Lathe Machine Report 2f104y

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Lathe Machine Report as PDF for free.

More details w3441

- Words: 2,352

- Pages: 28

TITLE : PERFORM MACHINING ACCORDING TO STANDARD OPERATION PROCEDURE (MACHINE PIN)

1.0

INTRODUCTION

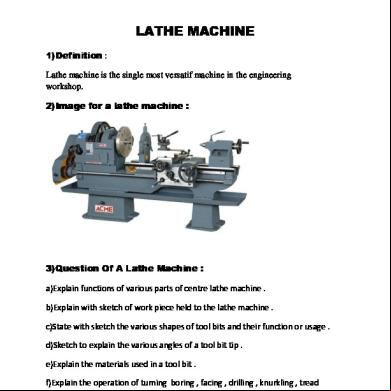

The lathe is a machine tool which held and rotates the workpiece (metal, wood and other materials) on its axis to perform various operations such as cutting, knurling, drilling and deformation with a tool bit that are applied to workpiece to create an object which has symmetry about an axis of rotation.

The basic lathe that was designed to cut cylindrical metal stock has been developed further to produce screw threads, tapered work, drilled holes, knurled surfaces and crackshafts.

Lathes are used in woodturning, metalworking, metal spinning, and glassworking. Lathes can be used to shape pottery, the most well known design being the potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce threedimensional solids of incredible complexity. The material is held in place by either one or two centers, at least one of which can be moved horizontally to accommodate varying material lengths. Examples of objects that can be produced on a lathe include candlestick holders, cue sticks, table legs, bowls, baseball bats, crankshafts and camshafts.

Lathe Machine Parts

Bed – mainly the whole machine. Carriage – an assembly that moves the tool post and cutting tool along the way. Carriage handwheel – a wheel with a handle used to move the carriage. Chuck – a clamping device for holding the workpiece in the lathe. Apron – the front part of the carriage assembly on which carriage handwheel is mounted. Cross slide - platform that moves perpendicular to the lathe axis under control of the cross slide hand wheel.

Cross slide handwheel – a wheel with handle used to move the cross slide in and out. Halfnut lever – a lever to engage the carriagewith leadscrew to move the carriage under power. Lead screw – a precision screw that runs the length of the bed and used to drive the carriage under power for turning and thread cutting operation. Tailstock – a cast iron assembly that can be slide along the ways and be locked in place. Used to hold long workpiece in place or mount a drill chuck for drilling operation. Ways - a precision ground surfaces along top of the bed on which saddle rides. the ways are precisely aligned with the centerline of the lathe.

2.0

Task Outcome

After following this workshop practical work, I am able to :

1.1 Use Vernier Caliper and steel ruler for measuring purposes. Know how to measure the exact dimension of workpiece to get the precise dimension for the project outcome. 2.1 Apply safety procedures while operating lathe machine and grinding machine. Know the way to comply with the safety procedures while operating a machine at all time. 3.1 Operate the lathe machine; adjust spindle speed and feed. Know how to determine the cutting speed according to the operations, materials and tool bits type and condition. 4.1 Cutting, drilling, parallel, stepped and taper turning, and knurling with a lathe machine. Know all the operations using lathe machine and how to execute them. 5.1 Grind tool bits according to the required angle for general purposes with a table grinding machine. Know how to grind tool bits for lathe work.

3.0

Tools Equipment

Center lathe machine

Mild steel

Tool bit holder

Cutting tool holder

Tool bit

Spanner

Allen key

Chuck lock

Ball bearing live center

Center drill

Drill chuck

Vernier Caliper

Steel Ruler

Cooler

Lubricant

4.0

Safety Precautions

There are safety precautions that must be complied with every time entering a workshop. These safety precautions are necessary to avoid accidents or unexpected and unfortunate things from happening. a. Never get into a workshop without permission. Student should not work in a workshop without the lecturer’s supervision. b. Listen and follow carefully to the instructions from the lecturer. If unsure about something, always ask the lecturer before proceeding with the activity. c. Always wears appropriate and suitable clothes during a workshop practical work. Long hair, jewelry (ring, bracelet, necklace, ect.), and loose or baggy clothing are hazardly dangerous in the workshop. Wear safety shoes whenever in a workshop. No sandals and slippers are allowed. d. Know where the emergency stop buttons are positioned in the workshop. If an accident occured at the other side of the workshop, use the emergency stop button to turn off all electrical power to machines.

