Overview Subcontracting En 4i2h6w

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Overview Subcontracting En as PDF for free.

More details w3441

- Words: 4,000

- Pages: 9

SAP AG

Subcontracting: Overview

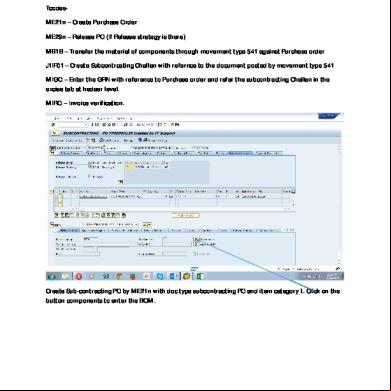

6XEFRQWUDFWLQJ2YHUYLHZ This document gives you an overview of subcontracting in the R/3 System. It comprises the following sections: • • • • • • • •

Basic BOM explosion Transfer posting to SC stock Goods receipt Materials planning Subcontracting monitoring list Special topics Tables and programs

%DVLF7HUPV 6XEFRQWUDFWLQJ6& In the SAP System, the term "subcontracting" describes the process of procuring a material from an external supplier (the subcontractor) who, however, requires certain components (provided by either the ordering firm or a third party) to manufacture this material.

%LOORI0DWHULDOV%20 A bill of materials is a list of the components that are provided to the subcontractor, together with details of the relevant quantities. The quantities may be negative, in which case by-products are involved (these are products created during the manufacture of the ordered product and which are returned to the ordering firm). The ordered item to which the BOM belongs is sometimes also referred to as an "assembly".

,WHP&DWHJRU\6XEFRQWUDFWLQJ A subcontracting item is denoted by the item category Subcontracting (identifier L, represented internally by the number 3). The item category must have previously been entered as "allowed" for the document type used (Customizing, document types). SC items may occur in requisitions, purchase orders, and scheduling agreements. When we refer to "subcontracting (SC) purchase orders" (also termed "subcontract orders") in the following, we also mean SC requisitions and SC scheduling agreements wherever appropriate. In the standard SAP System, this item category is not defined for requests for quotation (RFQs) or contracts. However, you can also enter SC items in an RFQ or a contract by copying the field selection keys PT0A and/or PT0K to create the keys PT3A and/or PT3K respectively. In this case, however, no BOM explosion is carried out and no component screen is offered. In the case of the SC scheduling agreement also, a BOM explosion is not carried out until delivery schedule lines are created (ME38). You cannot enter or display any components from within transactions ME32L or ME33L. In purchase requisitions, the components are assigned to the requisition item, whereas in purchase orders (POs) and scheduling agreements the BOM is attached to the schedule line (that is to say, different schedule lines for the same item may have different BOMs). This does not usually occur in purchase orders, but in the case of long-running scheduling agreements the BOM may change in the course of time. Notes: 21697 Termination of ME028 When Creating RFQ with Item Category L.

1 of 9

SAP AG

Subcontracting: Overview

6&,QIR5HFRUG The price for a material procured on a subcontracting basis can be stored in a subcontracting info record. In the source determination process for a subcontracting item, only SC info records and SC scheduling agreements are taken into .

6&6WRFN6HJPHQW Stocks of components provided to subcontractors are managed in a separate stock segment with the key "material, plant, vendor (and batch)" (SC stock). SC stock is part of the unrestricted-use stock belonging to the ordering firm’s own plant. (It can nevertheless be excluded from availability checks, for example.) You can view the SC stock situation by calling up the stock overview (transaction MMBE). When doing so, set the Also select special stocks indicator. Double-click on the Stock prov. to vendor line to get a breakdown by vendor. (You can also display the stocks using transaction ME2O – see below.) Negative quantities can also be allowed for SC stocks (Customizing, Inventory Management, Goods issue/Transfer posting -> Allow negative stocks, choose the Plant level, transaction OMJ1).

7KLUG3DUW\7ULDQJXODU 6XEFRQWUDFWLQJ In this case, the necessary components are provided to the subcontractor not by the ordering firm's own plant but by a third party, another external supplier. A third-party SC order contains an order item of the category Standard above the components and is issued to the external supplier A. The subcontractor B is entered in the Vendor field in the delivery address and the Subcontracting vendor indicator set. In the case of a goods receipt against such a PO, the relevant component is posted to the stock of material provided to vendor B. As of Release 4.0, third-party SC requisitions are also available, and as of Release 4.5 such requisitions can also be generated via Materials Planning (section MRP Areas below). Release Notes: 3.0A Purchasing -> Purchase Orders: Subcontracting/Third-Party Order Notes: 120163 Message to Subcontractor for Third-Party SC Order

%20([SORVLRQ Normally, the list of components to be provided to the subcontractor is not entered manually, but is already stored in the system as a master BOM (Logistics -> Production -> Master data -> Bills of material -> Bill of material -> Material BOM -> Create/Change/Display; transactions CS01, CS02, CS03). If just one BOM exists for a material, this is drawn when you create a subcontracting item. You can view the components (and change them, if necessary) via Item -> Components -> Overview. In order for a BOM item to be taken into in the explosion, the Relevant to production indicator must have been set, but the Material provision indicator must not be set. You can access both indicators in the BOM transaction via Goto -> Item -> Status/Long text. The Material provision indicator, especially, is sometimes erroneously set to L.

