Internship Report, Etihad Sugar Mills Limted, Ryk 64d47

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

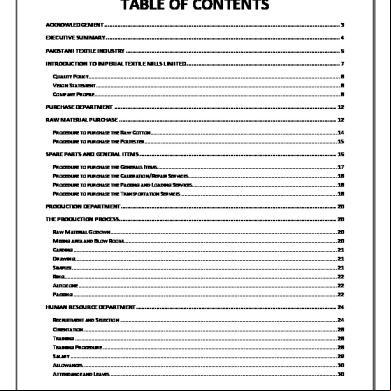

Overview 3e4r5l

& View Internship Report, Etihad Sugar Mills Limted, Ryk as PDF for free.

More details w3441

- Words: 2,934

- Pages: 13

Internship Report Muhammad Usman Habib (11053123-052)

Internship at Etihad Sugar Mills Limited. National Highway (N-5), Karamabad, District Rahim Yar Khan

Submitted by:

Supervised by:

Muhammad Usman Habib

Muhammad Nadeem (Chief Chemist)

Roll # 11053123-052

M. Zulfiqar (Deputy Chief Chemist)

University of Gujrat, Gujrat.

Engr. Zia-ul-Haq (Shift Chemist)

From 4th July 2014 To 17th July 2014 University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Dedication I dedicate this effort to my Parents, Teachers & Learned Chemists of ESML Who guide & Encourage me during the

Preparation of this report

And I want to say

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

ACKNOWLEDGEMENT All the thanks and praises for Allah who given guidance and wisdom to mankind and enabled me to complete this task. I am very thankful to all my Supervisors i.e. Mr. Muhammad Nadeem (Chief Chemist), Muhammad Zulfiqar (Deputy Chief Chemist), Engr. Zia-ul-Haq (Shift Chemist), Engr. Muhammad Shahzad and Muhammad Nazir, who helped me a lot to produce this report. I am thankful to my department who accepted my request to do internship in Etihad Sugar Mills Limited, Rahim Yar Khan. I am also grateful to all employees of the Etihad Sugar Mills Limited who guided me during the course of internship. The behavior of all the department supervisors is kind enough to me because they gave a lot of time to guide me the mechanism of Chemical Department in which I worked. I am also thankful to the Management of Etihad Sugar Mills Limited, Karamabad, Rahim Yar Khan, who gave me all the valuable and opportunities to complete Internship program and compile this report.

Muhammad Usman Habib

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Introduction to Sugar and Sugar Industry: The word sugar originates from the Sanskrit word sharkara which means sugar. It may also be traced through all the Aryan languages, as schaker in Persian, sukkar in Arabic, sincer in Assyrian, zucchero in Italian, sucre in French, zucher in German, saccharum in Latin and ozucarin Spanish etc stand as Testimony for its origin from sharkara. Sugar is a major form of carbohydrates and is found probably in all green plants. It occurs in significant amounts in most fruits and vegetables. There are three main simple sugars Sucrose, Fructose and Glucose. Sucrose is in fact a combination of fructose and glucose and the body quickly breaks down into these separate substances. All energy stored in food is derived originally from the sun and it is made by green plant life. The sun's energy acts upon the green chemical "chlorophyll" in the leaves of plants to produce sugars and starches from the carbon-dioxide in the atmosphere and the water from the roots by a process known as Photosynthesis. These carbohydrates (starches and sugar) acts as a plants food and energy supply. The energy need of human body is largely dependent on the carbohydrates that are derived from plants. The sugar is one of the essential commodities of the life which plays very important role in the dietary of human beings as it quickly raises the level of glucose in the blood. The sugar can be produced by many of the sources, but two are the main sources for production of sugar in Pakistan i.e. Sugarcane and Sugar Beet. The other sources are Maple, Palm, Coconut and Apple, but these sources are costly and their production is in negligible quantities. But, the main crop which is being used for production of Sugar all over the world is Sugarcane. In a nut shell, the process for sugarcane refining is carried out in following steps

Pressing of sugarcane to extract the juice.

Boiling the juice until it begins to thicken and sugar begins to crystallize.

Spinning the crystals in a centrifuge to remove the syrup, producing raw sugar.

Refining the raw sugar by washing and filtering to remove remaining non-sugar ingredients and color.

Crystallizing, drying and packaging the refined sugar.

