Classnotesforyou, 1 4kg25

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Classnotesforyou, 1 as PDF for free.

More details w3441

- Words: 1,638

- Pages: 26

Module – 3 Dynamics of fluid flow Eldho Mathew /Ajith M S Assistant professor Mechanical department ASIET

Dynamics of fluid flow • Study of fluid motion with the forces causing flow. • The dynamic behaviour of the fluid flow is analysed by the Newton’s second law of motion, which relates the acceleration with the forces. • The fluid is assumed to be incompressible and non-viscous.

Equations of motion • In the fluid flow, the following forces are present: (i) Fg, gravity force (ii) Fp, the pressure force (iii)Fv, force due to viscosity (iv) Ft, force due to turbulance (v) Fc, force due to compressibility. Newtons law yields m( dv/dt) = (Fg)+ (Fp)+ (Fv)+ (Ft)+ (Fc)

(i) If Fc is negligible, the resulting net force m( dv/dt) = (Fg)+ (Fp)+ (Fv)+ (Ft) and equation of motions are called Reynold’s equations of motion (ii) If Ft is negligible, the resulting equations of motion are known as Navier-Stokes equation m( dv/dt) = (Fg)+ (Fp)+ (Fv) (iii) If the flow is assumed to be ideal, viscous force (Fv) is zero and equations of motions are known as Euler’s equation of motion. m( dv/dt) = (Fg)+ (Fp)

Euler’s equation of motion Consider a stream line in which flow is taking place in s direction. The forces acting on the cylindrical element of cross section dA and length ds are 1. Pressure force pdA in the direction of flow. 2. Pressure force [p +(∂p/∂s)ds] dA opposite to the direction of flow. 3. Weight of element ρgdAds θ is the angle between the direction of flow and the line of action of the weight of element

Resultant force, Fs = mass of element x as So pdA - [p +(∂p/∂s)ds] dA – ρgdAdscosθ = ρdAdsas eq.1 where as is the acceleration in the direction of s. Now as = dv/dt, where v is a function of s and t = (∂v/∂s x ds/dt) +∂v/∂t (since ds/dt =v) If the flow is steady, ∂v/∂t = 0 So, as = v∂v/∂s Substituting the value of as in eq. no. 1and simplifying the equation, we get -(∂p/∂s)dsdA – ρgdAdscosθ = ρdAds x v∂v/∂s Dividing by ρdAds, we get, -∂p/ρ∂s –gcosθ = v∂v/∂s ∂p/ρ∂s + gcosθ + v∂v/∂s = 0

But from fig, we have cosθ = dz/ds So (1/ρ) dp/ds + g dz/ds + v dv/ds = 0 Or dp/ρ +gdz +vdv = 0 eq. 2 Eq. 2 is known as Euler’s equation of motion.

Bernoulli’s equation of motion Assumptions • The fluid is ideal, i.e. viscosity is zero • The flow is steady • The flow is incompressible • The flow is irrotational

Bernoulli’s equation of motion Bernoulli’s theorem “ It states that in a steady, ideal flow of an incompressible fluid, the total energy at any point of the fluid is constant. The total energy consists of pressure energy, kinetic energy and potential energy.” Bernoulli’s equation is obtained by integrating the Euler’s equation of motion as ʃdp/ρ + ʃgdz + ʃvdv = constant If flow is incompressible, ρ is constant and p/ρ + gz + v2/2 = constant Or p/ρg + v2/2g + z = constant p/ ρg = pressure head v2/2g = kinetic head z = potential head

Bernoulli’s equation for real fluid • All the real fluid are viscous and hence offer resistance to flow. • Thus there are always some losses in fluid flows and hence in the application of Bernoulli’s equation. • Thus the Bernoulli’s equation for real fluids between points 1 and 2 is given as p1/ρg + v12/2g + z1 = p2/ρg + v22/2g + z2 + hL Where hL is loss of energy between points 1 and 2.

