Emerging Technologies And Biological Systems For Biogas Upgrading b514i

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Emerging Technologies And Biological Systems For Biogas Upgrading as PDF for free.

More details w3441

- Words: 176,723

- Pages: 1,128

- Publisher: Academic Press

- Released Date: 2021-03-30

- Author: Nabin Aryal

Emerging Technologies and Biological Systems for Biogas Upgrading

Edited by

Nabin Aryal

Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Lars Ditlev Mørck Ottosen

Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Michael Vedel Wegener Kofoed

Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Deepak Pant

Separation and Conversion Technology, Flemish Institute for Technological Research (VITO), Mol, Belgium

Table of Contents

Cover image

Title page

Copyright

List of contributors

Foreword

Preface Part I: Introduction

Chapter 1. Status of biogas production and biogas upgrading: A global scenario

Abstract

Chapter outline

1.1 Introduction

1.2 State-of-the-art of biogas production and upgradation

1.3 Recent trends in biogas utilization: A global prospective

1.4 Anaerobic digestion

1.5 Biohythane

1.6 Electrochemically induced biogas upgradation

1.7 Challenges and way forward

Acknowledgments

References

Part II: Physiochemical upgrading systems

Chapter 2. Chemical absorption—amine absorption/stripping technology for biogas upgrading

Abstract

Chapter outline

2.1 Introduction

2.2 Process fundamentals

2.3 Research and development directions

2.4 Conclusions and future perspectives

References

Further reading

Chapter 3. Water scrubbing for biogas upgrading: developments and innovations

Abstract

Chapter outline

3.1 Introduction

3.2 Absorption methodologies

3.3 Absorption configurations

3.4 Chemical promoters in water absorption

3.5 Energy consumption

3.6 Methane slip and efficiency

3.7 Conclusions

References

Chapter 4. Factors affecting CO2 and CH4 separation during biogas upgrading in a water scrubbing process

Abstract

Chapter outline

4.1 Introduction

4.2 Approaches for CO2 removal from biogas

4.3 Water scrubbing technology

4.4 Water as a solvent for gases

4.5 Solubility of biogas components in water

4.6 Factors affecting biogas upgrading in water scrubbing process

4.7 Scrubbing column internals

4.8 Major challenges and future directions

4.9 Conclusion

Acknowledgments

References

Chapter 5. Recent developments in pressure swing adsorption for biomethane production

Abstract

Chapter outline

5.1 Introduction

5.2 Types of swing adsorption technologies

5.3 Parameters influencing pressure swing adsorption

5.4 Adsorption isotherm

5.5 Adsorption kinetics

5.6 Mathematical modeling

5.7 Conclusion and future perspectives

References

Chapter 6. Membrane-based technology for methane separation from biogas

Abstract

Chapter outline

6.1 Introduction: how the basic membrane processes for gas separation have evolved

6.2 Basic of gas separation on membranes

6.3 Membrane materials and structures

6.4 Theory of transport in gas separation on membranes

6.5 Membrane configurations and plant design for upgrading biogas

6.6 Recent developments in membrane-based CO2/CH4 separation

6.7 Summary and outlook

6.8 Future developments

References

Chapter 7. Cryogenic techniques: an innovative approach for biogas upgrading

Abstract

Chapter outline

7.1 Introduction

7.2 Cryogenic biogas upgrading

7.3 Cryogenic hybrid systems

7.4 Cryogenic-membrane processes

7.5 Full-scale experiences and technoeconomic studies

7.6 Comparison of documented technologies

7.7 Conclusions and future perspectives

Appendix I Conversion factor for unit transformations

Appendix II State forms for CO2 and CH4 as a function of temperature and pressure

Acknowledgments

References

Chapter 8. Power-to-gas for methanation

Abstract

Chapter outline

8.1 Introduction

8.2 Electrocatalytic methanation

8.3 Bioelectrochemical methanation

8.4 Challenges and future prospects

References

Chapter 9. Electrochemical approach for biogas upgrading

Abstract

Chapter outline

9.1 Introduction

9.2 Faradaic and energy efficiency

9.3 Electroreduction of CO2

9.4 Electrochemical oxidation of H2S

9.5 Biogas upgrading approach and its challenges

9.6 Concluding remarks and perspectives

Acknowledgments

References

Chapter 10. Siloxanes removal from biogas and emerging biological techniques

Abstract

Chapter outline

10.1 Introduction

10.2 Methods for reducing the content of volatile organic silicon compounds in biogas

10.3 Combined methods for volatile organic silicon compounds removal from biogas

10.4 Comparison of the methods for reducing the content of volatile organic silicon compounds in biogas

10.5 Conclusions and future perspective

References

Part III: Biological upgrading systems

Chapter 11. Technologies for removal of hydrogen sulfide (H2S) from biogas

Abstract

Chapter outline

11.1 Introduction

11.2 Technologies for removal of biogas contaminants

11.3 Physicochemical removal technologies

11.4 Ex situ removal using sulfur-oxidizing microorganisms

11.5 In situ H2S removal

11.6 Combined chemical-biological processes

11.7 Comparison of H2S removal techniques

11.8 Conclusions

References

Chapter 12. Biological upgrading of biogas through CO2 conversion to CH4

Abstract

Chapter outline

12.1 Biogas upgrading

12.2 Hydrogen generation and utilization

12.3 Methanation

12.4 Microbial basis for biomethanation

12.5 Reactor configurations

12.6 Factors controlling biomethanation

12.7 Reactor design for biological methanation

12.8 Future perspectives and applications

12.9 Conclusions

Abbreviations list

References

Chapter 13. Bioelectrochemical systems for biogas upgrading and biomethane production

Abstract

Chapter outline

13.1 Background

13.2 Fundamentals of bioelectrochemical biogas upgrading

13.3 Methane enrichment of biogas

13.4 Economical insights

13.5 Prospective and challenges

13.6 Conclusion

Acknowledgments

References

Chapter 14. Photosynthetic biogas upgrading: an attractive biological technology for biogas upgrading

Abstract

Chapter outline

14.1 Introduction

14.2 Positive attributes of photosynthetic “microalgae” toward biogas upgradation

14.3 CO2 and H2S removal through photosynthetic-bacterial associated biogas upgradation

14.4 Microalgae-based biogas upgrading and concomitant wastewater treatment

14.5 Photobioreactor designs for biogas upgradation

14.6 Impact of different process variables in biogas upgradation

14.7 The future prospects

14.8 Conclusion

References

Part IV: Policy implications for biogas upgrading

Chapter 15. Biogas upgrading and life cycle assessment of different biogas upgrading technologies

Abstract

Chapter outline

15.1 Introduction

15.2 Biomethanation

15.3 Brief overview of life cycle assessment

15.4 Life cycle assessment of biogas upgrading technologies

15.5 Conclusions

Acknowledgment

References

Further reading

Chapter 16. The role of techno-economic implications and governmental policies in accelerating the promotion of biomethane technologies

Abstract

Chapter outline

16.1 Introduction

16.2 Role of techno-economic studies in anaerobic digestion

16.3 Successful policies in anaerobic digestion implementation

16.4 Decision- system for biomethane implantation with technoeconomic analysis and policies

16.5 Conclusion

References

Chapter 17. Large-scale biogas upgrading plants: future prospective and technical challenges

Abstract

Chapter outline

17.1 Introduction

17.2 Biogas composition and feedstock types

17.3 Biogas upgrading for natural gas grid injection and transport fuel

17.4 State-of-the-art of large-scale biogas upgrading technologies

17.5 Conclusion and future perspective

References

Index

Copyright

Academic Press is an imprint of Elsevier 125 London Wall, London EC2Y 5AS, United Kingdom 525 B Street, Suite 1650, San Diego, CA 92101, United States 50 Hampshire Street, 5th Floor, Cambridge, MA 02139, United States The Boulevard, Langford Lane, Kidlington, Oxford OX5 1GB, United Kingdom

Copyright © 2021 Elsevier Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publisher’s permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

British Library Cataloguing-in-Publication Data A catalogue record for this book is available from the British Library

Library of Congress Catag-in-Publication Data A catalog record for this book is available from the Library of Congress

ISBN: 978-0-12-822808-1

For Information on all Academic Press publications visit our website at https://www.elsevier.com/books-and-journals

