An Inspection Test Plan 6o3q68

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View An Inspection Test Plan as PDF for free.

More details w3441

- Words: 5,214

- Pages: 16

An Inspection Test Plan (ITP) is a commonly required document that you'll need to submit with your construction quality control plan. Whether you're working on a private sector or government contract, clients today all want to see your inspection test plan. They want to .know exactly what inspections and tests you'll be forming to control quality on their project In addition to telling your client what inspections and tests you'll do to control quality, your ITP is also a checklist for you to log the results of your inspections and tests during the .project ?So what should you include on your inspection and test plan anyway :The following 7 tips will help you to create your inspection and test plans Before you can start, you'll need an inspection test plan form. Click on this link, and you (1 .can one free from our website: Inspection Test Plan Form Templates Complete the form by, first, adding your task inspections. List a task inspection for each (2 .Definable Feature of Work (DFOW), also known as a construction task or a phase of work Now, add your milestone inspections. These are inspections at the completion of each (3 major piece of work. For example, this could be at the completion of a foundation or each .floor in a high-rise .Next, look at your project specification, and add the required inspections and tests from it (4 .DO include tests that you hire an independent testing agency to perform• .DO include inspection hold points• DO NOT include inspections conducted by your client, as that is their own• .quality control, not yours Finally look in the Division 01 General Requirements section of your specification for any (5 special inspections to add to your inspection test plan. These could be such things as field .assessments and final closeout inspections

Click the image on the left to see the first page of a .completed Inspection Test Plan Once you have a good template and know what to include, putting together an inspection test .plan becomes very straightforward For all U.S. Army Corps of Engineers (USACE) and Naval Facilities (NAVFAC) Government projects, you’ll need to provide a list of your Definable Features of Work as .part of your contractor quality control plan If you’re not already familiar with the term, a Definable Feature of Work (DFOW) is what .you might think of as a construction task

The Corps of Engineers describes a DFOW as a task that is separate and distinct from other tasks and has control requirements and work crews unique to that task. A DFOW is identified by different trades or disciplines and is an item or activity on the construction schedule.1 So, for example, excavation, electrical, concrete, roofing, mechanical, HVAC, etc. .are all Definable Features of Work When it comes to deciding on your DFOW, you’ll want to define your features narrowly enough to ensure adequate quality controls, yet, not so narrowly that you cause yourself a lot .of unnecessary work Keep in mind that for each definable feature, you’ll be required to perform the Three Phases of Control, which means you’ll be performing a series of planning, inspection, and record .keeping procedures for each The following steps will help you find the right balance for your Definable Features of .Work Step One Start by including one DFOW for each specification in the CSI construction specifications .section of your contract e.g. 03 30 00 Cast-In-Place Concrete Developed by the U.S. Army Corps of Engineers, the three phases of control are required for all military-related quality control plans and are the core of their Construction Quality .Management Systems In fact, in addition to the USACE, the Navy Facilities Engineering Command (NAVFAC), the Air Force Civil Engineering Facility (AFCESA) and The National Aeronautics and Space istration (NASA) have all adopted the quality control policies and .procedures that make up the Three-Phase Control System So what are the three phases of control? As the owner of a construction company, you may already be performing them, but you'll need to explain how in your construction quality .control plan Essentially, if you’re reviewing your construction project requirements before you begin work, making sure your work starts correctly, and monitoring your work in process, then you’re performing the three phases of control. There’s a bit more to it than that, but that’s it .in a nutshell To give you a general understanding of what’s involved, I’ve put together a brief summary of the steps you’ll follow for each construction task, or as the Corps of Engineers calls them, for .(each Definable Feature of Work (DFOW Phase 1 - Preparatory Phase The Preparatory Phase occurs usually days or weeks in advance, before you begin each :construction task or DFOW. For this phase, your superintendent should do the following Review all the requirements for the task• Assess the current situation• Inspect the jobsite• Review the findings with staff, subcontractors, and the client• Phase 2 - Initial Phase

The Initial Phase occurs just prior to giving the go-ahead to begin work and ensures that the :task will start correctly. For this phase, your site supervisor should do the following Check that all requirements for personnel, materials, and equipment are in place• that the site has ed its job-ready inspection• Inspect the first article (after work begins) to make sure that it is appropriate to• continue work Phase 3 - Follow-up Phase The Follow-Up Phase occurs throughout the construction task. For this phase, your site :supervisor should do the following Monitor work on a daily basis to assure that all job requirements are being met in a• timely manner that the tasks or DFOW are being performed correctly up until their• completion To see how our construction quality control plan templates address the three phases of control, look at our cross-reference table of USACE requirements and a USACE.Navfac sample The three phases of control are something every construction company should be implementing. Not only do they ensure a consistent level of quality, by having your ThreePhase Control System in place, you’ll also have one more element that project owners are .looking for in a quality-driven company As a construction quality consultant, one trend I’m seeing is that more project owners are .asking for construction quality control plans. And, it’s clear that this practice is increasing Now, not only do you need to produce quality, defect-free work, you also need to formally .document your quality practices Explaining what you do and the specific ways you’ll carry out your quality practices on each project will become part of your project contract. It's no longer good enough to just say that .you control quality Once only a requirement on government projects, I’m also seeing more and more quality plans required on non-government projects as well (although, it is still more common on .(government jobs In any event, you'll want to be prepared to provide your clients with a well-formulated quality control plan including a quality manual, project plan, standard operating procedures and .submittal forms Here's a short list of do's and don'ts based on some of the common mistakes I see with quality .plan submittals Don’t appoint a superintendent as your quality manager. Clients want to see.1 independence between the person who is responsible for the overall quality of your .work and the person responsible for production Do include a separate policy in your quality manual for the preparation of your project.2 .quality plan Don’t forget to include local building codes in your quality plan. They apply even.3 .though your client may not have listed them in the contract specifications Do provide a cross-reference table between your client’s requirements and your.4 submittal. You need to make it easy for your client to see how you meet the contract

