Dg Set Abcd Check 3s5a55

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3b7i

Overview 3e4r5l

& View Dg Set Abcd Check as PDF for free.

More details w3441

- Words: 575

- Pages: 9

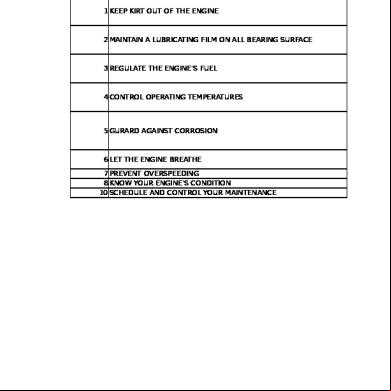

SR NO

MAINTENANCE STEPS 1 KEEP KIRT OUT OF THE ENGINE

2 MAINTAIN A LUBRICATING FILM ON ALL BEARING SURFACE

3 REGULATE THE ENGINE'S FUEL

4 CONTROL OPERATING TEMPERATURES

5 GURARD AGAINST CORROSION

6 LET THE ENGINE BREATHE 7 PREVENT OVERSPEEDING 8 KNOW YOUR ENGINE'S CONDITION 10 SCHEDULE AND CONTROL YOUR MAINTENANCE

1

2

3

4

5

6

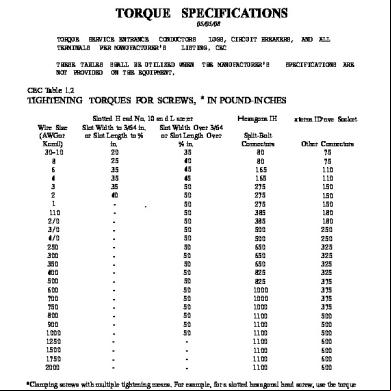

CUMMINS MAINTENANCE THIS IS A GENERAL MAINTENANCE PROGRAMME; IF YOUR ENGINE IS NOT FITTED WITH TURBOCHARGER, AIR COMPRESSOR, ETC, OMIT THAT PARTICULAR MAINTENANCE STEP. IF YOUR ENGINE IS FITTED WITH SOME SPECIAL COMPONENT OR ACCESSORY NOT SHOUN ON THE CHART, WRITE AND ASK FOR THE DETAILS FROM YOUR SERVICE REPRESENTATIVE. THE MAINTENANCE CHART HAS BEEN SPECIALLY PREPARED FOR AVERAGE INDIAN CONDITIONS, DETAILED INSTRUCTIONS ARE ONTAINED IN THE OPERATION AND MAINTENANCE MANUAL SUPPLIED WITH EACH ENGINE USE THE RECOMMENDED OIL WHOSE SPECIFIATIONS WILL MEET QUALITY REQUIREMENTS OF API CATEGORY CH4, DON’T MIS BRANDS OR GRADES OF OIL IN THE ENGINE. FOR DETAILS REFER OPERATION & MAINTENANCE MANUAL 3243773, THE LIFE OF THE FUEL FILTER, LUB OIL AND OTHER FILTERS WILL DEPEND ENTIRELY-UPON THE AMOUNT OF DUST, DIRT AND WATER IN THE OIL BESIDES OPERATING AND MAINTENANCE CONDITIONS AND ALSO THE TYPE OF GAS, FUEL AND LUB OIL USED IN THE ENGINE. FOR STARTER AND ALTERNATOR PLEASE FOLLOW MAINTENANCE SCHEDULE AS PER O&M SCHEDULE AS PER O&M MANUAL

A-CHECK (SECTION 4,5) DAILY/WEEKLY LUBRICATION CHECK ENGINE OIL LEVEL FUEL SYSTEM DRAIN SEDIMENTS FROM FUEL TANKS AIR SYSTEM CLEAN PRE-CLEANER DUST PAN WEEKLY CHECK AIR CLEANER RESTRICTION CLEAN/CHANGE AIR CLEANER ELEMENT IF REQUIRED COOLING SYSTEM CHECK COOLANT LEVEL OTHER MAINTENANCE

DRAIN AIR TANK CHECK & CORRECT LEAKS DRAIN FUEL FILTER/WATER SEPARATOR DAILY CHECK OIL LEVEL OF MARINE GEAR & RAW WATER PUMP

