Breech Lock 406k1b

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Breech Lock as PDF for free.

More details w3441

- Words: 1,060

- Pages: 19

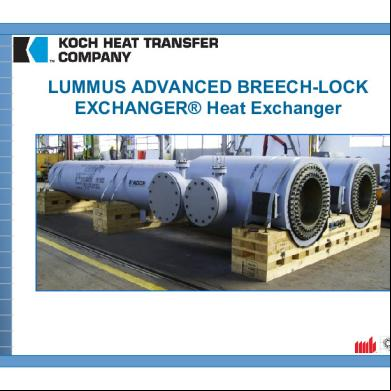

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger

What is a LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger? • It’s a special channel closure exchanger suitable for highpressure/high-temperature applications • Channel closure is obtained by screwing the cover on the channel body instead of using heavy bolting • Suitable for shell-and tube-side high-pressure applications (H/H type) and for tube-side only (H/L type) • Suitable for applications in refinery and petrochemical units, operating at high pressure and temperature with hydrogen-rich streams such as Hydrocrackers

History • The LUMMUS ADVANCED BREECH-LOCK EXCHANGER® heat exchanger was invented and developed in 1960 by Standard Oil Co. of California. • The first Breech-Lock exchanger was put into operation in 1966. • In 1982, ABB LUMMUS HEAT TRANSFER became a licensee for the worldwide marketing of high pressure Lummus Advanced Breech-Lock Exchanger heat exchangers. • In 1982, IMB became an ABB LHT licensee and contributed to the development of the LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger internals design. • Over 1,400 Breech-Lock high-pressure heat exchangers are in operation worldwide. Approximately 50% were manufactured by KHT/IMB.

Applications & Features • Plants with high-temperature/high-pressure hydrogen-rich streams

Applications : • • • •

Hydrocrackers Gas compression Ammonia synthesis Miscellaneous

Main Features: • • • •

Reliable high-pressure performance sealing Easy dismantling/reassembly for inspection and maintenance Reduced high-stressed zones in the channel In-service seating of internal gaskets

Closure Engineering Features: •

Hydrostatic load on the channel cover is absorbed by the channel threads and by the channel body

•

Tightening of channel-cover gasket by small bolts

•

Bolts are in line with gaskets center line; no bending moment on components due to the bolts loading

•

Spiral-wound or Kammprofile gaskets are used in the girth ts

•

Diaphragm makes cladding on channel cover superfluous

•

Channel cover is relatively thin and light.

Closure Advantages: •

Minimum of flanged ts due to integral construction of channel body

•

No internal threaded holes into weld overlaid channel portions (compared to boltedin design)

•

Retightening of tubesheet gasket during operation is possible without any shutdown

•

All channel parts can be easily removed without cutting or Grinding

•

No need for heavy crane or for hydraulic bolt tensioning devices to remove and reassemble channel cover and bolts

•

No need of welding and PWHT during reinstallation of channel parts or diaphragms

•

Over 1300 mm. (50”) Shell ID and 150 bar (2200 PSI) LUMMUS ADVANCED BREECH-LOCK EXCHANGER Heat Exchanger is cheaper

•

LUMMUS ADVANCED BREECH-LOCK EXCHANGER Heat Exchanger closure can be combined with enhanced heat transfer technologies such as Twisted Tube® heat exchanger, Helixchanger® or Low-Pressure Drop LOK-BAFFLE™ to get the best inservice overall performance.

Special Dismantling Jig Opening and closing activities are even quicker and easier No need of heavy cranage for dismantling as it’s self sustained on the exchanger Can be stored in split conditions It’s adjustable for different exchanger diameters

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger LOWER CAPITAL EXPENDITURE + EASIER MAINTENANCE + SHORTER SHUTDOWN TIME

HIGHER RELIABILITY & LOWER TOTAL LIFE-CYCLE COST

Reduced Bolt Size ◄ Design Pressure: 168 barg (2437 PSI) Design Temperature: 345 °C (653 °F) Shell ID: 1470 mm. (58”) Bolt size: 5” ¾ (# 20) Bolt weight: 120 Kg./each

► Design Pressure: 200 barg (2900 PSI) Design Temperature: 450 °C (842 °F) Shell ID: 1730 mm. (68”) Bolt size: 1” ½ (# 72) Bolt weight: 1,1 Kg./each

Reduced Bolt Size ◄ Design Pressure: 190 barg (2755 PSI) Design Temperature: 454 °C (850 °F) Shell ID: 858 mm. (34”) Bolt size: 3” ¾ (# 20) Bolt weight: 34 Kg./each

► Design Pressure: 195 barg (2828 PSI) Design Temperature: 454 °C (850 °F) Shell ID: 890 mm. (35”) Bolt size: 1” ½ (# 44) Bolt weight: 1,1 Kg./each

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger Not Just Another “Screw-Plug” Closure Exchanger •

Channel is thicker compared to other “screw plug” closures in order to guarantee no deformation during manufacturing or service