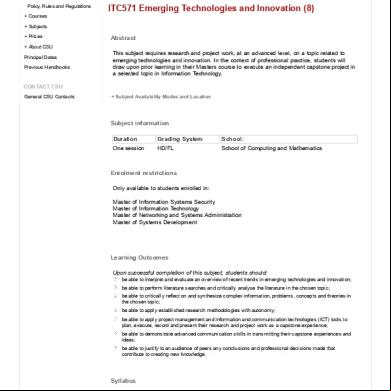

Front Cover Picture: The Aarhus University Research Biogas Plant. (Credit Dr. Michael Vedel Wegener Kofoed). Publisher: Candice Janco Acquisitions Editor: Peter Adamson Editorial Project Manager: Alice Grant Production Project Manager: Nirmala Arumugam Cover Designer: Mark Rogers

Typeset by MPS Limited, Chennai, India

List of contributors

Saumya Ahlawat, Department of Biosciences and Bioengineering, Indian Institute of Technology Guwahati, Guwahati, India

Nabin Aryal, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Prakash Aryal, Department of Chemical Engineering, Monash University, Clayton, VIC, Australia

Francisco Manuel Baena-Moreno, Chemical and Environmental Engineering Department, Technical School of Engineering, University of Seville, Sevilla, Spain

Anders Bentien, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

K.V. Christensen, Department of Green Technology, Faculty of Engineering, University of Southern Denmark, Odense M, Denmark

Carlos Dinamarca, Department of Process Energy and Environmental

Technology, University of South-Eastern Norway, Porsgrunn, Norway

M. Errico, Department of Green Technology, Faculty of Engineering, University of Southern Denmark, Odense M, Denmark

Lu Feng, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Kazimierz Gaj, Department of Environment Protection Engineering, Wroclaw University of Science and Technology, Wrocław, Poland

Luz M. Gallego, Chemical and Environmental Engineering Department, Technical School of Engineering, University of Seville, Sevilla, Spain

Vijay Kumar Garlapati, Department of Biotechnology and Bioinformatics, Jaypee University of Information Technology, Waknaghat, India

Anish Ghimire, Department of Environmental Science and Engineering, Kathmandu University, Dhulikhel, Nepal

Pooja Ghosh, Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi, India

Raju Gyawali, Nepal Electricity Authority, Government of Nepal, Kathmandu, Nepal

Moonmoon Hiloidhari, IDP in Climate Studies, Indian Institute of Technology Bombay, Mumbai, India

Mads Borgbjerg Jensen, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Rimika Kapoor, Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi, India

Mehak Kaushal, System Biology for Biofuel Group, International Centre for Genetic Engineering and Biotechnology, New Delhi, India

Dilip Khatiwada, Division of Energy Systems, Department of Energy Technology, KTH Royal Institute of Technology, Stockholm, Sweden

Michael Vedel Wegener Kofoed, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Dhamodharan Kondusamy Department of Civil Engineering, Indian Institute of Technology Guwahati, Guwahati, India

Institute of Soil, Water and Environmental Science, Agricultural Research Organization, Israel

Shilpi Kumari, Centre for Energy Studies, Indian Institute of Technology Delhi, New Delhi, India

Piet N.L. Lens, UNESCO—IHE Institute for Water Education, Delft, The Netherlands

Sunil Prasad Lohani, Department of Mechanical Engineering, Kathmandu University, Dhulikhel, Nepal

S. Venkata Mohan Bioengineering and Environmental Sciences Lab, Department of Energy and Environmental Engineering, CSIR-Indian Institute of Chemical Technology (CSIR-IICT), Hyderabad, India Academy of Scientific and Innovative Research (AcSIR), Ghaziabad, India

Henrik Bjarne Møller, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Benito Navarrete, Chemical and Environmental Engineering Department, Technical School of Engineering, University of Seville, Sevilla, Spain

Anirudh Bhanu Teja Nelabhotla, Department of Process Energy and Environmental Technology, University of South-Eastern Norway, Porsgrunn, Norway

Birgir Norddahl, Department of Green Technology, Faculty of Engineering, University of Southern Denmark, Odense M, Denmark

Lars Ditlev Mørck Ottosen, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Deepak Pant, Separation and Conversion Technology, Flemish Institute for Technological Research (VITO), Mol, Belgium

Kamal K. Pant, Department of Chemical Engineering, Indian Institute of Technology Delhi, New Delhi, India

Valerio Paolini, National Research Council of Italy, Institute of Atmospheric Pollution Research, Monterotondo, Italy

Grzegorz Pasternak, Laboratory of Microbial Electrochemical Systems, Department of Process Engineering and Technology of Polymer and Carbon Materials, Wroclaw University of Science and Technology, Wrocław, Poland

sco Petracchini, National Research Council of Italy, Institute of Atmospheric Pollution Research, Monterotondo, Italy

Ram Chandra Poudel, Department of Biological Sciences, University of Bergen, Bergen, Norway

Karthik Rajendran, Department of Environmental Science, SRM University-AP, Mangalagiri, India

M.C. Roda-Serrat, Department of Green Technology, Faculty of Engineering, University of Southern Denmark, Odense M, Denmark

Shivali Sahota, Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi, India

Manju Sapkota, Institute of Chemistry, Bioscience and Environmental Engineering, Faculty of Science and Technology, University of Stavanger, Stavanger, Norway

Marco Segreto, National Research Council of Italy, Institute of Atmospheric Pollution Research, Monterotondo, Italy

Surajbhan Sevda, Department of Biotechnology, National Institute of Technology Warangal, Warangal, India

Goldy Shah, Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi, India

Swati Sharma, Department of Biotechnology and Bioinformatics, Jaypee University of Information Technology, Waknaghat, India

J. Shanthi Sravan Bioengineering and Environmental Sciences Lab, Department of Energy and Environmental Engineering, CSIR-Indian Institute of Chemical Technology (CSIR-IICT), Hyderabad, India Academy of Scientific and Innovative Research (AcSIR), Ghaziabad, India

Athmakuri Tharak, Bioengineering and Environmental Sciences Lab, Department of Energy and Environmental Engineering, CSIR-Indian Institute of Chemical Technology (CSIR-IICT), Hyderabad, India

Laura Tomassetti, National Research Council of Italy, Institute of Atmospheric Pollution Research, Monterotondo, Italy

Marco Torre, National Research Council of Italy, Institute of Atmospheric Pollution Research, Monterotondo, Italy

Patrizio Tratzi, National Research Council of Italy, Institute of Atmospheric Pollution Research, Monterotondo, Italy

Fernando Vega, Chemical and Environmental Engineering Department, Technical School of Engineering, University of Seville, Sevilla, Spain

Virendra Kumar Vijay, Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi, India

Alastair James Ward, Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark

Foreword

Ashok Pandey, Editor-in-Chief, Bioresource Technology, Elsevier

Global energy demand is increasing to fulfill the growing human population needs, with fossil fuels being the most dominating source. One of the most significant environmental problems associated with fossil fuel use is the emission of greenhouse gases (GHGs), leading to global warming and creating problems related to climate change. Increasing the supply of renewable energy sources would replace fossil sources and significantly limit the dominating carbon-intensive fossil fuels in the future energy system. Therefore the development and utilization of renewable energy sources such as solar, bioenergy, wind, hydro, and geothermal are essential to mitigate the environmental problems associated with GHG emissions. Bioenergy, where biomass produced via photosynthesis can be converted to biofuel (biogas), heat, and electricity, is the most widely used form of renewable energy. Biogas can be produced from the anaerobic digestion process and can be utilized as a fuel for cooking, industrial processes, and transportation fuels. Nevertheless, biogas contains significant amounts of carbon dioxide and other constituents such as hydrogen sulfide that have to be removed prior to application as a natural gas substitute. By upgrading the biogas and thereby increasing its methane content, the resulting biomethane can replace natural gas obtained from fossil sources. Recently, emerging technologies for biogas upgrading, such as microbial-based and cryogenic-based technologies, have been developed. However, available information about these technologies is limited. This book represents a milestone by providing the technical knowledge and information on emerging biogas upgrading technologies. This book on Emerging Technologies and Biological Systems for Biogas Upgrading provides fundamental knowledge on anaerobic digestion, the global scenario of biogas production, state-of-the-art information on upgrading, and policy implications for promoting the utilization of upgraded biogas. The book deals with physiochemical upgrading systems with great insight into absorption, scrubbing, membrane separation, electrochemical, and cryogenic techniques. The book furthermore presents technologies currently under development, including biological and bioelectrochemical power-to-gas technologies employed for biogas upgrading. The editors have put together a host of highly relevant topics and experts in their respective fields to contribute with thoroughly described chapters.