For the sugar industry, capacity utilization is conceptually different from that applicable to industries in general. It depends on three crucial factors the actual number of ton of sugarcane crushed in a day, the recovery rate which generally depends on the quality of the cane and actual length of the crushing season.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

In Pakistan, the sugar industry possesses the organized and unorganized players. The unorganized players mainly produce Gur and Shakkar, the less refined forms of sugar and the organized players are Sugar Mills owners. In the world, the Brazil is a country that is largest producer of sugarcane as well as Refined Sugar.

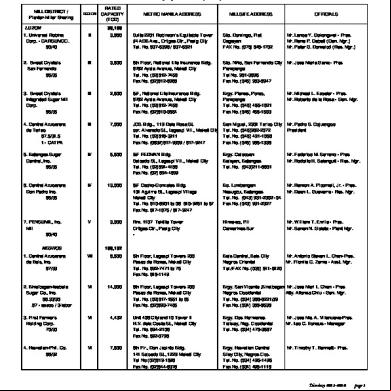

Main Competitors: According to Pakistan Sugar Mills Association (PSMA), there are 78 Sugar Mills in Pakistan (39 in Punjab, 32 in Sindh and 7 in NWFP). Although, 78 out of these 77 are the competitors for Etihad Sugar Mills Limited, but the most competition is lying in following nearest sugar mills:1.

JDW Sugar Mills Limited, Sadiqabad

2.

JDW Sugar Mills Limited (Unit-II), Sadiqabad

3.

RYK Mills Limited, Liaqatpur

4.

Hamza Sugar Mills Limited, Khanpur

5.

Ghotki Sugar Mills Limited, Ghotki

6.

SGM Sugar Mills Limited, Ghotki

7.

Ashraf Sugar Mills Limited, Bahawalpur

Introduction to Organization: Etihad Sugar Mills Limited, Karamabad, Rahim Yar Khan was established on 1 st June, 2006 as a Private Limited Company and is listed at Lahore Stock Exchange of Pakistan. The company is engaged in the manufacturing and sale of sugar. The company’s site is situated at Mouza Karamabad Abad, Tehsil & District Rahim Yar Khan. Its head office is situated at Lahore. The mills covered total 100 Acres out of which 74 acres is for Mills plant, yard and offices, rest of the 26 acres are for colony, quarters, grounds, hostels and Masjid.

Organization’s Products: The company’s main product is White Refined Sugar, however it has also following by products:-

1.

Bagasse

2.

Molasses

3.

Press Mud

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Organization’s Processing Departments: There are four main departments/houses in this Sugar mill but our main concern with Chemical department / Boiling House. 1. Mill House 2. Boiler House 3. Power House 4. Boiling House

Chemical Department: DGM (Production) is head of the department and he is responsible for all boiling / chemical procedures apply on the sugarcane juice. The chemical department is totally responsible for production of sugar from juice. They apply methods, heat and some chemicals to transform the sugar from sugarcane. The complete process of production of sugar is as under:-

Processing of sugar cane for manufacturing of white sugar in ETIHAD SUGAR MILLS:-

MILL HOUSE:

CANE TIPPERS: Loaded cane trolleys are tilted by hydraulic jacks into feeding tables. Feeding tables are 4 in Nos. and these tables transfer cane into carrier # 01. Length of the feeding table is 15.5m.

CANE CUTTERS: (03 Nos.) CANE CUTTER # 01 Motor 1000KW, Knives 40 Nos. It is driven by electric motor. It performs the duty of cane chopping and leveling. Its clearance is about 2 Ft.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

CANE CUTTER # 02 Motor 850KW, Knives 40 Nos. It cuts the cane into small pieces, its clearance is about 10” CANE CUTTER # 03 Motor 1000KW, Knives 80 Nos. It completely cuts the cane into small pieces at minimum clearance of 2”.

SHREDDER: Steam Turbine 3000KW, Swinging Hammers 88 Nos. It shreds the cane and raptures all the sugar cane cells to open position. Total No. of disc’s in this, is 23.

MILLS TENDEM: (06 Nos.) Mills tendem consists of 06 Mills driven by steam turbines having power 850KW each. Shredded cane is ed through series of 06 mills for extraction of juice. Imbibition water is sprayed on last mills for maximum extraction of juice. This extracted mixed juice is filtered through rotary screens. Here, the pH of the juice is 5.6. Screened juice is sent to Boiling House for processing and bagasse from last mills is sent to boilers as fuel.