e. Stay alert and proceed with caution at all times in the workshop. Notify the lecturer immediately if you notices something suspicious. f. Never fool around in the workshop. Jokes and pranks are dangerous and prohibited. g. Practical work must be personally monitored at all times. Do not wander around the workshop, or distract and interfere with other students work. h. Always wear safety goggles whenever operating a machine. Hot and sharp fragments of workpiece may be directly sent flying over to your eyes. i. Make sure all of the machines in the workshop have a good grounding before start using them. j. Report any damage to machines or equipment to the lecturer immediately as this could cause an accident. k. Report any accident or injury to the lecturer immediately, no matter how trivial it seems. Do not panic. l. Make sure to clean the machines and the space around the workplace after finished doing your work. Throw away all fragments of workpiece to the provided disposal space.

5.0 No

Procedures Description

Diagram

. (A) PREPARING WORKPIECE 1.

A cylindrical metal with the diameter of 40 mm and 83 mm long is cut out from the originally long cylindrical metal by using the horizontal band saw machine.

Horizontal band saw machine

Originally long cylindrical metal stock

83 mm long workpiece with 40 mm diameter

No

Description

Diagram

. (B) PREPARING GENERAL CUTTING TOOL BIT 1

A tool bit with the size of 5/16 inches grinded with the table grinding machine to produce a general type cutting tool bit for lathe work.

Table grinding machine

2

Grind the left side of the tool bit by facing the left side of the tool bit towards the grinding wheel at about 10° angle.

Grinding the left side relief

3

Grind the end of tool bit. Hold the tool bit angled downwards from the tip to the rear and with the tip pointing to the left at about 10° to 15° angle. Grinding the end relief

4

Lastly, grind the top surface to form the rake. Hold the piece so that the top is facing the grinding wheel at about 10° angle. Be careful not to grind down the cutting edge. Grinding the top side relief

Tool bit for general cutting purposes.

No

Description

Diagram

. (C) OPERATING

LATHE

MACHINE

(MACHINE

PROJECT) 1

The workpiece is mounted to the chuck on the lathe machine to start the lathe work.

Mount workpiece to chunk

2

Set the tool bit which has been grinded earlier using table grinding machine to the tool bit holder.

Set tool bit to tool bit holder

PIN

Adjust the tool bit holder to the cutting tool holder on the lathe machine’s tool post.

Adjust tool bit holder to cutting tool holder

Make sure that the tool bit tip is at the centre position by aligning it with tailstock center.

Aligning the tool bit tip with tailstock center

3

Adjust the drive mechanism for the desired rotation speed

and feed. The spindle rotation speed and feed depends on the tool bits and metal stock / materials quality and under a certain condition.

Spindle rotation speed control lever

4

Turn on the machine to start lathe work. Before that, make sure that the machine is in good condition and has good grounding. Always where the switch is so that the machine could be stopped immediately if any accident occurred. Lathe machine switch

5

Since the end of the workpiece is uneven, it must be leveled first by turning the end of the workpiece part by moving the tool bit from back to front. This operation is called facing.

[BEFORE] Uneven workpiece end

[AFTER] Leveled workpiece end

6

Next, reduce the diameter of the workpiece until it

reached 35 mm with the length exceeding 30 mm according to the biggest diameter of the project. This operation is call turning.

Diameter reduced to 35 mm with more than 30 mm length

7

Reduce the diameter of the back part by turning the workpiece until it reached the diameter of 25 mm with the length of 20 mm to match with the back part dimension of this project. Finished with the back part of the project with 25 mm diameter and 20 mm length

8

After finished with the back part of the project, turn over the workpiece to proceed with the front part of the project. Since the front end of the work piece is also uneven, it needs to be leveled by facing cut the end of the workpiece. The workpiece length

Level the end and reduce overall length of workpiece

should also be reduced from 83 mm to 80 mm based on the overall length of the project.

