordinate its marketing and management functions, having an excellent marketing net work all over India and in the international market. The major revenue for the group is from the sale of precured tread rubber and its market is entirely outside Kerala. MIDAS POLYMER COMPOUND PVT.LTD In 1977, the ministry of industry of government of India made a declaration that an industrial undertaking in which investment in plant and machinery does not exceed rupees 3 cores will be ed as SSI unit. Therefore the management decided to set up a TREADS. Treads is the wearing surface of the tyre which comes in s which the road surface. It is applied in the raw state as an extruded slab of rubber compound. In cross sections it is substantially rectangular across the centre tapering down in the very fine edges. Chervally, Chirakkadavu Panchayath, Manimala and Kottayam district for manufacturing rubber compounds and tyre retreading material viz. tread rubber and allied products. The company had acquired land on lease for 99 years at Chervally, Manimala and decided to construct a factory building with all infrastructure arrangements.

11

PHILOSOPHY OF THE COMPANY The company believes that the only way to give customer ever improving quality and economy is the courage to experiment with every aspect of production from inputs to process. With the best raw materials from all over the world and quality natural rubber close at hand MIDAS products world class rubber products.

OBJECTIVE OF THE COMPANY Quality Time delivery Cost minimization Profit maximization Consistency in sales and service More employment

SERVICES OF THE COMPANY The main feature of MIDAS is the quality of its product. There is no compromising regarding the quality of the product. For improving the quality of their product they adopt latest technology and quality control systems for every production stage.

VISION & MISSION OF THE COMPANY Increase its market share in future. Concentrate more on its quality aspect. To maximize the return on investment. To remain a leading producer of retreading materials in India. To continuously grow in business and become a significant player in world market. To achieve international level of excellence in technology and quality.

VALUE OF THE COMPANY High quality products Customer orientation Team work among the employees Profit for invention and innovation

12

PRODUCT PROFILE

13

PRODUCT PROFILE Midas materials are made to the strictest quality standards. Formulations for all products are developed to suite the exact requirements of the consumer’s. A heavy investment in R&D has also given an access to the best testing equipment available for testing control and development.

PRODUCTS OF MIDAS PVT. LTD Camel Black (Tread Rubber)

It is also known as hot process. It is kind retreading process in which the company makes the rubber sheet in plain form and is sold to the retreaders. It is the retreaders who convert sheet into different shape and design with customer specifications with the help of modules. Heavy vehicles generally process of retreading. This process gives more mileage compared to pre-cured treads. Under this process the retreaders themselves do buffing.

Cushion Gum Midas manufacturers high quality cushion gum for retreading process to suit temperature of 99c and 150c. This is associated product essential for the retreading process . Rubber Components Midas manufacturer’s custom made rubber compound master batches for a wide variety of uses mixed to the specification in K-4MK3 intermix.

14

ORGANISATIONAL STRUCTURE

15

ORGANISATIONAL STRUCTURE

MIDAS procured tread PVT Ltd is a company in the heart land of rubber country where research and development and customer orientation have come together to manufacture and supply the highest quality retreading materials. MIDAS has chosen to develop as a group of small scale industries unit as far as production is concerned. The small scale unit are at Kottayam, Ettumanoor and Kariakal. The head office at Kottayam controls the group. Here the functions of purchase, marketing, finance, etc are centralized. For a state, which is notorious for it, labour union discipline, MIDAS is an example of extremely good labour management and the company has had no serious problem till date. More over company pays the best wages in the area.

Managing Directors

Manager R & D

Purchase Manager

Sales Manager

Lab Assistant

Assistant

Despatch Manager

Stock Assistant

s Assistant

Computer Assistant

General Workers Assistant

16

ORGANISATIONAL STRUCTURE

Managing Partner

GM istration

GM Marketing

Despatch Manager

Depoh Manager

Service Engineer

HO Sales Executive

Head Office Sales Officer

s Manager

ant

Finance Manager

Data Entry Operator

Cashier

Depoh Sales Executive

17

FUNCTIONAL DEPARTEMENTS

18

PRODUCTION DEPARTMENT

19

PRODUCTION DEPARTMENT

Introduction

Production denotes the conversion of the raw materials to semi finished or finished product, with the help of certain production process. The main aim of any production system is to produce economically the goods and services required by the customer.