Bernoulli’s equation: applications The following devices are examples for the practical applications of Bernoulli’s equation. (1) Venturi meter (2) Orifice meter (3) Flow nozzle (4) Pitot tube Bernoulli’s equation is also applied for measurements of flow through pipes and open channels

Venturimeter • Used to measure the discharge of fluid flowing through a pipe • The cross-sectional area of the age is reduced to create a pressure difference. • By measuring the pressure difference, we can find the discharge through the pipe. Venturimeter consists of three parts (1) A short converging part (2) Throat (3) A long diverging part • The U tube manometer is fitted on limb at the inlet pipe and other limb at the throat. • The included angle of convergent part is 150 to 200 while that of divergent part is 50 to 70.

Apply Bernoulli’s equation between section (1) and (2) i.e between inlet and throat, we get P1/ρg +V12/2g +Z1 = P2/ρg +V22/2g +Z2 eq.1 When a pipe is horizontal, Z1 = Z2 Then (P1 – P2)/ρg = (V22 – V12)/2g eq.2 Here (P1 – P2)/ρg is the difference of pressure heads at section 1 and 2 and it is equal to h. So the equation becomes h = (V22 – V12)/2g eq.3 V22 – V12 = 2gh eq.4 Applying continuity equation at section 1 and 2 A1V1 = A2V2 or V1 = (A2V2)/A1

Substituting V1 = (A2V2)/A1 in eq.4, we get V22 – (A2V2/A1)2 = 2gh V22 – (A22V22/A12) = 2gh V22 [1- (A22/A12)] = 2gh V22 [(A12 - A22)/A12] = 2gh V22 = 2gh [A12/(A12 - A22)] V2 = =

Theoretical discharge (Qth) = A2V2 = The above discharge is theoretical one. The actual discharge will be less than the theoretical one. So Qact = Cd (Qth) = Cd

Where Cd = coefficient of venturimeter and it is less than one always.

• If the manometer contains liquid heavier than flowing liquid, then h= x [(Sh/Sf) -1] • If the manometer contains liquid lighter than the flowing liquid, then h = x [1- (SL/Sf)]

Orificemeter • It is a simple device used for measuring discharge of fluid through a pipe. • It works on basis of Bernoulli’s equation like venturimeter. • It consists of a flat circular plate having sharp edged hole concentric with a pipe. • The diameter of the orifice varies from 0.4 to 0.8 times the pipe diameter. • Orifice meter is fitted on the pipe line to measure discharge of fluid. A differential manometer is connected so that one limb connects at section 1 and the other at section 2.

Applying Bernoulli’s equation, P1/ρg +V12/2g +Z1 = P2/ρg +V22/2g +Z2 eq.1 [P1/ρg + Z1] – [P2/ρg + Z2] = (V22/2g) – (V12/2g) [P1/ρg + Z1] – [P2/ρg + Z2] = h = differential manometer head. So h = (V22 - V12)/2g V22 - V12 = 2gh eq.2 The section 2 is at the venacontracta and A2 is the area of the venacontracta.

• The ratio of the area of vena contracta to the area of the orifice is known as coefficient of contraction. Cc = Area of jet at vena contracta/area of orifice = A2/A0 According to continuity equation, A1V 1 = A2V2 So V1 = (A2V2)/A1 = (CcA0V2)/A1 Substitute V1 value in equation 2, we get V22 – [(Cc2A02V22)/A12] = 2gh V2 = eq.3

• Theoretical Discharge Q= V2A2 = V2 x A0Cc = x A0Cc eq.4

The above expression is simplified by using Cd =

or Cc =

Substituting the value of Cc in equation (4) we

get Q =

x A0 x

Q =

=

Pitot tube • Used for measuring the velocity of flow at any point in a pipe or a channel. • It is based on the principle that if the velocity of flow at a point becomes zero, the pressure is increased due to the conversion of the kinetic energy into pressure energy. • Consider two points (1) and (2) at same level in such a way that point (2) is just at the inlet of pitot tube and point (1) is far away from the tube.