ENGINE SERIES INTERVAL HOURS CALENDAR

BULLETIN NO 3243609-08-12-2006

B-CHECK (SECTION 6) REPEAT "A" LUBRICATION CHANGE ENGINE OIL CHANGE ENGINE FULL-FLOW OIL FILTER CHANGE BY - FILTER CHANGE MARINE GEAR OIL RECORD OIL PRESSURE FUEL SYSTEM CHECK HYD. GOV. OIL (IF APPLICABLE) CHECK THROTTLE LINKAGE LUBRICATE BALL TS OF THE THROTTLE LINKAGE OF HYD. GOVERNOR. CHANGE FUEL FILTER CLEAN FUEL TANK BREATHER CHECK ANEROID OIL AIR SYSTEM CLEAN / CHANGE CRANKCASE BREATHER CHECK AIR PIPING COOLING SYSTEM CHECK COOLANT INHIBITOR. ADD COOLANT CONCENTRATE, IF REQUIRED CHECK HEAT EXCHANGER ZINC PLUGS B EVERY 300HRS 6 MONTHS

FIRST 1500 HRS CHECK ALL STEPS OF C-CHECK AND ADDITIONS STEPS ADJUST INJECTORS AND VALVES REPLACE ROCKER COVER GASKETS

TO BE DONE AT FIRST 1500 HRS ONLY

C-CHECK(SECTION7) REPEAT "A"&"B" FUEL SYSTEM CHANGE HYD.GOV. OIL CHANGE ANEROID OIL CHECK ANEROID ADJUSTMENT REPLACE ANEROID BREATHER CLEAN FUEL TANK FROM INSIDE COOLING SYSTEM CLEAN RADIATOR/CHARGE AIR COOLER EXTERNALLY CHECK FAN HUB/IDLER AND WATER PUMP/IDLER OTHER MAINTENANCE INSPECT FOLLOWING PARTS & REPLACE AS REQUIRED (ALTERNATOR/ STARTER, ETC) CHECK AIR CLEANER EVACUATOR VALVE CHANGE IF REQUIRED

C EVERY 1500 HOURS/EVERY 1 YEAR

D-CHECK (SECTION 8) REPEAT "A,B AND C" FUEL SYSTEM CLEAN AND CALIBRATE INJECTORS IF REQUIRED REPLACE ROCKER COVER GASKETS CHECK FUEL PUMP CALIBRATION REPLACE ANEROID BELOWS & CALIBRATE IF PROVIDED AIR SYSTEM CLEAN TURBOCHARGER COMPRESSOR WHEEL AND DIFF IF REQUIRED CHECK TURBOCHARGER BEARING CLEARANCE TIGHTEN MANIFOLD NUTS OR CAPSCREWS COOLING SYSTEM

CHANGE COOLANT DESCALE COOLING SYSTEM OTHER MAINTENANCE CHECK VIBRATION DAMPER CHECK AIR COMPRESSOR CHECK SAFETY CONTROLS

D EVERY 6000 HRS, EVERY 2 HRS

1500 HRS. AFTER EVERY 'D' CHECK ALL STEPS OF C-CHECK AND ADDICTIONAL STEPS ADJUST INJECTORS AND VALVES IF REQUIRED REPLACE ROCKER COVER GASKETS

TO BE DONE AT 1500 HRS AFTER EVERY D CHECK

MAINTENANCE STEPS 1 KEEP KIRT OUT OF THE ENGINE

2 MAINTAIN A LUBRICATING FILM ON ALL BEARING SURFACE

3 REGULATE THE ENGINE'S FUEL

4 CONTROL OPERATING TEMPERATURES

5 GURARD AGAINST CORROSION

6 LET THE ENGINE BREATHE 7 PREVENT OVERSPEEDING 8 KNOW YOUR ENGINE'S CONDITION 10 SCHEDULE AND CONTROL YOUR MAINTENANCE

1

2

3

4

5

6

CUMMINS MAINTENANCE THIS IS A GENERAL MAINTENANCE PROGRAMME; IF YOUR ENGINE IS NOT FITTED WITH TURBOCHARGER, AIR COMPRESSOR, ETC, OMIT THAT PARTICULAR MAINTENANCE STEP. IF YOUR ENGINE IS FITTED WITH SOME SPECIAL COMPONENT OR ACCESSORY NOT SHOUN ON THE CHART, WRITE AND ASK FOR THE DETAILS FROM YOUR SERVICE REPRESENTATIVE. THE MAINTENANCE CHART HAS BEEN SPECIALLY PREPARED FOR AVERAGE INDIAN CONDITIONS, DETAILED INSTRUCTIONS ARE ONTAINED IN THE OPERATION AND MAINTENANCE MANUAL SUPPLIED WITH EACH ENGINE USE THE RECOMMENDED OIL WHOSE SPECIFIATIONS WILL MEET QUALITY REQUIREMENTS OF API CATEGORY CH4, DON’T MIS BRANDS OR GRADES OF OIL IN THE ENGINE. FOR DETAILS REFER OPERATION & MAINTENANCE MANUAL 3243773, THE LIFE OF THE FUEL FILTER, LUB OIL AND OTHER FILTERS WILL DEPEND ENTIRELY-UPON THE AMOUNT OF DUST, DIRT AND WATER IN THE OIL BESIDES OPERATING AND MAINTENANCE CONDITIONS AND ALSO THE TYPE OF GAS, FUEL AND LUB OIL USED IN THE ENGINE. FOR STARTER AND ALTERNATOR PLEASE FOLLOW MAINTENANCE SCHEDULE AS PER O&M SCHEDULE AS PER O&M MANUAL