What I like about this book is the information about the current state-of-the-art, the practical information, and highly qualified consortium of authors, who have contributed with their knowledge in each chapter, which will be highly beneficial for researchers, university students, biogas developers. and practitioners who are entering into the biogas production and biogas-upgrading field.

Preface

Nabin Aryal¹, Lars Ditlev Mørck Ottosen¹, Michael Vedel Wegener Kofoed¹ and Deepak Pant², ¹Department of Biological and Chemical Engineering, Aarhus University, Aarhus, Denmark, ²Separation and Conversion Technology, Flemish Institute for Technological Research (VITO), Mol, Belgium

Biogas is a methane-rich gas produced from biological degradation of biomass. The anaerobic digestion (AD) process has been commercially initiated to produce methane (CH4) from organic waste degradation that significantly contributes to global renewable energy production and consumption. Biogas has an important role in the global carbon cycle and has traditionally been used as an alternative renewable energy source. Especially in developing countries, a large part of the rural population relies on decentralized small-scale biogas digestors for meeting their household energy needs and furthermore for utilizing the digestate from such plants as a source of nutrient-rich fertilizer for their soils. Worldwide uncontrolled solid waste production leads to greenhouse gas (GHG) emissions in the form of carbon dioxide (CO2) and CH4, contributing significantly to climate change. Hence, harvesting biogas from the organic waste stream results in an environmentally sustainable source of renewable energy while reducing GHG emissions. According to the World Biogas Association, the annual biogas production in 2018 exceeded 60.8 billion m³, of which almost 54% was in Europe. The global production is projected to increase further worldwide, illustrating the worth of biogas, especially in a scenario with dramatic reductions in the consumption of fossil fuels. Biogas predominantly consists of 40%–60% CH4, 60%–40% CO2, and traces of hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), oxygen (O2), nitrogen (N2), siloxanes, carbon monoxide (CO), hydrocarbons, and volatile organic compounds. Primarily, the CO2 content in biogas lowers its heating value

compared to natural gas, and the presence of other constituents may cause corrosion and salt accumulation on the associated appliances such as boilers, burners, and gas engines. Biogas therefore has to be treated and conditioned to improve its gas heating value and downstream applicability. The gas can ultimately reach gas grid quality by upgrading it even further through removal or conversion of CO2. Recently, biogas upgrading has gained intense attention due to national targets for renewable energy production, environmental concerns, and the need to replace fossil fuels with sustainable fuel alternatives. Several technologies are today commercially available and implemented for biogas upgrading at commercial biogas plants, including water scrubbing, amine scrubbing, pressure swing adsorption, and membrane-based technologies. Among the implemented biogas upgrading technologies, water scrubbing is a widely applied technology that s for almost 40% of the total upgrading. These scrubbers upgrade the biogas by removing CO2 from biogas and emitting it to the atmosphere. The focus on reducing emissions from the biogas industry and utilizing biogas as a source of CO2 has spawned the development of alternative technologies for biological, bioelectrochemical, and chemical biogas upgrading. These technologies are at different technological readiness levels but all represent promising solutions for reducing the carbon footprint of the biogas industry and at the same time increasing its importance as a supplier of renewable energy and chemicals. As an example, biological methanation today constitutes a promising technology for converting biogas CO2 to CH4 by the use of electricity from renewable sources through a process that combines carbon capture and utilization with energy conversion (Power-to-X). The development and demonstration of new technologies is not only an academic exercise but also includes heavy industrial involvement. Nonetheless, comprehensive access to technical information on biogas upgrading technology remains limited. To overcome such a gap, this book intends to provide complete technical details on biogas upgrading. Each chapter of the book is designed to give a fully comprehensive and most recent state-of-the-art on different technologies currently in use or under development for biogas cleaning and upgrading. In this book, fundamental principles, state-of-the-art, biogas cleaning, and upgrading technologies for CO2, H2S, and siloxane removal or conversion have been elaborated. The book begins by outlining the global scenario of biogas production and upgrading processes, followed by an insight into

physicochemical upgrading systems that have been implemented at an industrial scale. The critical process parameter optimization of absorption/stripping technology, and optimization of cryogenic, membrane, and power-to-gas are discussed. The subsequent chapters describe biological cleaning and conversion of H2S, H2-mediated CO2 conversion, bioelectrochemical conversion of CO2 to CH4, and algal-based photosynthetic biogas upgrading. Finally, the implications of policies for biogas upgrading are provided. In a nutshell, the information in this book brings insights into technologies and processes for biogas treatment and upgrading. This book is aimed at a broad audience, mainly researchers, biogas specialists, academics, entrepreneurs, industrialists, policymakers, and others who wish to know the latest developments and future perspectives of biogas upgradation approaches for the enhancement of the existing digestors, and also discusses the bottlenecks of the various technologies that currently limit scale-up and commercialization. The chapters are written by experts in the field from all parts of the world. Consolidation of the most recent state-of-the-art into an independent chapter for each type of physical, chemical, or biotechnological upgrading system is the main aim of this book. A key point of the book is that it also provides guidance on which procedures should be followed under what conditions to get the best results in of upgrading. It is our sincere hope that this book will contribute to the necessary transition to environmentally benign and sustainable adoption of biogas in general and biogas upgrading approaches in particular. Though we have tried to be objective in our choice of topics to be covered in this book, some not so common themes which may become important in the future may have been missed out, we will try to cover them in the second edition of the book. This book is intended to have three roles and to serve three associated audiences, namely, the students and research community who will benefit from the lucid explanation of the possible applications of biogas upgradation for the betterment of environment, the policymakers who will find it easier to identify the pros and cons of different upgradation systems, and finally, the industries involved, as it will give them a feeling about the current loopholes (technological possibilities and possibilities for optimization) and ways to fix them. Each chapter begins with a fundamental explanation for general readers and ends with in-depth scientific details suitable for expert readers. The text in all the chapters is ed by numerous clear, illustrative, and informative diagrams, flowcharts, and comprehensive tables detailing the scientific advancements, providing an

opportunity to understand the process thoroughly and meticulously. Written in an eloquent style, the book comprehensively covers each point to give the reader a holistic picture of biogas treatment technologies and the future perspective of their use. The book may even be adopted as a textbook for university courses that deal with such courses related to both energy and the environment. Despite the best efforts of the authors and editors, along with extensive checks conducted by many experts in the field of biogas and AD, mistakes may have crept in inadvertently. We would appreciate if readers could highlight these and make comments or suggestions to improve and update the book contents for future editions.

Part I

Introduction

Outline

Chapter 1 Status of biogas production and biogas upgrading: A global scenario

Chapter 1

Status of biogas production and biogas upgrading: A global scenario

J. Shanthi Sravan¹, ², Athmakuri Tharak¹ and S. Venkata Mohan¹, ², ¹1Bioengineering and Environmental Sciences Lab, Department of Energy and Environmental Engineering, CSIR-Indian Institute of Chemical Technology (CSIR-IICT), Hyderabad, India, ²2Academy of Scientific and Innovative Research (AcSIR), Ghaziabad, India

Abstract

Biogas upgradation (BU) is an alternative route for carbon dioxide (CO2) sequestration for increasing biogas utilization/reuse in integrating processes for the commercialization of technologies. This chapter critically discusses the current state-of-the-art of BU in the global context with the specific concepts required for research and development (R&D) applications for centralized and decentralized applications for commercialization. It also discusses future perspectives that essentially help in overcoming the challenges faced at the R&D stage in of biogas production and reuse to achieve energy-intensive processes. Anaerobic digestion (AD) is a potential bioconversion process utilized for treating diverse waste/wastewaters for energy and product generation. Apart from its efficiency, AD also has few limitations that need to be overcome for recovering maximum methane (CH4). The integration of electrochemical processes with interference of electrodes as electron acceptors in microbial processes could beneficially help in direct utilization of electrical energy for BU by converting CO2 to CH4 to achieve higher process efficiency. It influences the overall CH4 yield, while providing new insights to counteract the operational instability of bioprocesses like AD through applied potential by altering the in situ microbial reactions. The integration of the centralized and decentralized biogas upgrading units in bioprocess units helps to improve the sustainability of the individual processes in a circular economy system. The industrial perspective for commercialization of BU as a technology reveals significant applications for decreasing the gaseous carbon footprints for enhanced biobased product generation using a biological route.