Applying Bernoulli’s equation at points (1) and (2), we get P1/ρg +V12/2g +Z1 = P2/ρg +V22/2g +Z2 eq.1 But Z1 = Z2 as points (1) and (2) are on same line. Also V2 = 0 Pressure head at (1) = P1/ρg = H Pressure head at (2) = P2/ρg = (h + H) H + V12/2g = h + H h = V12/2g, V1 = This is theoretical velocity. Actual velocity is given by (V1)act = Cv Where Cv = Coefficient of pitot tube.

The various arrangement of pitot tube adopted are (i) Pitot-tube along with a vertical piezometer (ii) Pitot tube connected with piezometer (iii) Pitot-tube and vertical piezometer tube with differential U-tube manometer (iv) Pitot - static tube, which consists of two circular concentric tubes one inside the other. The outlet is connected to the differential manometer where the difference of pressure head ‘h’ is measured by knowing the difference of the level of manometer liquid say’x’. Now h = x [(Sh/Sf) -1]

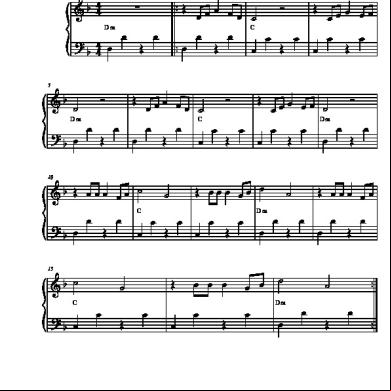

Notches and weirs Notch

Weir

• Opening in the side of a tank or reservoir which extends above the surface of the liquid. • It is a device, generally made of metal, for measuring discharge of a liquid. • Notches can be classified according to the shape of the opening as rectangular, triangular, trapezoidal and stepped notches

•

•

•

Concrete or masonary structure placed in an open channel over which the flow of liquid occurs. A weir is a notch on a larger scale which is sharp crested but also may have substantial width in the direction of flow. It is used both as a flow measuring device and a device to raise water levels. According to the shape weirs can be classified as rectangular, triangular, trapezoidal or Cippoletti weir.

• Nappe or vein :- The sheet of liquid flowing through a notch or weir is called nappe or vein. • Sill or crest :- The bottom edge of a notch or the top of a weir over which the liquid flows is called as the sill or crest.

Dynamics of fluid flow • Study of fluid motion with the forces causing flow. • The dynamic behaviour of the fluid flow is analysed by the Newton’s second law of motion, which relates the acceleration with the forces. • The fluid is assumed to be incompressible and non-viscous.

Equations of motion • In the fluid flow, the following forces are present: (i) Fg, gravity force (ii) Fp, the pressure force (iii)Fv, force due to viscosity (iv) Ft, force due to turbulance (v) Fc, force due to compressibility. Newtons law yields m( dv/dt) = (Fg)+ (Fp)+ (Fv)+ (Ft)+ (Fc)

(i) If Fc is negligible, the resulting net force m( dv/dt) = (Fg)+ (Fp)+ (Fv)+ (Ft) and equation of motions are called Reynold’s equations of motion (ii) If Ft is negligible, the resulting equations of motion are known as Navier-Stokes equation m( dv/dt) = (Fg)+ (Fp)+ (Fv) (iii) If the flow is assumed to be ideal, viscous force (Fv) is zero and equations of motions are known as Euler’s equation of motion. m( dv/dt) = (Fg)+ (Fp)

Euler’s equation of motion Consider a stream line in which flow is taking place in s direction. The forces acting on the cylindrical element of cross section dA and length ds are 1. Pressure force pdA in the direction of flow. 2. Pressure force [p +(∂p/∂s)ds] dA opposite to the direction of flow. 3. Weight of element ρgdAds θ is the angle between the direction of flow and the line of action of the weight of element