A-CHECK (SECTION 4,5) DAILY/WEEKLY LUBRICATION CHECK ENGINE OIL LEVEL FUEL SYSTEM DRAIN SEDIMENTS FROM FUEL TANKS AIR SYSTEM CLEAN PRE-CLEANER DUST PAN WEEKLY CHECK AIR CLEANER RESTRICTION CLEAN/CHANGE AIR CLEANER ELEMENT IF REQUIRED COOLING SYSTEM CHECK COOLANT LEVEL OTHER MAINTENANCE

DRAIN AIR TANK CHECK & CORRECT LEAKS DRAIN FUEL FILTER/WATER SEPARATOR DAILY CHECK OIL LEVEL OF MARINE GEAR & RAW WATER PUMP

ENGINE SERIES INTERVAL HOURS CALENDAR

BULLETIN NO 3243609-08-12-2006

B-CHECK (SECTION 6) REPEAT "A" LUBRICATION CHANGE ENGINE OIL CHANGE ENGINE FULL-FLOW OIL FILTER CHANGE BY - FILTER CHANGE MARINE GEAR OIL RECORD OIL PRESSURE FUEL SYSTEM CHECK HYD. GOV. OIL (IF APPLICABLE) CHECK THROTTLE LINKAGE LUBRICATE BALL TS OF THE THROTTLE LINKAGE OF HYD. GOVERNOR. CHANGE FUEL FILTER CLEAN FUEL TANK BREATHER CHECK ANEROID OIL AIR SYSTEM CLEAN / CHANGE CRANKCASE BREATHER CHECK AIR PIPING COOLING SYSTEM CHECK COOLANT INHIBITOR. ADD COOLANT CONCENTRATE, IF REQUIRED CHECK HEAT EXCHANGER ZINC PLUGS B EVERY 300HRS 6 MONTHS

FIRST 1500 HRS CHECK ALL STEPS OF C-CHECK AND ADDITIONS STEPS ADJUST INJECTORS AND VALVES REPLACE ROCKER COVER GASKETS

TO BE DONE AT FIRST 1500 HRS ONLY

C-CHECK(SECTION7) REPEAT "A"&"B" FUEL SYSTEM CHANGE HYD.GOV. OIL CHANGE ANEROID OIL CHECK ANEROID ADJUSTMENT REPLACE ANEROID BREATHER CLEAN FUEL TANK FROM INSIDE COOLING SYSTEM CLEAN RADIATOR/CHARGE AIR COOLER EXTERNALLY CHECK FAN HUB/IDLER AND WATER PUMP/IDLER OTHER MAINTENANCE INSPECT FOLLOWING PARTS & REPLACE AS REQUIRED (ALTERNATOR/ STARTER, ETC) CHECK AIR CLEANER EVACUATOR VALVE CHANGE IF REQUIRED

C EVERY 1500 HOURS/EVERY 1 YEAR

D-CHECK (SECTION 8) REPEAT "A,B AND C" FUEL SYSTEM CLEAN AND CALIBRATE INJECTORS IF REQUIRED REPLACE ROCKER COVER GASKETS CHECK FUEL PUMP CALIBRATION REPLACE ANEROID BELOWS & CALIBRATE IF PROVIDED AIR SYSTEM CLEAN TURBOCHARGER COMPRESSOR WHEEL AND DIFF IF REQUIRED CHECK TURBOCHARGER BEARING CLEARANCE TIGHTEN MANIFOLD NUTS OR CAPSCREWS COOLING SYSTEM

CHANGE COOLANT DESCALE COOLING SYSTEM OTHER MAINTENANCE CHECK VIBRATION DAMPER CHECK AIR COMPRESSOR CHECK SAFETY CONTROLS

D EVERY 6000 HRS, EVERY 2 HRS

1500 HRS. AFTER EVERY 'D' CHECK ALL STEPS OF C-CHECK AND ADDICTIONAL STEPS ADJUST INJECTORS AND VALVES IF REQUIRED REPLACE ROCKER COVER GASKETS

TO BE DONE AT 1500 HRS AFTER EVERY D CHECK