Keywords

Biomethane; CO2 sequestration; Electron donor;

Microbial fuel cell (MFC); Anaerobic digestion (AD); Waste biorefinery; Oxidation-reduction rate (ORR); Direct interspecies electron transfer (DIET); Selfsustainable systems

Chapter outline

Outline

1.1 Introduction 3

1.2 State-of-the-art of biogas production and upgradation 4

1.3 Recent trends in biogas utilization: A global prospective 6

1.4 Anaerobic digestion 8

1.4.1 Mechanism of anaerobic digestion 9 1.4.2 Factors affecting biogas production 11

1.5 Biohythane 14

1.6 Electrochemically induced biogas upgradation 16

1.7 Challenges and way forward 18

Acknowledgments 19

References 19

1.1 Introduction

Biogas is considered one of the most sought-after bioenergy resources across the world to overcome the environmental and energy challenges. It has numerous applications in the household, domestic, transportation, gas grid areas, and as a substrate for platform chemicals generation. Conventionally, biogas upgradation (BU) is performed by physico-chemical (absorption, adsorption, membrane seperation, and cryogenic) and biological (in situ and ex situ) processes which are site/case specific (Baena-Moreno et al., 2020; Kapoor et al., 2019; Vrbova and Ciahotny, 2017; Munoz et al., 2015). Limitations need to be addressed for managing of energy and carbon flux, which could essentially benefit the process efficiency (Aryal et al., 2018; Salihu and Alam, 2015). BU technologies need to focus mainly on the reuse of impurities such as CO2, H2S, and other gases generated from individual processes in the presence of electron donors which are essential to produce methane (CH4) with above 90% productivity (Nelabhotla et al., 2019; Sahota et al., 2018; Scholz et al., 2013). BU can potentially enhance the conversion rate/efficiency of organic substrates with further use of impurities such as CO2, H2S, etc. in the presence of electron donors like H2 and volatile fatty acids (VFAs) towards CH4 production and its applications (Sravan et al., 2020; Nelabhotla and Dinamarca, 2018; Venkata Mohan et al., 2016b; Jiang et al., 2013). Electrochemical interference towards CH4 production, called electromethanogenesis (EM), can influence the direct interspecies electron transfer (DIET) with a focus on creating a microbe– electrode synergy that neutralizes the disruptors influence (from side reactions) on enhancing the biogas production (Zhou et al., 2017; Lovley, 2017; Simon, 2015). BU for centralized and decentralized applications needs to provide specific interventions and strategies that could beneficially influence the microbial electrometabolism and its energy dynamics, while focusing on the techno-economics toward increasing the overall CH4 yields at an industrial scale.

1.2 State-of-the-art of biogas production and upgradation

Biogas is an important source of renewable energy that contributes significantly in of overall calorific value (Baena-Moreno et al., 2020; Koonaphapdeelert et al., 2020; Curto and Martin, 2019). Biogenic solid and liquid wastes are degraded in anaerobic digestors for CH4 generation along with other gases and heat generation (Gotz et al., 2016; Prasad et al., 2017; Singhal et al., 2017; Subbarao, 2018; Venkata Mohan et al., 2017). The breakdown of organic matter contributes to various biogas constituents, namely, CH4 (50–70%), CO2 (30– 50%), and other trace gases(0.1–3%) (Baena-Moreno et al., 2019; Bharathiraja et al., 2018; Kulkarni and Ghanegaonar, 2020; Maurya et al., 2019). Biogas utilization in the gas grid as energy requires a CH4 content of at least 90%, with decreased CO2, H2, H2S, etc., composition (Angelidaki et al., 2018; Kadam and Panwar, 2017). Usually processes like absorption, membrane seperation, scrubbing, and water washing are used to remove the excess CO2 generated (Adnan et al., 2019; Angelidaki et al., 2018). In situ integrated processes that could potentially upgrade the biogas to CH4 within the anaerobic digestion (AD) system could benefit the energy sector (Sarker et al., 2018; Luo and Angelidaki, 2012). Alternative processes to upgrade biogas to CH4 include utilizing the excessive CO2 in the presence of H2 in the AD systems. This upgraded CH4 could be used to meet the requirements of the gas grid and other energy systems (Fig. 1.1).

Figure 1.1 Scientometric analysis of the current state-of-the-art on biogas upgradation.

Globally, biogas is being exploited with great interest as a substitute for natural gas. Hence, increasing the calorific value of biogas by removing CO2 and other trace gases for CH4 upgradation is essential (Kapoor et al., 2019; Sun et al., 2015a). BU by fixation of CO2 and H2 in the presence of redox intermediates to CH4 remains undeveloped, but is gaining interest in the context of renewable energy utilization (Alvarez-Gutierrez et al., 2016; Angelidaki et al., 2019). Commercial biogas upgrading systems using conventional processes can perform only the separation of CH4 from CO2 and require additional integration of individual processes to increase the efficiency of CH4 conversion and to also avoid carbon emissions (Baena-Moreno et al., 2020; Xu et al., 2018; Rodero et al., 2018; Vrbova and Ciahotny, 2017; Yuan et al., 2013). The lower density of H2 requires higher storage capacities, while its transportation and direct utilization as a technology is still under development. Hence, the transformation of H2 to CH4 is considered appropriate and could be considered beneficial for its utilization as a natural gas (Fig. 1.2).

Figure 1.2 Various biogas upgradation techniques/processes.

Methane is advantageous over H2 due to its higher volumetric energy density and its readily available existant infrastructure for its utilization/storage towards application feasibility (Luo et al., 2012). H2 is readily utilized in lab-scale systems for converting CO2 to CH4 with increased conversion efficiency (Luo et al., 2012; Maegaard et al., 2019; Sun et al., 2015b). The increased H2 utilization influences VFA accumulation because of homoacetogenesis leading to higher acidification (Liu et al., 2016). The major limitations to BU are pH regulation and CO2 utilization, where the pH range needs to be maintained between 6.5– 8.5 to increase the CH4 production (Bassani et al., 2015; Luo and Angelidaki, 2012). A biological method of BU is considered as a potential alternative for CH4 production using various microbial genera such as hydrogenotrophic methanogens, acetoclastic methanogens, and microalgae (Meier et al., 2017; Muha et al., 2012). In this process, CO2 and H2 are biologically converted to CH4 involving the action of hydrogenotrophic methanogens without any additional energy inputs [Eq. (1.1)].

(1.1)

H2 injection with a stoichiometric ratio of 4:1 between H2 and CO2 during hydrogenotrophic methanogenesis increases CO2 utilization thus leading to a pH increase, which is one of the main influencing parameters for efficient performance of the methanogenic population (Liu et al., 2016; Luo and Angelidaki, 2012; Maegaard et al., 2019; Siegert et al., 2015). Higher alkaline pH values usually limit the methanogenic activity, while CO2 utilization helps overcome the substrate inhibition for autotrophic hydrogenotrophic methanogens towards CH4 production. The methanogenic population in AD systems usually consists of acetoclastic and hydrogenotrophic methanogens, majorly contributing

to the CH4 production (Liu et al., 2018; Christy et al., 2014; Luo et al., 2012; Sarkar and Venkata Mohan, 2020). A higher H2 presence helps towards the enrichment of hydrogenotrophic methanogens like Methanomicrobium, Methanoculleus, and Methanobacterium, which relatively increases the rate of methanogenesis (Luo and Angelidaki, 2012; Bassani et al., 2015).

1.3 Recent trends in biogas utilization: A global prospective

Biogas is one of the most important sources of renewable energy produced from anaerobic digestors and could contribute significantly in of energy value (Curto and Martin, 2019). Biological CH4 production is produced by dark fermentation, where the organic substrate is converted into biogas, biofuels, and other value-added intermediate products. Electrodes and a polarizing microenvironment with applied potential could be beneficial in regulating the microbial metabolism and increasing the substrate conversion rate towards BU (Castellano-Hinojosa et al., 2018; Dou et al., 2018; Liu et al., 2016; Nikhil et al., 2015; Schroder et al., 2015; Zhao et al., 2016). Apart from these, redox intermediates (activated carbon/biochar/magnetic field) act as redox shuttles for electron acceptance, influencing the microbial electrogenic activity towards decreased losses and increasing CH4 recovery. Integration of a polarized microenvironment with dark fermentation, called electromethanogenesis (EM) could be innovative in increasing the CH4 conversion rate, productivity, and calorific value. EM regulates the electron flux with the endogenous or applied potential establishing synergistic redox microbe–electrode and microbe–microbe interactions (Sravan et al., 2020; Modestra et al., 2015a,b). Microbial activity with deprived electrons needs an increased energy conversion rate and therefore could utilize the applied potential to regulate their metabolism, resulting in higher CH4 production (Ren et al., 2019; Villano et al., 2017; Jin et al., 2017). BU/EM systems emphasize electrode material placement, biocatalyst, system design, and operation. Dark fermentation is mainly focused on short-chain carboxylic acids (C2–C6) and alcohol production, with respect to methanogenic microbial suppression losing a highly significant amount of energy in the form of biogas. However, EM stresses streamlining towards higher CH4 production to meet the increasing demands with regulated microbial metabolism, microenvironment, and energetics. Biogas production has recently focused specifically on CO2 capture.