specifications. This also makes it easy for you to cross check that you have addressed .each required element in your contract specifications Don’t forget to include a standard operating procedure for each submittal form. Often.5 companies will have forms but not the accompanying procedures, which should .include the purpose, scope, and references regarding the forms Do look for quality-related specifications in all sections of your contract, even.6 sections other than the QA/QC section. Quality-related requirements can be included .throughout the contract The trend of requiring formal quality plans as part of construction contract submittals is here to stay. Whether you’re putting a quality plan submittal together now or will need one in the .future, keep these tips in mind and you’ll avoid some of the more common problems You certainly don’t want to leave something out of your construction quality control plan that is needed or will get your plan rejected. On the other hand, you don’t want to add any .unnecessary complexity either For starters, you’ll want to remove procedures that your client doesn’t actually require... And .(more importantly) that you don’t intend to do Next, you’ll want to remove unnecessary detail in your quality control plan that can work .against you Don’t get me wrong, I’m not saying you should try to get away with the bare minimum level .of construction quality controls However, I am saying that you should consider the different levels of quality controls suitable for different projects and modify your construction quality control plan accordingly. The goal is to promise the right level of quality controls to make everyone happy -- you, your client, .and your workers Whether you’re purchasing a construction quality control plan template or developing your :plan from scratch, you’ll want to pay attention to these six Dos and Don’ts .Don’t say your Quality Manager performs ALL your inspections.1 The role of your quality manager is to provide oversight and to validate that your quality processes are working. Construction superintendents will do most of your inspections. So, make sure to specify which inspections your quality manager will do and which ones your .superintendents will do Do customize the list of records you’ll keep based on each project’s.1 .requirements Some projects are short and simple, and therefore, don’t require a high level of record keeping. On the other hand, some projects do warrant detailed record keeping. You should modify your construction quality control plan to reflect the record keeping needs of each .project .Don’t submit every form you own.1 Here again, it’s important that you only submit the forms you need for each specific project. Otherwise, your client will expect you to carry out all the procedures connected with the .forms you include in your quality control plan .Do limit the detail on your list of Quality Controlled Construction Tasks.1 A good practice is to list all the phases of construction (i.e. definable features of work) where you do an inspection at the completion of the task. It’s not necessary to include all the phases .of construction that are on your project schedule

.Don’t add too much detail to your inspection forms.1 Inspection forms are for recording the completion of inspections. They’re records that the inspections took place, not records of your quality control standards. A good practice is to include about a dozen of your most important checkpoints, not a long list of minor .construction details. Adding too many checkpoints can complicate matters for you .Don’t address each punch item as a nonconformance.1 Most punch items are work in process corrections and not nonconformances. They’re easily corrected and don’t require the same level of quality controls as nonconformances. Your quality manual should differentiate work in process corrections from nonconformances. I suggest you handle items as nonconformances if they meet BOTH of these criteria: (a) items that do not meet project quality standards; and (b) only items remaining after the final task .inspection has been completed The key to managing costs and liabilities is to provide the appropriate level of quality controls for each project. Your quality control plan is an extension of your contract and thus, a legally binding document. Promise too little and your client won’t be happy. Promise too .much and you won’t be happy. Promise just the right amount and everyone is happy ?What is your approach to simplifying your construction quality control plan One of the most common problems I find with construction quality management is a lack of .consistency from project to project .It’s not that organizations don’t have quality management systems in place It’s that, oftentimes, there's no consistency in of how they approach quality from one project to the next or even from one superintendent to the next. Like franchises, you want all .your projects to maintain consistent quality Take McDonald’s for instance, whether you like the brand (or the food) or not, you have to agree that as a franchise, the company is very successful. Why? Umm...because the food is .cheap? While this is certainly true, it’s not the reason for McDonald’s success Consistency... just about every McDonald's has the same basic layout, menu, ordering process, and quality of food. All this standardization creates consistency for the customer, for the employees, and for the franchise owners – all with an unskilled workforce. And, it’s a .consistency that’s based on what works The same consistent quality should apply to construction quality management in your organization. Keep in mind, most people at your organization are busy dealing with their .normal workload, plus the inevitable firefighting that crops up on a regular basis In our fast-paced world of construction, work procedures have to make sense in a hurry, or they'll just go by the wayside. You can't expect people to always figure out things on the fly. .You need some standardization so you can have consistent quality management Some companies may have a single, unifying quality policy for the entire organization, but may not implement it the same from one project to the next. For example, if you leave it up to each project manager to re-invent the wheel on every project, you’ll sacrifice consistent .construction quality A much more effective approach would be to create a company-wide quality management system that you can use on all projects. Such a system might include your quality policies in a quality assurance/quality control manual, project-specific quality plan, inspection procedures, quality improvement processes, and quality system analytics. Having a

standardized company-wide quality management system creates consistency across all .projects People working on multiple projects will perform the same procedures, and these procedures will become second-nature for them. This consistency makes it more likely that the .procedures will actually be executed properly Keep in mind that these quality policies do not have to be overly prescriptive. You’re not trying to standardize every aspect of the work; you’re just trying to create a common .framework for people to use to consistently manage quality Your framework should be flexible enough to be adapted to different projects and teams. On the other hand, your framework should definitely be standardized enough so that any employee plucked away from one project and dropped down into another project would .quickly know what to do with regards to quality ?The goal is consistent quality. It’s your brand, how do you want to franchise it ?What is your approach to consistency with regard to construction quality management If you want a shot at winning a government construction contract, you'll want to dive in and .tackle the mound of documents you'll need for your comprehensive quality control plan Government quality control plans require a substantial collection of documents, records, and forms. Their purpose is to communicate what you do to assure consistent quality results on .every job A good quality control plan will show your clients that your company can fit into their quality .systems ?What documents do you need

Most government agencies with comprehensive QA/QC requirements want specific :submittals during each phase of construction. The phases include Bid Qualification Phase• Pre-Construction Phase• Construction Phase•

Here is a list of most of the documents or submittals you'll need for each phase of .construction Bid Qualification Phase Submittal Documents - qualify your company to manage and deliver quality work Quality Manual - explains your company’s quality methods and policies• Standard Operating Procedures - (SOPs) detail the work steps you use to• carry out your quality methods and policies

Pre-Construction Phase Submittal Documents -part of your project quality plan-- detail .how you will manage and deliver quality on this project Organization Chart – identifies the management team responsible for• ensuring project quality Quality Personnel’s Qualifications form – lists the qualifications of your• quality management team Quality Personnel’s Appointment letter– gives your quality management• team authority for ensuring project quality