Production is the process of transferring input into output. It is the core of every business activities, Midas polymer compound production of tread rubber and rubber compounds is NO.1 in India. It is the largest mixing plant in India with a production capacity of 2000 tonnes per month. The company processing compounds is the number one mixing unit by Ceat Ltd. Midas polymer is the number one mixing unit by ceat since it started its operation for Ceat Ltd.

20

LINE OF STRUCTURE

Director

Factory Manager

s Manager

Manager

Production Manager

Shift Engineer

Loading Supervisor

Shift Supervisor

Workers

21

RAW MATERIALS LIST The main raw materials are

Natural Rubber. Synthetic Rubber. Carbon Black. Process Oil. Zinc Oxide. Anti-oxidants. Sulphur. Accelerations.

SHIFT The company adopts 3 shift systems. These are 8.30 AM TO 4.30 PM 4.30 AM TO 12.30 PM 12.30 PM TO 8.30 AM In these shift 200 workers are divided and work is assigned to them.

AVERAGE DAILY PRODUCTION

Rubber Compound - 60 tonnes Tread Rubber

- 09 tonnes

Cushion Gum

- 500 – 600 kg

22

MACHINES USED K-4 Intermix Accessories

- 2No

Air Compressor

- 1No

Mixing Mill with Accessories

- 5No

Extender with Accessories

- 1No

Calendaring Machine with Accessories

- 1No

725 Kav Generator Dust Collector & Chimney

- 1No

Overhead Crane

- 1No

Electric Good Lift

- 1No

Hand/Mechanical Pallet Trunk

- 4No

Oil Batching & Accessories

- 1No

Weight Bridge 30mt Capacity

- 1No

Electric Weighting Machines

- 1No

Industrial Vacuum Cleaner

- 1No

PRODUCTION LAYOUT It is the process of arranging the machines in to one line depending upon the sequence of operation. Materials are fed in to the first machine and finished product comes out of the last machine. This layout is called product layout or known as straight line layout.

RAW MATERIAL FLOW Purchase of chemicals and raw materials are done by the customer. Incoming, inspection of the chemicals and raw materials are also conducted by the customer.

INPUT OUTPUT PROCESS 1. Raw Materials

Stage I

2. Production Control

Stage II

3. Output

Stage III

4. Storage

Stage IV

5. Despatch

Stage V

23

PROCESS OF MANUFACTURING

The important steps involved in the manufacture of procured tread are described below: 1. Mastication and Mixing. 2. Maturation. 3. Pre-warming. 4. Extrusion. 5. Cooling. 6. Weighting. 7. Moulding and Vulcanisation. 8. Post Curing. 9. Buffing. 10. Inspection and packing.

Mastication and Mixing The compounding ingredients and rubber are waited as par received. The raw material is firstly masticated on a two roll mixing mill for reducing the viscosity and increasing the plasticity after attaining a certain level of plasticity. The mill temperature is kept at 72 degree Celsius by ing cold water through the core of the rolls. To the masticated rubber other compounding ingredients are added which gets dispersed easily.

Maturation The sheeted compound is kept for 24 hours for maturation. The process is done to get technological properties to the compound. During the maturation the ingredients are well immersed in the rubber to get good technological properties.

24

Pre-Warming Pre-warming is done on a16” X 42” mill. The matured compound is stiff, during this operation, the temperature and plasticity of the compound is increased. This facilitates easy extrusion through the dye. At the end of preparing, the nip is adjusted to 15mm and small strips are directly fed to the extruder.

Extrusion Extrusion is the processing operation intended to shape the compound in the required shape. The production of procured tread, small strips of the mixed compound is fed to the extruder and it is forced through the dye and the material comes out in the dimension 7” width and 22mm thickness. On the starting of the extrusion process the dye is heated and when the process is progressing the temperature of the barrel may increase resulting in the vulcanisation of the compound. In order to prevent this, ing cold water through the extruder controls temperature.

