Maintenance Checklist 4e3aj

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Maintenance Checklist as PDF for free.

More details w3441

- Words: 586

- Pages: 6

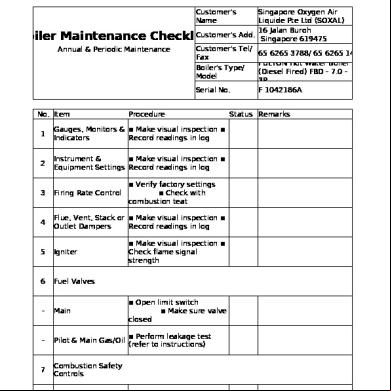

Customer's Name

Singapore Oxygen Air Liquide Pte Ltd (SOXAL) 16 Jalan Buroh Customer's Add. Singapore 619475 Customer's Tel/ 65 6265 3788/ 65 6265 1441 Fax FULTON Hot Water Boiler Boiler's Type/ (Diesel Fired) FBD - 7.0 Model 3P Serial No. F 1042186A

Boiler Maintenance Checklist Annual & Periodic Maintenance

No. Item

Procedure

1

Gauges, Monitors & ▪ Make visual inspection ▪ Indicators Record readings in log

2

Instrument & ▪ Make visual inspection ▪ Equipment Settings Record readings in log

3

Firing Rate Control

4

Flue, Vent, Stack or ▪ Make visual inspection ▪ Outlet Dampers Record readings in log

5

Igniter

6

Fuel Valves

-

Main

▪ Open limit switch ▪ Make sure valve closed

-

Pilot & Main Gas/Oil

▪ Perform leakage test (refer to instructions)

7

Combustion Safety Controls

-

Flame Failure

Status Remarks

▪ factory settings ▪ Check with combustion teat

▪ Make visual inspection ▪ Check flame signal strength

▪ Close fuel supply ▪ Check safety shutdown

1 of 4

-

-

▪ Check flame signal readings on control display (OR) ▪ Test meter-high/low fire ▪ As required - after any adjustment to flame, Pilot Turndown Test scanner mount or pilot adjustment Flame Signal Strength

-

Refractory Hold-in

▪ Refer to pilot turndown test instructions

-

Low Water Fuel Cutoff & Alarm

▪ Refer to boiler instructions - Slow drain test as per ASME pressure vessel code

-

High Limit ▪ Refer to boiler Temperature Safety instructions Control

-

Operating Temperature Control

▪ Refer to boiler instructions

-

Low Housing & Damper Position Interlocks

▪ Refer to boiler instructions

-

Atomizing Air Steam Interlock

▪ Refer to boiler instructions

-

High & Low Gas ▪ Refer to boiler Pressure Interlocks instructions

-

High & Low Oil ▪ Refer to boiler Pressure Interlocks instructions

-

High & Low Oil Temperature Interlocks

-

Fuel Valve Interlock ▪ Refer to boiler Switch instructions

-

Combustion Air Purge Switch

▪ Refer to boiler instructions

▪ Refer to boiler instructions

2 of 4

-

Burner Position Interlock

▪ Refer to boiler instructions

-

Low Fire Start Interlock

▪ Refer to boiler instructions

-

Automatic ▪ Refer to boiler Changeover Control instructions (Dual Fuel)

-

Safety Valves

▪ In accordance to ASME pressure vessel code

-

Inspect Burner Component

▪ Refer to boiler instructions

8

Atomizing Air Compressor

-

Belting Tension

▪ Refer to boiler instructions

-

Lubrication Oil Level

▪ Check minimum oil level to be 1/3 gauge glass

-

▪ Check minimum Operating Pressure operating pressure to be 15-25PSI

9

Oil Transfer Pump

-

Oil Pressure

▪ Check minimum oil pressure to be 1.5bar

-

Motor & Pump Coupling

▪ Replace & tighten (if necessary)

-

Oil Filter

▪ Clean or Replace

10 Miscellaneous

3 of 4

-

Handhole & Manhole

▪ Make visual inspection

-

Electrical Connections & Components

▪ Check for degenerate/loosen parts

-

Drain Valves, Main Stop Valve, Check Valve etc.

▪ Make visual inspection

Note: Before g this document, please that the content you are g is correct. You acknowledged that the above job carried out is completed to your satisfaction.