Quality Training Plan – establishes your training plan for quality-related• activities Regulatory codes and standards form - lists the regulatory codes and• standards you comply with Industry standards form – outlines the industry standards you comply with• Inspection and Test Plan form– describes the inspections and tests you• conduct Selection of key suppliers and subcontractors form – explains you supplier• and subcontractor selection process Material and equipment specification form – records specifications for the• material and equipment you use Communications plan form - records a summary of monthly project status• reports

Construction Phase Submittal Documents - provide a record of how you carried out your project quality plan Inspection and Test Records – records the results from your planned• inspections and tests Nonconformance Reporting – documents any work or materials found• during inspections and tests that don’t meet (conform to) your standards Daily Construction Reporting – summarizes what happened on the job site• that day Training Records – lists training sessions that were conducted for• preventive as well as improvement purposes Quality System Audits – defines the preventive actions you take because• of your monthly project quality system audits and your annual company.wide quality system audit Document Control Records – explains the controls you use to keep your• quality system records up-to-date, accurate, and safe

The way you show your client that you have a good QA/QC program with good systems in place is by showing them your system documentation. In other words, you need to show them .a good quality control plan Get started with developing your quality control plan by documenting the quality processes .you do now Follow that up with a plan to improve upon your existing quality systems, and you'll be ready .for that government construction contract .And, don't forget... always document your quality processes

.Get Two Free Project Quality Plan Submittal Forms

About the Author - Ed Caldeira is founder of Caldeira Quality, specializing in First Time Quality construction quality programs and FTQ360 performance .management software. He can be reached at www.FirstTimeQuality.com Comments Click here to read/write comments 0 Tags: quality control, quality assurance, quality plan, government, submittals

Steps: Understanding Construction Quality Control Plan Requirements 4 Posted by Ed Caldeira on Sun, Jan 10, 2010 @ 10:08 PM Email Article |

Twitter |

Facebook |

LinkedIn |

StumbleUpon

This is the first in a series designed for general contractors to take some of the frustration out of understanding your client’s quality assurance and quality control plan .requirements It's also intended to help you develop a quality plan to meet .those requirements :Here are a few steps to follow Identify all the quality requirements within your .1 contract There's usually a quality assurance specifications section in your contract. That's where most of your quality .requirements will be Also check other sections for “quality assurance” and “submittals” subheadings where your client may list additional requirements. These requirements will be a combination of project-specific, client-specific and industry .standard requirements Know which construction industry quality standards you need to address

.2

:There are two widely used construction industry standards for quality FTA Quality Assurance and Quality Control Guidelines – used for most• state and city transportation projects USACE/NAVFAC/AFCESA/NASA Quality Control Requirements – used for• government and military construction projects

You can a copy of the USACE and FTA standards from our website by clicking on .the links above .Both of these construction industry standards are variations of ISO9000 quality standards Make an action items list of your requirements

.3

Since most contract specifications are in paragraph or narrative form, it will be helpful to .break the requirements down into an actionable list. Hint: Just look for the action verbs

Below, I’ve highlighted action items by their action verb in FTA industry standard - Element 1: Management Responsibility Management should designate a representative who shall have defined ...“ authority and responsibility for ensuring that the quality policy is implemented and maintained. Management should also identify those persons responsible for the quality assurance function and should define in writing the ”.responsibility, authority, and interrelation of those persons Create a Cross-Reference Table or Checklist for Each Requirement

.4

Next, cross-reference the sections of your quality plan that meet your contract requirements .with the requirements you've identified This will help you keep all of your contract requirements straight and make sure you address .each one in your quality plan submittal To see a cross-reference tables of how our quality plans conform to the FTA and USACE :requirements, click on the following links Cross-Reference Table - FTA Quality Assurance Quality Control Guidelines Cross-Reference Table - USACE Quality Control Requirements For some more examples of quality manual, project plan and SOPs that meet contract .requirements, look at the Table of Contents and some sample pages from our quality plans Need help figuring out your contract requirements or developing ?your construction quality plan submittal . me for a free contract specifications review Comments Click here to read/write comments 0 Tags: specifications, quality control, quality plan

Things Construction Superintendents Can Do Reduce Punch Lists 5 Posted by Ed Caldeira on Wed, Dec 09, 2009 @ 09:06 PM Email Article |

Twitter |

Facebook |

LinkedIn |

There is no reason for your superintendents to continue to act as the subcontractors’ quality control inspector and creator of .punchlists Here are 5 things superintendents can do to reduce punchlists and .improve subcontractor quality performance Communicate Expectations #1 Superintendents that set high expectations for first time quality ON THEIR JOBSITE get the best performance from their .subcontractors Successful superintendents constantly reinforce their quality standards during production meetings and conversations. They make it clear, “Deliver 100% first time quality – don’t depend on ”!me to create your punch lists

StumbleUpon

Recognize Positive Behaviors #2 Everyone appreciates a bit of positive recognition. Subcontractors are no different. Even though you pay them to do a quality job, subcontractors will go the extra mile if they think .you appreciate their extra effort For other subcontractors whose performance varies, catch them when they do well and use .the opportunity to recognize them. , behaviors that are recognized get repeated Mentor and Teach #3 Teach your subcontractor to inspect their own work and punch it out before calling you to inspect. Ask the subcontractor to be with you while you do your inspection. The result will .surely be a reduced number of punch items The Last Resort #4 If communicating expectations, and recognizing efforts, coupled with guided improvement does not work, ask the owner for an action plan that will address the issue of repeated punch .items .Follow-up diligently and adjust the plan until the issues are resolved Measure Success #5 Make your team’s progress come alive. Use inspection scores or punch item count data to .track overall progress. Share it with your subcontractors The best superintendents go on to ask their subcontractors, “how good can we get?” and .involve them in developing a plan to make it happen In Conclusion Field superintendents that follow this proactive partnering approach will see positive results. .In other words, punch lists will be shorter, and you will have fewer problems Just make it clear that delivering 100% complete first time quality work -- without depending .on superintendents for punchlists is your subcontractor’s responsibility Comments Click here to read/write comments 0 Tags: building, construction, best-practices, quality control, quality assurance, subcontractor performance

Measuring Construction Quality Using Inspection Forms Posted by Ed Caldeira on Wed, Dec 09, 2009 @ 08:20 AM Email Article |