9

The diameter of the front part of the project is then reduced to 25 mm with the length of 30 mm. After finished turning this front part, all the part that left is the central part of the project with diameter of 35 mm and 10 mm long.

Shape of workpiece after finished turning the front part. The central part’s diameter is 30 mm and the length is 10 mm.

10 Adjusting the tool slide to 5° angle for taper turning operation on the front part of workpiece.

Set the tool slide angle to 5°

11 Start taper turning the front part of the workpiece by moving the tool slide to the left and right. Don’t use the carriage slide because it still moves in straight line along the ways. Turning the workpiece until the tip of the front part reached the diameter of 20mm.

Front part of workpiece that has been tapered to the diameter of 20 mm

12 Next, make a hole to the front part end of the workpiece by using center drill. Use a higher spindle rotation speed for this drilling operation. The purpose of this operation is to make some room for the ball bearing live center to hold the front

Drilling the workpiece

part of workpiece to stabilize it during the knurling operation.

Hole on the centre of workpiece

13 Adjust the ball bearing live center to fit in the hole and hold the front part of workpiece for knurling operation.

Adjusting ball bearing live center to hold workpiece

14 Mount the knurling tool to the toolpost and adjust it with the central part of workpiece as that is the only part involved in this operation.

Adjusting knurling tool to workpiece.

15 For knurling operation, the spindle rotation speed should be slower to ensure that all parts are properly knurled. This operation also requires strong pressure. This is the last process of this project.

Knurling the centre part of workpiece

6.0

Discussions

Lathe machine can produce a lot of objects such as machinery parts, musical instruments and some of the objects that we use in our daily life. There are a lot of operations that can be performed using lathe machine. This operations includes facing operation, turning operation, taper turning operation, drilling operation and knurling operation. By knowing how to execute this operation, I am able to finished this machine pin project effectively. Different operation requires different spindle rotation speed. Rotation speed is the rotational frequency of the spindle, measured in revolutions per minute (RPM). Drilling operation requires a higher speed while knurling operation requires a slower rotation speed. As for turning operation, the rotation speed differs according to the materials type and the tool bits quality. The measurement of the workpiece must be taken from time to time to ensure that the dimension of the project is precise and accurate. The workpiece must be kept under observation at all time to prevent the occurrence of any error that may ruin the project’s final result. There are no accident occurred while I was following this practical task because I always followed the safety procedures while operating a machine. This is the most important thing because when there’s an accident, it will pose problems to many parties and the project cannot be done in time.

7.0

Conclusions

After done following this workshop practical task (machine pin project), there are a lot of things that I have learned. I am able to use Vernier Caliper and steel ruler for measuring purposes. I have learned how to take the reading from vernier scale and how to calculate the observed reading of an object. I have also learned the way to calculate the actual reading of an object if the Vernier caliper and steel ruler have zero error. The lecturer also explained about the safety precautions that have to be followed when taking a measurement so that the reading of an object will be precise and accurate. I’m also able to grind the tool bits using table grinding machine according to the required angle to produce general cutting tool bits. I’m able to apply all the safety procedures while operating lathe and grinding machine to avoids accidents from happening. Last but not least, the lecturers have explained and demonstrated to us the operations that can be done with a lathe machine such as facing, turning, taper turning, drilling and knurling. Now, I am able to operate the lathe machine with more proficient and confident.

8.0

References

1. Steve Krar, Arthur Gill, Peter Smid. (2011). Technology Of Machine Tools (7th ed.) McGraw-Hill. 2. Arthur R. Meyers, Thomas J. Slattery. (2001). Basic Machining Reference Handbook (2nd ed.) Industrial Press Inc. 3. David A. Stephenson, John S. Agapiou. (1997). Metal Cutting Theory And Practice (2nd ed.) CRC Taylor & Francis. 4. Stella Carter. (Jun 21, 2011). Lathe Cutting Tools. Retrieved from, http://lathe.ezinemark.com/lathe-cutting-tools18140012c5e.html. 5. Joe Martin. (2007). Grinding Your Own Lathe Tools. Retrieved from, http://www.sherline.com/grinding.htm.