$OWHUQDWLYH%20V If several alternative BOMs exist, there is no possibility of selecting the desired BOM interactively. Instead, selection can be controlled via the following mechanisms:

2 of 9

SAP AG

• •

•

Subcontracting: Overview

Selection by quantity: A lot size interval for which the BOM is valid can be entered in the BOM header. A prerequisite is that the Selection method indicator is not set in the material master record (MRP 4 view). Selection by date: Can be set in the IMG under Production -> Basic Data -> Bill of Material -> Alternative Determination -> Define Alternative Determination for Multiple BOMs (transaction OS32). A prerequisite is that the Selection method indicator the is set to 1 in the material master record (MRP 4 view). Selection by production version: Can be used if the same material has different BOMs with different suppliers. You create different production versions in the material master record of the assembly (pushbutton in MRP 4 view) and assign an alternative BOM to the versions on the detail screen. You then enter the valid production version in the info record in each case.

If no selection mechanism has been defined and several alternatives exist, the first one found is drawn. Release Notes: 3.0B Purchasing -> General: BOM Determination in Subcontracting Items Notes: 13023 27169 81200 83085 90632 123961

Why was a BOM not Exploded? Subcontract Order: Rounding Error in Component Quantity Incorrect Requirement Dates in Subcontract Orders BOM from PReq is Exploded Again in Purchase Order ME38 ME22 BOM Explosion of Schedule Lines ME21 Bill of Material is not Exploded

1HZ%20([SORVLRQ If the BOM is changed in the master data for a certain material, the BOM can be updated in purchase orders for which no GR has yet taken place. This is done via the menu option Item -> Components -> New BOM explosion. The function can also be used if the BOM has been changed manually and you wish to revert to the original BOM. Notes: 16029 "New BOM Explosion" - Error Message

&RPSRQHQWVIURP$QRWKHU3ODQW Although the BOM item contains a plant, the latter cannot be maintained when the BOM is processed. During the explosion process, the plant for which the BOM has been created is always assigned to the components. By means of a trick, you can cause a different plant to be drawn at the time of explosion. A special procurement key for which the Withdr. altern. plant indicator is set in Customizing is assigned to the relevant component in the material master record (IMG: Production -> Requirements Planning -> Master Data -> Define Special Procurement Type, transaction OMD9).

7UDQVIHU3RVWLQJWR6&6WRFN Subcontracting stocks (stocks of material provided to the subcontractor) are built up through transfers from "restricted-use" stock (transaction MB1B, movement type 541, transfer posting from Restricted to Subcontracting). This can be done manually, with reference to an SC order (function To purchase order...“) or via the SC stock monitoring list (see below). Note: Since there is no order-related SC stock (as in R/2), transfer postings can be carried out as often as you like with reference to one and the same purchase order. The link to the purchase order is

3 of 9

SAP AG

Subcontracting: Overview

merely an entry aid for the components. In particular, no PO history records are written in the case of such transfer postings. Notes: 76823 MB1B Subcontract Order: Sign Display not Possible 84505 MB1B: Negative Components are Proposed 133427 MB1B Components Grouped Together from Different Plants

*RRGV5HFHLSW In the event of a goods receipt against an SC order, the system suggests the components to be booked out (with movement type 543; for by-products, where an inward movement is involved, movement type 545 is suggested). If there is only one delivery schedule line, the suggested (default) quantity is proportional to the GR quantity. The case where the GR covers several delivery schedule lines and different BOMs exist is more complicated. The precise logic behind the default quantities is described in Note 110158. The default quantities can be changed manually prior to posting (if the subcontractor has used more or less of the material provided, for example). In particular, they can be set to 0. This is done, for instance, if no SC stock exists. The components must then be booked out subsequently (see below). The quantities withdrawn are updated in the reservation when the GR is posted. These are basically proportional to the GR quantity. A manual change to the quantity used or consumed has no effect. Example: GR of 100 pc of material A; the BOM contains 10 pc of material B. However, only 9 are booked out because the subcontractor did not use more. The quantity withdrawn is nevertheless updated by 10 since otherwise a residual requirement of 1 pc would be left and would appear in the stock/requirements list (wrongly, because the requirement de facto no longer exists). Components are also suggested for posting back to the relevant stock in the case of a GR reversal or a return delivery (movement type 544 or, for co-products, 546). Again, refer to Note 110158 for the logic behind the default quantities. The consumption/usage figures for components are updated in the PO history (transaction/event key 7) and can be displayed in list form from the basic PO history list via Views -> SC consumption. After a goods receipt, the BOM in the purchase order can no longer be changed. This is because no reasonable default quantity could otherwise be determined in the event of a reversal. In the case of a partial goods receipt, you can get round this as follows: you can reduce the scheduled quantity (as per the schedule line) to the GR quantity and enter a new schedule line covering the remaining quantity. You can change the BOM in this new schedule line. Subsequent adjustment (transaction MB04): If it transpires that the subcontractor has used more (or fewer) components than planned, or if no components were booked out at the time of goods receipt due to lack of stock (see above), you have the option of booking out components retrospectively using the "subsequent adjustment" facility. No default quantities are provided in this case. Notes: 81928 109939 110158 120306 132835

SC Order: By-Products Posted as Outward Movement Display of PO History for Components in Different UoM New Proposal Logic for GR for SC Scheduling Agreement MB01 Rounding When Proposing SC Components Subcontract Order: Problems During Reversal or MB04

Valuation at the time of GR: The value of the finished product, which is debited to the material , comprises the value of the SC order (that is, the price for the processing/assembly work, normally stored in the info record) and the material/component costs. Example: The manufacture of product P by vendor L from the components K1 and K2 (1 pc of P from 1 pc of K1 and 3 pc of K2)

4 of 9

SAP AG

Subcontracting: Overview

costs 50.00 per pc. If a GR of 1 pc of P is recorded, the value of the stock increases by 50 + 10 + 3 x 5 = 75.