Twitter |

Facebook |

LinkedIn |

StumbleUpon

Quality is subjective. That's why it's important that everyone in your .organization use the same guidelines for measuring it When doing an inspection, I suggest you measure the level of avoidable problems you encounter and rate them using a rating scale :of 1 to 5 Perfect, no problems, 100% = 5 Very good, 1-2 minor problems = 4 Good, 3-5 minor problems = 3 Poor, 6+ minor problems, hotspot or a major problem = 2 Very poor, excessive problems = 1 Use your First Time Quality Inspection Forms to record your ratings and make sure to .include notes for any measurements under a 5 Adding notes and comments is a good way to give to the subcontractor or crew .whose work you are measuring Constructive will encourage subcontractors and crews to make improvements to their work, while positive for a job well done will encourage more of the same top .quality work :Comments might include ",Overspray on floors" ",Outlets covered by drywall" ".Concrete not level" ",!Great Job" ",No Problems" Strongly encourage your superintendents to give accurate quality measurements. Afer all, it .will be difficult to measure improvements if superintendents give inflated scores Make sure everyone knows that the purpose of measuring is to gauge the current level of .quality and to work together towards improving it Standard operating procedures are written instructions that explain the work steps you use to .carrying out your construction quality methods and policies I’m going to explain how to write standard operating procedures for your construction quality .plan. But, first, let me explain why you should have them Why you need SOPs While your construction QA/QC manual describes your quality approach, your SOPs are the .instruction sheets that provide the additional and much needed detail Here’s an example. Say you have a policy for handling nonconformances — and you should .if you’re following quality best practices :In your quality manual, you describe your nonconformance policy by saying Should a nonconformance be identified by an inspection, there is a systematic method to “ ”.control the item to prevent inadvertent coverup

That’s just a basic policy overview; your quality manual will cover the topic at length, but .you get the idea

So, when your inspector identifies a nonconformance, what work steps will he or she follow to prevent an inadvertent cover-up? Will your inspector use a tag, ?warning tape, or both And, how do you know that your nonconformance policy was followed? Moreover, how do ?your records help you prove it in court if you’re involved in defect litigation .That’s where your standard operating procedures come in Format for Writing Standard Operating Procedures .SOPs contain specific information and follow a generally accepted format In the header portion, you’ll identify the section in your QA/QC manual where you’ve .described this particular quality policy Next, to prevent old versions from mistakenly being used, you’ll list the version date. Then, .you’ll add the approval date and who approved the procedure :For the main body of the SOP, you’ll include the following Purpose • Scope • (Responsible Person(s • References • Procedure •

Click on the thumbnail to enlarge the example of an SOP for :construction nonconformance reporting Notice how the body of the procedure has numbered steps that describe the work process .step-by-step ?How much detail should you add A general guideline is to keep the procedure as simple as possible, but not so simple that the .lack of details could adversely affect quality I have seen many SOPs that fail to find the right balance between completeness and simplicity. Too simple and you do not achieve your goal for controlling a quality process. Too complex and you cause unnecessary work for yourself (the procedure writer) as well as .the people responsible for carrying out the work

Multiply the efficiency by the number of procedures and the balance you find can determine .the success of your quality system If you need help developing your construction quality plan SOPs, our personalized quality plan template packages come with a complete library of standard operating procedures and .forms. a sample or us for details

Construction Quality Plan Offerings What's included (Click on the (links for more information

Bid Plans

Submittal-Ready Quality Plan Templates

Custom Quality Plans

Personalization includes your company name, project and workrelated information Money-Back Guarantee 100% Compliance with USACE, NavFac, FTA-DOT, TSA, DOE, DoD or ISO 9000 Requirements Comprehensive Quality Manual see Table of Contents Project Quality Plan - see Table of Contents Library of Submittal Forms Standard Operating Procedures see Table of Contents hour phone 1/2 consultation Customization for complex or nonstandard specifications

Available

Submittal Acceptance Guarantee Submittal Preparation

Available

Quality Plan Template Personalization :Your template will include your information from the following areas Company Name• Company Logo• Project Name• # Contract• Project Quality Personnel Names

To be included on your organization chart, appointment letters, and various QC forms .throughout your project plan Quality Manager• Director of Quality• Project Manager• Design Manager• Superintendent• President• Scopes of Work Your standard construction tasks or features of work• Standards and Qualifications Your industry standards• Required licenses for both your company and qualified personnel•

Learn More We've developed a set of templates to comply with the USACE-Navfac requirements :including A Project Quality Plan, Quality Manual, Procedures & Submittal Forms• USACE-Navfac Compliance• Personalized, easy to edit, and reusable in MS Word format• (Expert advice and (web/phone review meeting included• Satisfaction Money-Back Guarantee 100%•

USACE-Navfac QC Plan Sample Pages your 20 page sampling from selected sections of our USACE-Navfac Quality Plan .Templates We'll prepare a template to meet your needs and personalize it with your company, project .and work-related information Submittal-Ready USACE-Navfac Templates and Custom Quality Plans :include A Project Quality Plan, Quality Manual, Procedures & Submittal Forms•

USACE-Navfac Compliance• Personalized, easy to edit, and reusable in MS Word format• (Expert advice and (web/phone review meeting included• Satisfaction Money-Back Guarantee 100%•

Don't want to the sample, us at 410-451-8006 and we'll tell you everything .you need to know

Quality Plan Sample Pages

. your 25 page sampling from selected sections of our comprehensive templates We'll prepare a template to meet your needs and personalize it with your company, project .and work-related information :Submittal-Ready Templates and Custom Quality Plans include A Project Quality Plan, Quality Manual, Procedures & Submittal Forms• USACE, NAVFAC, FTA-DOT, TSA, DOE, ISNetworld, or ISO 9000 compliance• Personalized, easy to edit, and reusable in MS Word format• (Expert advice and (web/phone review meeting included• Satisfaction Money-Back Guarantee 100%•