Project Dimension Drawing

1.0

INTRODUCTION

The lathe is a machine tool which held and rotates the workpiece (metal, wood and other materials) on its axis to perform various operations such as cutting, knurling, drilling and deformation with a tool bit that are applied to workpiece to create an object which has symmetry about an axis of rotation.

The basic lathe that was designed to cut cylindrical metal stock has been developed further to produce screw threads, tapered work, drilled holes, knurled surfaces and crackshafts.

Lathes are used in woodturning, metalworking, metal spinning, and glassworking. Lathes can be used to shape pottery, the most well known design being the potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce threedimensional solids of incredible complexity. The material is held in place by either one or two centers, at least one of which can be moved horizontally to accommodate varying material lengths. Examples of objects that can be produced on a lathe include candlestick holders, cue sticks, table legs, bowls, baseball bats, crankshafts and camshafts.

Lathe Machine Parts

Bed – mainly the whole machine. Carriage – an assembly that moves the tool post and cutting tool along the way. Carriage handwheel – a wheel with a handle used to move the carriage. Chuck – a clamping device for holding the workpiece in the lathe. Apron – the front part of the carriage assembly on which carriage handwheel is mounted. Cross slide - platform that moves perpendicular to the lathe axis under control of the cross slide hand wheel.

Cross slide handwheel – a wheel with handle used to move the cross slide in and out. Halfnut lever – a lever to engage the carriagewith leadscrew to move the carriage under power. Lead screw – a precision screw that runs the length of the bed and used to drive the carriage under power for turning and thread cutting operation. Tailstock – a cast iron assembly that can be slide along the ways and be locked in place. Used to hold long workpiece in place or mount a drill chuck for drilling operation. Ways - a precision ground surfaces along top of the bed on which saddle rides. the ways are precisely aligned with the centerline of the lathe.

2.0

Task Outcome

After following this workshop practical work, I am able to :

1.1 Use Vernier Caliper and steel ruler for measuring purposes. Know how to measure the exact dimension of workpiece to get the precise dimension for the project outcome. 2.1 Apply safety procedures while operating lathe machine and grinding machine. Know the way to comply with the safety procedures while operating a machine at all time. 3.1 Operate the lathe machine; adjust spindle speed and feed. Know how to determine the cutting speed according to the operations, materials and tool bits type and condition. 4.1 Cutting, drilling, parallel, stepped and taper turning, and knurling with a lathe machine. Know all the operations using lathe machine and how to execute them. 5.1 Grind tool bits according to the required angle for general purposes with a table grinding machine. Know how to grind tool bits for lathe work.

3.0

Tools Equipment

Center lathe machine

Mild steel

Tool bit holder

Cutting tool holder

Tool bit

Spanner

Allen key

Chuck lock

Ball bearing live center

Center drill

Drill chuck

Vernier Caliper

Steel Ruler

Cooler

Lubricant

4.0

Safety Precautions

There are safety precautions that must be complied with every time entering a workshop. These safety precautions are necessary to avoid accidents or unexpected and unfortunate things from happening. a. Never get into a workshop without permission. Student should not work in a workshop without the lecturer’s supervision. b. Listen and follow carefully to the instructions from the lecturer. If unsure about something, always ask the lecturer before proceeding with the activity. c. Always wears appropriate and suitable clothes during a workshop practical work. Long hair, jewelry (ring, bracelet, necklace, ect.), and loose or baggy clothing are hazardly dangerous in the workshop. Wear safety shoes whenever in a workshop. No sandals and slippers are allowed. d. Know where the emergency stop buttons are positioned in the workshop. If an accident occured at the other side of the workshop, use the emergency stop button to turn off all electrical power to machines.