0DWHULDOV3ODQQLQJ *HQHUDWLRQRI6&5HTXLVLWLRQVRU6&6FKHGXOLQJ$JUHHPHQW6FKHGXOH/LQHV YLD053 If a material is procured externally and supplies are planned automatically, you can stipulate via the special procurement key in the material master record that SC requisitions or (if an appropriate source list entry exists) SC scheduling agreement schedule lines are generated in the course of the planning run. For the special procurement key, the Special procurement indicator must be set to L for subcontracting. At the time of the MRP run, a BOM explosion is also carried out. However, requisitions are also generated even if no valid BOM exists – the components are then missing (see "SC Items Without Components" below).

6&5HTXLUHPHQWVLQWKH6WRFN5HTXLUHPHQWV/LVW The requirements of components in a plant arising through SC orders (sometimes also referred to as dependent requirements) can be displayed in the stock/requirements list (transaction MD04). They can be identified through the MRP element LB-BED. By double clicking on the line, you can display the document behind the requirement (planned order, requisition, purchase order, scheduling agreement). Notes: 104270 Requirement in the Incorrect SC MRP Segment

3ODQQLQJRI6&6WRFNV As of Release 4.5, so-called "MRP areas" enable you to carry out separate requirements planning for SC stocks. An MRP area can cover a plant, one or more storage locations, or an SC stock. The following settings are necessary: • • •

In Customizing, you must activate the MRP areas at client level (IMG: Production -> Requirements Planning -> Master Data -> Define MRP Areas -> Activate Requirements Planning for MRP Areas, transaction OM01). In the subsequent workstep "Define MRP Areas" (transaction OMIZ), you can then define an MRP area of the category 03 (vendor) for each subcontractor/plant. When MRP areas have been activated, the pushbutton MRP areas appears in the MRP 1 view of the material master record. The MRP parameters must also be maintained for the individual MRP areas in the material master record. In particular, you can stipulate via the special procurement key whether supplies of the SC stock are to be maintained through transfers from your own plant or through deliveries by an external supplier (via third-party subcontracting orders).

If MRP areas are active, the planning run or the stock/requirements list is invoked for each MRP area. Depending on the setting in the material master record, the MRP run generates either stock transfer reservations (planned transfer postings to SC stock) or third-party SC requisitions for an SC MRP area. Release Notes: 4.5A Requirements Planning -> Planning Execution: Requirements Planning with MRP Areas MRP Area: Subcontracting/Third-Party Processing

5 of 9

SAP AG

Subcontracting: Overview

6XEFRQWUDFWLQJ0RQLWRULQJ/LVW The subcontracting monitoring list (which can be accessed in Purchasing under Purchase order -> Reporting -> SC stocks per vendor, transaction ME2O), gives you an overview of subcontracting stocks (stocks of materials with subcontractors) grouped by vendor, material, plant. You can see the current stock figures and which outward movements are to be expected due to open SC orders. As of Release 4.0, inward movements stemming from open deliveries are also shown (see below). As of Release 4.5, planned receipts through stock transfer reservations and third-party SC orders or requisitions and outward movements through open SC requisitions are additionally shown. The report is documented, with a link to the documentation in MM Inventory Management. Via the list, the can do the following: • •

Post a transfer of components from unrestricted-use stock to SC stock (Post Goods Issue function) Create a delivery for the components in SD (as of Release 4.0).

When the GI for the delivery is posted, the components are booked out of "unrestricted-use" stock and into "SC" stock. The following pre-settings are necessary before you can create an SD delivery: • • • •

•

A sales organization, a distribution channel, and a division must be assigned to the plant from which the components are to be delivered (Customizing for Purchasing: Purchase Order -> Set up Stock Transport Order -> Plant, transaction OMGN). The components must be created for the sales organization, the distribution channel, and the division of the supplying plant. A customer (a/c payable, or debtor) record must be assigned to the SC vendor in the latter’s master record. This record must be created for the sales organization, distribution channel, and division of the supplying plant. A delivery type must be entered for the provision of components to the subcontractor (Purchasing IMG: Purchase Order -> Set up Subcontract Order, transaction OMGM). Delivery type LB is available in the standard system. The Preceding document required indicator must be set to L for this delivery type in Customizing for Shipping (Deliveries -> Define Delivery Types, transaction 0VLK). Furthermore, a partner schema containing the partner role Vendor should be assigned to the delivery type (Shipping IMG: Basic Shipping Functions -> Partners -> Partner Determination > Define and Assign Partner Determination Procedures, transaction VOPA). A shipping point must be assigned to the combination "shipping condition" (from the customer/debtor master record assigned to the SC vendor), "loading group" (from the material master record of the component), and "plant" (Shipping IMG: Basic Shipping Functions -> Shipping Point and Goods Receiving Point Determination -> Assign Shipping Points, transaction OVL2).

The system generates a log both in the case of a transfer posting and when a delivery is created. In Release 4.0 this log can be displayed from the list via Environment -> Goods issue -> Processing log. As of Release 4.5, it is displayed to the immediately after the GI or deliveries is/are posted. The log contains useful messages (explaining why a delivery could not be created, for example). In Release 4.0, the individual deliveries can be displayed via the Open deliveries function. As of Release 4.5, they appear directly in the list. If stock transfer reservations are displayed, a GI or a delivery is generally posted with reference to the reservations. The reservations are thereby cancelled out and disappear from the list. You can also explicitly choose the reservations you wish to convert. (Selecting no reservations is the same as selecting all reservations.) Note that when a delivery is created with reference to a stock transfer reservation, the reservation is not closed with regard to materials planning until the GI for the delivery is posted.