Construction QA/QC Plans for Bids Good for when you need an overview of your QA/QC plan for a bid and for a simple project .that doesn't require a more comprehensive quality plan This abbreviated plan is 5-6 pages long. It's a quality system framework that will describe :your company's QA/QC philosophy for the following areas Project Quality Management• Organization Quality Management• Documented Standards and Specifications• Formal Qualifications of Employees• Formal Qualifications of Subcontractors and Suppliers• Documented Field Inspections• Control and Prevention of Nonconformances• Cross-Reference Table for compliance with USACE, NAVFAC, FTA-DOT,• TSA, DOE, and ISO 9000 when applicable

It also includes a table of contents from our more comprehensive quality plan so you can .show your clients what your complete quality plan will include

Click the image on the left to see the first page of a .completed Inspection Test Plan Once you have a good template and know what to include, putting together an inspection test .plan becomes very straightforward For all U.S. Army Corps of Engineers (USACE) and Naval Facilities (NAVFAC) Government projects, you’ll need to provide a list of your Definable Features of Work as .part of your contractor quality control plan If you’re not already familiar with the term, a Definable Feature of Work (DFOW) is what .you might think of as a construction task

The Corps of Engineers describes a DFOW as a task that is separate and distinct from other tasks and has control requirements and work crews unique to that task. A DFOW is identified by different trades or disciplines and is an item or activity on the construction schedule.1 So, for example, excavation, electrical, concrete, roofing, mechanical, HVAC, etc. .are all Definable Features of Work When it comes to deciding on your DFOW, you’ll want to define your features narrowly enough to ensure adequate quality controls, yet, not so narrowly that you cause yourself a lot .of unnecessary work Keep in mind that for each definable feature, you’ll be required to perform the Three Phases of Control, which means you’ll be performing a series of planning, inspection, and record .keeping procedures for each The following steps will help you find the right balance for your Definable Features of .Work Step One Start by including one DFOW for each specification in the CSI construction specifications .section of your contract e.g. 03 30 00 Cast-In-Place Concrete Developed by the U.S. Army Corps of Engineers, the three phases of control are required for all military-related quality control plans and are the core of their Construction Quality .Management Systems In fact, in addition to the USACE, the Navy Facilities Engineering Command (NAVFAC), the Air Force Civil Engineering Facility (AFCESA) and The National Aeronautics and Space istration (NASA) have all adopted the quality control policies and .procedures that make up the Three-Phase Control System So what are the three phases of control? As the owner of a construction company, you may already be performing them, but you'll need to explain how in your construction quality .control plan Essentially, if you’re reviewing your construction project requirements before you begin work, making sure your work starts correctly, and monitoring your work in process, then you’re performing the three phases of control. There’s a bit more to it than that, but that’s it .in a nutshell To give you a general understanding of what’s involved, I’ve put together a brief summary of the steps you’ll follow for each construction task, or as the Corps of Engineers calls them, for .(each Definable Feature of Work (DFOW Phase 1 - Preparatory Phase The Preparatory Phase occurs usually days or weeks in advance, before you begin each :construction task or DFOW. For this phase, your superintendent should do the following Review all the requirements for the task• Assess the current situation• Inspect the jobsite• Review the findings with staff, subcontractors, and the client• Phase 2 - Initial Phase

The Initial Phase occurs just prior to giving the go-ahead to begin work and ensures that the :task will start correctly. For this phase, your site supervisor should do the following Check that all requirements for personnel, materials, and equipment are in place• that the site has ed its job-ready inspection• Inspect the first article (after work begins) to make sure that it is appropriate to• continue work Phase 3 - Follow-up Phase The Follow-Up Phase occurs throughout the construction task. For this phase, your site :supervisor should do the following Monitor work on a daily basis to assure that all job requirements are being met in a• timely manner that the tasks or DFOW are being performed correctly up until their• completion To see how our construction quality control plan templates address the three phases of control, look at our cross-reference table of USACE requirements and a USACE.Navfac sample The three phases of control are something every construction company should be implementing. Not only do they ensure a consistent level of quality, by having your ThreePhase Control System in place, you’ll also have one more element that project owners are .looking for in a quality-driven company As a construction quality consultant, one trend I’m seeing is that more project owners are .asking for construction quality control plans. And, it’s clear that this practice is increasing Now, not only do you need to produce quality, defect-free work, you also need to formally .document your quality practices Explaining what you do and the specific ways you’ll carry out your quality practices on each project will become part of your project contract. It's no longer good enough to just say that .you control quality Once only a requirement on government projects, I’m also seeing more and more quality plans required on non-government projects as well (although, it is still more common on .(government jobs In any event, you'll want to be prepared to provide your clients with a well-formulated quality control plan including a quality manual, project plan, standard operating procedures and .submittal forms Here's a short list of do's and don'ts based on some of the common mistakes I see with quality .plan submittals Don’t appoint a superintendent as your quality manager. Clients want to see.1 independence between the person who is responsible for the overall quality of your .work and the person responsible for production Do include a separate policy in your quality manual for the preparation of your project.2 .quality plan Don’t forget to include local building codes in your quality plan. They apply even.3 .though your client may not have listed them in the contract specifications Do provide a cross-reference table between your client’s requirements and your.4 submittal. You need to make it easy for your client to see how you meet the contract

specifications. This also makes it easy for you to cross check that you have addressed .each required element in your contract specifications Don’t forget to include a standard operating procedure for each submittal form. Often.5 companies will have forms but not the accompanying procedures, which should .include the purpose, scope, and references regarding the forms Do look for quality-related specifications in all sections of your contract, even.6 sections other than the QA/QC section. Quality-related requirements can be included .throughout the contract The trend of requiring formal quality plans as part of construction contract submittals is here to stay. Whether you’re putting a quality plan submittal together now or will need one in the .future, keep these tips in mind and you’ll avoid some of the more common problems You certainly don’t want to leave something out of your construction quality control plan that is needed or will get your plan rejected. On the other hand, you don’t want to add any .unnecessary complexity either For starters, you’ll want to remove procedures that your client doesn’t actually require... And .(more importantly) that you don’t intend to do Next, you’ll want to remove unnecessary detail in your quality control plan that can work .against you Don’t get me wrong, I’m not saying you should try to get away with the bare minimum level .of construction quality controls However, I am saying that you should consider the different levels of quality controls suitable for different projects and modify your construction quality control plan accordingly. The goal is to promise the right level of quality controls to make everyone happy -- you, your client, .and your workers Whether you’re purchasing a construction quality control plan template or developing your :plan from scratch, you’ll want to pay attention to these six Dos and Don’ts .Don’t say your Quality Manager performs ALL your inspections.1 The role of your quality manager is to provide oversight and to validate that your quality processes are working. Construction superintendents will do most of your inspections. So, make sure to specify which inspections your quality manager will do and which ones your .superintendents will do Do customize the list of records you’ll keep based on each project’s.1 .requirements Some projects are short and simple, and therefore, don’t require a high level of record keeping. On the other hand, some projects do warrant detailed record keeping. You should modify your construction quality control plan to reflect the record keeping needs of each .project .Don’t submit every form you own.1 Here again, it’s important that you only submit the forms you need for each specific project. Otherwise, your client will expect you to carry out all the procedures connected with the .forms you include in your quality control plan .Do limit the detail on your list of Quality Controlled Construction Tasks.1 A good practice is to list all the phases of construction (i.e. definable features of work) where you do an inspection at the completion of the task. It’s not necessary to include all the phases .of construction that are on your project schedule