BOILER HOUSE: BOILERS: (04 NOS.) Main object of boiler is to produce steam at pressure 23Kg/cm2 and temperature of 350ºC. Bagasse is fed to boilers, furnaces where it is burnt and produces steam. Surplus bagasse is sent to bagasse yard, which is sold out. In case of shortage of bagasse, furnace oil is burnt as standby fuel. 03, Boilers (Capacity 80ton/hour) 01, Boiler (Capacity 40ton/hour)

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

POWER HOUSE:

STEAM TURBINE GENERATORS: (03 Nos.) Steam Turbine Generators 03 Nos., Steam produced by boilers is used for the operation of steam turbine generators. 16MW power is used for the operation of all electric motors installed in Mills. 02, Steam Turbine Generators (Capacity 5MW) 01, Steam Turbine Generators (Capacity 6MW)

BOILING HOUSE: JUICE HEATERS: 1. Condensate & Primary Juice Heaters: (04 Nos.) (H.S. 350m2 each) Screened juice is ed through juice heaters in series and temperature is raised up to 65ºC by using steam / vapors. There are 3 Primary juice heaters and 1 condensate heater. 2. Defecations Tanks: (02 Nos.) Here milk of lime (M.O.L.) is added in heated juice and after some retention time, juice is ed through secondary juice heaters. Here, the pH of the juice will increase to 7.2. 3. Secondary Juice Heaters: (05 Nos.) Limed mixed juice is ed through secondary juice heaters and temperature is raised up to 105ºC for further treatment in juice clarifiers. 03, Secondary Juice Heaters, (H.S. 350m2 each) 02, Secondary Juice Heaters, (H.S. 400m2 each) 4. Juice Clarifier (03 Nos.) (Capacity 170m3 each) After secondary heating poly electrolyte is used before entering of juice in clarifiers it stays there for 1 to 1:30 hours to complete the reaction between M.O.L. and impurities of the juice. The impurities settle down in the clarifier.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Settling is speedy by addition of poly electrolyte. The clear juice from clarifier is decanted and ed through rotary screens. This filtered juice is sent to series of evaporators. Settled impurities (Muddy Juice) is taken out from the bottom of the clarifiers and is sent to vacuum filters for filtration.

VACUUM FILTERS: (04 Nos.) Muddy juice taken from clarifiers is mixed with Bagacillo in Mud Mixer and sent to the troughs of vacuum filters. Vacuum filter drum rotates and mud climbs over the drum. Hot water is sprayed by Nozzles on the drum. Remaining juice and washing water is sucked through tubes by vacuum. Sucked filtered juice is returned to defecation tank and mud is sent out by scrapping the mud from drums of vacuum filters. It is manure for cane growers. Filtering Area of these, are 58m2.

EVAPORATORS: (09 Nos.) Decanted juice from juice clarifier called clear juice is taken into series of evaporators. It is boiled with help of exhaust steam (obtained from turbines of mills and power house). The thick juice obtained from evaporators called syrup is fed to pans. The brix of this thick syrup is about 65-67%. 02, Evaporators, Capacity 5000m2, No. of tubes 14000 02, Evaporators, Capacity 3000m2, No. of tubes 10200 01, Evaporators, Capacity 2500m2, No. of tubes 8500 02, Evaporators, Capacity 1100m2, No. of tubes 3600 01, Evaporators, Capacity 4000m2, No. of tubes 10000 01, Evaporators, Capacity 1800m2, No. of tubes 6800 While three more Falling film evaporators are in under construction, after them, the brix of syrup would increase up to 70%. 03, Evaporators, Capacity 5000m2, No. of tubes 10000

CONDENSERS: (18 Nos.) Vapors from Evaporators and Vacuum pans are send to Condensers where these vapors are converted into Water and then this water is further send to

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Injection tanks. Total no. of condensers are 18 but management proposed one more condenser to install in the site.

COOLING TOWERS: (14 Nos.) There are 14 cooling towers that are used to low down the temperature of water which is in the injection tank. There is a fan for each cooling tower, 1450 rpm and motor that rotates it has power of 45KW.

