Pressure Vessel Nozzle Loads ppz

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Pressure Vessel Nozzle Loads as PDF for free.

More details w3441

- Words: 640

- Pages: 2

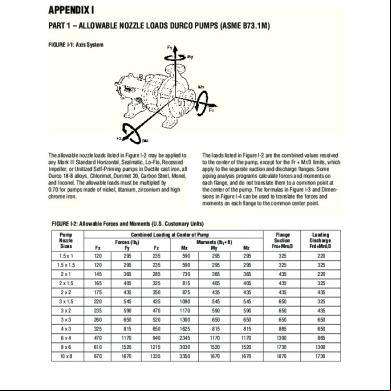

Pressure Vessel Nozzle Loads - Design Considerations Consideration of the effect that nozzles impose on pressure equipment and tanks can be one of the more challenging aspects of design. Conventional designs will use the area replacement method of AS1210 or ASME VIII Division 1 to ensure that the design of the nozzle is acceptable for internal and external pressure. This approach considers the disruption of primary stresses in the vessel shell due to the opening. In addition to the nozzle effects on pressure containment, the effect of external forces due to attached pipes is also a concern. It is of interest to learn that it was only as recently as 1979 that analytical methods were developed to address external loads on nozzles. Since that time, the advent of Finite Element Analysis (FEA) has permitted more comprehensive consideration of the stress field around an externally loaded nozzle. While pressure design is easily defined, evaluation of external nozzle loads is not as straightforward. The piping to nozzle interface can often be a cause of concern for piping and vessel designers. To address this problem and facilitate the design process for large projects, many consultancies have adopted a nominal convention for nozzle load limits that both the vessel and piping designers adhere to. One such convention is commonly referred to as 40D/60D: Nozzle Forces, N (FA, VL, VC) = 40×DN (mm) Nozzle Moments, Nm (MT, ML, MC) = 60×DN (mm)

Such a specification is of little use without additional information such as: Where is the origin of the load convention? (nozzle to shell center-line, nozzle to shell junction, end of nozzle) Should the loads be evaluated concurrently? Is there cyclic loading? While such a practice may lead to a more efficient design process, in many cases it does not lead to an efficient mechanical design. Since each nozzle is designed for the maximum loading, which is often concurrent in each principal force and moment, nozzles are often over-designed for external loading. An experienced piping designer will know that it is highly unlikely for an actual nozzle load (calculated from flexibility analysis) to be of similar proportions in each direction. Consider the case of a 3000mm diameter vessel with a 1200mm branch and a proposition to 40D-60D nozzle load specifications. There are significant implications, not just on the local shell but the whole vessel. For the piping designer there are various modeling techniques which will allow for calculation of nozzle loads. Depending on the nature of the loads, be it primary (force controlled) or secondary (displacement controlled), certain modeling techniques can be utilized to give a more accurate prediction. For displacement controlled loads, consideration of the vessel and nozzle flexibility may reduce loads compared to consideration of the nozzle as a piping anchor. However when primary loads control, consideration of flexibility will have little benefit. Further accuracy for nozzle loads can be achieved by considering the actual material modulus at the design condition. While this is not appropriate for the B31.3 displacement stress range, it is suitable for analysis of equipment loads. The piping designer must also consider whether it is applicable to only provide the maximum envelope of absolute loads. While this is often a conservative assumption, it is not always the case. Any design that includes cyclic loading will need to consider the six nozzle load components (including direction) in each case that forms the cycle. For design of critical nozzles, FEC recommends the use of finite element methods to determine the acceptability of nozzle loads. Since analytical methods are typically conservative, the finite element analysis approaches lead to more efficient design. If the vessel to pipe interaction is modeled appropriately within the guidance of the relevant design standards, the use of finite element methods will ensure an efficient mechanical design and a more comprehensive review of the system.

Such a specification is of little use without additional information such as: Where is the origin of the load convention? (nozzle to shell center-line, nozzle to shell junction, end of nozzle) Should the loads be evaluated concurrently? Is there cyclic loading? While such a practice may lead to a more efficient design process, in many cases it does not lead to an efficient mechanical design. Since each nozzle is designed for the maximum loading, which is often concurrent in each principal force and moment, nozzles are often over-designed for external loading. An experienced piping designer will know that it is highly unlikely for an actual nozzle load (calculated from flexibility analysis) to be of similar proportions in each direction. Consider the case of a 3000mm diameter vessel with a 1200mm branch and a proposition to 40D-60D nozzle load specifications. There are significant implications, not just on the local shell but the whole vessel. For the piping designer there are various modeling techniques which will allow for calculation of nozzle loads. Depending on the nature of the loads, be it primary (force controlled) or secondary (displacement controlled), certain modeling techniques can be utilized to give a more accurate prediction. For displacement controlled loads, consideration of the vessel and nozzle flexibility may reduce loads compared to consideration of the nozzle as a piping anchor. However when primary loads control, consideration of flexibility will have little benefit. Further accuracy for nozzle loads can be achieved by considering the actual material modulus at the design condition. While this is not appropriate for the B31.3 displacement stress range, it is suitable for analysis of equipment loads. The piping designer must also consider whether it is applicable to only provide the maximum envelope of absolute loads. While this is often a conservative assumption, it is not always the case. Any design that includes cyclic loading will need to consider the six nozzle load components (including direction) in each case that forms the cycle. For design of critical nozzles, FEC recommends the use of finite element methods to determine the acceptability of nozzle loads. Since analytical methods are typically conservative, the finite element analysis approaches lead to more efficient design. If the vessel to pipe interaction is modeled appropriately within the guidance of the relevant design standards, the use of finite element methods will ensure an efficient mechanical design and a more comprehensive review of the system.