e. Stay alert and proceed with caution at all times in the workshop. Notify the lecturer immediately if you notices something suspicious. f. Never fool around in the workshop. Jokes and pranks are dangerous and prohibited. g. Practical work must be personally monitored at all times. Do not wander around the workshop, or distract and interfere with other students work. h. Always wear safety goggles whenever operating a machine. Hot and sharp fragments of workpiece may be directly sent flying over to your eyes. i. Make sure all of the machines in the workshop have a good grounding before start using them. j. Report any damage to machines or equipment to the lecturer immediately as this could cause an accident. k. Report any accident or injury to the lecturer immediately, no matter how trivial it seems. Do not panic. l. Make sure to clean the machines and the space around the workplace after finished doing your work. Throw away all fragments of workpiece to the provided disposal space.

5.0 No

Procedures Description

Diagram

. (A) PREPARING WORKPIECE 1.

A cylindrical metal with the diameter of 40 mm and 83 mm long is cut out from the originally long cylindrical metal by using the horizontal band saw machine.

Horizontal band saw machine

Originally long cylindrical metal stock

83 mm long workpiece with 40 mm diameter

No

Description

Diagram

. (B) PREPARING GENERAL CUTTING TOOL BIT 1

A tool bit with the size of 5/16 inches grinded with the table grinding machine to produce a general type cutting tool bit for lathe work.

Table grinding machine

2

Grind the left side of the tool bit by facing the left side of the tool bit towards the grinding wheel at about 10° angle.

Grinding the left side relief

3

Grind the end of tool bit. Hold the tool bit angled downwards from the tip to the rear and with the tip pointing to the left at about 10° to 15° angle. Grinding the end relief

4

Lastly, grind the top surface to form the rake. Hold the piece so that the top is facing the grinding wheel at about 10° angle. Be careful not to grind down the cutting edge. Grinding the top side relief

Tool bit for general cutting purposes.

No

Description

Diagram

. (C) OPERATING

LATHE

MACHINE

(MACHINE

PROJECT) 1

The workpiece is mounted to the chuck on the lathe machine to start the lathe work.

Mount workpiece to chunk

2

Set the tool bit which has been grinded earlier using table grinding machine to the tool bit holder.

Set tool bit to tool bit holder

PIN

Adjust the tool bit holder to the cutting tool holder on the lathe machine’s tool post.

Adjust tool bit holder to cutting tool holder

Make sure that the tool bit tip is at the centre position by aligning it with tailstock center.

Aligning the tool bit tip with tailstock center

3

Adjust the drive mechanism for the desired rotation speed

and feed. The spindle rotation speed and feed depends on the tool bits and metal stock / materials quality and under a certain condition.

Spindle rotation speed control lever

4

Turn on the machine to start lathe work. Before that, make sure that the machine is in good condition and has good grounding. Always where the switch is so that the machine could be stopped immediately if any accident occurred. Lathe machine switch

5

Since the end of the workpiece is uneven, it must be leveled first by turning the end of the workpiece part by moving the tool bit from back to front. This operation is called facing.

[BEFORE] Uneven workpiece end

[AFTER] Leveled workpiece end

6

Next, reduce the diameter of the workpiece until it

reached 35 mm with the length exceeding 30 mm according to the biggest diameter of the project. This operation is call turning.

Diameter reduced to 35 mm with more than 30 mm length

7

Reduce the diameter of the back part by turning the workpiece until it reached the diameter of 25 mm with the length of 20 mm to match with the back part dimension of this project. Finished with the back part of the project with 25 mm diameter and 20 mm length

8

After finished with the back part of the project, turn over the workpiece to proceed with the front part of the project. Since the front end of the work piece is also uneven, it needs to be leveled by facing cut the end of the workpiece. The workpiece length

Level the end and reduce overall length of workpiece

should also be reduced from 83 mm to 80 mm based on the overall length of the project.

9

The diameter of the front part of the project is then reduced to 25 mm with the length of 30 mm. After finished turning this front part, all the part that left is the central part of the project with diameter of 35 mm and 10 mm long.