Resultant force, Fs = mass of element x as So pdA - [p +(∂p/∂s)ds] dA – ρgdAdscosθ = ρdAdsas eq.1 where as is the acceleration in the direction of s. Now as = dv/dt, where v is a function of s and t = (∂v/∂s x ds/dt) +∂v/∂t (since ds/dt =v) If the flow is steady, ∂v/∂t = 0 So, as = v∂v/∂s Substituting the value of as in eq. no. 1and simplifying the equation, we get -(∂p/∂s)dsdA – ρgdAdscosθ = ρdAds x v∂v/∂s Dividing by ρdAds, we get, -∂p/ρ∂s –gcosθ = v∂v/∂s ∂p/ρ∂s + gcosθ + v∂v/∂s = 0

But from fig, we have cosθ = dz/ds So (1/ρ) dp/ds + g dz/ds + v dv/ds = 0 Or dp/ρ +gdz +vdv = 0 eq. 2 Eq. 2 is known as Euler’s equation of motion.

Bernoulli’s equation of motion Assumptions • The fluid is ideal, i.e. viscosity is zero • The flow is steady • The flow is incompressible • The flow is irrotational

Bernoulli’s equation of motion Bernoulli’s theorem “ It states that in a steady, ideal flow of an incompressible fluid, the total energy at any point of the fluid is constant. The total energy consists of pressure energy, kinetic energy and potential energy.” Bernoulli’s equation is obtained by integrating the Euler’s equation of motion as ʃdp/ρ + ʃgdz + ʃvdv = constant If flow is incompressible, ρ is constant and p/ρ + gz + v2/2 = constant Or p/ρg + v2/2g + z = constant p/ ρg = pressure head v2/2g = kinetic head z = potential head

Bernoulli’s equation for real fluid • All the real fluid are viscous and hence offer resistance to flow. • Thus there are always some losses in fluid flows and hence in the application of Bernoulli’s equation. • Thus the Bernoulli’s equation for real fluids between points 1 and 2 is given as p1/ρg + v12/2g + z1 = p2/ρg + v22/2g + z2 + hL Where hL is loss of energy between points 1 and 2.

Bernoulli’s equation: applications The following devices are examples for the practical applications of Bernoulli’s equation. (1) Venturi meter (2) Orifice meter (3) Flow nozzle (4) Pitot tube Bernoulli’s equation is also applied for measurements of flow through pipes and open channels

Venturimeter • Used to measure the discharge of fluid flowing through a pipe • The cross-sectional area of the age is reduced to create a pressure difference. • By measuring the pressure difference, we can find the discharge through the pipe. Venturimeter consists of three parts (1) A short converging part (2) Throat (3) A long diverging part • The U tube manometer is fitted on limb at the inlet pipe and other limb at the throat. • The included angle of convergent part is 150 to 200 while that of divergent part is 50 to 70.

Apply Bernoulli’s equation between section (1) and (2) i.e between inlet and throat, we get P1/ρg +V12/2g +Z1 = P2/ρg +V22/2g +Z2 eq.1 When a pipe is horizontal, Z1 = Z2 Then (P1 – P2)/ρg = (V22 – V12)/2g eq.2 Here (P1 – P2)/ρg is the difference of pressure heads at section 1 and 2 and it is equal to h. So the equation becomes h = (V22 – V12)/2g eq.3 V22 – V12 = 2gh eq.4 Applying continuity equation at section 1 and 2 A1V1 = A2V2 or V1 = (A2V2)/A1

Substituting V1 = (A2V2)/A1 in eq.4, we get V22 – (A2V2/A1)2 = 2gh V22 – (A22V22/A12) = 2gh V22 [1- (A22/A12)] = 2gh V22 [(A12 - A22)/A12] = 2gh V22 = 2gh [A12/(A12 - A22)] V2 = =

Theoretical discharge (Qth) = A2V2 = The above discharge is theoretical one. The actual discharge will be less than the theoretical one. So Qact = Cd (Qth) = Cd

Where Cd = coefficient of venturimeter and it is less than one always.