6 of 9

SAP AG

Subcontracting: Overview

Remarks concerning data selection for the report: In the case of selection via the assembly, only those components that occur as dependent requirements covered by an SC requisition or an SC purchase order in one of the selected assemblies are listed. That is to say, a complete BOM explosion is not carried out for the assembly. If there is currently no dependent requirement for a component, the latter will not found in selections via the assembly. The selection criteria additionally available up to and including Release 4.0 under the "dynamic selections" facility are no longer ed as of Release 4.5 because, under certain circumstances, they only filter out certain requirements and can thus lead to an inaccurate representation of the stock/requirements situation. For the same reason, no authorization check is now carried out at the time of document selection. Release Notes: 4.0A 4.5A

Purchasing -> Purchase Orders: Delivery for Materials Provided for Subcontracting Purchasing -> Purchase Orders: Monitoring of Subcontracting Stocks

Notes: 114724 Undesired Delivery Split (Deliveries of Components Provided for Subcontracting Work) 131707 ME2O Termination DYNPRO_CONVERSION When Posting Goods Issue

6SHFLDO7RSLFV 6XEFRQWUDFWLQJDQG0DNHWR2UGHU It is possible to assign an SC purchase order to "make to order" (individual customer) or "make for project" (individual project) production (in the standard system, with the assignment categories E and Q). Via the Individual/collective indicator in the material master record (MRP 4 view), you can determine whether the components are to be withdrawn from SC stock (as in the case of an unassigned SC order) or from individual customer or project stock. The details are explained in Note 68908. Notes: 68908 69460 78165 103912 121540

Subcontract Orders Assigned to Individual Customers ME2O Components in Special Stock Offered WBS Element Not Written to Component Booking SC Components out of Sales Order Stock SC Order with Make-to-Order: ATP Check Components

&KHFNLQJ$YDLODELOLW\RI&RPSRQHQWV If you switch from the component overview screen to the detail screen for a component, you can confirm the availability of the component using the Availability check function. In the process, the checking group is drawn from the material master record and the checking rule is derived from the MRP group of the ordered part (in this connection, refer to Note 114547). The availability check must be initiated manually. There is currently no means of initiating the check automatically. Notes: 114547 Availability of Components: Incorrect Checking Rule 117807 Availability Check when Converting Subcontracting Requisition 121540 SC Order with Make-to-Order: ATP Check Component

6&,WHPVZLWKRXW&RPSRQHQWV In the case of purchase requisitions that are generated by other applications, it may happen that an SC requisition has no components. In the case of requisitions generated by MRP, this only occurs if

7 of 9

SAP AG

Subcontracting: Overview

no valid BOM could be determined. In the case of requisitions generated from sales orders or networks, this is always the case. There are technical reasons for this: the function module that generates the requisitions does not cater for subcontracting. Although the missing components temporarily lead to wrong information with regard to requirements, if the requisitions are speedily converted the missing BOM explosion is provided in the purchase order (however, for this to happen, Note 127705 should be installed). Notes: 76785 83854 102595 116571 127705

Subcontracting Requisitions and POs w/o Components Component w. SOBSL f. Stock Transfer/Subcontracting Subcontracting Requisitions Generated from SD/PS have no Components Outline Agreement Requisition with Item Category "Subcontracting" Conversion of SC Requisition w/o BOM: Error Message ME154

([WHUQDO3URFHVVLQJ2SHUDWLRQVZLWK6XEFRQWUDFWLQJ As of Release 4.0, it is possible to make available the components for operations of the category "external procurement" as SC components in production orders. To do so, you must set the Subcontracting indicator on the external processing screen for the operation. When the order is saved (or released), a subcontracting requisition without a material number, assigned to the production order and having the operation components as "components to be provided" is created. The components cannot be changed in the requisition. When the requisition is converted into a purchase order, the components are copied and can then also be changed. Release Notes: 4.0A Production Planning and Control -> Production Orders: Provision of Components for External Processing

7DEOHVDQG3URJUDPV Technically, the link between purchasing document and BOM is established through the pointer RSNUM in the purchase requisition (table EBAN) or delivery schedule line (table EKET). The components are in table RESB under the reservation number RSNUM and are numbered according to the item number (RSPOS). In turn, the reservation points to the requirement source document via the fields BELN, EBELP, EBELE (schedule line) or BANFN, BNFPO (requisition). Further tables in connection with subcontracting: MSLB MAST STPO VRSLI

SC Stocks Material to BOM Link BOM Item Index: Stock Transfer Reservation - Delivery

Programs: The function group for component processing in Purchasing is EINK (most important function module: ME_COMPONENTS_MAINTAIN). The function modules are invoked from the routines in the includes MM06BFLB (requisition) or MM06EFLB (purchase order/scheduling agreement) (most important routine: MDPM_MAINTAIN). The component screen is invoked from the detail screen in each case via the module CALL_KOMPONENTEN. The rest of the component processing (component screen, BOM explosion, update) is handled by function modules from Requirements Planning, of which the most important are: MD_AUFLOESEN_MDBA (BOM explosion) MD_BEARBEITEN_KOMPONENTEN (component screen) MD_HINZUFUEGEN_KOMPONENTEN, MD_VERAENDERN_KOMPONENTEN, ... The associated function groups are M61Z, M61Q, and M61P.