VACUUM PANS: (FOR A, B & C MASSECUITES) 05, Batch Pan, Capacity 70Ton each, H.S. 380m2 03, Continues Pan, Capacity 68m3 each, H.S. 700m2 02, Continues Pan, Capacity 102m3 each, H.S. 948m2 The syrup is fed into pans where it is again boiled to produce mixture of crystals and molasses called Massecuite. There are 05 pans for A Massecuite, 03 pans for B Massecuite and 02 pans for C Massecuite. Massecuite which is prepared in the A-Pans, is dropped into relative crystallizers. Similarly B and C Massecuite which are prepared in relative pans, are dropped into relative crystallizers.

MASSECUITE CRYSTALLIZERS: (17 Nos.) Prepared massecuite from pans is sent into crystallizers for further crystallization by motion of massecuite by scrolls driven by gear and motor. The massecuite is transferred to centrifugal station by massecuites pumps. There are 10 crystallizers for 10 vacuum pans. 07 vertical crystallizers are also placed to cool down the Massecuite B and C before sending to centrifugal section.

CENTRIFUGES K-1100: (29 Nos.) Massecuite is ed through Centrifuges which separates crystals of sugar and molasses. First separate molasses, “A” Heavy is again boiled in B-Pans for B-Massecuite. B-Massecuite is again ed through Centrifuges for separation of sugar crystals and molasses. This obtained molasses called B-Heavy is again boiled in C-Pans for C-Massecuite. C-Massecuite is again ed through Centrifuges for separation of sugar crystals and final molasses. This final molasses is sent out in molasses ponds for sale as a raw material for distilleries and sugar crystals separated from B & C Massecuite are used as seed in pans and sugar crystals obtained from A-Massecuite are taken into sugar remelter.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

13, Centrifuges for A-Heavy 07, Centrifuges for B-Heavy 03, Centrifuges for C-Heavy (Double Cure) 06, Centrifuges for C-Heavy

SUGAR REMELTER: (Capacity 30ton/hour.) Here sugar is remelted by using hot water and steam with 02 Nos. stirrers. This remelt is called raw liquor. This raw liquor is sent to Talo station.

TALO CLARIFIER: Raw liquor before taking into clarifier is treated with phosphoric acid, color quest, lime sucrate and Talo float. These chemicals are used to remove remaining impurities in sugar. In Talo clarifier with some retention time these impurities float up in clarifier and clear liquor is taken out from bottom side. Floated impurities called scum is removed from clarifier by scraper driven by gear and motor. The clear (fine) liquor is sent to pan station. The removed serum is sent back to defecation tank.

REFINE PANS: (06 Nos.) (Capacity 70 ton each) Fine liquor is taken into pan. It is boiled for some time to get required brix for crystallization. Very small fine crystals seed (obtained from the sugar grader not bagable) is fed into it. Required crystal size is obtained by further boiling called the refine massecuite. Prepared massecuite is dropped into crystallizers. From which it is pumped to refine Centrifuges for separation of crystals and molasses.

REFINE CENTRIFUGES TSK (05 Nos.) Refine Centrifuges are automatic batch type Centrifuges which separates fine sugar crystals and molasses. This molasses is reused for making more refine massecuites. Fine crystals (Sugar) is dropped into hopper which shift it to sugar dryers.

SUGAR DRYER: (03 Nos.) While sugar es through these dryers, remaining moisture is removed by blowing hot air through them. Hot air is ed by fans called blowers fitted for this purpose.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

SUGAR ELEVATORS: (03 Nos.) Elevators lift the dried sugar through buckets at some height and feed to sugar grader for its size wise separation.

SUGAR GRADERS: (04 Nos.) Here, sugar travels over graders moving to and fro. At sugar grader frames of screens of different mesh are fitted. Through which fine, very small crystals (seed) and extra-large size crystals are separated and sugar crystals of required size drop into sugar bins.

SUGAR BINS (03 Nos.) Sugar bins are used for holding bag able sugar.

AUTOMATIC WEIGHING MACHINE (02 Nos.) Automatic weighing machines are installed under sugar bins, machine drops sugar after 50Kgs accurate weight into poly propylene bag attached under it manually. The weight of these bags is re-checked by electronic weighing scales kept under. After that the bags sewing is done by sewing machines (02 Nos.) fitted over wooden conveyors. These sewed bags are sent to sugar go down where it is stacked up to the height of 50 layers by sugar stacker.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Future Prospects of the Organization: Etihad Sugar Mills Limited focuses on the future growth of sugar mills in sugar industry, which they are planning to start corporate farming at about 1000 acres initially.