• If the manometer contains liquid heavier than flowing liquid, then h= x [(Sh/Sf) -1] • If the manometer contains liquid lighter than the flowing liquid, then h = x [1- (SL/Sf)]

Orificemeter • It is a simple device used for measuring discharge of fluid through a pipe. • It works on basis of Bernoulli’s equation like venturimeter. • It consists of a flat circular plate having sharp edged hole concentric with a pipe. • The diameter of the orifice varies from 0.4 to 0.8 times the pipe diameter. • Orifice meter is fitted on the pipe line to measure discharge of fluid. A differential manometer is connected so that one limb connects at section 1 and the other at section 2.

Applying Bernoulli’s equation, P1/ρg +V12/2g +Z1 = P2/ρg +V22/2g +Z2 eq.1 [P1/ρg + Z1] – [P2/ρg + Z2] = (V22/2g) – (V12/2g) [P1/ρg + Z1] – [P2/ρg + Z2] = h = differential manometer head. So h = (V22 - V12)/2g V22 - V12 = 2gh eq.2 The section 2 is at the venacontracta and A2 is the area of the venacontracta.

• The ratio of the area of vena contracta to the area of the orifice is known as coefficient of contraction. Cc = Area of jet at vena contracta/area of orifice = A2/A0 According to continuity equation, A1V 1 = A2V2 So V1 = (A2V2)/A1 = (CcA0V2)/A1 Substitute V1 value in equation 2, we get V22 – [(Cc2A02V22)/A12] = 2gh V2 = eq.3

• Theoretical Discharge Q= V2A2 = V2 x A0Cc = x A0Cc eq.4

The above expression is simplified by using Cd =

or Cc =

Substituting the value of Cc in equation (4) we

get Q =

x A0 x

Q =

=

Pitot tube • Used for measuring the velocity of flow at any point in a pipe or a channel. • It is based on the principle that if the velocity of flow at a point becomes zero, the pressure is increased due to the conversion of the kinetic energy into pressure energy. • Consider two points (1) and (2) at same level in such a way that point (2) is just at the inlet of pitot tube and point (1) is far away from the tube.

Applying Bernoulli’s equation at points (1) and (2), we get P1/ρg +V12/2g +Z1 = P2/ρg +V22/2g +Z2 eq.1 But Z1 = Z2 as points (1) and (2) are on same line. Also V2 = 0 Pressure head at (1) = P1/ρg = H Pressure head at (2) = P2/ρg = (h + H) H + V12/2g = h + H h = V12/2g, V1 = This is theoretical velocity. Actual velocity is given by (V1)act = Cv Where Cv = Coefficient of pitot tube.

The various arrangement of pitot tube adopted are (i) Pitot-tube along with a vertical piezometer (ii) Pitot tube connected with piezometer (iii) Pitot-tube and vertical piezometer tube with differential U-tube manometer (iv) Pitot - static tube, which consists of two circular concentric tubes one inside the other. The outlet is connected to the differential manometer where the difference of pressure head ‘h’ is measured by knowing the difference of the level of manometer liquid say’x’. Now h = x [(Sh/Sf) -1]

Notches and weirs Notch

Weir

• Opening in the side of a tank or reservoir which extends above the surface of the liquid. • It is a device, generally made of metal, for measuring discharge of a liquid. • Notches can be classified according to the shape of the opening as rectangular, triangular, trapezoidal and stepped notches

•

•

•

Concrete or masonary structure placed in an open channel over which the flow of liquid occurs. A weir is a notch on a larger scale which is sharp crested but also may have substantial width in the direction of flow. It is used both as a flow measuring device and a device to raise water levels. According to the shape weirs can be classified as rectangular, triangular, trapezoidal or Cippoletti weir.

• Nappe or vein :- The sheet of liquid flowing through a notch or weir is called nappe or vein. • Sill or crest :- The bottom edge of a notch or the top of a weir over which the liquid flows is called as the sill or crest.