8 of 9

SAP AG

Subcontracting: Overview

Further Programs FB ME_READ_COMP_GOODS_ISSUE: Provision of Components (GI with Ref. to Purchase Order) FB ME_READ_COMP_GOODS_RECEIPT: Suggestion of Components (GR against SC order) Report RM06ELLB: SC Stock Monitoring List

9 of 9

Subcontracting: Overview

6XEFRQWUDFWLQJ2YHUYLHZ This document gives you an overview of subcontracting in the R/3 System. It comprises the following sections: • • • • • • • •

Basic BOM explosion Transfer posting to SC stock Goods receipt Materials planning Subcontracting monitoring list Special topics Tables and programs

%DVLF7HUPV 6XEFRQWUDFWLQJ6& In the SAP System, the term "subcontracting" describes the process of procuring a material from an external supplier (the subcontractor) who, however, requires certain components (provided by either the ordering firm or a third party) to manufacture this material.

%LOORI0DWHULDOV%20 A bill of materials is a list of the components that are provided to the subcontractor, together with details of the relevant quantities. The quantities may be negative, in which case by-products are involved (these are products created during the manufacture of the ordered product and which are returned to the ordering firm). The ordered item to which the BOM belongs is sometimes also referred to as an "assembly".

,WHP&DWHJRU\6XEFRQWUDFWLQJ A subcontracting item is denoted by the item category Subcontracting (identifier L, represented internally by the number 3). The item category must have previously been entered as "allowed" for the document type used (Customizing, document types). SC items may occur in requisitions, purchase orders, and scheduling agreements. When we refer to "subcontracting (SC) purchase orders" (also termed "subcontract orders") in the following, we also mean SC requisitions and SC scheduling agreements wherever appropriate. In the standard SAP System, this item category is not defined for requests for quotation (RFQs) or contracts. However, you can also enter SC items in an RFQ or a contract by copying the field selection keys PT0A and/or PT0K to create the keys PT3A and/or PT3K respectively. In this case, however, no BOM explosion is carried out and no component screen is offered. In the case of the SC scheduling agreement also, a BOM explosion is not carried out until delivery schedule lines are created (ME38). You cannot enter or display any components from within transactions ME32L or ME33L. In purchase requisitions, the components are assigned to the requisition item, whereas in purchase orders (POs) and scheduling agreements the BOM is attached to the schedule line (that is to say, different schedule lines for the same item may have different BOMs). This does not usually occur in purchase orders, but in the case of long-running scheduling agreements the BOM may change in the course of time. Notes: 21697 Termination of ME028 When Creating RFQ with Item Category L.

1 of 9

SAP AG

Subcontracting: Overview

6&,QIR5HFRUG The price for a material procured on a subcontracting basis can be stored in a subcontracting info record. In the source determination process for a subcontracting item, only SC info records and SC scheduling agreements are taken into .

6&6WRFN6HJPHQW Stocks of components provided to subcontractors are managed in a separate stock segment with the key "material, plant, vendor (and batch)" (SC stock). SC stock is part of the unrestricted-use stock belonging to the ordering firm’s own plant. (It can nevertheless be excluded from availability checks, for example.) You can view the SC stock situation by calling up the stock overview (transaction MMBE). When doing so, set the Also select special stocks indicator. Double-click on the Stock prov. to vendor line to get a breakdown by vendor. (You can also display the stocks using transaction ME2O – see below.) Negative quantities can also be allowed for SC stocks (Customizing, Inventory Management, Goods issue/Transfer posting -> Allow negative stocks, choose the Plant level, transaction OMJ1).

7KLUG3DUW\7ULDQJXODU 6XEFRQWUDFWLQJ In this case, the necessary components are provided to the subcontractor not by the ordering firm's own plant but by a third party, another external supplier. A third-party SC order contains an order item of the category Standard above the components and is issued to the external supplier A. The subcontractor B is entered in the Vendor field in the delivery address and the Subcontracting vendor indicator set. In the case of a goods receipt against such a PO, the relevant component is posted to the stock of material provided to vendor B. As of Release 4.0, third-party SC requisitions are also available, and as of Release 4.5 such requisitions can also be generated via Materials Planning (section MRP Areas below). Release Notes: 3.0A Purchasing -> Purchase Orders: Subcontracting/Third-Party Order Notes: 120163 Message to Subcontractor for Third-Party SC Order

%20([SORVLRQ Normally, the list of components to be provided to the subcontractor is not entered manually, but is already stored in the system as a master BOM (Logistics -> Production -> Master data -> Bills of material -> Bill of material -> Material BOM -> Create/Change/Display; transactions CS01, CS02, CS03). If just one BOM exists for a material, this is drawn when you create a subcontracting item. You can view the components (and change them, if necessary) via Item -> Components -> Overview. In order for a BOM item to be taken into in the explosion, the Relevant to production indicator must have been set, but the Material provision indicator must not be set. You can access both indicators in the BOM transaction via Goto -> Item -> Status/Long text. The Material provision indicator, especially, is sometimes erroneously set to L.

$OWHUQDWLYH%20V If several alternative BOMs exist, there is no possibility of selecting the desired BOM interactively. Instead, selection can be controlled via the following mechanisms:

2 of 9

SAP AG

• •

•

Subcontracting: Overview

Selection by quantity: A lot size interval for which the BOM is valid can be entered in the BOM header. A prerequisite is that the Selection method indicator is not set in the material master record (MRP 4 view). Selection by date: Can be set in the IMG under Production -> Basic Data -> Bill of Material -> Alternative Determination -> Define Alternative Determination for Multiple BOMs (transaction OS32). A prerequisite is that the Selection method indicator the is set to 1 in the material master record (MRP 4 view). Selection by production version: Can be used if the same material has different BOMs with different suppliers. You create different production versions in the material master record of the assembly (pushbutton in MRP 4 view) and assign an alternative BOM to the versions on the detail screen. You then enter the valid production version in the info record in each case.