Vision: To be the lead in sugar industry by building the company’s image through quality improvement, competitive prices and meeting social obligations.

Mission: 1.

To endeavor to be the market leader by offer high quality sugar to our valuable customers at competitive prices.

2.

To continue improving operating performance and profitability thereby ensuring growth for the company.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship at Etihad Sugar Mills Limited. National Highway (N-5), Karamabad, District Rahim Yar Khan

Submitted by:

Supervised by:

Muhammad Usman Habib

Muhammad Nadeem (Chief Chemist)

Roll # 11053123-052

M. Zulfiqar (Deputy Chief Chemist)

University of Gujrat, Gujrat.

Engr. Zia-ul-Haq (Shift Chemist)

From 4th July 2014 To 17th July 2014 University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Dedication I dedicate this effort to my Parents, Teachers & Learned Chemists of ESML Who guide & Encourage me during the

Preparation of this report

And I want to say

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

ACKNOWLEDGEMENT All the thanks and praises for Allah who given guidance and wisdom to mankind and enabled me to complete this task. I am very thankful to all my Supervisors i.e. Mr. Muhammad Nadeem (Chief Chemist), Muhammad Zulfiqar (Deputy Chief Chemist), Engr. Zia-ul-Haq (Shift Chemist), Engr. Muhammad Shahzad and Muhammad Nazir, who helped me a lot to produce this report. I am thankful to my department who accepted my request to do internship in Etihad Sugar Mills Limited, Rahim Yar Khan. I am also grateful to all employees of the Etihad Sugar Mills Limited who guided me during the course of internship. The behavior of all the department supervisors is kind enough to me because they gave a lot of time to guide me the mechanism of Chemical Department in which I worked. I am also thankful to the Management of Etihad Sugar Mills Limited, Karamabad, Rahim Yar Khan, who gave me all the valuable and opportunities to complete Internship program and compile this report.

Muhammad Usman Habib

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Introduction to Sugar and Sugar Industry: The word sugar originates from the Sanskrit word sharkara which means sugar. It may also be traced through all the Aryan languages, as schaker in Persian, sukkar in Arabic, sincer in Assyrian, zucchero in Italian, sucre in French, zucher in German, saccharum in Latin and ozucarin Spanish etc stand as Testimony for its origin from sharkara. Sugar is a major form of carbohydrates and is found probably in all green plants. It occurs in significant amounts in most fruits and vegetables. There are three main simple sugars Sucrose, Fructose and Glucose. Sucrose is in fact a combination of fructose and glucose and the body quickly breaks down into these separate substances. All energy stored in food is derived originally from the sun and it is made by green plant life. The sun's energy acts upon the green chemical "chlorophyll" in the leaves of plants to produce sugars and starches from the carbon-dioxide in the atmosphere and the water from the roots by a process known as Photosynthesis. These carbohydrates (starches and sugar) acts as a plants food and energy supply. The energy need of human body is largely dependent on the carbohydrates that are derived from plants. The sugar is one of the essential commodities of the life which plays very important role in the dietary of human beings as it quickly raises the level of glucose in the blood. The sugar can be produced by many of the sources, but two are the main sources for production of sugar in Pakistan i.e. Sugarcane and Sugar Beet. The other sources are Maple, Palm, Coconut and Apple, but these sources are costly and their production is in negligible quantities. But, the main crop which is being used for production of Sugar all over the world is Sugarcane. In a nut shell, the process for sugarcane refining is carried out in following steps

Pressing of sugarcane to extract the juice.

Boiling the juice until it begins to thicken and sugar begins to crystallize.

Spinning the crystals in a centrifuge to remove the syrup, producing raw sugar.

Refining the raw sugar by washing and filtering to remove remaining non-sugar ingredients and color.

Crystallizing, drying and packaging the refined sugar.