Electrochemical CO2 reduction to CH4 selectively orients for BU using bioelectrochemical systems (BES), and is described as power to gas technology (Collet et al., 2017; Stangeland et al., 2017; Zhao et al., 2016; Xu et al., 2014). Overcoming the limitations of DIET and cathode development shows a marked effect on CO2 reduction and CH4 production, involving electroactive microbial catalysis with polarized electrodes and applied potential (Dykstra and Pavlostathis, 2017; Fu et al., 2015; Sravan et al., 2020). An optimum pH of 7.0– 7.5 helps to increase the biogas productivity and also favors enrichment of electroactive methanogens. Several studies have approached in the direction of integrating BES with AD for biogas upgradation with increased purity. A polarized microbial environment with the interference of electrodes in the microenvironment favors the conversion of raw biogas components with the of intermediate acceptors to CH4 (Jiang et al., 2019; Sravan et al., 2020; Venkata Mohan et al., 2014; Xu et al., 2014). In situ developed or applied potential regulates the charge transfer kinetics between the electroactive microbial populations and inert electrode surfaces, enhancing the CH4 production (Ren et al., 2019; Paiano et al., 2019). Applied potential drives the methanogenic metabolic pathways in order to increase the substrate conversion rates along with productivity (Sarkar and Venkata Mohan, 2020; Sravan et al., 2020; Meier et al., 2017; Liu et al., 2016). Hydrogenotrophic methanogens were studied to increase the CH4 production from endogenous H2 produced by reutilizing it as an additional electron donor, whereas acetoclastic methanogens were involved in the inhibition of H2 towards CH4 production. Different types of feedstocks like municipal solid waste, spent wash, domestic food waste, and C1 gases like CO2 and CO were used in BES to achieve higher BU rates (Jiang et al., 2013; Zhen et al., 2017) (Fig. 1.3).

Figure 1.3 Integration of anaerobic digestors with biogas upgradation to increase methane production.

1.4 Anaerobic digestion

AD is a conventional process for the biological conversion of organic substrate to biogas, mainly CH4 and CO2, with other trace gases along with other valueadded products. AD requires a longer operation time to achieve effective substrate removal and value-addition yields. The lower conversion efficiencies during AD (upto 60%) are considered as a disadvantage for the process performance. Recently, BU has gained significance for the improvement of CH4 content in total biogas yields, along with value-addition with AD–BES integration. The biological conversion efficiency of organic substrate in the presence of H2 and CO2 to CH4 occurs at the anode/cathode in BES, and is also called the EM process (Siegert et al., 2015). Single-chambered AD and BES have shown improved CH4 efficiency with the presence/enrichment of hydrogenotrophic methanogens that are significantly involved in H2 and CO2 conversion to CH4 (Sarkar and Venkata Mohan, 2020; Sravan et al., 2020). CH4 production was also improved in a single-chambered BES, involving H2 gas recycling at the anode towards higher waste utilization and process intensification. Membraneless single-chambered systems are robust for CH4 production rather than being confined to hydrogen at a slightly acidified pH. AD–BES integration showed a significant increase in CH4 composition in the biogas (Sravan et al., 2020; Liu et al., 2018; Chen et al., 2016).

(1.2)

(1.3)

1.4.1 Mechanism of anaerobic digestion

The organic substrate during AD is catabolized through anaerobic fermentation and anaerobic respiration under dark conditions in the absence of oxygen as an electron acceptor. Microorganisms conserve energy through an internally balanced oxidation–reduction reaction (ORR) in anaerobic fermentation, whereas in anaerobic respiration it uses nitrates, sulfates, fumarates, etc., as the electron acceptor rather than oxygen. AD involves four steps, i.e., hydrolysis, acidogenesis, acetogenesis, and methanogenesis. The multi-molecular organic substrates are converted into simple, chemically stabilized molecules using H2 and acid as intermediate metabolites, and finally to CH4 and CO2 (Sarkar and Venkata Mohan, 2020).

1.4.1.1 Hydrolysis and acidogenesis

During hydrolysis, the microorganisms initially hydrolyze the complex organic polymers to monomers and further ferment them to a mixture of organic acids and alcohols, mainly through the Embden–Meyerhof–Parnas or Entner– Doudoroff pathways (Angelidaki et al., 2018). The hydrolysis rate mainly depends on the particle size, pH, gas diffusion/production, and enzyme adsorption on the waste particles in AD (Appels et al., 2008). Extracellular enzymes belonging to the hydrolases group such as amylase, protease, and lipase produced by specific hydrolytic bacteria are used during hydrolysis. Biochemical pathways end with pyruvate as a key intermediate which is utilized as an internal electron acceptor for the NADH reoxidation for production of VFAs (C2–C6) such as acetate, propionate, butyrate, lactate, valerate, and caproate, along with H2 and formate. In acidogenesis, the acidifying bacteria involving hydrogenation and dehydrogenation convert organic substrates and hydrolysis products to organic acids, alcohols, aldehydes, CO2, and H2. Pyruvate during anaerobic respiration can be further oxidized to acetate using acetogenic bacteria for comparatively higher production of oxidized end products (acetate and CO2), which inherently increases the overall ATP yield.

1.4.1.2 Acetogenesis

Acetogenesis is performed by a Wood–Ljungdahl pathway involving a phylogenetically diverse bacterial group (acetogens) which is specifically characterized by CO2 reduction to the acetyl-co-enzyme A. The acetyl-CoA pathway serves towards electron acceptance and carbon assimilation with energy conservation, where the carbon sources are used effectively as electron donors/acceptors for enrichment of autotrophic/heterotrophic bacteria. In acetogens, the electron donors are CO, H2, formate, methyl chloride, pyruvate, lactate, oxalate, etc., and the electron acceptors are CO2, fumarate, nitrate, thiosulfate, dimethyl sulfoxide, pyruvate acetaldehyde, and H+. Acetogenesis directly illustrates the biogas production efficiency in the system, with approximately 70% of CH4 coming from acetate reduction, in which approximately 25% of acetates and 11% of H2 are produced. Hence, it is crucial to target the acetogenic phase for higher CH4 output with an integrated approach towards increasing its energy and calorific value.

1.4.1.3 Methanogenesis

Methanogenesis is the final process for CH4 production by methanogenic microorganisms, which convert acidogenesis/acetogenesis products (VFAs, H2, CO2, H2S, and alcohols) into CH4. Methanogens are classified into two groups based on the substrate availability. Hydrogenotrophic methanogens use H2/formate as an energy source in the presence of certain electron donor like alcohols and CO2 to reduce to CH4. Methanogens are either obligate that use only H2/formate as the sole electron donor or more flexible and use other forms of energy sources. Methylotrophic methanogens are a more versatile group that include organic substrates such as VFA, H2, CO2, CO, and alcohols for methanogenesis using the methyl-S-CoM pathway. Hydrogen and interspecies formate transfer happens during methanogenic syntropy where acetate acts as an

efficient electron carrier between the syntrophic partners. The electron transfer with direct of microbes without production of H2 occurs in the presence of conductive pili and is called DIET (Sravan et al., 2020, Lovley, 2017; Raghavulu et al., 2012). H2 utilization provides optimized conditions for the enrichment of acidogenic bacteria, which produce short-chain carboxylic acids (VFAs) in the acidification phase followed by low H2 production in the acetogenic phase. These conversions produce CO2-rich gas which can be effectively converted to CH4. Microbial communities show significant variations in diversity in a short period of time by varying different reactions in single process. Microbial diversity is directly influenced by the operating parameters, namely, substrate and its composition, pH, temperature, pretreatment, and retention time (Sunny and Joseph, 2018; Venkata Mohan et al., 2008).