If no selection mechanism has been defined and several alternatives exist, the first one found is drawn. Release Notes: 3.0B Purchasing -> General: BOM Determination in Subcontracting Items Notes: 13023 27169 81200 83085 90632 123961

Why was a BOM not Exploded? Subcontract Order: Rounding Error in Component Quantity Incorrect Requirement Dates in Subcontract Orders BOM from PReq is Exploded Again in Purchase Order ME38 ME22 BOM Explosion of Schedule Lines ME21 Bill of Material is not Exploded

1HZ%20([SORVLRQ If the BOM is changed in the master data for a certain material, the BOM can be updated in purchase orders for which no GR has yet taken place. This is done via the menu option Item -> Components -> New BOM explosion. The function can also be used if the BOM has been changed manually and you wish to revert to the original BOM. Notes: 16029 "New BOM Explosion" - Error Message

&RPSRQHQWVIURP$QRWKHU3ODQW Although the BOM item contains a plant, the latter cannot be maintained when the BOM is processed. During the explosion process, the plant for which the BOM has been created is always assigned to the components. By means of a trick, you can cause a different plant to be drawn at the time of explosion. A special procurement key for which the Withdr. altern. plant indicator is set in Customizing is assigned to the relevant component in the material master record (IMG: Production -> Requirements Planning -> Master Data -> Define Special Procurement Type, transaction OMD9).

7UDQVIHU3RVWLQJWR6&6WRFN Subcontracting stocks (stocks of material provided to the subcontractor) are built up through transfers from "restricted-use" stock (transaction MB1B, movement type 541, transfer posting from Restricted to Subcontracting). This can be done manually, with reference to an SC order (function To purchase order...“) or via the SC stock monitoring list (see below). Note: Since there is no order-related SC stock (as in R/2), transfer postings can be carried out as often as you like with reference to one and the same purchase order. The link to the purchase order is

3 of 9

SAP AG

Subcontracting: Overview

merely an entry aid for the components. In particular, no PO history records are written in the case of such transfer postings. Notes: 76823 MB1B Subcontract Order: Sign Display not Possible 84505 MB1B: Negative Components are Proposed 133427 MB1B Components Grouped Together from Different Plants

*RRGV5HFHLSW In the event of a goods receipt against an SC order, the system suggests the components to be booked out (with movement type 543; for by-products, where an inward movement is involved, movement type 545 is suggested). If there is only one delivery schedule line, the suggested (default) quantity is proportional to the GR quantity. The case where the GR covers several delivery schedule lines and different BOMs exist is more complicated. The precise logic behind the default quantities is described in Note 110158. The default quantities can be changed manually prior to posting (if the subcontractor has used more or less of the material provided, for example). In particular, they can be set to 0. This is done, for instance, if no SC stock exists. The components must then be booked out subsequently (see below). The quantities withdrawn are updated in the reservation when the GR is posted. These are basically proportional to the GR quantity. A manual change to the quantity used or consumed has no effect. Example: GR of 100 pc of material A; the BOM contains 10 pc of material B. However, only 9 are booked out because the subcontractor did not use more. The quantity withdrawn is nevertheless updated by 10 since otherwise a residual requirement of 1 pc would be left and would appear in the stock/requirements list (wrongly, because the requirement de facto no longer exists). Components are also suggested for posting back to the relevant stock in the case of a GR reversal or a return delivery (movement type 544 or, for co-products, 546). Again, refer to Note 110158 for the logic behind the default quantities. The consumption/usage figures for components are updated in the PO history (transaction/event key 7) and can be displayed in list form from the basic PO history list via Views -> SC consumption. After a goods receipt, the BOM in the purchase order can no longer be changed. This is because no reasonable default quantity could otherwise be determined in the event of a reversal. In the case of a partial goods receipt, you can get round this as follows: you can reduce the scheduled quantity (as per the schedule line) to the GR quantity and enter a new schedule line covering the remaining quantity. You can change the BOM in this new schedule line. Subsequent adjustment (transaction MB04): If it transpires that the subcontractor has used more (or fewer) components than planned, or if no components were booked out at the time of goods receipt due to lack of stock (see above), you have the option of booking out components retrospectively using the "subsequent adjustment" facility. No default quantities are provided in this case. Notes: 81928 109939 110158 120306 132835

SC Order: By-Products Posted as Outward Movement Display of PO History for Components in Different UoM New Proposal Logic for GR for SC Scheduling Agreement MB01 Rounding When Proposing SC Components Subcontract Order: Problems During Reversal or MB04

Valuation at the time of GR: The value of the finished product, which is debited to the material , comprises the value of the SC order (that is, the price for the processing/assembly work, normally stored in the info record) and the material/component costs. Example: The manufacture of product P by vendor L from the components K1 and K2 (1 pc of P from 1 pc of K1 and 3 pc of K2)

4 of 9

SAP AG

Subcontracting: Overview

costs 50.00 per pc. If a GR of 1 pc of P is recorded, the value of the stock increases by 50 + 10 + 3 x 5 = 75.