Shape of workpiece after finished turning the front part. The central part’s diameter is 30 mm and the length is 10 mm.

10 Adjusting the tool slide to 5° angle for taper turning operation on the front part of workpiece.

Set the tool slide angle to 5°

11 Start taper turning the front part of the workpiece by moving the tool slide to the left and right. Don’t use the carriage slide because it still moves in straight line along the ways. Turning the workpiece until the tip of the front part reached the diameter of 20mm.

Front part of workpiece that has been tapered to the diameter of 20 mm

12 Next, make a hole to the front part end of the workpiece by using center drill. Use a higher spindle rotation speed for this drilling operation. The purpose of this operation is to make some room for the ball bearing live center to hold the front

Drilling the workpiece

part of workpiece to stabilize it during the knurling operation.

Hole on the centre of workpiece

13 Adjust the ball bearing live center to fit in the hole and hold the front part of workpiece for knurling operation.

Adjusting ball bearing live center to hold workpiece

14 Mount the knurling tool to the toolpost and adjust it with the central part of workpiece as that is the only part involved in this operation.

Adjusting knurling tool to workpiece.

15 For knurling operation, the spindle rotation speed should be slower to ensure that all parts are properly knurled. This operation also requires strong pressure. This is the last process of this project.

Knurling the centre part of workpiece

6.0

Discussions

Lathe machine can produce a lot of objects such as machinery parts, musical instruments and some of the objects that we use in our daily life. There are a lot of operations that can be performed using lathe machine. This operations includes facing operation, turning operation, taper turning operation, drilling operation and knurling operation. By knowing how to execute this operation, I am able to finished this machine pin project effectively. Different operation requires different spindle rotation speed. Rotation speed is the rotational frequency of the spindle, measured in revolutions per minute (RPM). Drilling operation requires a higher speed while knurling operation requires a slower rotation speed. As for turning operation, the rotation speed differs according to the materials type and the tool bits quality. The measurement of the workpiece must be taken from time to time to ensure that the dimension of the project is precise and accurate. The workpiece must be kept under observation at all time to prevent the occurrence of any error that may ruin the project’s final result. There are no accident occurred while I was following this practical task because I always followed the safety procedures while operating a machine. This is the most important thing because when there’s an accident, it will pose problems to many parties and the project cannot be done in time.

7.0

Conclusions

After done following this workshop practical task (machine pin project), there are a lot of things that I have learned. I am able to use Vernier Caliper and steel ruler for measuring purposes. I have learned how to take the reading from vernier scale and how to calculate the observed reading of an object. I have also learned the way to calculate the actual reading of an object if the Vernier caliper and steel ruler have zero error. The lecturer also explained about the safety precautions that have to be followed when taking a measurement so that the reading of an object will be precise and accurate. I’m also able to grind the tool bits using table grinding machine according to the required angle to produce general cutting tool bits. I’m able to apply all the safety procedures while operating lathe and grinding machine to avoids accidents from happening. Last but not least, the lecturers have explained and demonstrated to us the operations that can be done with a lathe machine such as facing, turning, taper turning, drilling and knurling. Now, I am able to operate the lathe machine with more proficient and confident.

8.0

References

1. Steve Krar, Arthur Gill, Peter Smid. (2011). Technology Of Machine Tools (7th ed.) McGraw-Hill. 2. Arthur R. Meyers, Thomas J. Slattery. (2001). Basic Machining Reference Handbook (2nd ed.) Industrial Press Inc. 3. David A. Stephenson, John S. Agapiou. (1997). Metal Cutting Theory And Practice (2nd ed.) CRC Taylor & Francis. 4. Stella Carter. (Jun 21, 2011). Lathe Cutting Tools. Retrieved from, http://lathe.ezinemark.com/lathe-cutting-tools18140012c5e.html. 5. Joe Martin. (2007). Grinding Your Own Lathe Tools. Retrieved from, http://www.sherline.com/grinding.htm.

Project Dimension Drawing