Cooling The continuously extruded slab is ed into a tank containing cold water which helps to decrease dyes level. After a certain time, the slab is taken and cut into a length of 128” and is wrapped in a polythene film. This avoids sticking problem when the slab is weighted and the subsequent handling operation.

Weighting The polythene wrapped slab is weighted to the required weight. A 5% excess weight is taken for flash. Then it is taken for moulding.

25

Moulding & Vulcanization The weighted slab is then transferred to the moulding section. A polythene sheet is removed and the green compound is loaded in the pre heated lubrication mould, which is having the trade pattern in it. A silicon emulsion is used as the mould – releasing agents. This helps easy striping of the cured slab. The mould is then closed and it is then transferred to the platens of the hydraulic press and then the pleasure is applied. The maximum pressure applied for the production of procured tread is2250 amt. At temperature of 160 degree Celsius the suggested compound will have a cured cycle of 12-14 minutes. After curing, the press is opened and from the mould he strips of cured tread are taken after finishing operation.

Post -Curing Post-curing is carried out to improve the technological properties and also help to complete the curing process. This can be done on two ways, either by exposing the tread to 60 degree Celsius far 3-4 hours or keeping the product in room temperature for 24 hours. The proposed product is post cured in room temperature for 24 hours.

Buffing The cured tread is buffered on the base side to present a clean surface which is properly prepared for adhesion to the casing by means of bonding layer of cushion gum. It is compactable to both tread and wide variety of tyre compound to which the tread is a adhering and this can be done on a buffing machine.

Inspection & packing The buffer trade is inspected for ensuring the quality. The hardness is checked and visual inspection is done where there is any air bubble in the tread. Check all the dimensions of the tread. After the packing is done, the tread is covered within polythene film and it is rolled and put in the cardboard box and sealed. A label is pasted on the box which indicates the trade name and size of the trade. It is then transferred to the customer.

26

QUALITY CONTROL The word quality refers to the degree of excellence of a product. Modern age is the area of quality. The compensation today is cutthroat and every producer tries of to improve the quality of the product to lure the customer. To him for improving quality control is a must. Quality control is a systematic control of those variables which affect the excellence of the ultimate product. The company uses all types of production oriented quality control, Q1, Q2, Q3, Q4, Q5, & Q6. The factory manager and the production manager are assigned for quality control. The absolute quality controls are properly checked in the research and development group located at Ettumanoor.

PRODUCTION FLOW OF RUBBERCOMPOUND

A

• Weighing approved chemicals (Q1)

B

• Mixing of Raw Materials and Chemicals (Q2) • Milling - First and Second (Q3)

C

D

• Sheeting (Batch of Master compounds) Q4

E

• Weighing & Storage (Q5)

F

• Despatch (Q6)

27

FINANCE DEPARTEMENT

28

FINANCE DEPARTEMENT

Introduction Finance is the life blood of the business. For every activities related to business finance is required. Finance may be defined as the money at the time when it is wanted. His efficiency of production and marketing operations is directly influenced by the marketing which the finance function of the enterprise is performed by the finance division.

Maintenance of s s in Midas are maintained as per the requirements of the companies Act 1956. The company maintain detailed of its asset and liabilities, income and expenditure. At the end of the year s are finalized and annual s are prepared. They are properly audited.

Main Functions Cash Management. Taxation. Credit istration. Management & Control. Obtaining Finance. Financial ing. Banking Relationship.

29

Main Functions (Contd...) Internal Auditing. Funds Management. Evaluation Of Group Finance. Preparation Of Financial Report. Expense Analysis.

Line of Structure

Managing Partner

GM istration

Finance Manager

Data Entry Operator

Cashier

30

Cost of the Project Table Sl. No.