For the sugar industry, capacity utilization is conceptually different from that applicable to industries in general. It depends on three crucial factors the actual number of ton of sugarcane crushed in a day, the recovery rate which generally depends on the quality of the cane and actual length of the crushing season.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

In Pakistan, the sugar industry possesses the organized and unorganized players. The unorganized players mainly produce Gur and Shakkar, the less refined forms of sugar and the organized players are Sugar Mills owners. In the world, the Brazil is a country that is largest producer of sugarcane as well as Refined Sugar.

Main Competitors: According to Pakistan Sugar Mills Association (PSMA), there are 78 Sugar Mills in Pakistan (39 in Punjab, 32 in Sindh and 7 in NWFP). Although, 78 out of these 77 are the competitors for Etihad Sugar Mills Limited, but the most competition is lying in following nearest sugar mills:1.

JDW Sugar Mills Limited, Sadiqabad

2.

JDW Sugar Mills Limited (Unit-II), Sadiqabad

3.

RYK Mills Limited, Liaqatpur

4.

Hamza Sugar Mills Limited, Khanpur

5.

Ghotki Sugar Mills Limited, Ghotki

6.

SGM Sugar Mills Limited, Ghotki

7.

Ashraf Sugar Mills Limited, Bahawalpur

Introduction to Organization: Etihad Sugar Mills Limited, Karamabad, Rahim Yar Khan was established on 1 st June, 2006 as a Private Limited Company and is listed at Lahore Stock Exchange of Pakistan. The company is engaged in the manufacturing and sale of sugar. The company’s site is situated at Mouza Karamabad Abad, Tehsil & District Rahim Yar Khan. Its head office is situated at Lahore. The mills covered total 100 Acres out of which 74 acres is for Mills plant, yard and offices, rest of the 26 acres are for colony, quarters, grounds, hostels and Masjid.

Organization’s Products: The company’s main product is White Refined Sugar, however it has also following by products:-

1.

Bagasse

2.

Molasses

3.

Press Mud

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Organization’s Processing Departments: There are four main departments/houses in this Sugar mill but our main concern with Chemical department / Boiling House. 1. Mill House 2. Boiler House 3. Power House 4. Boiling House

Chemical Department: DGM (Production) is head of the department and he is responsible for all boiling / chemical procedures apply on the sugarcane juice. The chemical department is totally responsible for production of sugar from juice. They apply methods, heat and some chemicals to transform the sugar from sugarcane. The complete process of production of sugar is as under:-

Processing of sugar cane for manufacturing of white sugar in ETIHAD SUGAR MILLS:-

MILL HOUSE:

CANE TIPPERS: Loaded cane trolleys are tilted by hydraulic jacks into feeding tables. Feeding tables are 4 in Nos. and these tables transfer cane into carrier # 01. Length of the feeding table is 15.5m.

CANE CUTTERS: (03 Nos.) CANE CUTTER # 01 Motor 1000KW, Knives 40 Nos. It is driven by electric motor. It performs the duty of cane chopping and leveling. Its clearance is about 2 Ft.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

CANE CUTTER # 02 Motor 850KW, Knives 40 Nos. It cuts the cane into small pieces, its clearance is about 10” CANE CUTTER # 03 Motor 1000KW, Knives 80 Nos. It completely cuts the cane into small pieces at minimum clearance of 2”.

SHREDDER: Steam Turbine 3000KW, Swinging Hammers 88 Nos. It shreds the cane and raptures all the sugar cane cells to open position. Total No. of disc’s in this, is 23.

MILLS TENDEM: (06 Nos.) Mills tendem consists of 06 Mills driven by steam turbines having power 850KW each. Shredded cane is ed through series of 06 mills for extraction of juice. Imbibition water is sprayed on last mills for maximum extraction of juice. This extracted mixed juice is filtered through rotary screens. Here, the pH of the juice is 5.6. Screened juice is sent to Boiling House for processing and bagasse from last mills is sent to boilers as fuel.