.Don’t add too much detail to your inspection forms.1 Inspection forms are for recording the completion of inspections. They’re records that the inspections took place, not records of your quality control standards. A good practice is to include about a dozen of your most important checkpoints, not a long list of minor .construction details. Adding too many checkpoints can complicate matters for you .Don’t address each punch item as a nonconformance.1 Most punch items are work in process corrections and not nonconformances. They’re easily corrected and don’t require the same level of quality controls as nonconformances. Your quality manual should differentiate work in process corrections from nonconformances. I suggest you handle items as nonconformances if they meet BOTH of these criteria: (a) items that do not meet project quality standards; and (b) only items remaining after the final task .inspection has been completed The key to managing costs and liabilities is to provide the appropriate level of quality controls for each project. Your quality control plan is an extension of your contract and thus, a legally binding document. Promise too little and your client won’t be happy. Promise too .much and you won’t be happy. Promise just the right amount and everyone is happy ?What is your approach to simplifying your construction quality control plan One of the most common problems I find with construction quality management is a lack of .consistency from project to project .It’s not that organizations don’t have quality management systems in place It’s that, oftentimes, there's no consistency in of how they approach quality from one project to the next or even from one superintendent to the next. Like franchises, you want all .your projects to maintain consistent quality Take McDonald’s for instance, whether you like the brand (or the food) or not, you have to agree that as a franchise, the company is very successful. Why? Umm...because the food is .cheap? While this is certainly true, it’s not the reason for McDonald’s success Consistency... just about every McDonald's has the same basic layout, menu, ordering process, and quality of food. All this standardization creates consistency for the customer, for the employees, and for the franchise owners – all with an unskilled workforce. And, it’s a .consistency that’s based on what works The same consistent quality should apply to construction quality management in your organization. Keep in mind, most people at your organization are busy dealing with their .normal workload, plus the inevitable firefighting that crops up on a regular basis In our fast-paced world of construction, work procedures have to make sense in a hurry, or they'll just go by the wayside. You can't expect people to always figure out things on the fly. .You need some standardization so you can have consistent quality management Some companies may have a single, unifying quality policy for the entire organization, but may not implement it the same from one project to the next. For example, if you leave it up to each project manager to re-invent the wheel on every project, you’ll sacrifice consistent .construction quality A much more effective approach would be to create a company-wide quality management system that you can use on all projects. Such a system might include your quality policies in a quality assurance/quality control manual, project-specific quality plan, inspection procedures, quality improvement processes, and quality system analytics. Having a

standardized company-wide quality management system creates consistency across all .projects People working on multiple projects will perform the same procedures, and these procedures will become second-nature for them. This consistency makes it more likely that the .procedures will actually be executed properly Keep in mind that these quality policies do not have to be overly prescriptive. You’re not trying to standardize every aspect of the work; you’re just trying to create a common .framework for people to use to consistently manage quality Your framework should be flexible enough to be adapted to different projects and teams. On the other hand, your framework should definitely be standardized enough so that any employee plucked away from one project and dropped down into another project would .quickly know what to do with regards to quality ?The goal is consistent quality. It’s your brand, how do you want to franchise it ?What is your approach to consistency with regard to construction quality management If you want a shot at winning a government construction contract, you'll want to dive in and .tackle the mound of documents you'll need for your comprehensive quality control plan Government quality control plans require a substantial collection of documents, records, and forms. Their purpose is to communicate what you do to assure consistent quality results on .every job A good quality control plan will show your clients that your company can fit into their quality .systems ?What documents do you need

Most government agencies with comprehensive QA/QC requirements want specific :submittals during each phase of construction. The phases include Bid Qualification Phase• Pre-Construction Phase• Construction Phase•

Here is a list of most of the documents or submittals you'll need for each phase of .construction Bid Qualification Phase Submittal Documents - qualify your company to manage and deliver quality work Quality Manual - explains your company’s quality methods and policies• Standard Operating Procedures - (SOPs) detail the work steps you use to• carry out your quality methods and policies

Pre-Construction Phase Submittal Documents -part of your project quality plan-- detail .how you will manage and deliver quality on this project Organization Chart – identifies the management team responsible for• ensuring project quality Quality Personnel’s Qualifications form – lists the qualifications of your• quality management team Quality Personnel’s Appointment letter– gives your quality management• team authority for ensuring project quality

Quality Training Plan – establishes your training plan for quality-related• activities Regulatory codes and standards form - lists the regulatory codes and• standards you comply with Industry standards form – outlines the industry standards you comply with• Inspection and Test Plan form– describes the inspections and tests you• conduct Selection of key suppliers and subcontractors form – explains you supplier• and subcontractor selection process Material and equipment specification form – records specifications for the• material and equipment you use Communications plan form - records a summary of monthly project status• reports

Construction Phase Submittal Documents - provide a record of how you carried out your project quality plan Inspection and Test Records – records the results from your planned• inspections and tests Nonconformance Reporting – documents any work or materials found• during inspections and tests that don’t meet (conform to) your standards Daily Construction Reporting – summarizes what happened on the job site• that day Training Records – lists training sessions that were conducted for• preventive as well as improvement purposes Quality System Audits – defines the preventive actions you take because• of your monthly project quality system audits and your annual company.wide quality system audit Document Control Records – explains the controls you use to keep your• quality system records up-to-date, accurate, and safe