Item

Amt in Lakhs

01

Land Levelling (15000 cum at Rs.300)

45.00

02

Building (500 sqm at Rs.3000)

150.00

03

Plant & Machinery (Installation expenses included)

250.00

04

Industrial Electrification

90.00

05

Water Supply

20.00

06

Weighbridge and Electronic Weighing Machine

7.50

07

Other tools for handling materials

20.00

08

Genset with sound proof covering

35.00

09

Pollution Control Equipment

12.50

10

Other assets including furniture and fixtures

20.00

Total

650.00

31

PURCHASE DEPARTMENT

32

PURCHASE DEPARTMENT The company purchase of raw materials from approved suppliers only. The approved given on the basis of quality text of raw materials price negotiations and delivery. The company does make forecasting on purchase. The major purchase raw materials like carbon, natural rubber are bought based on the principles of purchase. The company adopt mainly just in time purchase.

LINE OF STRUCTURE

Managing Partner

Director

Purchase Manager

Office Supdt

Office Assistant

33

FUNCTIONS OF PURCHASE DEPARTMENT. Raw Material Pure Study. Market Intelligence Report Analysis. Complete Purchase Policy. Turnover Analysis. Pure Negotiation. Turnover Analysis. Purchase Order. Follow Up Rating Under Supplies. Vendor rating. Purchase Monitoring Invoice Checking etc.

CREDIT PATTERN The company’s purchases are of bulk nature and payment is immediately made. There is 0% credit against cash purchase. For certain raw materials like rubber chemicals, the company does take a credit time of 15 to 30 days. Annual contract is made for carbon black. The company also provide advance payment for reputed suppliers. The amount is being advanced to the companies and interested

JUST IN TIME PURCHASE

The Midas adopts just in time purchase policies. Purchase is made at the right time. The raw material like rubber is bought to be production plant, in one day advance of the production.

34

PURCHASE CONCEPT

A

• Right Qualtiy Material

B

• Right Price

C

• Right Delivery

35

SUPPLIERS INFORMATION TABLE

RAW MATERIALS

NAME OF THECOMPANY

Carbon Black

Philips Carbon Hi-tech Carbon

Synthetic Rubber

Indian Petrochemicals Ltd. Bayer AG Hyundai Petrochemicals, Korea

Rubber Chemicals

Bayer India Mai Ltd National Organic Chemicals Ltd ICL Ltd

Process Oil

Indian Oil Corporation

Natural Rubber

Local Suppliers Rubber Dealers Rubber Marketing Federation

36

MARKETING DEPARTMENT

37

MARKETTING DEPARTMENT

Introduction Marketing concept was born out of the awareness that a business to start with the determination of consumer wants and ends the satisfaction of those who wants. Marketing is the economic process by which goods and services are exchanged between the markets and the s, and there value is determined in of money price.

LINE OF STRUCTURE

Managing Partner

GM Marketing

Despatch Manager Sales Officers

HO Sales Executives

Head Office Engineers

Service

Depot Manager

Depot Sales Executive

38

MARKETTING PROCESS CHART

Depot Dealers

Product

Despatch

C & F Agents

Customer

Consumer

Corporation

MARKETING SERVICES Uncompromising Quality. Economy. Distribution Network. Technology.

MIDAS MARKETING It is ed as a partnership company as per the Indian partnership Act of 1932. JOHN ZACHARIACH BUILDING, THIRUNAKKARA, KOTTAYAM, KERALA is the ed partnership office of Midas. The business of the partnership shall be carried at Kottayam with branches, agency offices, distribution centres etc. The object of the partnership shall be to carry on business as dealers distributors, consignment, agents, commission agent, sales representatives, exporters, importers and merchants of all kind of rubbers and rubber products, procured tread rubbers, cushion gum, tread gum, vulcanising solution, other retreading materials from rubbers, bushes, sheets, flaps, channels, industrial lining, transmission belt tubes, tyres and other compounds, articles and appliances made with or form, and involving the use of natural rubber and synthetic rubber and all type of raw materials use in the manufacture of the product.

EXPORT MARKETING Midas exports its products to developing markets of the world including: Middle East 39

Africa & South America and South East Asia.

TARGET OF THE COMPANY

The company is targeting an export of about 1000 tonnes in the next five years. Moreover Midas has planned to form dealers network in the International market. The immediate plans are to double the export every year. Last year they participated in various shows organised into Brazil , Singapore, China and Italy for Globalizing their product.