BOILER HOUSE: BOILERS: (04 NOS.) Main object of boiler is to produce steam at pressure 23Kg/cm2 and temperature of 350ºC. Bagasse is fed to boilers, furnaces where it is burnt and produces steam. Surplus bagasse is sent to bagasse yard, which is sold out. In case of shortage of bagasse, furnace oil is burnt as standby fuel. 03, Boilers (Capacity 80ton/hour) 01, Boiler (Capacity 40ton/hour)

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

POWER HOUSE:

STEAM TURBINE GENERATORS: (03 Nos.) Steam Turbine Generators 03 Nos., Steam produced by boilers is used for the operation of steam turbine generators. 16MW power is used for the operation of all electric motors installed in Mills. 02, Steam Turbine Generators (Capacity 5MW) 01, Steam Turbine Generators (Capacity 6MW)

BOILING HOUSE: JUICE HEATERS: 1. Condensate & Primary Juice Heaters: (04 Nos.) (H.S. 350m2 each) Screened juice is ed through juice heaters in series and temperature is raised up to 65ºC by using steam / vapors. There are 3 Primary juice heaters and 1 condensate heater. 2. Defecations Tanks: (02 Nos.) Here milk of lime (M.O.L.) is added in heated juice and after some retention time, juice is ed through secondary juice heaters. Here, the pH of the juice will increase to 7.2. 3. Secondary Juice Heaters: (05 Nos.) Limed mixed juice is ed through secondary juice heaters and temperature is raised up to 105ºC for further treatment in juice clarifiers. 03, Secondary Juice Heaters, (H.S. 350m2 each) 02, Secondary Juice Heaters, (H.S. 400m2 each) 4. Juice Clarifier (03 Nos.) (Capacity 170m3 each) After secondary heating poly electrolyte is used before entering of juice in clarifiers it stays there for 1 to 1:30 hours to complete the reaction between M.O.L. and impurities of the juice. The impurities settle down in the clarifier.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Settling is speedy by addition of poly electrolyte. The clear juice from clarifier is decanted and ed through rotary screens. This filtered juice is sent to series of evaporators. Settled impurities (Muddy Juice) is taken out from the bottom of the clarifiers and is sent to vacuum filters for filtration.

VACUUM FILTERS: (04 Nos.) Muddy juice taken from clarifiers is mixed with Bagacillo in Mud Mixer and sent to the troughs of vacuum filters. Vacuum filter drum rotates and mud climbs over the drum. Hot water is sprayed by Nozzles on the drum. Remaining juice and washing water is sucked through tubes by vacuum. Sucked filtered juice is returned to defecation tank and mud is sent out by scrapping the mud from drums of vacuum filters. It is manure for cane growers. Filtering Area of these, are 58m2.

EVAPORATORS: (09 Nos.) Decanted juice from juice clarifier called clear juice is taken into series of evaporators. It is boiled with help of exhaust steam (obtained from turbines of mills and power house). The thick juice obtained from evaporators called syrup is fed to pans. The brix of this thick syrup is about 65-67%. 02, Evaporators, Capacity 5000m2, No. of tubes 14000 02, Evaporators, Capacity 3000m2, No. of tubes 10200 01, Evaporators, Capacity 2500m2, No. of tubes 8500 02, Evaporators, Capacity 1100m2, No. of tubes 3600 01, Evaporators, Capacity 4000m2, No. of tubes 10000 01, Evaporators, Capacity 1800m2, No. of tubes 6800 While three more Falling film evaporators are in under construction, after them, the brix of syrup would increase up to 70%. 03, Evaporators, Capacity 5000m2, No. of tubes 10000

CONDENSERS: (18 Nos.) Vapors from Evaporators and Vacuum pans are send to Condensers where these vapors are converted into Water and then this water is further send to

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Injection tanks. Total no. of condensers are 18 but management proposed one more condenser to install in the site.

COOLING TOWERS: (14 Nos.) There are 14 cooling towers that are used to low down the temperature of water which is in the injection tank. There is a fan for each cooling tower, 1450 rpm and motor that rotates it has power of 45KW.

VACUUM PANS: (FOR A, B & C MASSECUITES) 05, Batch Pan, Capacity 70Ton each, H.S. 380m2 03, Continues Pan, Capacity 68m3 each, H.S. 700m2 02, Continues Pan, Capacity 102m3 each, H.S. 948m2 The syrup is fed into pans where it is again boiled to produce mixture of crystals and molasses called Massecuite. There are 05 pans for A Massecuite, 03 pans for B Massecuite and 02 pans for C Massecuite. Massecuite which is prepared in the A-Pans, is dropped into relative crystallizers. Similarly B and C Massecuite which are prepared in relative pans, are dropped into relative crystallizers.