The way you show your client that you have a good QA/QC program with good systems in place is by showing them your system documentation. In other words, you need to show them .a good quality control plan Get started with developing your quality control plan by documenting the quality processes .you do now Follow that up with a plan to improve upon your existing quality systems, and you'll be ready .for that government construction contract .And, don't forget... always document your quality processes

.Get Two Free Project Quality Plan Submittal Forms

About the Author - Ed Caldeira is founder of Caldeira Quality, specializing in First Time Quality construction quality programs and FTQ360 performance .management software. He can be reached at www.FirstTimeQuality.com Comments Click here to read/write comments 0 Tags: quality control, quality assurance, quality plan, government, submittals

Steps: Understanding Construction Quality Control Plan Requirements 4 Posted by Ed Caldeira on Sun, Jan 10, 2010 @ 10:08 PM Email Article |

Twitter |

Facebook |

LinkedIn |

StumbleUpon

This is the first in a series designed for general contractors to take some of the frustration out of understanding your client’s quality assurance and quality control plan .requirements It's also intended to help you develop a quality plan to meet .those requirements :Here are a few steps to follow Identify all the quality requirements within your .1 contract There's usually a quality assurance specifications section in your contract. That's where most of your quality .requirements will be Also check other sections for “quality assurance” and “submittals” subheadings where your client may list additional requirements. These requirements will be a combination of project-specific, client-specific and industry .standard requirements Know which construction industry quality standards you need to address

.2

:There are two widely used construction industry standards for quality FTA Quality Assurance and Quality Control Guidelines – used for most• state and city transportation projects USACE/NAVFAC/AFCESA/NASA Quality Control Requirements – used for• government and military construction projects

You can a copy of the USACE and FTA standards from our website by clicking on .the links above .Both of these construction industry standards are variations of ISO9000 quality standards Make an action items list of your requirements

.3

Since most contract specifications are in paragraph or narrative form, it will be helpful to .break the requirements down into an actionable list. Hint: Just look for the action verbs

Below, I’ve highlighted action items by their action verb in FTA industry standard - Element 1: Management Responsibility Management should designate a representative who shall have defined ...“ authority and responsibility for ensuring that the quality policy is implemented and maintained. Management should also identify those persons responsible for the quality assurance function and should define in writing the ”.responsibility, authority, and interrelation of those persons Create a Cross-Reference Table or Checklist for Each Requirement

.4

Next, cross-reference the sections of your quality plan that meet your contract requirements .with the requirements you've identified This will help you keep all of your contract requirements straight and make sure you address .each one in your quality plan submittal To see a cross-reference tables of how our quality plans conform to the FTA and USACE :requirements, click on the following links Cross-Reference Table - FTA Quality Assurance Quality Control Guidelines Cross-Reference Table - USACE Quality Control Requirements For some more examples of quality manual, project plan and SOPs that meet contract .requirements, look at the Table of Contents and some sample pages from our quality plans Need help figuring out your contract requirements or developing ?your construction quality plan submittal . me for a free contract specifications review Comments Click here to read/write comments 0 Tags: specifications, quality control, quality plan

Things Construction Superintendents Can Do Reduce Punch Lists 5 Posted by Ed Caldeira on Wed, Dec 09, 2009 @ 09:06 PM Email Article |

Twitter |

Facebook |

LinkedIn |

There is no reason for your superintendents to continue to act as the subcontractors’ quality control inspector and creator of .punchlists Here are 5 things superintendents can do to reduce punchlists and .improve subcontractor quality performance Communicate Expectations #1 Superintendents that set high expectations for first time quality ON THEIR JOBSITE get the best performance from their .subcontractors Successful superintendents constantly reinforce their quality standards during production meetings and conversations. They make it clear, “Deliver 100% first time quality – don’t depend on ”!me to create your punch lists

StumbleUpon

Recognize Positive Behaviors #2 Everyone appreciates a bit of positive recognition. Subcontractors are no different. Even though you pay them to do a quality job, subcontractors will go the extra mile if they think .you appreciate their extra effort For other subcontractors whose performance varies, catch them when they do well and use .the opportunity to recognize them. , behaviors that are recognized get repeated Mentor and Teach #3 Teach your subcontractor to inspect their own work and punch it out before calling you to inspect. Ask the subcontractor to be with you while you do your inspection. The result will .surely be a reduced number of punch items The Last Resort #4 If communicating expectations, and recognizing efforts, coupled with guided improvement does not work, ask the owner for an action plan that will address the issue of repeated punch .items .Follow-up diligently and adjust the plan until the issues are resolved Measure Success #5 Make your team’s progress come alive. Use inspection scores or punch item count data to .track overall progress. Share it with your subcontractors The best superintendents go on to ask their subcontractors, “how good can we get?” and .involve them in developing a plan to make it happen In Conclusion Field superintendents that follow this proactive partnering approach will see positive results. .In other words, punch lists will be shorter, and you will have fewer problems Just make it clear that delivering 100% complete first time quality work -- without depending .on superintendents for punchlists is your subcontractor’s responsibility Comments Click here to read/write comments 0 Tags: building, construction, best-practices, quality control, quality assurance, subcontractor performance

Measuring Construction Quality Using Inspection Forms Posted by Ed Caldeira on Wed, Dec 09, 2009 @ 08:20 AM Email Article |

Twitter |

Facebook |

LinkedIn |

StumbleUpon

Quality is subjective. That's why it's important that everyone in your .organization use the same guidelines for measuring it When doing an inspection, I suggest you measure the level of avoidable problems you encounter and rate them using a rating scale :of 1 to 5 Perfect, no problems, 100% = 5 Very good, 1-2 minor problems = 4 Good, 3-5 minor problems = 3 Poor, 6+ minor problems, hotspot or a major problem = 2 Very poor, excessive problems = 1 Use your First Time Quality Inspection Forms to record your ratings and make sure to .include notes for any measurements under a 5 Adding notes and comments is a good way to give to the subcontractor or crew .whose work you are measuring Constructive will encourage subcontractors and crews to make improvements to their work, while positive for a job well done will encourage more of the same top .quality work :Comments might include ",Overspray on floors" ",Outlets covered by drywall" ".Concrete not level" ",!Great Job" ",No Problems" Strongly encourage your superintendents to give accurate quality measurements. Afer all, it .will be difficult to measure improvements if superintendents give inflated scores Make sure everyone knows that the purpose of measuring is to gauge the current level of .quality and to work together towards improving it Standard operating procedures are written instructions that explain the work steps you use to .carrying out your construction quality methods and policies I’m going to explain how to write standard operating procedures for your construction quality .plan. But, first, let me explain why you should have them Why you need SOPs While your construction QA/QC manual describes your quality approach, your SOPs are the .instruction sheets that provide the additional and much needed detail Here’s an example. Say you have a policy for handling nonconformances — and you should .if you’re following quality best practices :In your quality manual, you describe your nonconformance policy by saying Should a nonconformance be identified by an inspection, there is a systematic method to “ ”.control the item to prevent inadvertent coverup