MENT

Advertising is an avoidable part of marketing. The Midas spent only an average amount of ment. So the ment cost is minimum. The company keeps its position in branding. It includes 12 lakh labels around India.

AFTER SALES The company provides a clear cut after sale services to the customers. The service engineers provide all kind of assistance to retreaters’. The after sales programs cover: Periodical Assistance Market & Sales Service Engineers visit Forecasting Analysis etc

40

SALES DEPARTMENT

41

SALES DEPARTMENT Introduction

The concept of sales is that the company has to promote and push. Their product aggressively sold in the market. It cannot expect the product to get picked up automatically by the customer.

TECHNIQUES FOR IMPROVING THE SALES Heavy Advertising High power personal selling Large scale Sales Promotion

LINE OF STRUCTURE

Managing Director

Director

Sales Manager

Department Manager

Stock Assistant

s Assistant

Computer Assistant

General Workers Asstt

42

FUNCTION The sale of Midas products is based on the following sales policies and norms: Sales department receives the order from agents, dealers, contractors, etc and es the order to the factory for production. Then the product is moved to the dispatch manager and is sold to the customers as per the order. Order receiving and dispatch are the major function of the sales department

DISTRIBUTION CHANNEL

Direct Dealers C & F Agents People in Retread business Licensed Parties Contractors.

The company sells its products through the above distribution channels. Midas has dealers in all states. The company do supply its product based on agreement.

43

PROCESS CHART

Sales Order - Sales Manager Final Product - Factory Manager Despatch Manager Consumers Customers

DEPOTS AND SALES OFFICES OF THE COMPANY

Sl. No. 01 02 03 04 05

Place Coimbatore Vijayawada Baroda Jodhpur Bhopal

Tamil Nadu Andhra Pradesh Gujarat Rajasthan Madhya Pradesh

TABLE FOR TOTAL SALES OF LAST TWO YEARS

Products Tread Rubber Bonding Gum

Total Sales 2006-07

Total Sales 2007-08

6,34,65,787,.65

8,56,43,543.87

44

SALES FORECASTING

Major forecasting is done at production meeting held at every month. The include production engineers, factory managers, supervisors, sales personal’s etc. The product of the company is seasonal nature. So seasonal forecasting is also conducted along with the meeting. Forecasting are conducted in monthly, quarterly, yearly, basis.

SALES PROMOTION POLICIES Sales promotion policies of the company are as follows; 1. Right quality product, right price, right time deliver 2. The executives makes periodical visit to the dealers and agents on their arrival to the head office. 3. Meetings and seminar are conducted occasionally and proper sales analysis is made for promotion. 4. The company safeguards the customer’s interest and keeps a very strong relationship with them. 5. The sales executives make a visit to the agents and retreading people, to provide all kind of assistance.

PRICE Price = Cost +Profit

This is due to the fact that these are agri-products and are seasonal in nature. The price rate of the company is much less compared to is competitors.

45

HUMAN RESOURCE DEPARTMENT

46

HUMAN RESOURCE DEPARTMENT Introduction

Production is the combined process of factors like the Land, Labour, Capital, Enterprise, and Management. All these factors occupy a significant place in production. Yet labour and man-power are most important. There may be land, capital, enterprise, but they cannot function without the active labour force.

Personal management is the specialized branch of management, that deals with people n any organization, there has to be someone concerned with the welfare and performance of persons who are a part of the operation. When an individual or a team of individuals takes on this task of seeing to programs and setting policies that impact everyone associated with the company, they are engaged in the process of personnel management, sometimes referred to as human resources management.

The function of a personnel manager usually begins with the staffing process. Someone has to be focused on screening and interviewing persons, with an eye to placing individuals with the right skill sets in the right position within the company. Along with placement, the HR manager may also oversee or at least be involved in the creation of entry level training programs, as well as continuing education opportunities for existing employees.

47

Determining company policies and procedures as they relate to personnel is another important aspect of the personnel management process. HR functions often include drafting vacation, sick leave, and bereavement policies that apply to all employees of the company. The personnel management team often is also responsible for managing the health care program provided to the employees as well.