1.4.2 Factors affecting biogas production

1.4.2.1 Hydrolysis

Hydrolysis is a key rate-limiting factor during AD that influences the conversion efficiency of the waste into CH4 and associated products. Efficient pretreatment strategies (physical and chemical) have been mostly focused on overcoming sludge hydrolysis (Venkata Mohan et al., 2008). The various pretreatment strategies directly influence the specificity of products generated by influencing the granular size of the sludge that leads to the enrichment/inactivation of biocatalyst (Sarkar and Venkata Mohan, 2016). Hence, the microbes involve a higher rate of degradation by recycling the carbon and nutrients in the digesters. Anaerobic digesters when integrated with BES influence on increasing the fermentation efficiency by cascading the individual processes towards higher utilization of redox equivalents. The increase in the electrocatalytic rates and electrometabolism shows a significant impact on the microbe–electrode interaction and biofilm formation.

1.4.2.2 pH

The optimal pH range is a critical parameter that influences the AD process, thereby affecting the CH4 output and product synthesis. pH represents the hydrogen ion concentration in the digestion medium and its variations have a direct influence on the growth rate and metabolism of the microbial community. A near neutral pH (6.8–7.4) is considered as the ideal pH for the enrichment, growth, and relative abundance of methanogenic microbial community towards increasing the CH4 production (Liu et al., 2018; Sravan et al., 2020). Studies on acidogenesis have confirmed the variations in relative abundance of a particular species at certain pH ranges. pH 6 was found to be more suitable for the growth of Clostridium butyricum and pH 8 for Propionibacterium sp. to dominate and perpetuate their communities during AD. Methanogenesis is another important process during AD that is regulated at an optimal pH range of 6.5–8.2, but in most cases pH 7 is considered as ideal for its production (Liu et al., 2018; Cavinato et al., 2013). The development of these specific microbial communities has greatly influenced the VFA composition, where at the optimal pH range the enzymatic activity of the microorganisms is higher, leading to the production of higher amounts of fatty acids (Hajji et al., 2016). The production of VFA in relation to the optimal pH also needs to consider the COD conversion efficiency of the microorganisms which reflects their metabolic activity. A positive correlation between the pH and hydrolysis was also established and is known to influence the conversion efficiency of the organic substrates to products (Venkata Mohan et al., 2016a). Integration of AD-BES processes is by an electrocatalysis mechanism for supplementation of additional electrons to the existing process and decreasing the energy requirements for BU and the synthesis of other products. Therefore, pH needs to be considered as the most influential factor that controls the rate-limiting factors involved during the AD process for higher product synthesis.

1.4.2.3 Temperature

Ambient temperature is a requirement of the AD process, where it exhibits faster reaction rates with stability at higher organic loading of substrate for increased biogas production. Variations in temperature result in variations in the profile of the microorganisms, giving them stability to tolerate adverse conditions (Sunny and Joseph, 2018). Thermophilic (55–70°C) and mesophilic (37°C) conditions are the most prevalent conditions involved during AD (Liu et al., 2018; Dobre et al., 2014). Thermophilic conditions have the advantage of higher biodegradability with the provision of heat energy resulting in higher product synthesis. It is more suitable for acidification while inhibiting biogas production. It can influence the effluents from the process which are environmentally susceptible, while lower biogas output and energy inputs affect the overall economics of the process. Mesophilic conditions provide comparatively better stability and microbial abundance, with the capacity to produce higher CH4 yields. Hence, thermophilic conditions are mostly suitable for acidogenesis, and mesophilic conditions for the methanogenesis process. AD microorganisms are directly influenced by optimal temperature changes that can vary the biogas production and product synthesis quantities. The integration of electrochemical processes with conventional fermentation could increase the rate of product synthesis.

1.4.2.4 Substrate load

A higher substrate load is a parameter that leads to bacterial inhibition decreases the productivity of the AD process (Jiang et al., 2013; Babaee and Shayegan, 2011). A higher organic loading rate (OLR) increases the rate of hydrolysis/acidification compared with methanogenesis, which eventually leads to increased VFA production and bacterial inhibition (Pasupuleti et al., 2014). The increased VFAs lower the pH, making the microenvironment acidic and thereby negatively influencing the methanogenic microorganisms which cannot further convert the VFAs to CH4. Hence effluent recirculation and integration of AD-BES have great potential to decrease the overloading inhibition. Microbial community profiling varies with organic load with Firmicutes being predominant at lower OLR and Gammaproteobacteria, Actinobacteria, Bacteroidetes, and Deferribacteres being observed at higher substrate loads.

1.4.2.5 C/N ratio

An optimal substrate load also needs to reflect specific levels of nutrients in the form of carbon to nitrogen (C/N) ratio. Provision of sufficient amounts of nutrients to the microbial community helps in the maintenance of biomass and faster utilization of nitrogen, resulting in higher biogas production. Lower C/N ratios decrease nitrogen inhibition, which is toxic to methanogens and leads to reduced utilization of carbon sources. The presence of nitrogen in the organic substrate benefits as an important element for the synthesis of amino acids and proteins, while proteins are further converted to ammonia, which helps in maintaining a favorable pH microenvironment for microorganisms. A higher nitrogen content causes toxic effects, while lower quantities of nitrogen cause nutrient limitation (Khalid et al., 2011). The C/N ratio range of 20:1 to 35:1 is considered optimum, and the ratio of 25:1 is considered ideal for the AD process (Christy et al., 2014; Ellabban et al., 2014). The C/N ratio of 25:1 resulted in three-fold higher biogas production when compared to a C/N ratio of 15:1. Hence, an ideal substrate load with a specific C/N ratio would help in higher biogas production by influencing the metabolism of microorganisms involved in the AD process.

1.4.2.6 Hydraulic retention time

The hydraulic retention time (HRT) critically influences an increase in biogas production/upgradation. It indicates the period of time at which the productivity could start to decline, while the organic fermentable substrate remains in the anaerobic digester. Increased HRT will require a large digester volume, increasing the overall operational cost, while a shorter HRT will remove the active bacterial population (Sreekrishnan et al., 2004). Maximum CH4 production and its upgradation essentially occur at optimized HRTs. The optimized HRT mainly depends on the type of biocatalyst (mixed or pure

culture) and the OLR. A shorter retention period leads to VFA accumulation that causes severe fouling, resulting in decreased biogas production, whereas if the retention time is longer, the biogas components are not utilized effectively, resulting in decreased biogas production (Chen et al., 2016; Dobre et al., 2014). HRT also depends on the reactor size and volume (L/D ratio), where in lab-scale operations, the HRT is much less because of the small reactor size, but in contrast the HRT in centralized biogas systems is high to due pilot-level operations. Hence, HRT needs to be considered for BU for increased CH4 production during an integrated process.

1.5 Biohythane

Biohydrogen (H2) is a clean and sustainable energy-dense fuel which is biologically produced during anaerobic fermentation (AF)/AD, photofermentation, biophotolysis, and integration of these individual processes (Pasupuleti et al., 2014; Venkata Mohan et al., 2009). The global economy is expected to rely on H2 as a primary source of energy with zero carbon emissions and high energy-carrying capacity (Venkata Mohan and Sarkar, 2017; Sharma and Ghoshal, 2015). H2 is produced by obligatory acetogenic bacteria using renewable organic sources (Roy and Das, 2016; Sarkar and Venkata Mohan, 2020; Venkata Mohan et al., 2009). Biogenic waste with organic fraction act as a carbon and energy source for the microorganisms for H2 production. The production of H2 by the acidogenic/dark-fermentation process is at a higher rate and is a versatile process which is light independent, and converts biogenic organic wastes predominantly to VFAs (acetic, propionic, and butyric acids) along with simultaneous H2 production (Sarkar and Venkata Mohan, 2017; Dahiya et al., 2018). H2 production through dark fermentation as an individual process has certain limitations. The gaseous energy recovery in of only H2 is not sufficient for its commercial viability and application, where only 20–30% of total gaseous energy is recovered through H2 production (Sarkar and Venkata Mohan, 2016; Edison, 2014; Bauer et al., 2013). Integrated processes need to be commercialized for the economic feasibility of H2 production via dark fermentation which is worthy of commercialization, where it could be essentially integrated with AD. AD processes are easy to scale up, and the integration of these two processes can lead to >50–60% gaseous energy recovery (Sen et al., 2016). The integration of AD and dark fermentation processes would also help to decrease the operational cost. The development of such processes would lead to decentralized use of both H2 and CH4. Hence, integrated processes with varied microorganisms and individual capabilities need to be exploited to overcome the disadvantages of individual processes and to enhance the system energetics. Biohythane, an alternate renewable biofuel, can be potentially produced when H2 and CH4 are mixed in appropriate ratios with a blend of 75±90% (v/v) CH4