MASSECUITE CRYSTALLIZERS: (17 Nos.) Prepared massecuite from pans is sent into crystallizers for further crystallization by motion of massecuite by scrolls driven by gear and motor. The massecuite is transferred to centrifugal station by massecuites pumps. There are 10 crystallizers for 10 vacuum pans. 07 vertical crystallizers are also placed to cool down the Massecuite B and C before sending to centrifugal section.

CENTRIFUGES K-1100: (29 Nos.) Massecuite is ed through Centrifuges which separates crystals of sugar and molasses. First separate molasses, “A” Heavy is again boiled in B-Pans for B-Massecuite. B-Massecuite is again ed through Centrifuges for separation of sugar crystals and molasses. This obtained molasses called B-Heavy is again boiled in C-Pans for C-Massecuite. C-Massecuite is again ed through Centrifuges for separation of sugar crystals and final molasses. This final molasses is sent out in molasses ponds for sale as a raw material for distilleries and sugar crystals separated from B & C Massecuite are used as seed in pans and sugar crystals obtained from A-Massecuite are taken into sugar remelter.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

13, Centrifuges for A-Heavy 07, Centrifuges for B-Heavy 03, Centrifuges for C-Heavy (Double Cure) 06, Centrifuges for C-Heavy

SUGAR REMELTER: (Capacity 30ton/hour.) Here sugar is remelted by using hot water and steam with 02 Nos. stirrers. This remelt is called raw liquor. This raw liquor is sent to Talo station.

TALO CLARIFIER: Raw liquor before taking into clarifier is treated with phosphoric acid, color quest, lime sucrate and Talo float. These chemicals are used to remove remaining impurities in sugar. In Talo clarifier with some retention time these impurities float up in clarifier and clear liquor is taken out from bottom side. Floated impurities called scum is removed from clarifier by scraper driven by gear and motor. The clear (fine) liquor is sent to pan station. The removed serum is sent back to defecation tank.

REFINE PANS: (06 Nos.) (Capacity 70 ton each) Fine liquor is taken into pan. It is boiled for some time to get required brix for crystallization. Very small fine crystals seed (obtained from the sugar grader not bagable) is fed into it. Required crystal size is obtained by further boiling called the refine massecuite. Prepared massecuite is dropped into crystallizers. From which it is pumped to refine Centrifuges for separation of crystals and molasses.

REFINE CENTRIFUGES TSK (05 Nos.) Refine Centrifuges are automatic batch type Centrifuges which separates fine sugar crystals and molasses. This molasses is reused for making more refine massecuites. Fine crystals (Sugar) is dropped into hopper which shift it to sugar dryers.

SUGAR DRYER: (03 Nos.) While sugar es through these dryers, remaining moisture is removed by blowing hot air through them. Hot air is ed by fans called blowers fitted for this purpose.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

SUGAR ELEVATORS: (03 Nos.) Elevators lift the dried sugar through buckets at some height and feed to sugar grader for its size wise separation.

SUGAR GRADERS: (04 Nos.) Here, sugar travels over graders moving to and fro. At sugar grader frames of screens of different mesh are fitted. Through which fine, very small crystals (seed) and extra-large size crystals are separated and sugar crystals of required size drop into sugar bins.

SUGAR BINS (03 Nos.) Sugar bins are used for holding bag able sugar.

AUTOMATIC WEIGHING MACHINE (02 Nos.) Automatic weighing machines are installed under sugar bins, machine drops sugar after 50Kgs accurate weight into poly propylene bag attached under it manually. The weight of these bags is re-checked by electronic weighing scales kept under. After that the bags sewing is done by sewing machines (02 Nos.) fitted over wooden conveyors. These sewed bags are sent to sugar go down where it is stacked up to the height of 50 layers by sugar stacker.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.

Internship Report Muhammad Usman Habib (11053123-052)

Future Prospects of the Organization: Etihad Sugar Mills Limited focuses on the future growth of sugar mills in sugar industry, which they are planning to start corporate farming at about 1000 acres initially.

Vision: To be the lead in sugar industry by building the company’s image through quality improvement, competitive prices and meeting social obligations.

Mission: 1.

To endeavor to be the market leader by offer high quality sugar to our valuable customers at competitive prices.

2.

To continue improving operating performance and profitability thereby ensuring growth for the company.

University of Gujrat. Chemical Engineering Department, Hafiz Hayat Campus, Gujrat.