Breech Lock Presentation 126r5l

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Breech Lock Presentation as PDF for free.

More details w3441

- Words: 424

- Pages: 24

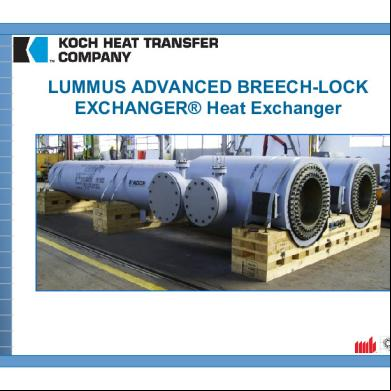

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

Invented and developed in 1960 by Standard Oil Co. of California . The first breech-lock was put into operation in 1966.

Rights of technology remain with Chevron Research Company of California.

In 1982, ABB LUMMUS HEAT TRANSFER became a licensee for the worldwide marketing of high pressure Breech-Lock heat exchangers.

Since 1982 IMB was ABB LHT licensee and contributed to the further developement of the Breech-Lock internals design.

Over 600 Breech-Lock high pressure heat exchangers are in operation worldwide. Approximately 300 have been manufactured by IMB.

Finds applications in refinery units operating at high pressure and temperature with hydrogen rich streams such as Hydrocrackers.

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

APPLICATIONS High Temperature/High Pressure Units: Hydrocrackers / Hydrotreaters Gas Compression Ammonia Synthesis Miscellaneous

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

by curtesy of SHELL PERNIS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

MAIN FEATURES Reliable High Pressure Performance Sealing Easy Dismantling/Reassembly for Inspection Avoidance of High Stressed Zones in Pressure Parts In Service Seating of Internal Gaskets

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

Closure Features and Advantages Hydrostatic Load Of Channel Cover Is Absorbed by the Channel Forging No Threaded Holes in Forging or in the Cladding Tightening of Gasket by Relatively Small Bolts Spiral Wound Gaskets are Used in the Girth ts Channel Cover is Relatively Thin and Light Re-Tightening of Tubesheet Gasket During Operation Possible. Easy and Quick Maintenance All Channel Parts can be Removed Without Cutting.

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS HYDROTEST CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS PRIMARY LOADING CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS SECONDARY LOADING CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS LOADING CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

Assembling & Dismantling Jig Unique, proprietary design Self sustained on the equipment Self alligning Reduced maintenance time One single jig is suitable for different size item Easy to store

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

Invented and developed in 1960 by Standard Oil Co. of California . The first breech-lock was put into operation in 1966.

Rights of technology remain with Chevron Research Company of California.

In 1982, ABB LUMMUS HEAT TRANSFER became a licensee for the worldwide marketing of high pressure Breech-Lock heat exchangers.

Since 1982 IMB was ABB LHT licensee and contributed to the further developement of the Breech-Lock internals design.

Over 600 Breech-Lock high pressure heat exchangers are in operation worldwide. Approximately 300 have been manufactured by IMB.

Finds applications in refinery units operating at high pressure and temperature with hydrogen rich streams such as Hydrocrackers.

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

APPLICATIONS High Temperature/High Pressure Units: Hydrocrackers / Hydrotreaters Gas Compression Ammonia Synthesis Miscellaneous

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

by curtesy of SHELL PERNIS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

MAIN FEATURES Reliable High Pressure Performance Sealing Easy Dismantling/Reassembly for Inspection Avoidance of High Stressed Zones in Pressure Parts In Service Seating of Internal Gaskets

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

Closure Features and Advantages Hydrostatic Load Of Channel Cover Is Absorbed by the Channel Forging No Threaded Holes in Forging or in the Cladding Tightening of Gasket by Relatively Small Bolts Spiral Wound Gaskets are Used in the Girth ts Channel Cover is Relatively Thin and Light Re-Tightening of Tubesheet Gasket During Operation Possible. Easy and Quick Maintenance All Channel Parts can be Removed Without Cutting.

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS HYDROTEST CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS PRIMARY LOADING CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS SECONDARY LOADING CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS LOADING CONDITION

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS

Assembling & Dismantling Jig Unique, proprietary design Self sustained on the equipment Self alligning Reduced maintenance time One single jig is suitable for different size item Easy to store

BREECH-LOCK CLOSURE

HIGH PRESSURE HEAT EXCHANGERS