Midas group as well as the company does not have a Human Resource development departments as well as personal department. Other department managers like s and istration are given the charge of personal department. The personal department who is in charge of s and istration look forward the personal activities of the workers.

LINE OF STRUCTURE

Managing Director

Director

Manager Personnel In-Charge

Factory Manager

Manager s & istration

48

FUNCTIONS OF PERSONAL DEPARTMENT

Recruitment Maintenance of personnel files Time keeping Selection Management development Organisation change & organisation development Job analysis Human resources planning Wages and salaries istration Training Introduction & orientation Performance appraisal Career planning & development.

49

WAGES

Daily wages are usually given to the workers. Wages = basic pay + dearness allowance Dearness allowance is given as per the norms of the statistical department, government of Kerala

OTHER BENEFITS

The other benefits provide by the company are as follows;

Medical aids Loans Night Bata Overtime allowances Production incentives Insurance Medical allowance leave with wages Provident fund

TIME AND ATTENDENCE

Strict policy is followed by the company regarding the attendance and timing.

1. Attendance card

- it is manufactured for the workers.

2. Attendance - it is maintained for the office staff.

50

HEALTH AND SAFETY

Following are the safety measures done by the company as per safety precaution act. All type of safety cover for rotations pasts Break system for machinery.. Safety belt for above three meters. Pressure vessels safety certificate given by the factory inspector. Fire fighting equipment. Environment safety. All kind of electrical safety.

JOB ROTAION & JOB SCHEDULE

The rotation and job schedule are favourably done for the both office staff and workers. Factory manager does job rotation and job schedule for workers.

TRADE UNION

The trade union is operating in the company is CITU, INTUC,BMS. Agreement is made between the union and the company. It includes bonus wages and other allowances.

51

RESEARCH AND DEVELOPMENT

52

RESEARCH AND DEVELOPMENT Introduction The base of all present quality products belongs to the research & development of Midas R & D. R & D comprises of major three functions that include product development quality checking and control & research. Apart from this after sale services are also done as part of research and development. It can be called as Testing Centre. Midas has a well equipped laboratory which we used to develop new product and carry out quality an daily production. It constantly develops new compounds for various uses, and for improved mileage and properties. Midas value the customers on how their products performs on the road to help improve it in the future. MIDAS conducts road test programs to ensure that the laboratory results convert to real world benefits for its customers.

LINE OF STRUCTURE Managing Director

Director

Manaager R & D

Lab Technicians .

53

FINDINGS & SUGGESTIONS

54

FINDINGS & SUGGESTIONS

1. The company should maintain an adequate quantum of current asset in relation to current liabilities as to keep a good amount of liquidity in the system.

2. The inventory of slow moving items in store should be reduced to the maxim possible level to increase profitability.

3. The company should improve debt collection efforts to bring down the amount tied up in debtors.

4. The company can start a unit to treat worn tyres, which an increase their profit level. Due importance be given to ments as it is the soul of marketing.

55

CONCLUSION

56

CONCLUSION

Midas established in 1969 and has an experience on more than 35 years in tread industry. It started as a small tread rubber unit in Ettumanoor near Kottayam district. But Midas is the market leader in the field. Maintain the consistency in quality and services is the main aim of the company. Midas is now India’s popular brand of tyre retreading materials more than 1000 tonnes of sales per month. The dynamic leadership and innovative ideas made Midas as one of the leading manufacturers of tread rubber and aligned product in India.

The main objective of the study is to understand and find out the functioning of various departments in the organisation. The study gave a detailed knowledge about the establishment and functioning of istrative and related functional department in MIDAS pvt ltd

57

BIBLOGRAPHY

REFERENCE BOOKS

1. Research Methodology & Technique, 2nd edition. Kotharic C.R 2. Production & Operation Management, 5th edition. Evertte E Adam & Ronald J Ebert. 3. Marketing Management, 10th edition. Philip Kotler 4. Finance Management, 2nd edition. Subir Kumar Banarjee.

JOURNALS & MAGAZINE

1. Company Magazines. 2. Annual Report.

WEBSITE

1. www.midastreads.com

58

59

60

61

62

63