0DWHULDOV3ODQQLQJ *HQHUDWLRQRI6&5HTXLVLWLRQVRU6&6FKHGXOLQJ$JUHHPHQW6FKHGXOH/LQHV YLD053 If a material is procured externally and supplies are planned automatically, you can stipulate via the special procurement key in the material master record that SC requisitions or (if an appropriate source list entry exists) SC scheduling agreement schedule lines are generated in the course of the planning run. For the special procurement key, the Special procurement indicator must be set to L for subcontracting. At the time of the MRP run, a BOM explosion is also carried out. However, requisitions are also generated even if no valid BOM exists – the components are then missing (see "SC Items Without Components" below).

6&5HTXLUHPHQWVLQWKH6WRFN5HTXLUHPHQWV/LVW The requirements of components in a plant arising through SC orders (sometimes also referred to as dependent requirements) can be displayed in the stock/requirements list (transaction MD04). They can be identified through the MRP element LB-BED. By double clicking on the line, you can display the document behind the requirement (planned order, requisition, purchase order, scheduling agreement). Notes: 104270 Requirement in the Incorrect SC MRP Segment

3ODQQLQJRI6&6WRFNV As of Release 4.5, so-called "MRP areas" enable you to carry out separate requirements planning for SC stocks. An MRP area can cover a plant, one or more storage locations, or an SC stock. The following settings are necessary: • • •

In Customizing, you must activate the MRP areas at client level (IMG: Production -> Requirements Planning -> Master Data -> Define MRP Areas -> Activate Requirements Planning for MRP Areas, transaction OM01). In the subsequent workstep "Define MRP Areas" (transaction OMIZ), you can then define an MRP area of the category 03 (vendor) for each subcontractor/plant. When MRP areas have been activated, the pushbutton MRP areas appears in the MRP 1 view of the material master record. The MRP parameters must also be maintained for the individual MRP areas in the material master record. In particular, you can stipulate via the special procurement key whether supplies of the SC stock are to be maintained through transfers from your own plant or through deliveries by an external supplier (via third-party subcontracting orders).

If MRP areas are active, the planning run or the stock/requirements list is invoked for each MRP area. Depending on the setting in the material master record, the MRP run generates either stock transfer reservations (planned transfer postings to SC stock) or third-party SC requisitions for an SC MRP area. Release Notes: 4.5A Requirements Planning -> Planning Execution: Requirements Planning with MRP Areas MRP Area: Subcontracting/Third-Party Processing

5 of 9

SAP AG

Subcontracting: Overview

6XEFRQWUDFWLQJ0RQLWRULQJ/LVW The subcontracting monitoring list (which can be accessed in Purchasing under Purchase order -> Reporting -> SC stocks per vendor, transaction ME2O), gives you an overview of subcontracting stocks (stocks of materials with subcontractors) grouped by vendor, material, plant. You can see the current stock figures and which outward movements are to be expected due to open SC orders. As of Release 4.0, inward movements stemming from open deliveries are also shown (see below). As of Release 4.5, planned receipts through stock transfer reservations and third-party SC orders or requisitions and outward movements through open SC requisitions are additionally shown. The report is documented, with a link to the documentation in MM Inventory Management. Via the list, the can do the following: • •

Post a transfer of components from unrestricted-use stock to SC stock (Post Goods Issue function) Create a delivery for the components in SD (as of Release 4.0).

When the GI for the delivery is posted, the components are booked out of "unrestricted-use" stock and into "SC" stock. The following pre-settings are necessary before you can create an SD delivery: • • • •

•

A sales organization, a distribution channel, and a division must be assigned to the plant from which the components are to be delivered (Customizing for Purchasing: Purchase Order -> Set up Stock Transport Order -> Plant, transaction OMGN). The components must be created for the sales organization, the distribution channel, and the division of the supplying plant. A customer (a/c payable, or debtor) record must be assigned to the SC vendor in the latter’s master record. This record must be created for the sales organization, distribution channel, and division of the supplying plant. A delivery type must be entered for the provision of components to the subcontractor (Purchasing IMG: Purchase Order -> Set up Subcontract Order, transaction OMGM). Delivery type LB is available in the standard system. The Preceding document required indicator must be set to L for this delivery type in Customizing for Shipping (Deliveries -> Define Delivery Types, transaction 0VLK). Furthermore, a partner schema containing the partner role Vendor should be assigned to the delivery type (Shipping IMG: Basic Shipping Functions -> Partners -> Partner Determination > Define and Assign Partner Determination Procedures, transaction VOPA). A shipping point must be assigned to the combination "shipping condition" (from the customer/debtor master record assigned to the SC vendor), "loading group" (from the material master record of the component), and "plant" (Shipping IMG: Basic Shipping Functions -> Shipping Point and Goods Receiving Point Determination -> Assign Shipping Points, transaction OVL2).

The system generates a log both in the case of a transfer posting and when a delivery is created. In Release 4.0 this log can be displayed from the list via Environment -> Goods issue -> Processing log. As of Release 4.5, it is displayed to the immediately after the GI or deliveries is/are posted. The log contains useful messages (explaining why a delivery could not be created, for example). In Release 4.0, the individual deliveries can be displayed via the Open deliveries function. As of Release 4.5, they appear directly in the list. If stock transfer reservations are displayed, a GI or a delivery is generally posted with reference to the reservations. The reservations are thereby cancelled out and disappear from the list. You can also explicitly choose the reservations you wish to convert. (Selecting no reservations is the same as selecting all reservations.) Note that when a delivery is created with reference to a stock transfer reservation, the reservation is not closed with regard to materials planning until the GI for the delivery is posted.