and 10±25% (v/v) H2 to make an alternative to fossil-based fuels (Pasupuleti and Venkata Mohan, 2015; Sarkar and Venkata Mohan, 2016). H2 and CH4 are the most widely used biofuels due to their high calorific values of 143 and 55 kJ/g, respectively (Pasupuleti et al., 2014; Sharma and Ghoshal, 2015; Edison, 2014). Biohythane is H2-enriched CH4 that has the scope to be a good alternative to the increasing demands for compressed natural gas (CNG) as an engine fuel. H2 is considered as a clean energy fuel since it does not release even a small fraction of CO2 into the atmosphere during combustion (Roy and Das, 2016). On the other hand, CH4 combustion generates greenhouse gases such as CO2. Also, utilization and combustion of both CH4 and H2 do not show any evidence for the release of NOX (nitrous oxide) or SOX (sulfur oxide). The lower ignition power of CH4 and highly flammable nature of H2 are usually considered as drawbacks while individually using them as vehicle fuels. The individual limitations of H2 and CH4 can be overcome with this blending in optimized proportions to form biohythane (Sarkar and Venkata Mohan, 2016; Dahiya et al., 2018). Its appropriate blending makes it a fuel that is clean with a good calorific efficiency (Pasupuleti and Venkata Mohan, 2015; Sarkar and Venkata Mohan, 2017; Sen et al., 2016). Biohythane has numerous practical applications as a vehicular fuel and is comparatively advantageous over CNG. Its high H2-reducing power increases the combustion rate and burning capacity of CH4 (Roy and Das, 2016; Moreno et al., 2012). It is an eco-friendly fuel due to its advantage of reducing the impact of greenhouse gas emissions on the environment, while the H2 presence helps to decrease the carbon in the gas mixture. Biohythane production was evaluated from the lab to semi-pilot scale, while more recently the blending of flammable H2 gas with CH4 grid injections as a technology was established on a large scale for biohythane production in vehicle fuel plants. Biohythane mimics the hydrogen-enriched compressed natural gas (H-CNG) composition. H-CNG supplemented with emission-free hydrogen (H2) has application feasibility in both residential (heating and cooking) and transport sectors (vehicle engines) as fuel with lower emissions being the prime advantage (Talibi et al., 2017). HCNG helps in increasing the flammability limits, speed propagation, pressure rise, and deflagration index when compared to CNG. European Union project “NATURALHY” studied the blending of H2 to natural gas for clean combustion of CNG with efficient calorific value and lower ignition energy requirement (Cinti et al., 2019). H-CNG in recent times is receiving significant prominence as an energy carrier, due to its application flexibility with the existing engines (Khab et al., 2019; Miao et al., 2011). This application flexibility could help in

injecting H2 in the existing gas pipelines/natural gas grids for both industrial and household purposes related to the transition toward hydrogen economy and would be a beneficial factor for commercial application of the technology at the root level. The molecular H2 as a blend (25–50%) in CNG is currently being derived from fossils in the market which could be environment-impacting with significant emissions being produced (Cetinkaya et al., 2012). Hence, the alternate biological (AD)/bioelectrochemical (BES) and their integrated processes producing green/low-carbon H2 need to be considered to further suit the advantages of H-CNG. Regulation of process parameters such as pretreatment, pH, microenvironment, and specific bacterial enrichment needs to be considered to substantially produce higher H2 than CH4.

1.6 Electrochemically induced biogas upgradation

BU involves a synergy of microbial interactions that show a regulatory influence on electron flux, resulting in the conversion/utilization/reduction of CO2 for CH4 production (Deng et al., 2020; Sarkar and Venkata Mohan, 2020; Sravan et al., 2020). Fermentation redox intermediates (H2, CO2, VFAs, etc.) from the microbial metabolic side reactions counter the targeted end-product due to endogenous losses. BU depends on the syntrophic interactions between fermentative and methanogenic microorganisms to increase electron transfer via mediated/direct interspecies electron transfer (MIET/DIET) to increase the H2 utilization and other electron carriers and redox intermediates towards enhanced CH4 production (Sravan et al., 2020; Deng et al., 2020; Yang et al., 2019). Microbial interactions for increased electrogenic activity could be triggered for increased performance during AD, with the polarized potential developed due to electrode placement or by the external supplementation of potential towards higher CH4 production, described as electromethanogenesis (EM). Electrode placement or applied potential to a microenvironment influences on increasing the reaction/electron transfer rates with respect to conventional fermentations towards increasing the CH4 content in total biogas (Sravan et al., 2020; Deng et al., 2020; Meier et al., 2017). It influences an increase in the microbial electrocatalysis while controlling electron flux, energy utilization, and system buffering for CO2 conversion in the presence of H2 and VFA to CH4. The EM strategy in the presence of electrodes or applied potential helps in efficiently neutralizing/reducing the overpotentials and electrochemical losses to overcome the limitations of BU. Hydrogenotrophic methanogenesis aids in the in situ H2 utilization or reducing equivalents (e− and H+) for CO2 reduction to enhance additional CH4 production (Sravan et al., 2018, 2020). Hydrogenotrophic methanogens directly utilize H+ and e− with the use of lower activation energy as an electrocatalytic activity for CO2 reduction to form CH4. The use of lower activation energy aids in establishing efficient microbe–electrode interactions to increase the CO2 reduction.

Homoacetogens directly involve CO2 and H2 reduction to acetic acid, which is utilized further for CH4 production (Villano et al., 2010). Syntrophic interactions of homoacetogenic and hydrogenotrophic bacteria towards CH4 utilize H2 as an electron donor, while inhibiting medium/long-chain fatty acid formation with regulated microbial metabolism (Rader and Logan, 2010).

(1.4)

(1.5)

EM also depends on the metabolic microenvironment which is vital to understand the metabolic pathways for the targeted products (Sarkar and Venkata Mohan, 2020; Jiang et al., 2019; Paiano et al., 2019). The anodic metabolic function of the BES effectively contributes to energy generation with respect to substrate oxidation (Sravan et al., 2020; Moscoviz et al., 2016; Nealson and Rowe, 2016). Enriched microbes under the specified microenvironment increase the process efficiency by creating equilibrium between substrate oxidation and oxygen utilization (Nealson and Rowe, 2016; Raghavulu et al., 2012). EM in synergy with microbe–electrode interactions and the specific microenvironment helps in regulating metabolite biosynthesis for CH4 production and could be considered as an essential unit operation in the waste biorefinery.

1.6.1 Conductive materials in biogas upgradation

Direct interspecies electrons transfer (DIET), a syntrophic metabolism where free electrons flow from one cell to another through shared physical (microbe-

microbe/microbe-electrode) and electrical connections (via conductive pili) without the requirement of reduced electron carriers (redox mediators) like molecular hydrogen or formate. Biogas production from the conventional AD has several rate-limiting factors such as a) accumulation of intermediate compounds like VFA that affects the process forward b) development H2 partial pressure in the digester leads to inhibition of specific co-enzymes of methanogenic bacteria c) inhibition of ammonia traces developed d) washout of the methanogenic biofilm during feeding (Baek et al., 2018; Fagbohungbe et al., 2015). Conducting materials act as efficient redox mediators by shuttling electrons between the syntrophic microorganisms. Conductive materials provide the regulatory influence of electron transfer between the microbe-microbe and microbe-electrode in a specified redox environment in AF/AD for BU. Parent inoculum, pretreatment, pH, microenvironment, etc., critically influence DIET with conductive materials for BU in AD, BES, and integrated systems (Baek et al., 2018; Zhao et al., 2017). The conductive materials mediated DIET with varied concentrations have shown to be highly efficient in the enhancement of CH4 yield. In AD, the transfer of electrons between two different syntrophic microbial communities such as bacteria and archaea is a vital process for methanogens to get control of energy barriers and catabolized complex organics. Amendment of the several conductive materials to AD, accelerate DIET between microbes leading to increased process efficiencies (Cheng et al., 2020). Conductive materials viz., granular activated carbon (GAC), carbon cloth, biochar, reduced graphene, iron conducting materials like magnetite (Fe3O4), carbon nanotubes are being successfully implemented as an approach to improve the AD process for improved CH4 production (Tan et al., 2021; Zhao et al., 2017; Cheng et al., 2020). The higher surface area of the conductive materials favours the growth of the methanogens with tendency to form dense aggregates of biofilm. Higher conductivity and biocompatibility of conductive materials positively influences the DIET between the microbes leading towards process intensification resulting in increased CH4 content.