•

Narrow tolerance for channel & lock ring thread for safer operation

•

Internal bolts are not prone to deformation or to overstressing

•

Seal gasket, confined into the diaphragm, guarantees sealing even during transient conditions

•

Detailed design has been improved and optimized over the years even on minor details that can heavily affect reliability and maintenance,

•

Effective operations and maintenance manual includes a detailed plan for preventive maintenance

•

Dedicated team with extensive experience for training, site service and supervision during LUMMUS ADVANCED BREECH-LOCK EXCHANGER Heat Exchanger shutdown and maintenance

Closure design assessment made by a customer

Screw-Plug Item 52E-1:

LUMMUS ADVANCED BREECHLOCK EXCHANGER® Item 63E-4:

Shell Design: • 2925 psig / 750ºF • 202 barg / 399 °C Tube Design: • 2685 psig / 867ºF • 185 barg / 564 °C

Shell Design: • 2130 psig / 800ºF • 147 barg / 426 °C Tube Design: • 2395 psig / 750ºF • 165 barg / 399 °C

Channel Barrel Wall Thickness: • 2.911” (74 mm.)

Channel Barrel Wall Thickness: • 3.189” (81 mm.)

One of the Biggest Ever Built Design Pressure: 179 bar shell s. – 200 bar tube s. 2596 PSI shells. – 2900 PSI tube s. Design Temperature: 454 °C shell s. – 427 °C tube s. 850 °F shell s. – 800 °F tube s. Shell ID: 1981 mm. (78”) Weight: 180 Tons/each Stacked at Cremona river port and shipped to the site in stacked condition.

U.S. Refinery - Clean Fuel Plant

Design Pressure: 196 bar shell s. – 178 bar tube s. 2843 PSI shell s. – 2582 PSI tube s. Design Temperature: 430 C shell s. – 454 C tube s. 806 F shell s. – 850 F tube s. Shell ID: 864 mm. (34”) Weight: 35 Tons/each No.3 Breech-Lock Exchangers hydrotested in stacked condition and then shipped separately

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger with TWISTED TUBE® Bundle for a German Refinery Service: Hydrocracking Combined Feed/Effluent Client’s design: 10 Exchangers Twisted Tube® Bundle Design: 7 exchangers

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger with TWISTED TUBE® bundle for German Refinery Design Pressure: 154 bar s.s. – 136 bar t.s. 2234 PSI s.s – 1972 PSI t.s. Design Temperature: 450 °C s.s. – 454 °C t.s. 842 °F s.s. – 850 °F t.s. Shell ID: 1370 mm. (54”) Weight: 56 Tons.

Price Comparison

HIGH-PRESSURE SHELL & TUBE WITH LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger CLOSURE

Thank you for your attention!

What is a LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger? • It’s a special channel closure exchanger suitable for highpressure/high-temperature applications • Channel closure is obtained by screwing the cover on the channel body instead of using heavy bolting • Suitable for shell-and tube-side high-pressure applications (H/H type) and for tube-side only (H/L type) • Suitable for applications in refinery and petrochemical units, operating at high pressure and temperature with hydrogen-rich streams such as Hydrocrackers

History • The LUMMUS ADVANCED BREECH-LOCK EXCHANGER® heat exchanger was invented and developed in 1960 by Standard Oil Co. of California. • The first Breech-Lock exchanger was put into operation in 1966. • In 1982, ABB LUMMUS HEAT TRANSFER became a licensee for the worldwide marketing of high pressure Lummus Advanced Breech-Lock Exchanger heat exchangers. • In 1982, IMB became an ABB LHT licensee and contributed to the development of the LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger internals design. • Over 1,400 Breech-Lock high-pressure heat exchangers are in operation worldwide. Approximately 50% were manufactured by KHT/IMB.

Applications & Features • Plants with high-temperature/high-pressure hydrogen-rich streams

Applications : • • • •

Hydrocrackers Gas compression Ammonia synthesis Miscellaneous

Main Features: • • • •

Reliable high-pressure performance sealing Easy dismantling/reassembly for inspection and maintenance Reduced high-stressed zones in the channel In-service seating of internal gaskets

Closure Engineering Features: •

Hydrostatic load on the channel cover is absorbed by the channel threads and by the channel body

•

Tightening of channel-cover gasket by small bolts

•

Bolts are in line with gaskets center line; no bending moment on components due to the bolts loading

•

Spiral-wound or Kammprofile gaskets are used in the girth ts

•

Diaphragm makes cladding on channel cover superfluous

•

Channel cover is relatively thin and light.