That’s just a basic policy overview; your quality manual will cover the topic at length, but .you get the idea

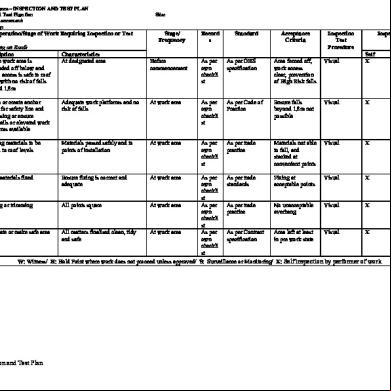

So, when your inspector identifies a nonconformance, what work steps will he or she follow to prevent an inadvertent cover-up? Will your inspector use a tag, ?warning tape, or both And, how do you know that your nonconformance policy was followed? Moreover, how do ?your records help you prove it in court if you’re involved in defect litigation .That’s where your standard operating procedures come in Format for Writing Standard Operating Procedures .SOPs contain specific information and follow a generally accepted format In the header portion, you’ll identify the section in your QA/QC manual where you’ve .described this particular quality policy Next, to prevent old versions from mistakenly being used, you’ll list the version date. Then, .you’ll add the approval date and who approved the procedure :For the main body of the SOP, you’ll include the following Purpose • Scope • (Responsible Person(s • References • Procedure •

Click on the thumbnail to enlarge the example of an SOP for :construction nonconformance reporting Notice how the body of the procedure has numbered steps that describe the work process .step-by-step ?How much detail should you add A general guideline is to keep the procedure as simple as possible, but not so simple that the .lack of details could adversely affect quality I have seen many SOPs that fail to find the right balance between completeness and simplicity. Too simple and you do not achieve your goal for controlling a quality process. Too complex and you cause unnecessary work for yourself (the procedure writer) as well as .the people responsible for carrying out the work

Multiply the efficiency by the number of procedures and the balance you find can determine .the success of your quality system If you need help developing your construction quality plan SOPs, our personalized quality plan template packages come with a complete library of standard operating procedures and .forms. a sample or us for details

Construction Quality Plan Offerings What's included (Click on the (links for more information

Bid Plans

Submittal-Ready Quality Plan Templates

Custom Quality Plans

Personalization includes your company name, project and workrelated information Money-Back Guarantee 100% Compliance with USACE, NavFac, FTA-DOT, TSA, DOE, DoD or ISO 9000 Requirements Comprehensive Quality Manual see Table of Contents Project Quality Plan - see Table of Contents Library of Submittal Forms Standard Operating Procedures see Table of Contents hour phone 1/2 consultation Customization for complex or nonstandard specifications

Available

Submittal Acceptance Guarantee Submittal Preparation

Available

Quality Plan Template Personalization :Your template will include your information from the following areas Company Name• Company Logo• Project Name• # Contract• Project Quality Personnel Names

To be included on your organization chart, appointment letters, and various QC forms .throughout your project plan Quality Manager• Director of Quality• Project Manager• Design Manager• Superintendent• President• Scopes of Work Your standard construction tasks or features of work• Standards and Qualifications Your industry standards• Required licenses for both your company and qualified personnel•

Learn More We've developed a set of templates to comply with the USACE-Navfac requirements :including A Project Quality Plan, Quality Manual, Procedures & Submittal Forms• USACE-Navfac Compliance• Personalized, easy to edit, and reusable in MS Word format• (Expert advice and (web/phone review meeting included• Satisfaction Money-Back Guarantee 100%•

USACE-Navfac QC Plan Sample Pages your 20 page sampling from selected sections of our USACE-Navfac Quality Plan .Templates We'll prepare a template to meet your needs and personalize it with your company, project .and work-related information Submittal-Ready USACE-Navfac Templates and Custom Quality Plans :include A Project Quality Plan, Quality Manual, Procedures & Submittal Forms•

USACE-Navfac Compliance• Personalized, easy to edit, and reusable in MS Word format• (Expert advice and (web/phone review meeting included• Satisfaction Money-Back Guarantee 100%•

Don't want to the sample, us at 410-451-8006 and we'll tell you everything .you need to know

Quality Plan Sample Pages

. your 25 page sampling from selected sections of our comprehensive templates We'll prepare a template to meet your needs and personalize it with your company, project .and work-related information :Submittal-Ready Templates and Custom Quality Plans include A Project Quality Plan, Quality Manual, Procedures & Submittal Forms• USACE, NAVFAC, FTA-DOT, TSA, DOE, ISNetworld, or ISO 9000 compliance• Personalized, easy to edit, and reusable in MS Word format• (Expert advice and (web/phone review meeting included• Satisfaction Money-Back Guarantee 100%•

Construction QA/QC Plans for Bids Good for when you need an overview of your QA/QC plan for a bid and for a simple project .that doesn't require a more comprehensive quality plan This abbreviated plan is 5-6 pages long. It's a quality system framework that will describe :your company's QA/QC philosophy for the following areas Project Quality Management• Organization Quality Management• Documented Standards and Specifications• Formal Qualifications of Employees• Formal Qualifications of Subcontractors and Suppliers• Documented Field Inspections• Control and Prevention of Nonconformances• Cross-Reference Table for compliance with USACE, NAVFAC, FTA-DOT,• TSA, DOE, and ISO 9000 when applicable

It also includes a table of contents from our more comprehensive quality plan so you can .show your clients what your complete quality plan will include