Date :

Date :

4 of 4

Customer's Name

Singapore Oxygen Air Liquide Pte Ltd (SOXAL) Customer's 16 Jalan Buroh Singapore 619475 Add. Customer's Tel/ Fax 65 6265 3788/ 65 6265 1441 FULTON Hot Water Boiler Boiler's (Diesel Fired) FBD - 7.0 Type/ 3P Model Serial No. F 1042185A

Boiler Maintenance Checklist Annual & Periodic Maintenance

No.

Item

Procedure

Remarks

5 of 4

6265 1441

6 of 4

Singapore Oxygen Air Liquide Pte Ltd (SOXAL) 16 Jalan Buroh Customer's Add. Singapore 619475 Customer's Tel/ 65 6265 3788/ 65 6265 1441 Fax FULTON Hot Water Boiler Boiler's Type/ (Diesel Fired) FBD - 7.0 Model 3P Serial No. F 1042186A

Boiler Maintenance Checklist Annual & Periodic Maintenance

No. Item

Procedure

1

Gauges, Monitors & ▪ Make visual inspection ▪ Indicators Record readings in log

2

Instrument & ▪ Make visual inspection ▪ Equipment Settings Record readings in log

3

Firing Rate Control

4

Flue, Vent, Stack or ▪ Make visual inspection ▪ Outlet Dampers Record readings in log

5

Igniter

6

Fuel Valves

-

Main

▪ Open limit switch ▪ Make sure valve closed

-

Pilot & Main Gas/Oil

▪ Perform leakage test (refer to instructions)

7

Combustion Safety Controls

-

Flame Failure

Status Remarks

▪ factory settings ▪ Check with combustion teat

▪ Make visual inspection ▪ Check flame signal strength

▪ Close fuel supply ▪ Check safety shutdown

1 of 4

-

-

▪ Check flame signal readings on control display (OR) ▪ Test meter-high/low fire ▪ As required - after any adjustment to flame, Pilot Turndown Test scanner mount or pilot adjustment Flame Signal Strength

-

Refractory Hold-in

▪ Refer to pilot turndown test instructions

-

Low Water Fuel Cutoff & Alarm

▪ Refer to boiler instructions - Slow drain test as per ASME pressure vessel code

-

High Limit ▪ Refer to boiler Temperature Safety instructions Control

-

Operating Temperature Control

▪ Refer to boiler instructions

-

Low Housing & Damper Position Interlocks

▪ Refer to boiler instructions

-

Atomizing Air Steam Interlock

▪ Refer to boiler instructions

-

High & Low Gas ▪ Refer to boiler Pressure Interlocks instructions

-

High & Low Oil ▪ Refer to boiler Pressure Interlocks instructions

-

High & Low Oil Temperature Interlocks

-

Fuel Valve Interlock ▪ Refer to boiler Switch instructions

-

Combustion Air Purge Switch

▪ Refer to boiler instructions

▪ Refer to boiler instructions

2 of 4

-

Burner Position Interlock

▪ Refer to boiler instructions

-

Low Fire Start Interlock

▪ Refer to boiler instructions

-

Automatic ▪ Refer to boiler Changeover Control instructions (Dual Fuel)

-

Safety Valves

▪ In accordance to ASME pressure vessel code

-

Inspect Burner Component

▪ Refer to boiler instructions

8

Atomizing Air Compressor

-

Belting Tension

▪ Refer to boiler instructions

-

Lubrication Oil Level

▪ Check minimum oil level to be 1/3 gauge glass

-

▪ Check minimum Operating Pressure operating pressure to be 15-25PSI

9

Oil Transfer Pump

-

Oil Pressure

▪ Check minimum oil pressure to be 1.5bar

-

Motor & Pump Coupling

▪ Replace & tighten (if necessary)

-

Oil Filter

▪ Clean or Replace

10 Miscellaneous

3 of 4

-

Handhole & Manhole

▪ Make visual inspection

-

Electrical Connections & Components

▪ Check for degenerate/loosen parts

-

Drain Valves, Main Stop Valve, Check Valve etc.

▪ Make visual inspection

Note: Before g this document, please that the content you are g is correct. You acknowledged that the above job carried out is completed to your satisfaction.

Date :

Date :

4 of 4

Customer's Name

Singapore Oxygen Air Liquide Pte Ltd (SOXAL) Customer's 16 Jalan Buroh Singapore 619475 Add. Customer's Tel/ Fax 65 6265 3788/ 65 6265 1441 FULTON Hot Water Boiler Boiler's (Diesel Fired) FBD - 7.0 Type/ 3P Model Serial No. F 1042185A

Boiler Maintenance Checklist Annual & Periodic Maintenance

No.

Item

Procedure

Remarks

5 of 4

6265 1441

6 of 4