Closure Advantages: •

Minimum of flanged ts due to integral construction of channel body

•

No internal threaded holes into weld overlaid channel portions (compared to boltedin design)

•

Retightening of tubesheet gasket during operation is possible without any shutdown

•

All channel parts can be easily removed without cutting or Grinding

•

No need for heavy crane or for hydraulic bolt tensioning devices to remove and reassemble channel cover and bolts

•

No need of welding and PWHT during reinstallation of channel parts or diaphragms

•

Over 1300 mm. (50”) Shell ID and 150 bar (2200 PSI) LUMMUS ADVANCED BREECH-LOCK EXCHANGER Heat Exchanger is cheaper

•

LUMMUS ADVANCED BREECH-LOCK EXCHANGER Heat Exchanger closure can be combined with enhanced heat transfer technologies such as Twisted Tube® heat exchanger, Helixchanger® or Low-Pressure Drop LOK-BAFFLE™ to get the best inservice overall performance.

Special Dismantling Jig Opening and closing activities are even quicker and easier No need of heavy cranage for dismantling as it’s self sustained on the exchanger Can be stored in split conditions It’s adjustable for different exchanger diameters

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger LOWER CAPITAL EXPENDITURE + EASIER MAINTENANCE + SHORTER SHUTDOWN TIME

HIGHER RELIABILITY & LOWER TOTAL LIFE-CYCLE COST

Reduced Bolt Size ◄ Design Pressure: 168 barg (2437 PSI) Design Temperature: 345 °C (653 °F) Shell ID: 1470 mm. (58”) Bolt size: 5” ¾ (# 20) Bolt weight: 120 Kg./each

► Design Pressure: 200 barg (2900 PSI) Design Temperature: 450 °C (842 °F) Shell ID: 1730 mm. (68”) Bolt size: 1” ½ (# 72) Bolt weight: 1,1 Kg./each

Reduced Bolt Size ◄ Design Pressure: 190 barg (2755 PSI) Design Temperature: 454 °C (850 °F) Shell ID: 858 mm. (34”) Bolt size: 3” ¾ (# 20) Bolt weight: 34 Kg./each

► Design Pressure: 195 barg (2828 PSI) Design Temperature: 454 °C (850 °F) Shell ID: 890 mm. (35”) Bolt size: 1” ½ (# 44) Bolt weight: 1,1 Kg./each

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger Not Just Another “Screw-Plug” Closure Exchanger •

Channel is thicker compared to other “screw plug” closures in order to guarantee no deformation during manufacturing or service

•

Narrow tolerance for channel & lock ring thread for safer operation

•

Internal bolts are not prone to deformation or to overstressing

•

Seal gasket, confined into the diaphragm, guarantees sealing even during transient conditions

•

Detailed design has been improved and optimized over the years even on minor details that can heavily affect reliability and maintenance,

•

Effective operations and maintenance manual includes a detailed plan for preventive maintenance

•

Dedicated team with extensive experience for training, site service and supervision during LUMMUS ADVANCED BREECH-LOCK EXCHANGER Heat Exchanger shutdown and maintenance

Closure design assessment made by a customer

Screw-Plug Item 52E-1:

LUMMUS ADVANCED BREECHLOCK EXCHANGER® Item 63E-4:

Shell Design: • 2925 psig / 750ºF • 202 barg / 399 °C Tube Design: • 2685 psig / 867ºF • 185 barg / 564 °C

Shell Design: • 2130 psig / 800ºF • 147 barg / 426 °C Tube Design: • 2395 psig / 750ºF • 165 barg / 399 °C

Channel Barrel Wall Thickness: • 2.911” (74 mm.)

Channel Barrel Wall Thickness: • 3.189” (81 mm.)

One of the Biggest Ever Built Design Pressure: 179 bar shell s. – 200 bar tube s. 2596 PSI shells. – 2900 PSI tube s. Design Temperature: 454 °C shell s. – 427 °C tube s. 850 °F shell s. – 800 °F tube s. Shell ID: 1981 mm. (78”) Weight: 180 Tons/each Stacked at Cremona river port and shipped to the site in stacked condition.

U.S. Refinery - Clean Fuel Plant

Design Pressure: 196 bar shell s. – 178 bar tube s. 2843 PSI shell s. – 2582 PSI tube s. Design Temperature: 430 C shell s. – 454 C tube s. 806 F shell s. – 850 F tube s. Shell ID: 864 mm. (34”) Weight: 35 Tons/each No.3 Breech-Lock Exchangers hydrotested in stacked condition and then shipped separately

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger with TWISTED TUBE® Bundle for a German Refinery Service: Hydrocracking Combined Feed/Effluent Client’s design: 10 Exchangers Twisted Tube® Bundle Design: 7 exchangers

LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger with TWISTED TUBE® bundle for German Refinery Design Pressure: 154 bar s.s. – 136 bar t.s. 2234 PSI s.s – 1972 PSI t.s. Design Temperature: 450 °C s.s. – 454 °C t.s. 842 °F s.s. – 850 °F t.s. Shell ID: 1370 mm. (54”) Weight: 56 Tons.

Price Comparison

HIGH-PRESSURE SHELL & TUBE WITH LUMMUS ADVANCED BREECH-LOCK EXCHANGER® Heat Exchanger CLOSURE

Thank you for your attention!