6 of 9

SAP AG

Subcontracting: Overview

Remarks concerning data selection for the report: In the case of selection via the assembly, only those components that occur as dependent requirements covered by an SC requisition or an SC purchase order in one of the selected assemblies are listed. That is to say, a complete BOM explosion is not carried out for the assembly. If there is currently no dependent requirement for a component, the latter will not found in selections via the assembly. The selection criteria additionally available up to and including Release 4.0 under the "dynamic selections" facility are no longer ed as of Release 4.5 because, under certain circumstances, they only filter out certain requirements and can thus lead to an inaccurate representation of the stock/requirements situation. For the same reason, no authorization check is now carried out at the time of document selection. Release Notes: 4.0A 4.5A

Purchasing -> Purchase Orders: Delivery for Materials Provided for Subcontracting Purchasing -> Purchase Orders: Monitoring of Subcontracting Stocks

Notes: 114724 Undesired Delivery Split (Deliveries of Components Provided for Subcontracting Work) 131707 ME2O Termination DYNPRO_CONVERSION When Posting Goods Issue

6SHFLDO7RSLFV 6XEFRQWUDFWLQJDQG0DNHWR2UGHU It is possible to assign an SC purchase order to "make to order" (individual customer) or "make for project" (individual project) production (in the standard system, with the assignment categories E and Q). Via the Individual/collective indicator in the material master record (MRP 4 view), you can determine whether the components are to be withdrawn from SC stock (as in the case of an unassigned SC order) or from individual customer or project stock. The details are explained in Note 68908. Notes: 68908 69460 78165 103912 121540

Subcontract Orders Assigned to Individual Customers ME2O Components in Special Stock Offered WBS Element Not Written to Component Booking SC Components out of Sales Order Stock SC Order with Make-to-Order: ATP Check Components

&KHFNLQJ$YDLODELOLW\RI&RPSRQHQWV If you switch from the component overview screen to the detail screen for a component, you can confirm the availability of the component using the Availability check function. In the process, the checking group is drawn from the material master record and the checking rule is derived from the MRP group of the ordered part (in this connection, refer to Note 114547). The availability check must be initiated manually. There is currently no means of initiating the check automatically. Notes: 114547 Availability of Components: Incorrect Checking Rule 117807 Availability Check when Converting Subcontracting Requisition 121540 SC Order with Make-to-Order: ATP Check Component

6&,WHPVZLWKRXW&RPSRQHQWV In the case of purchase requisitions that are generated by other applications, it may happen that an SC requisition has no components. In the case of requisitions generated by MRP, this only occurs if

7 of 9

SAP AG

Subcontracting: Overview

no valid BOM could be determined. In the case of requisitions generated from sales orders or networks, this is always the case. There are technical reasons for this: the function module that generates the requisitions does not cater for subcontracting. Although the missing components temporarily lead to wrong information with regard to requirements, if the requisitions are speedily converted the missing BOM explosion is provided in the purchase order (however, for this to happen, Note 127705 should be installed). Notes: 76785 83854 102595 116571 127705

Subcontracting Requisitions and POs w/o Components Component w. SOBSL f. Stock Transfer/Subcontracting Subcontracting Requisitions Generated from SD/PS have no Components Outline Agreement Requisition with Item Category "Subcontracting" Conversion of SC Requisition w/o BOM: Error Message ME154

([WHUQDO3URFHVVLQJ2SHUDWLRQVZLWK6XEFRQWUDFWLQJ As of Release 4.0, it is possible to make available the components for operations of the category "external procurement" as SC components in production orders. To do so, you must set the Subcontracting indicator on the external processing screen for the operation. When the order is saved (or released), a subcontracting requisition without a material number, assigned to the production order and having the operation components as "components to be provided" is created. The components cannot be changed in the requisition. When the requisition is converted into a purchase order, the components are copied and can then also be changed. Release Notes: 4.0A Production Planning and Control -> Production Orders: Provision of Components for External Processing

7DEOHVDQG3URJUDPV Technically, the link between purchasing document and BOM is established through the pointer RSNUM in the purchase requisition (table EBAN) or delivery schedule line (table EKET). The components are in table RESB under the reservation number RSNUM and are numbered according to the item number (RSPOS). In turn, the reservation points to the requirement source document via the fields BELN, EBELP, EBELE (schedule line) or BANFN, BNFPO (requisition). Further tables in connection with subcontracting: MSLB MAST STPO VRSLI

SC Stocks Material to BOM Link BOM Item Index: Stock Transfer Reservation - Delivery

Programs: The function group for component processing in Purchasing is EINK (most important function module: ME_COMPONENTS_MAINTAIN). The function modules are invoked from the routines in the includes MM06BFLB (requisition) or MM06EFLB (purchase order/scheduling agreement) (most important routine: MDPM_MAINTAIN). The component screen is invoked from the detail screen in each case via the module CALL_KOMPONENTEN. The rest of the component processing (component screen, BOM explosion, update) is handled by function modules from Requirements Planning, of which the most important are: MD_AUFLOESEN_MDBA (BOM explosion) MD_BEARBEITEN_KOMPONENTEN (component screen) MD_HINZUFUEGEN_KOMPONENTEN, MD_VERAENDERN_KOMPONENTEN, ... The associated function groups are M61Z, M61Q, and M61P.

8 of 9

SAP AG

Subcontracting: Overview

Further Programs FB ME_READ_COMP_GOODS_ISSUE: Provision of Components (GI with Ref. to Purchase Order) FB ME_READ_COMP_GOODS_RECEIPT: Suggestion of Components (GR against SC order) Report RM06ELLB: SC Stock Monitoring List

9 of 9