1.7 Challenges and way forward

BU has the scope and possibility for practical applications with an integrated electrochemical strategy. BU increases the CH4 yields by enhancing the reduction of CO2 during the process (Sravan et al., 2020; Chen and Liu, 2017; Zhao et al., 2016; Beese-Vasbender et al., 2015). The calorific value of biogas is directly proportional to its CH4 content. Hence, increasing the CH4 composition in the biogas increases the energy and economic value, while also decreasing the transportation and storage costs. The increase in CH4 composition in biogas also significantly improves the feasibility and compatibility of its utilization in natural gas distribution (Mamun et al., 2016). CH4 can be used effectively as a vehicle fuel or directly injected into the gas grid for storage due to its high calorific energy content (Persson et al., 2006). The biogas can also be used directly for diverse applications such as for heating using gas-based boilers and cooking using gas stoves and ovens (Harasimowicz et al., 2007). BU applications are also associated with the removal of organic substrates and harmful trace components as an additional benefit during the process. BU with integrated bioelectrochemical strategy for the conversion of CO2 to CH4 has potential feasibility for application in replacing the stripping tower in a water scrubbing unit (Vijayanand and Singaravelu, 2017; Cheng et al., 2009). The integration of electrochemical energy with AD possibly regulates the rate of CO2 utilization with specificity towards product synthesis by nongenetically regulating the microbial metabolism. It also influences the direct electron transfer with effective microbe–electrode interactions during the operation. The syntrophic interactions between the microbes and electrode, through extracellular electron transfer, catalyze the anodic and/or cathodic reactions. The electrochemically driven BU provides a solution for excessive CO2 produced in the process to be directly transformed into CH4 rather than its separation from the biogas, significantly increasing the productivity and energy value of biogas plants. The integrated bioprocesses with energy and waste components require a thorough life-cycle and techno-economic analysis to assess the environmental impact and economic feasibility under different conditions of operation. The mechanisms and variations in microbial diversity with respect to the microbe– electrode interactions (anode/cathode) need to be further understood to enable

improved CH4 production for industrial scale applications. These studies would benefit from a transfer of knowledge to large-scale operations with overall process understanding, while overcoming several technology related challenges. Symbiotic integration of multiple processes as a single unit can efficiently contribute to the cost economics and environmental sustainability along with specified products generation from the systems (Fig. 1.4).

Figure 1.4 Biogas grid supply schematic for industrial and household purposes.

Acknowledgments

The Department of Biotechnology (DBT), Government of India, ed this research (BT/HRD/35/01/02/2018) in the form of Tata Innovation Fellowship to SVM. JSS acknowledges CSIR for providing research fellowship. The authors wish to thank CSIR-IICT for ing the research (Manuscript No. IICT/Pubs./2021/008).

References

Adnan et al., 2019 Adnan AI, Ong MY, Nomanbhay S, Chew KW, Show PL. Technologies for biogas upgrading to biomethane: a review. Bioengineering. 2019;6(4):92. Alvarez-Gutierrez et al., 2016 Alvarez-Gutierrez N, Garcia S, Gil MV, Rubiera F, Pevida C. Dynamic performance of biomass-based carbons for CO2/CH4 separation Approximation to a pressure swing adsorption process for biogas upgrading. Energy Fuels. 2016;30(6):5005–5015. Angelidaki et al., 2018 Angelidaki I, Treu L, Tsapekos P, et al. Biogas upgrading and utilization: current status and perspectives. Biotechnol Adv. 2018;36(2):452–466. Angelidaki et al., 2019 Angelidaki I, Xie L, Luo G, et al. Biogas upgrading: current and emerging technologies. Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels Academic Press 2019;817–843. Appels et al., 2008 Appels L, Baeyens J, Degre’ve J, Dewil R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci. 2008;34(6):755–781. Aryal et al., 2018 Aryal N, Kvist T, Ammam F, Pant D, Ottosen LD. An overview of microbial biogas enrichment. Bioresour Technol. 2018;264:359– 369. Babaee and Shayegan, 2011 Babaee, A., Shayegan, J., 2011 Effect of organic loading rates (OLR) on production of methane from anaerobic digestion of vegetables waste. In: World Renewable Energy Congress-Sweden, 8–13 May, 2011, Linköping University Electronic Press, Linköping, Sweden, No. 057, pp. 411–417. Baek et al., 2018 Baek, G., Kim, J., Kim, J., Lee, C., 2018. Role and potential of

direct interspecies electron transfer in anaerobic digestion. Energies 11, 107. Baena-Moreno et al., 2020 Baena-Moreno FM, le Saché E, Pastor-Pérez L, Reina TR. Biogas as a renewable energy source: focusing on principles and recent advances of membrane-based technologies for biogas upgrading. Membranes for Environmental Applications Cham: Springer; 2020;95–120. Baena-Moreno et al., 2019 Baena-Moreno FM, Rodríguez-Galán M, Vega F, Vilches LF, Navarrete B. Recent advances in biogas purifying technologies. Int J Green Energy. 2019;16(5):401–412. Bassani et al., 2015 Bassani I, Kougias PG, Treu L, Angelidaki I. Biogas upgrading via hydrogenotrophic methanogenesis in two-stage continuous stirred tank reactors at mesophilic and thermophilic conditions. Environ Sci Technol. 2015;49(20):12585–12593. Bauer et al., 2013 Bauer F, Persson T, Hulteberg C, Tamm D. Biogas upgrading– technology overview, comparison and perspectives for the future. Biofuels, Bioprod Bioref. 2013;7(5):499–511. Beese-Vasbender et al., 2015 Beese-Vasbender PF, Grote JP, Garrelfs J, Stratmann M, Mayrhofer KJ. Selective microbial electrosynthesis of methane by a pure culture of a marine lithoautotrophic archaeon. Bioelectrochemistry. 2015;102:50–55. Bharathiraja et al., 2018 Bharathiraja B, Sudharsana T, Jayamuthunagai J, Praveen kumar R, Chozhavendhan S, Iyyappan J. Biogas production–a review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew Sustain Energy Rev. 2018;90:570–582. Castellano-Hinojosa et al., 2018 Castellano-Hinojosa A, Armato C, Pozo C, González-Martínez A, González-López J. New concepts in anaerobic digestion processes: recent advances and biological aspects. Appl Microbiol Biotechnol. 2018;102(12):5065–5076. Cavinato et al., 2013 Cavinato C, Bolzonella D, Pavan P, Fatone F, Cecchi F. Mesophilic and thermophilic anaerobic co-digestion of waste activated sludge and source sorted biowaste in pilot-and full-scale reactors. Renew Energy. 2013;55:260–265.

Cetinkaya et al., 2012 Cetinkaya, E., Dincer, I., Naterer, G.F., 2012. Life cycle assessment of various hydrogen production methods. Int. J. Hydrog. Energy. 37 (3), 2071–2080. Chen et al., 2016 Chen C, Guo W, Ngo HH, et al. Challenges in biogas production from anaerobic membrane bioreactors. Renew Energy. 2016;98:120– 134. Chen and Liu, 2017 Chen Q, Liu T. Biogas system in rural China: upgrading from decentralized to centralized?. Renew Sustain Energy Rev. 2017;78:933– 944. Chen et al., 2015 Chen XY, Vinh-Thang H, Ramirez AA, Rodrigue D, Kaliaguine S. Membrane gas separation technologies for biogas upgrading. RSC Adv. 2015;5(31):24399–24448. Cheng et al., 2020 Cheng, Q., Xu, C., Huang, W., Jiang, M., Yan, J., Fan, G., Zhang, J., Chen, K., Xiao, B., Song, G., 2020. Improving anaerobic digestion of piggery wastewater by alleviating stress of ammonia using biochar derived from rice straw. Environ. Technol. Innov. 19, 100948. Cheng et al., 2009 Cheng S, Xing D, Call DF, Logan BE. Direct biological conversion of electrical current into methane by electromethanogenesis. Environ Sci Technol. 2009;43:3953–3958. Christy et al., 2014 Christy PM, Gopinath LR, Divya D. A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renew Sustain Energy Rev. 2014;34:167–173. Cinti et al., 2019 Cinti, G., Bidini, G., Hemmes, K., 2019. Comparison of the solid oxide fuel cell system for micro-CHP using natural gas with a system using a mixture of natural gas and hydrogen. Appl. Energy. 238, 69–77. Collet et al., 2017 Collet P, Flottes E, Favre A, et al. Techno-economic and life cycle assessment of methane production via biogas upgrading and power to gas technology. Appl Energy. 2017;192:282–295. Curto and Martin, 2019 Curto D, Martin M. Renewable based biogas upgrading. J Clean Prod. 2019;224:50–59.